Grinding machine

A grinding machine and manipulator technology, which is applied in the directions of grinding machine parts, grinding feed motion, grinding workpiece supports, etc., can solve the problems of difficult blade clamping, difficult cutting edge processing, low efficiency, etc. Production efficiency, simple and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

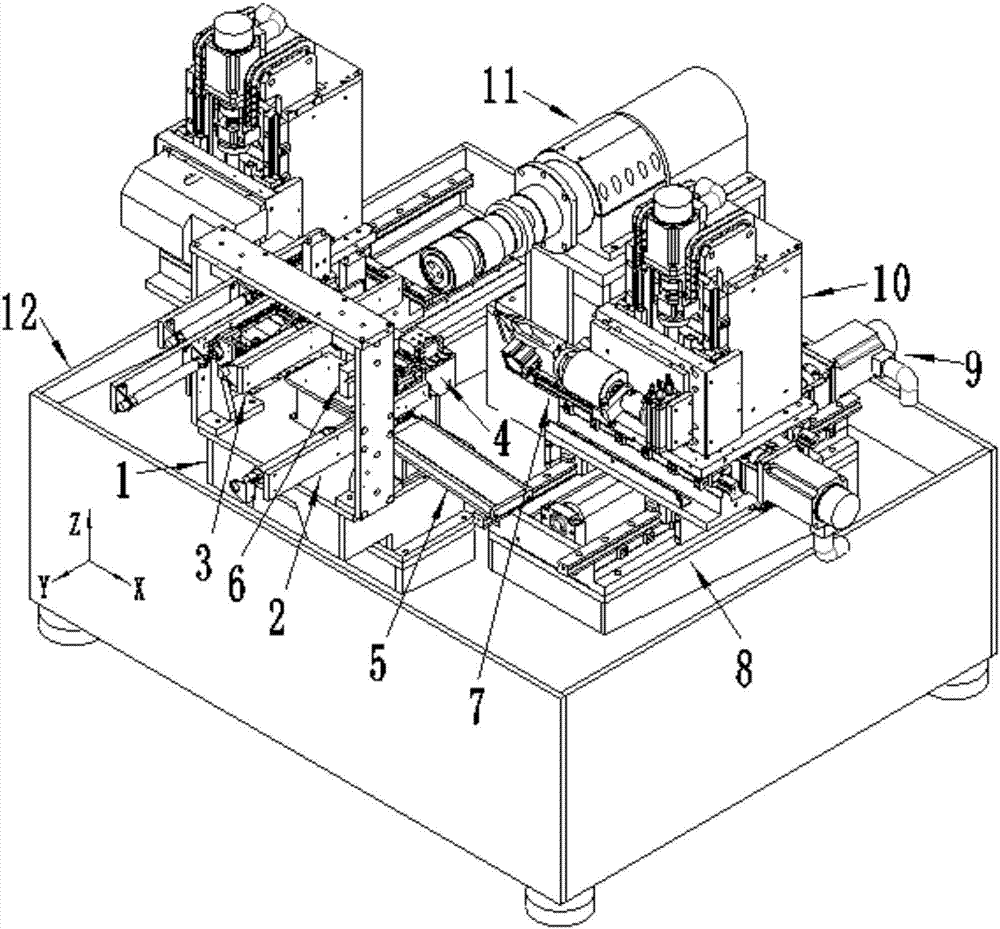

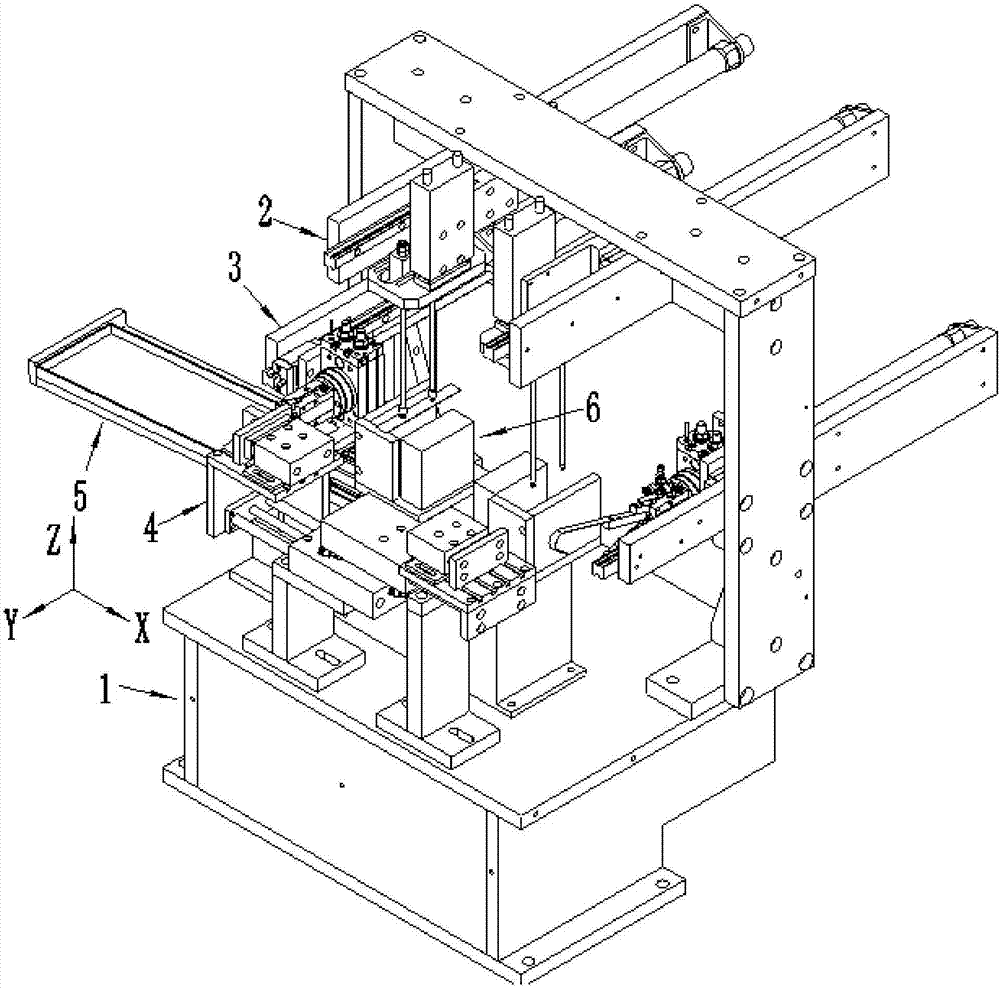

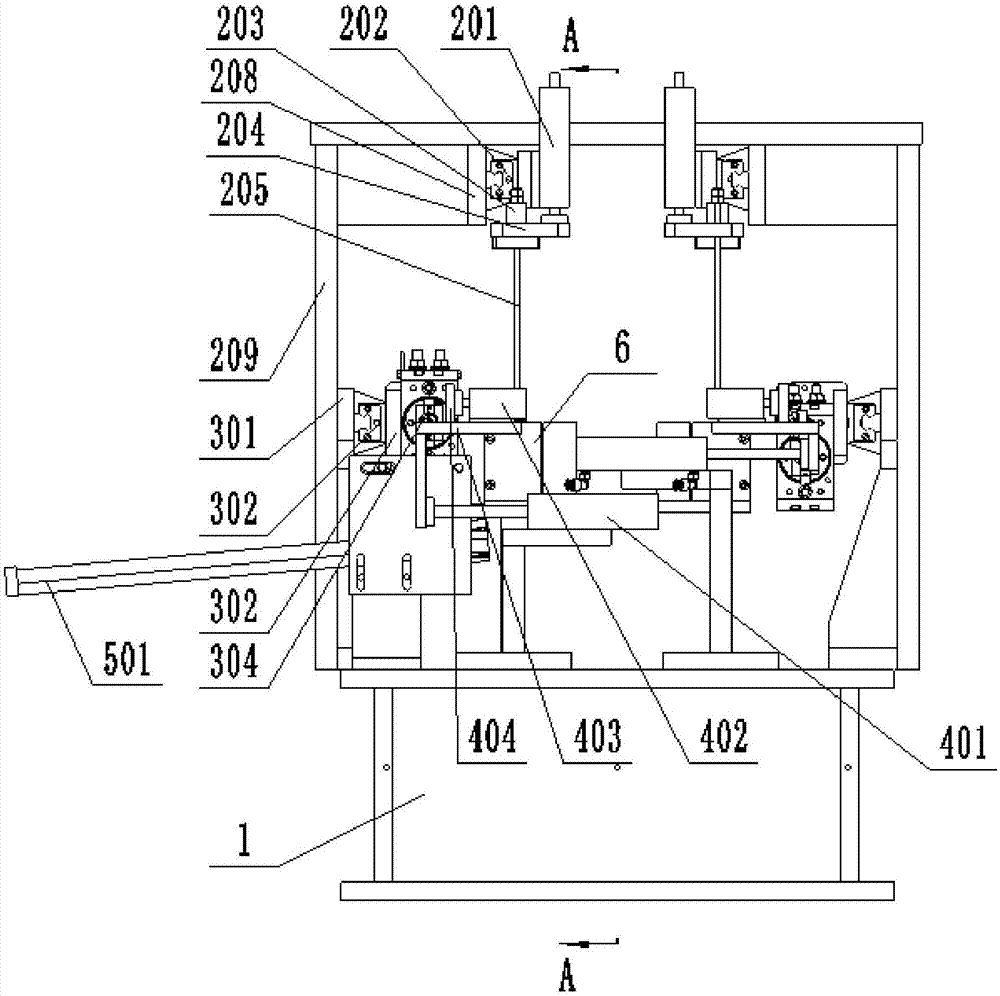

[0058] Such as figure 1 As shown, the present embodiment provides a kind of grinder, mainly carries out automatic grinding processing to the blade edge of mechanical blades such as alloy blade, ceramic blade, to improve blade grinding quality and efficiency, and it mainly comprises frame 12, X-axis moving assembly 9. Y-axis moving assembly 8, Z-axis