Passive adaptive multifunctional detection device for nuclear fuel assembly

A nuclear fuel assembly and detection device technology, applied in the direction of measuring devices, electromagnetic measuring devices, nuclear power generation, etc., can solve the problems of poor safety assurance, low measurement accuracy, and limited measurement accuracy, and achieve smooth alignment and improve detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

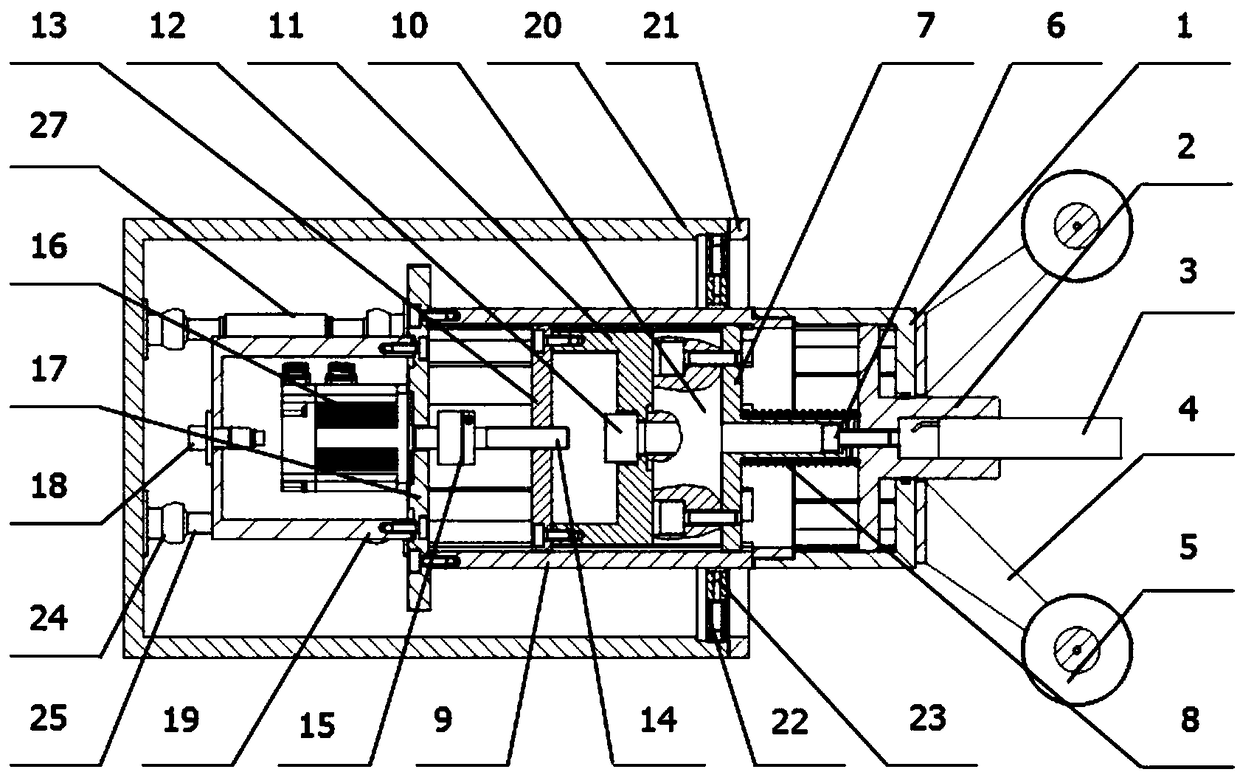

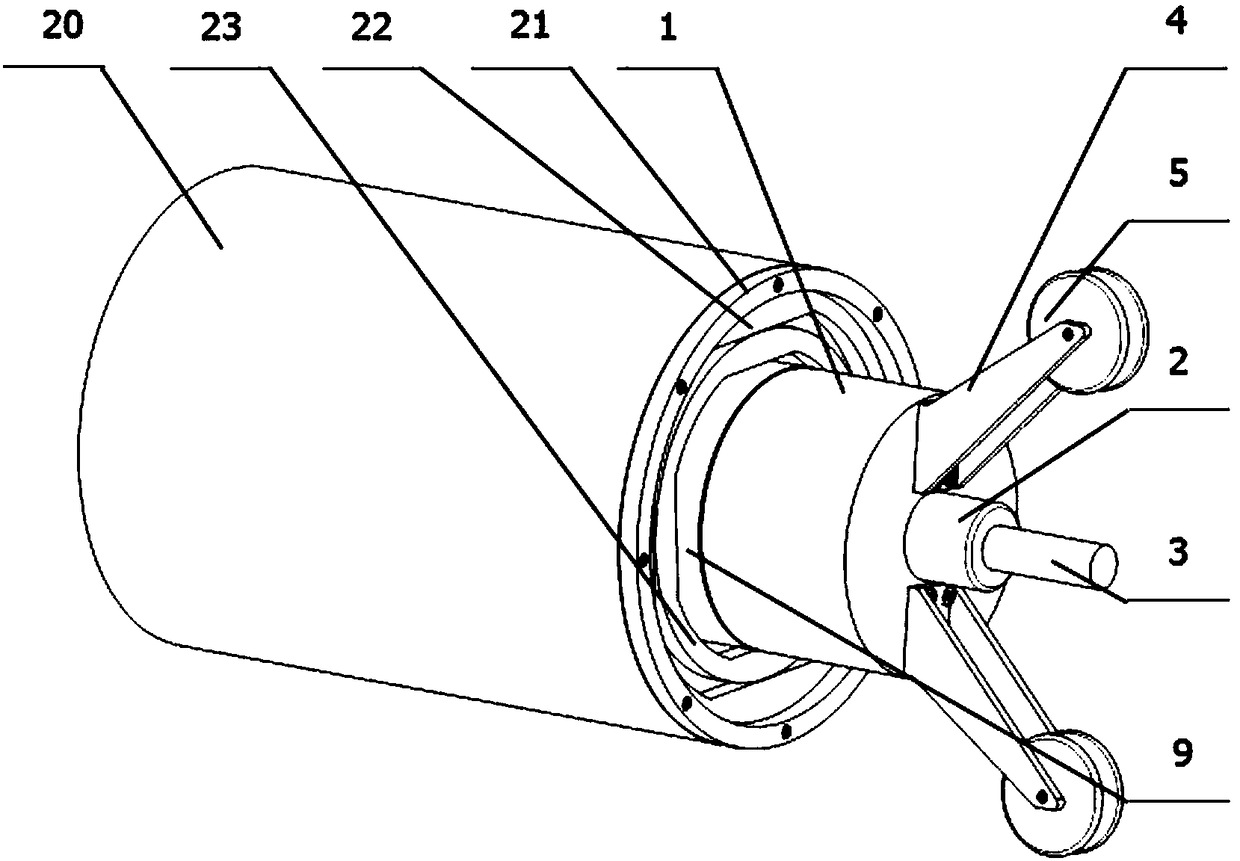

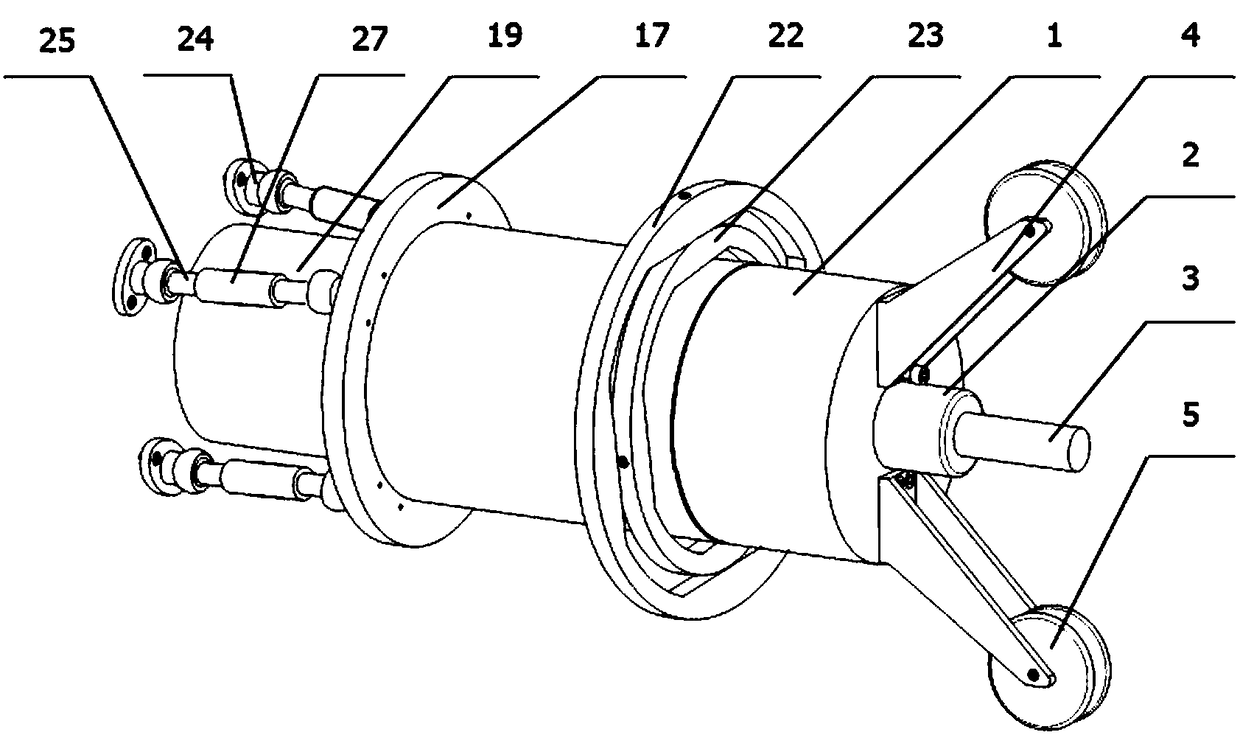

[0043] This embodiment is a passive self-adaptive nuclear fuel assembly multifunctional detection device, including an oxide film thickness detection mechanism, a probe flexible feeding mechanism and a deformation detection mechanism; the deformation detection mechanism is in contact with the nuclear fuel assembly to be detected, and the probe flexible feeding mechanism The oxide film thickness detection mechanism and the deformation detection mechanism are respectively rigidly connected, and the oxide film thickness detection mechanism is in contact with the nuclear fuel assembly to be detected under the action of the flexible feeding mechanism of the probe.

[0044] The oxide film thickness detection mechanism includes a probe spline groove 1, a spline slider 2, an eddy current probe 3, a guide wheel support 4, and a guide wheel 5; the probe spline groove 1 is a cylindrical structural part, and the probe spline groove The inner surface of the left end of the keyway is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com