Top hammer type impact rotary power head of hydraulic drilling machine

A technology of rotary power head and hydraulic drilling rig, which is applied to the driving device of rotary combined drilling, drilling equipment, earthwork drilling and mining, etc., which can solve the problems of fast impact frequency and cost reduction, so as to increase the impact frequency, reduce cost, and improve The effect of strike efficiency and strike force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the hydraulic drilling rig topper type impact rotary power head will be described below in conjunction with the accompanying drawings.

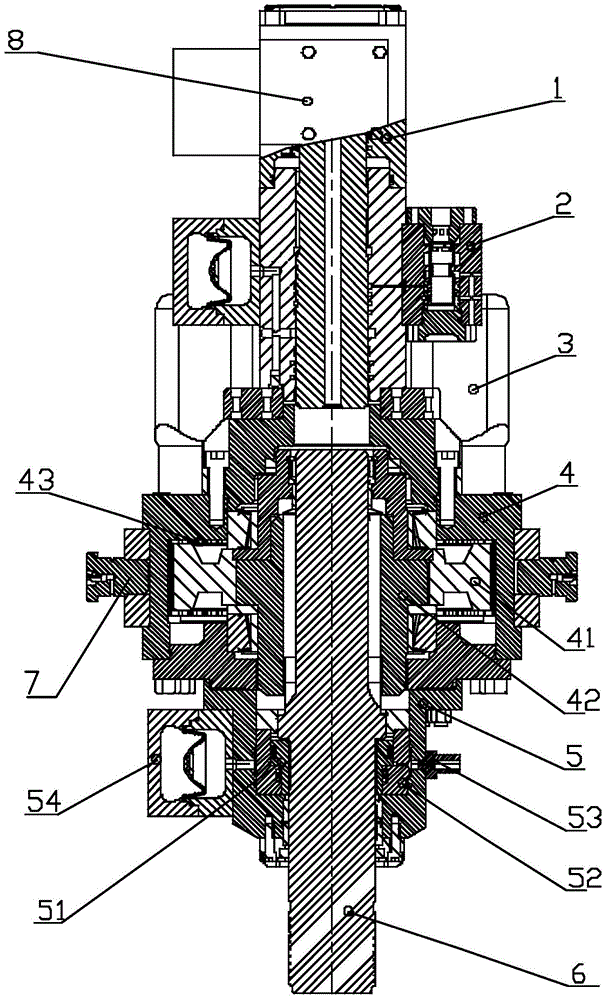

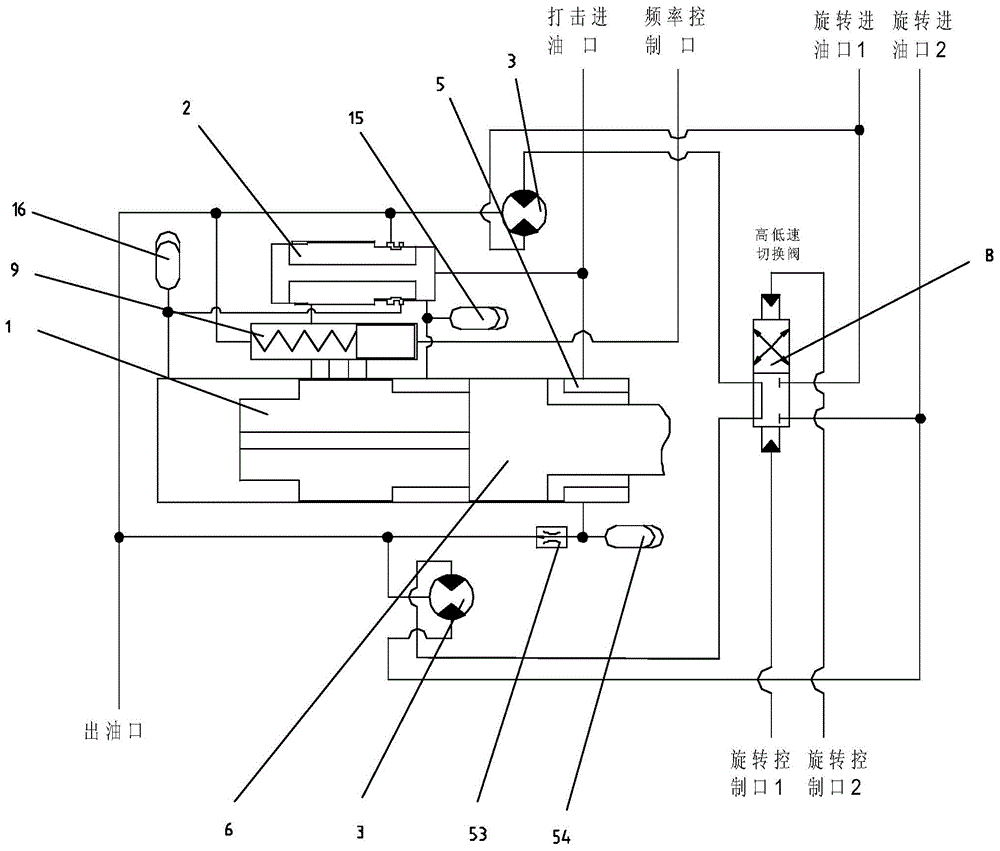

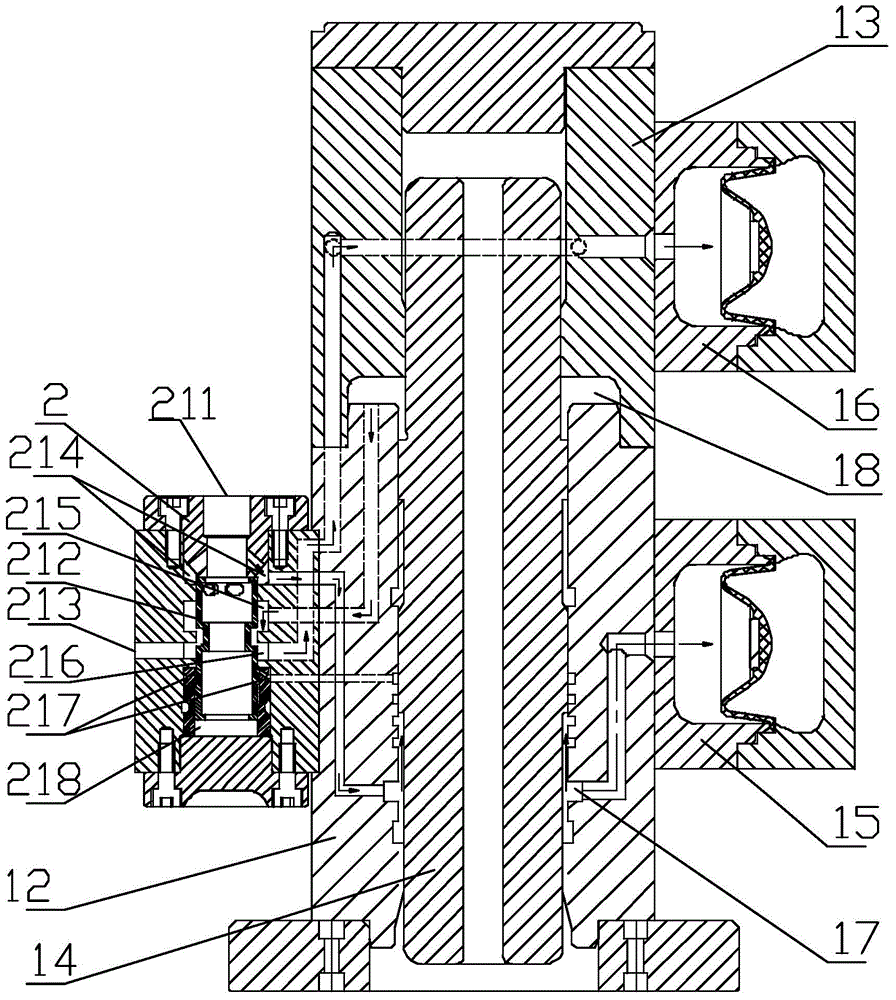

[0024] like Figure 1 to Figure 5 As shown, a hydraulic drilling rig top hammer impact rotary power head includes an impact mechanism and a rotation mechanism. The impact mechanism includes a strike group 1, a frequency group and a limit group 2. , spline shaft 6, reverse buffer, the limit group 2 is respectively connected with the strike group and the frequency group through the oil circuit, the limit group 2 controls the piston movement of the strike group 1, and the frequency group and the strike group Connect and control the hitting frequency of the pistons of the striking group 1, the striking group 1 includes a base and a piston 14 installed in the base, the rotating group includes a gear box 4 and a support seat 7, and the turning group includes an inverted The casing 5, the fixed ring 52 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com