Laminating equipment

A technology for laminating equipment and mounting boards, which is applied in layered products, lamination devices, laminations, etc., and can solve problems such as the thickness of the lamination does not meet the predetermined requirements, the cracking of the lamination substrate, and the yellowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

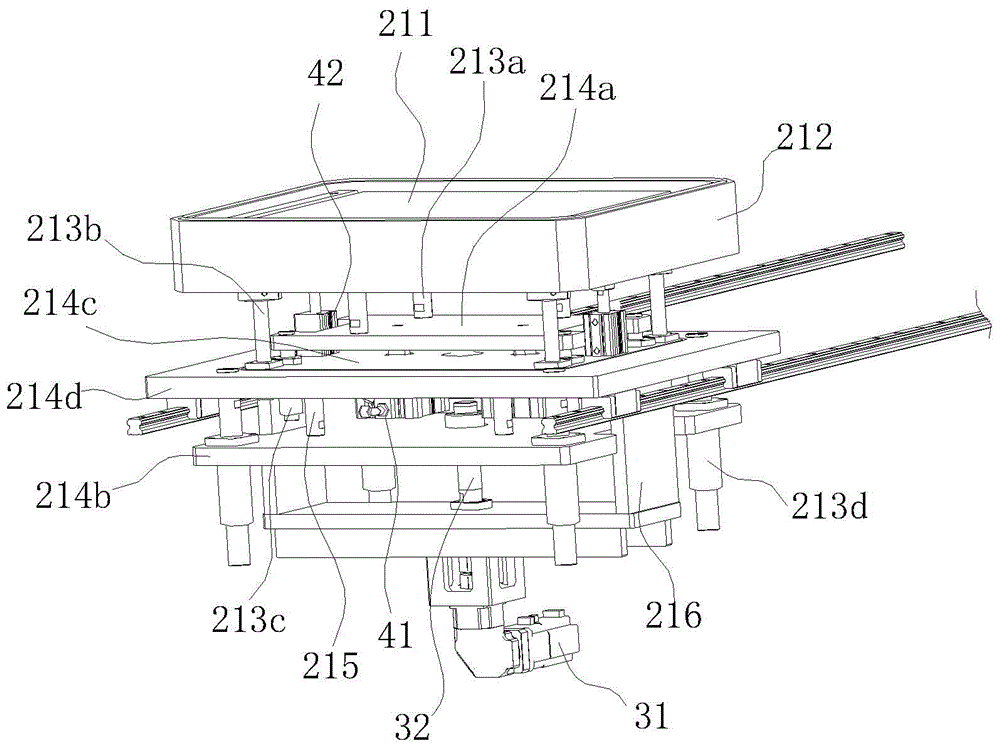

[0031] The up and down described in the present invention are based on the position of the laminating equipment in the drawings, which does not limit the protection scope of the present invention.

