Air suspension flexibility space buttjunction platform

A space docking and docking platform technology, which is applied to workbenches, manufacturing tools, etc., can solve problems such as lack of flexibility of the docking platform, workpiece offset, and alignment failure, so as to facilitate operation control, assembly and disassembly maintenance, and meet docking requirements. The effect of preventing excessive torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

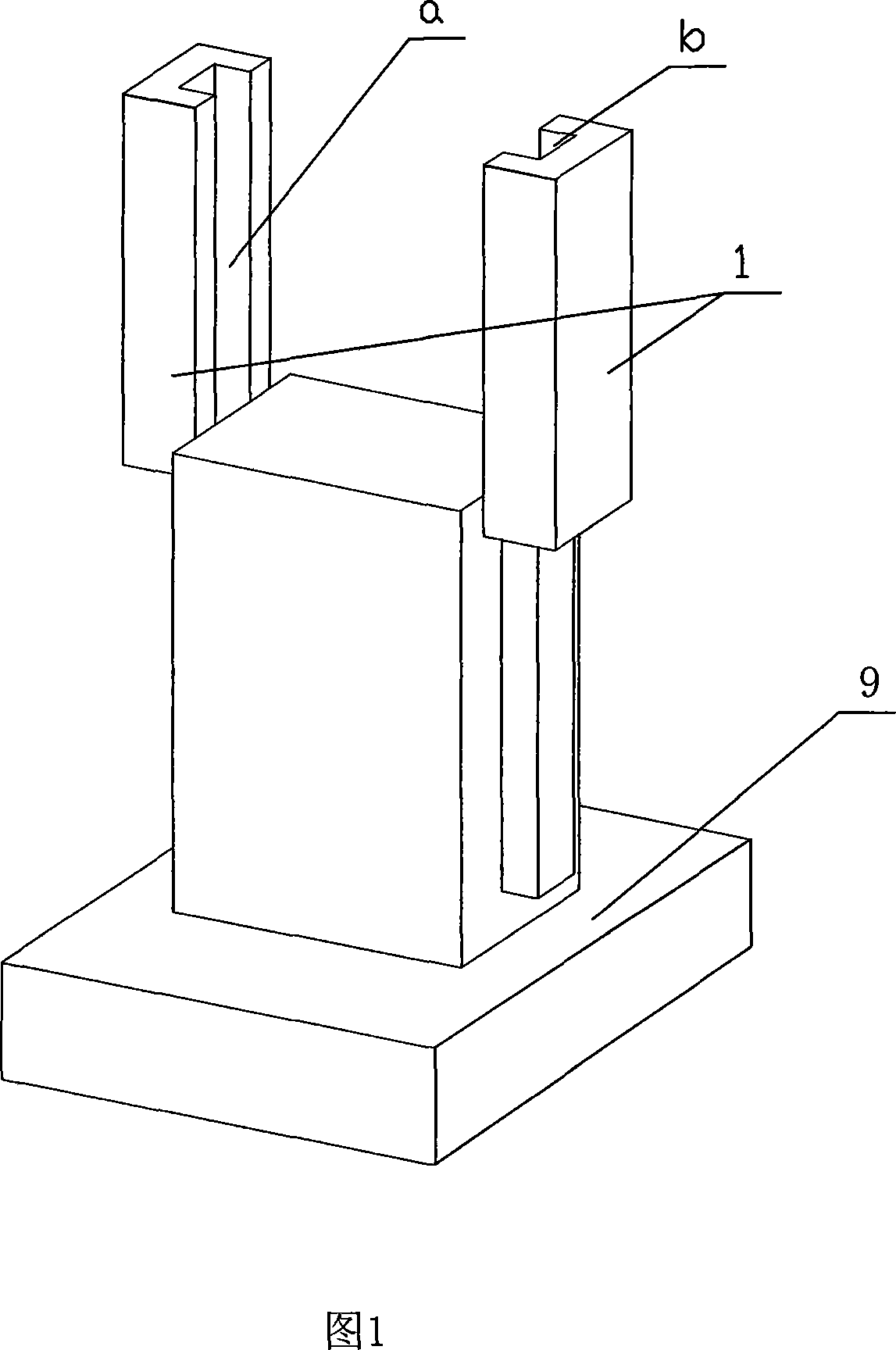

