Full-pose-and-position active-passive compliant robot and valve screwing-twisting method utilizing robot

An active-passive, robotic technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as inability to achieve precise positioning in robot operations, robot damage, and inability of robots to move in a large range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

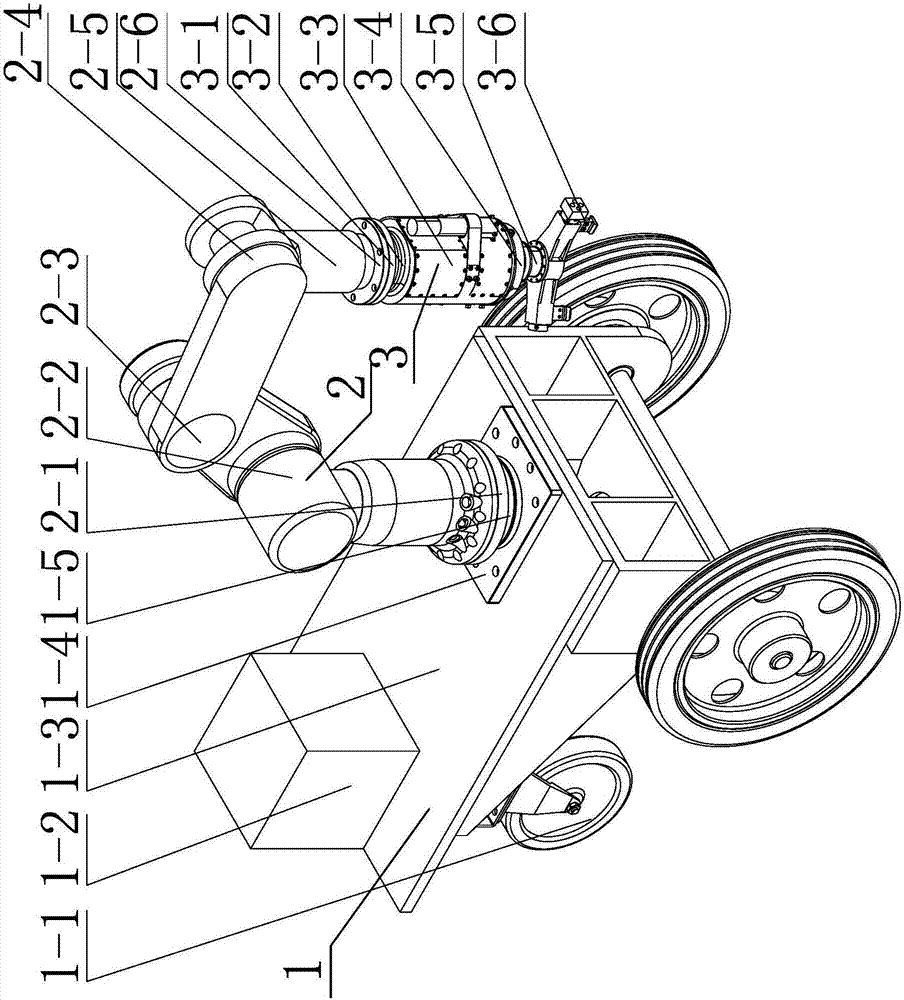

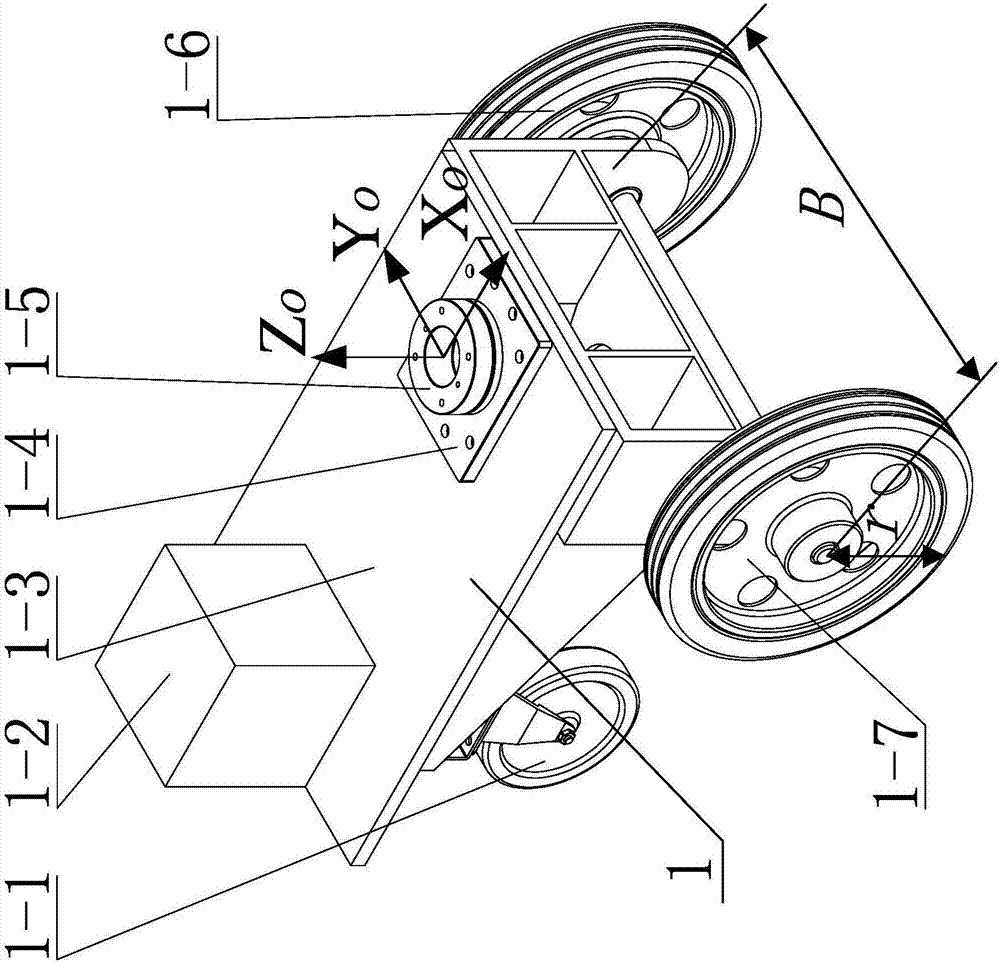

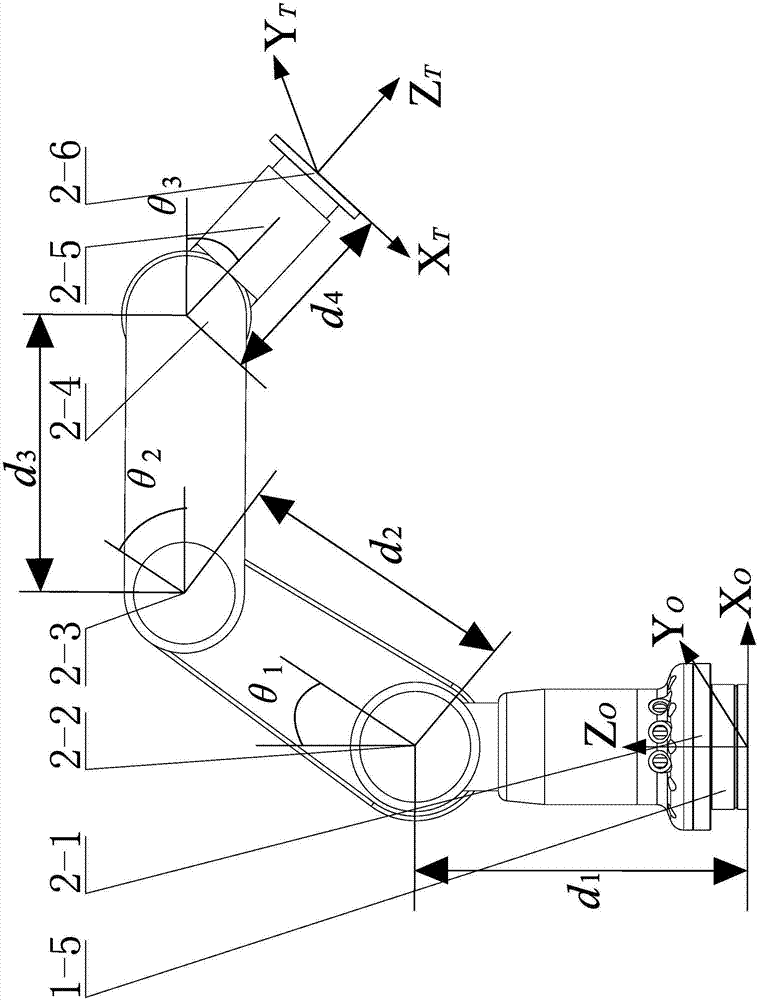

[0041] Specific implementation mode 1: This implementation mode provides an active and passive compliant robot in all poses. figure 1 , figure 2 , image 3 and Figure 4 To illustrate, the full-position active-passive compliant robot described in this embodiment includes a wheeled mobile platform 1 , a four-degree-of-freedom robotic arm 2 and a passive compliant end effector 3 . The wheeled mobile platform 1 and the four-degree-of-freedom mechanical arm 2 are connected by screws, and a six-dimensional force sensor 1-5 is installed therebetween; the four-degree-of-freedom mechanical arm 2 and the passive compliant end effector 3 are connected by screws, and a six-dimensional force sensor 1-5 is installed therebetween. There are six-dimensional force sensors 3-2.

[0042] Such as figure 1 and figure 2 , the wheeled mobile platform 1 includes a driven wheel 1-1, a counterweight body 1-2, a mobile vehicle body 1-3, a six-dimensional force mounting flange 1-4, a six-dimensio...

specific Embodiment approach 2

[0046] Specific implementation mode two: combination figure 1 , Figure 4 , Figure 5 and Figure 6 A method for screwing a valve using the robot described above is given,

