A shoulder damping fasten

A shock-absorbing fastener and shoulder-type technology, which is applied in the field of rail transit, can solve the problems of reducing the life of anchor bolts, adverse effects on safety and stability, and increasing the length of anchor bolts, so as to avoid the action of transverse shear force and reduce the impact The risk of shearing, the effect of reducing the height of the tunnel section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

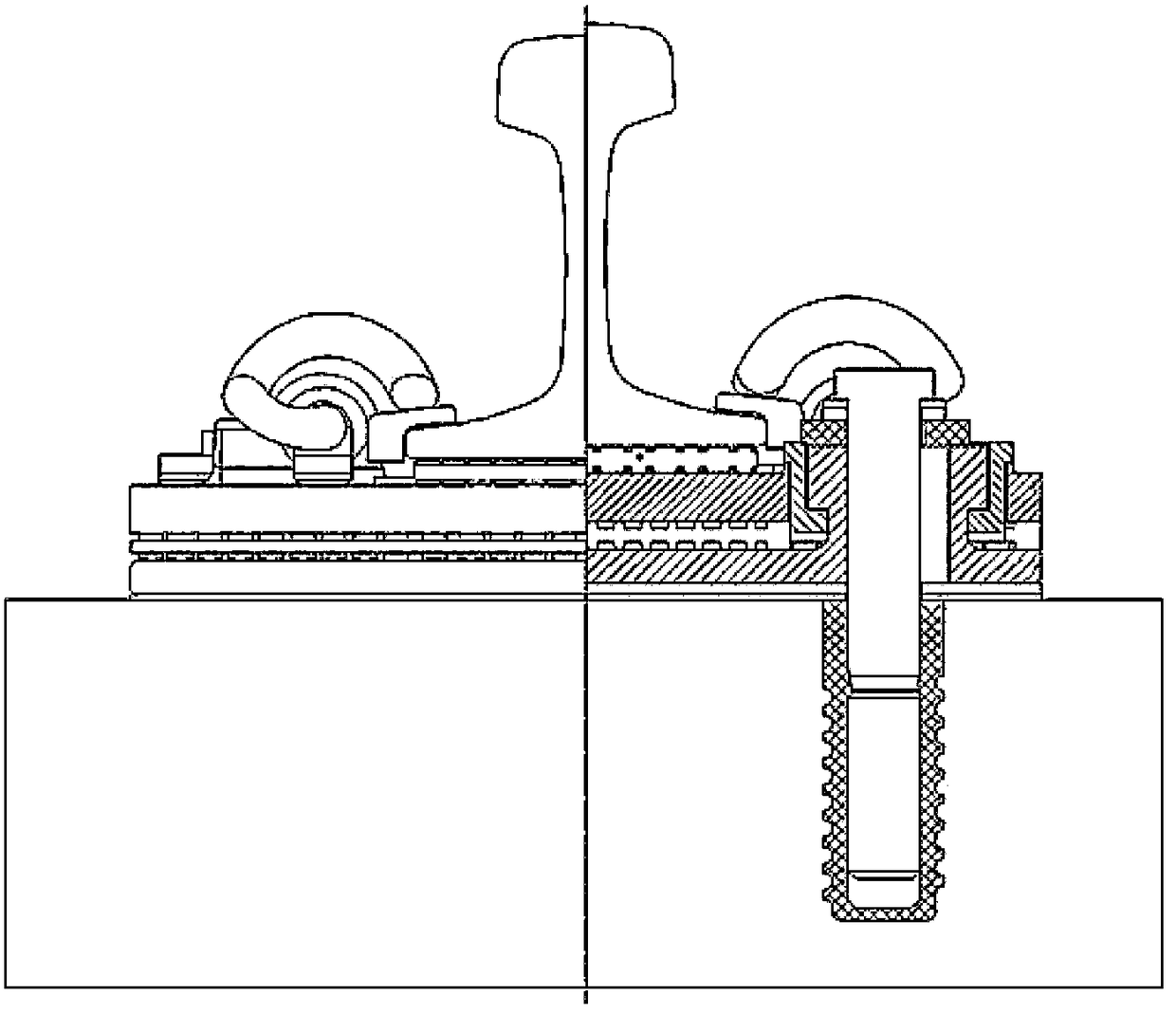

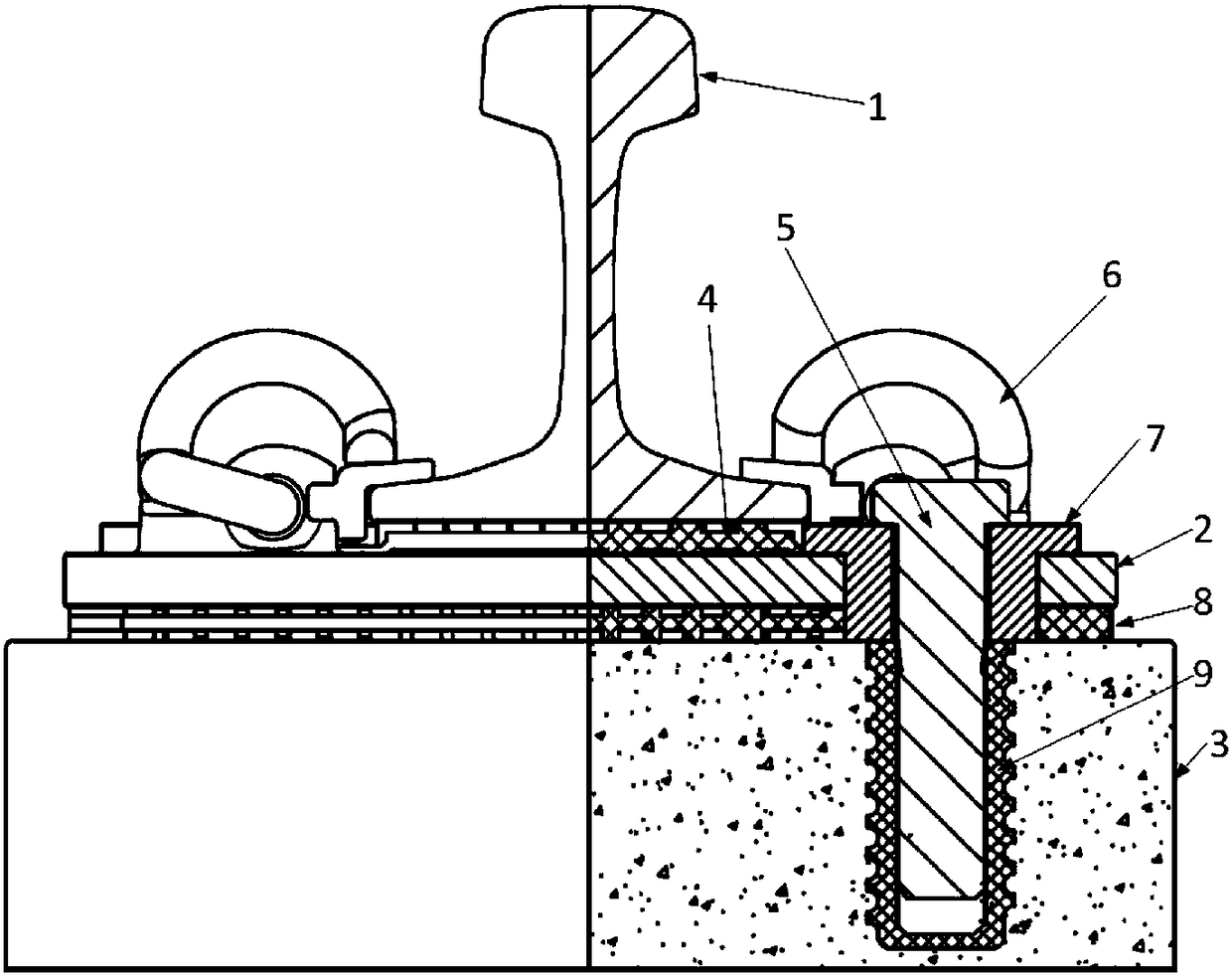

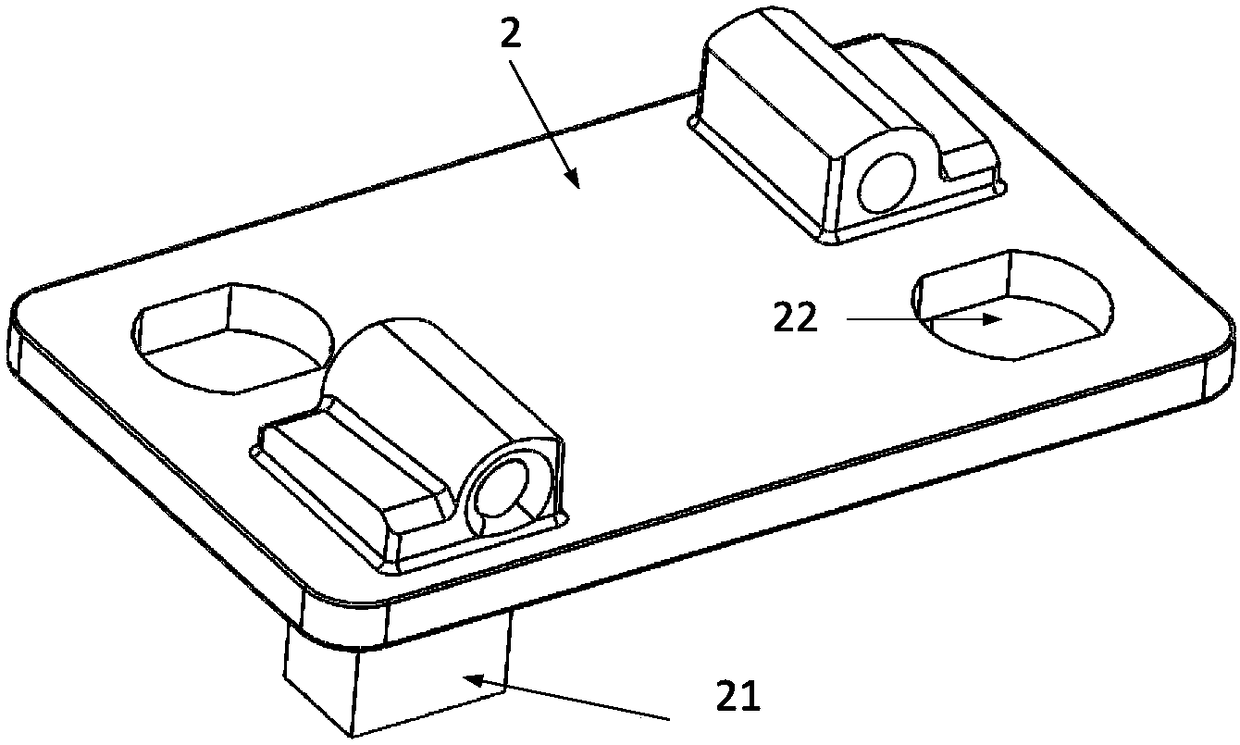

[0072] Such as figure 2 As shown, the embodiment of the present invention provides a shoulder-type vibration damping fastener, which includes a backing plate 2, an anchor bolt 5, a spring bar 6, a spring bar seat, and a gauge block. The backing plate 2 is provided with a through hole 22, The anchor bolt 5 penetrates the through hole 22 of the backing plate 2 and fixes the backing plate 2 to the track foundation 3; at least two spring bar seats are provided on the upper surface of the backing plate 2, and one end of the spring bar 6 is set on the spring bar seat On the top, the other end of the elastic strip 6 presses the gauge block.