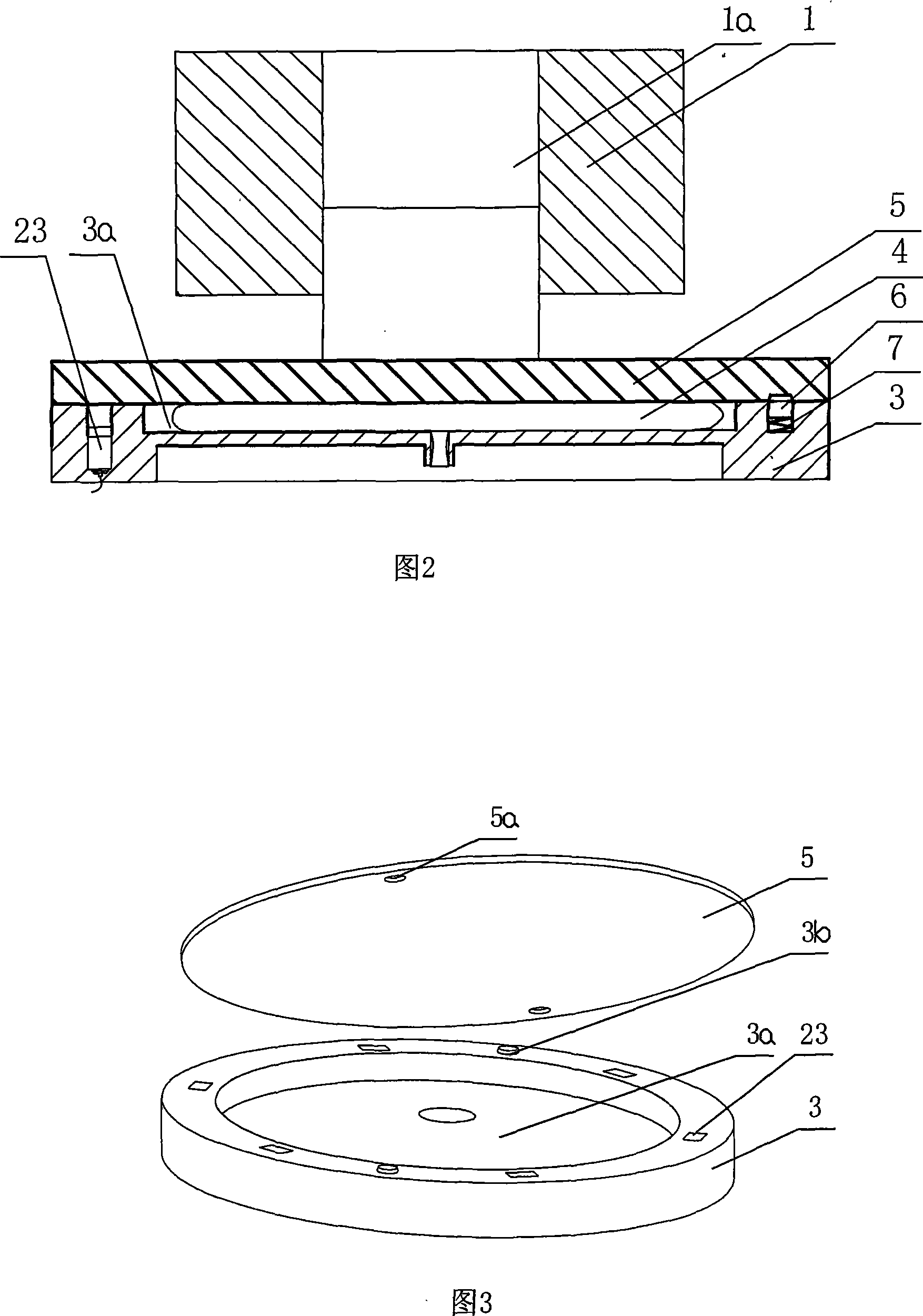

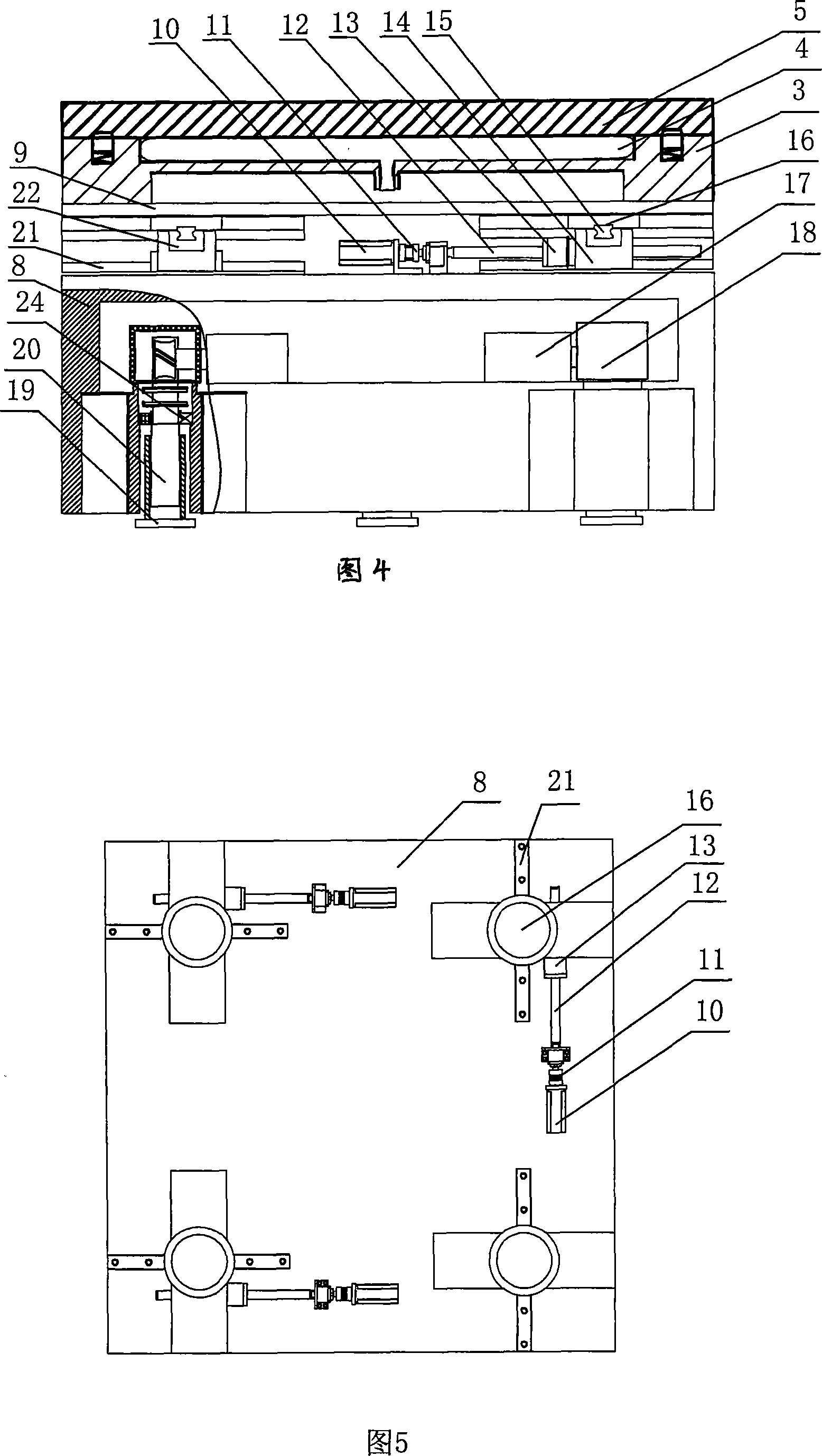

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] As shown in Figures 2 and 3: an air-suspension flexible space docking platform, an air-suspension flexible assembly platform is arranged on the mechanical self-adjusting docking platform, and the air-suspension flexible assembly platform consists of a base 3, an airbag 4, and positioning pins 6 and positioning spring 7, wherein the floating body 5 is placed on the base 3, the upper middle of the base 3 has a circular groove 3a, the circular groove 3a is equipped with the airbag 4, and the inlet of the airbag 4 The air port passes through the lower end of the base 3, and at least two positioning holes 3b are formed on the periphery of the upper end of the base 3. The positioning spring 7 is installed in the positioning hole 3b, and the positioning pin 6 is placed on the positioning spring 7. The positioning pin 6 protrudes from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com