[0047] After the operator determines the position of the operation target valve 4, he drives the wheeled mobile platform 1 to move to the front of the valve, and then drives the four-degree-of-freedom mechanical arm 2 to adjust the operation posture of the screwing valve. However, errors may occur in the judgment of the valve position, which may cause a rigid collision between the end operation fingers 3-6 and the handwheel of the operation target valve 4, resulting in excessive collision force. The present invention uses the passive and compliant end effector 3 to solve this problem. When a rigid collision occurs, the passive and compliant end effector will adjust its own structure to avoid the rigid collision.

specific Embodiment approach 3

[0048] Specific implementation mode three: combination figure 1 , figure 2 and Figure 5 This embodiment will be described. During the process of the terminal working fingers 3-6 entering the valve handwheel, if there is a large deviation in the judgment of the valve position, a radial contact force will be generated between the terminal working fingers 3-6 and the valve handwheel, and as the fingers The continuous entry, the contact force is getting bigger and bigger. The present invention solves this problem by combining the six-dimensional force sensors 1-5 to drive the wheeled mobile work platform 1 to move through an impedance control algorithm. to combine figure 2 It can be seen that when a radial contact force occurs, the six-dimensional force sensor 1-5 will detect the force and moment because is caused by the contact force in the Y direction, therefore, it is only necessary to eliminate The radial contact force can be eliminated. The selected impedance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com