[0073] Preferably, the above-mentioned backing plate 2 is provided with a limit stop shoulder for limiting the lateral displacement between the backing plate 2 and the track foundation 3, and the limit stop shoulder is matedly connected with a groove provided on the track foundation 3.

[0074] Combine image 3 , Figure 4 As shown, in this embodime...

Embodiment 2

[0095] The shoulder-type vibration damping fastener provided in this embodiment has a main structure similar to that of the first embodiment, and also includes a backing plate 2, an anchor bolt 5, a spring bar 6, a spring bar seat, and a gauge block. The specific structure and Please refer to the record of the first embodiment for the connection relationship between the two. This embodiment aims to illustrate the difference between the two.

[0096] Combine Figure 15 , Figure 16 As shown, in this embodiment, the above-mentioned through hole 22 penetrates the protruding structure 21.

[0097] In the specific operation, the above-mentioned through hole 22 and the convex structure 21 are arranged at the same position on the backing plate, that is, the through hole 22 penetrates the arrangement of the convex structure 21. The above-mentioned preferred setting can effectively reduce the total weight of the backing plate 2; The provision of the hollow through holes of the structure 21 ...

Embodiment 3

[0099] The shoulder-type vibration damping fastener provided by this embodiment has a main structure similar to that of the second embodiment, and also includes a backing plate 2, an anchor bolt 5, a spring bar 6, a spring bar seat, and a gauge block. The specific structure and Please refer to the record of the first embodiment for the connection relationship between the two. This embodiment aims to illustrate the difference between the two.

[0100] Combine Figure 17 , Figure 18 As shown, in this embodiment, the above-mentioned buffer layer 32 and the embedded casing 9 may be an integral structure.

[0101] In the specific operation, the above-mentioned buffer layer 32 and the embedded sleeve 9 can be directly integrally formed, that is, directly formed during the manufacturing process; they can also be connected separately, that is, connected after being separately manufactured; those skilled in the art , The corresponding setting method can be selected according to the actual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com