Intelligent gas spring

A gas spring, intelligent technology, applied in the direction of spring, spring/shock absorber, gas shock absorber, etc., can solve problems such as gas leakage, reduce wind resistance, improve ride comfort and control stability, improve sensitivity and precision The effect of reliability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

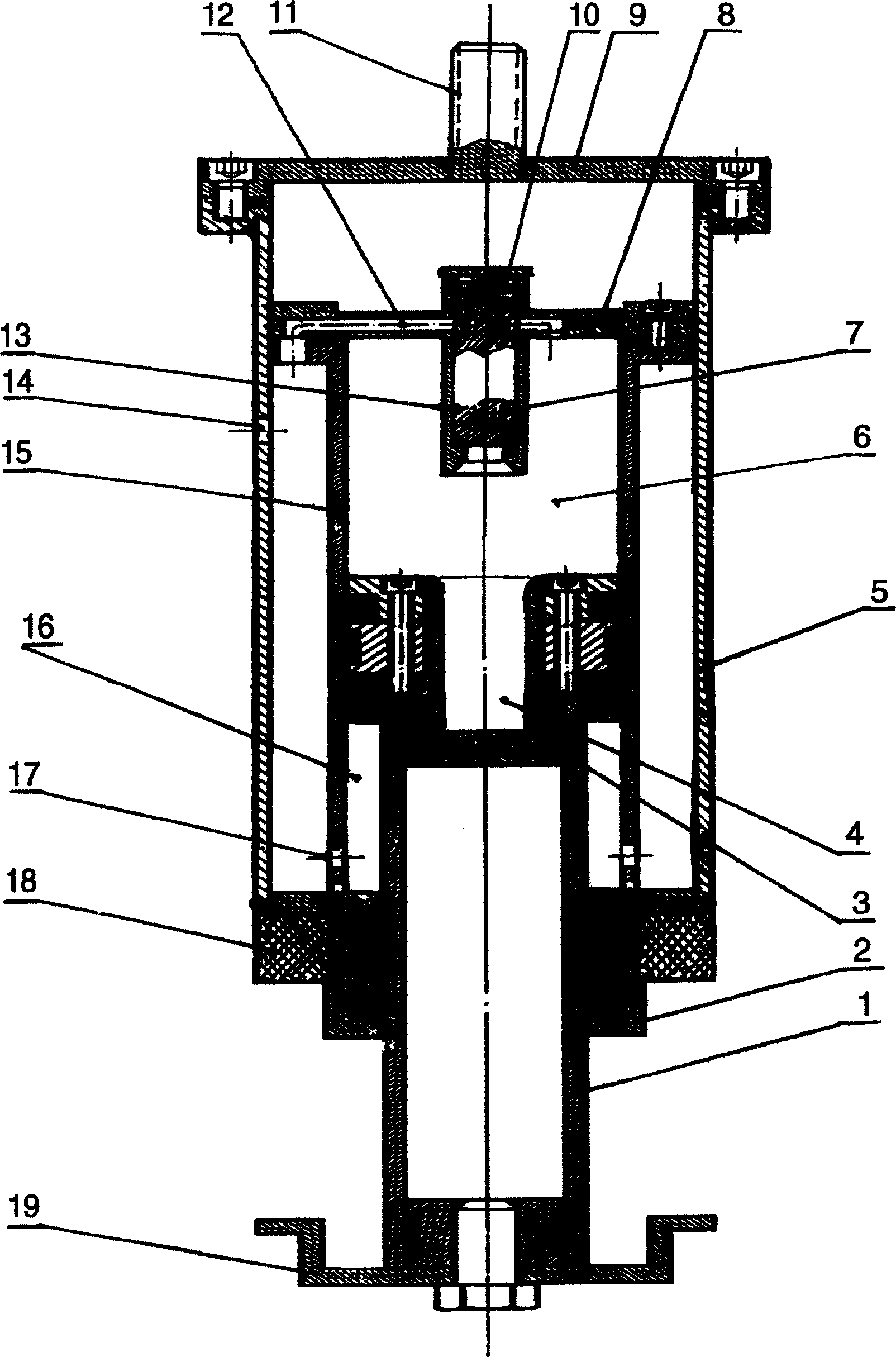

[0011] The intelligent gas spring proposed by the present invention is implemented in this way: it is fixedly installed with the housing 5 of the upper end cover 9 and the lower end cover 2; 5, the inner cylinder body 15, inner cylinder head 8 and piston 3 fixedly installed in the housing 5 are divided into the main air chamber 6 and the auxiliary air chamber 16, and the auxiliary through hole 17 is made on the inner cylinder body 15 wall, and the inner cylinder The opening and closing air passage 12 connecting the main air chamber 6 and the auxiliary air chamber 16 is made in the wall of the cover 8, and the stroke valve 13 for controlling opening or blocking the opening and closing air passage 12 is fixedly installed on the inner cylinder head 8. There is a damping cylinder 4 that is compatible with the stroke valve 13, oil is filled in the damping cylinder 4 and the auxiliary air chamber 16, and the lower end of the piston rod 1 of the piston 3 is equipped with a coupling 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com