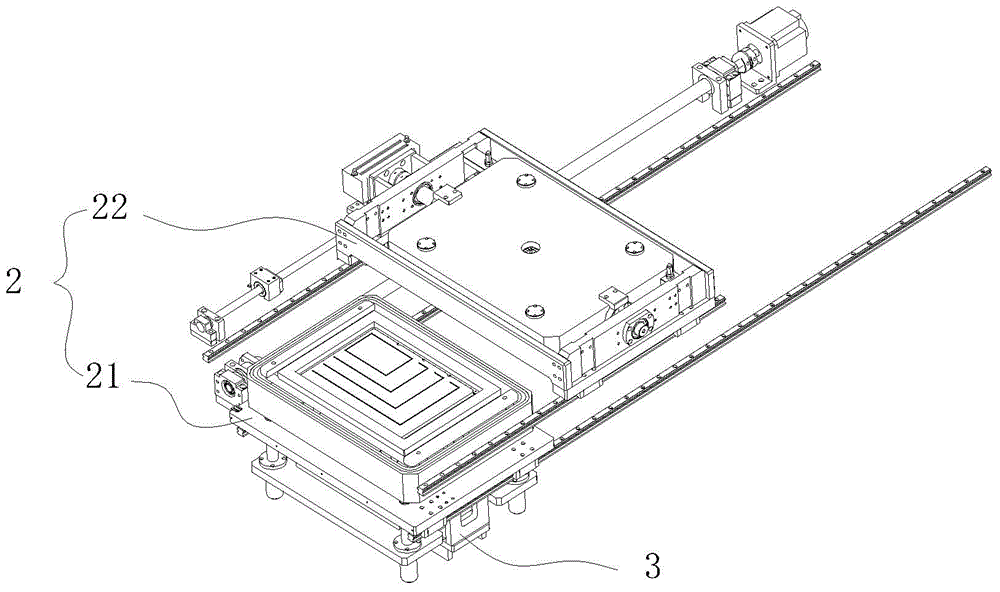

[0032] see Figure 1~2 . The bonding equipment includes a frame 1 (not shown), a bonding mechanism 2 and a lifting mechanism 3 .

[0033] Specifically, the frame 1 carries the bonding mechanism 2 and the lifting mechanism 3 .

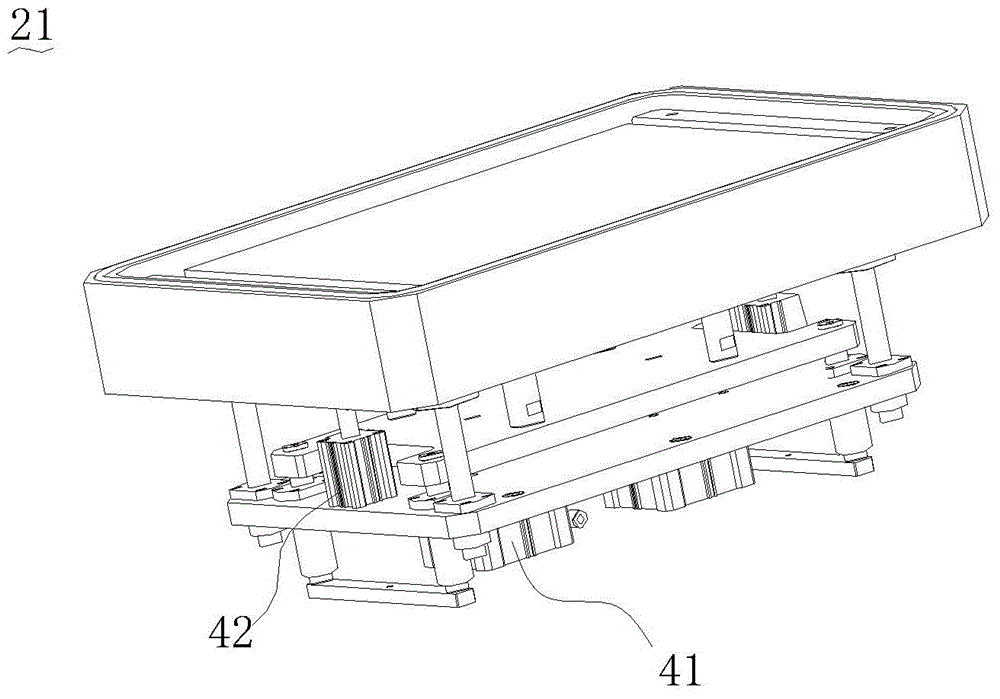

[0034] The bonding mechanism 2 includes a first cavity 21 and a second cavity 22, the first cavity 21 and the second cavity 22 are set up and down, and the first cavity 21 can be on the top and the second cavity 22 can be on the bottom, or it can be The first cavity 21 is on the bottom and the second cavity 22 is on the top. The first cavity 21 is close to the second cavity 22 , the templates installed on the two cavities 11 are relatively attached, and the relative movement between the first cavity 21 and the second cavity 22 is controlled by the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com