moving assembly 10, automatic loading and unloading device, manipulator part 7 and grinding wheel spindle assembly 11. Among them, the X-axis moving assembly 9, the Y-axis moving assembly 8, the Z-axis moving assembly 10, the automatic pick-and-place device, the manipulator part 7 and the grinding wheel spindle assembly 11 are all arranged on the frame 12; the automatic pick-and-place device is used to treat The blade of processing carries out cloth, so that manipulator part 7 clamps blade, and it also collects the finished product blade after processing simultaneously; Manipulator part 7 is used for sending the blade to be process...

Embodiment 2

[0079] In this embodiment, the grinding machine in Embodiment 1 is used to grind the blade, and the operation method is described accordingly, so as to complete the integrated operation of picking and unloading, grinding and collecting the blade. Specifically in this embodiment, taking ceramic blades as an example to carry out the loading and unloading operation, the steps are: first stack the blades in the material placement area 6; then, use the feeding mechanism 2 to grab the blades to be processed, and place the blades to be processed Place it on the material distribution mechanism 4; then, use the material distribution mechanism 4 to adjust the position of the blade to be processed so that the manipulator 750 grabs it; then, the manipulator 750 grasps the replacement processing blade and puts it on the grinding wheel spindle assembly 11 for grinding, and the finished product blade after processing Then put back the material distribution mechanism 4 by the manipulator 750; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com