Poultry gizzard surface cleaning device

A surface cleaning and equipment technology, applied in poultry cleaning/disinfection, poultry processing, poultry transmission/conveying devices, etc., can solve the problems of butter removal and inability to produce in an assembly line, so as to prevent danger, reduce labor costs, and prevent pressure bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

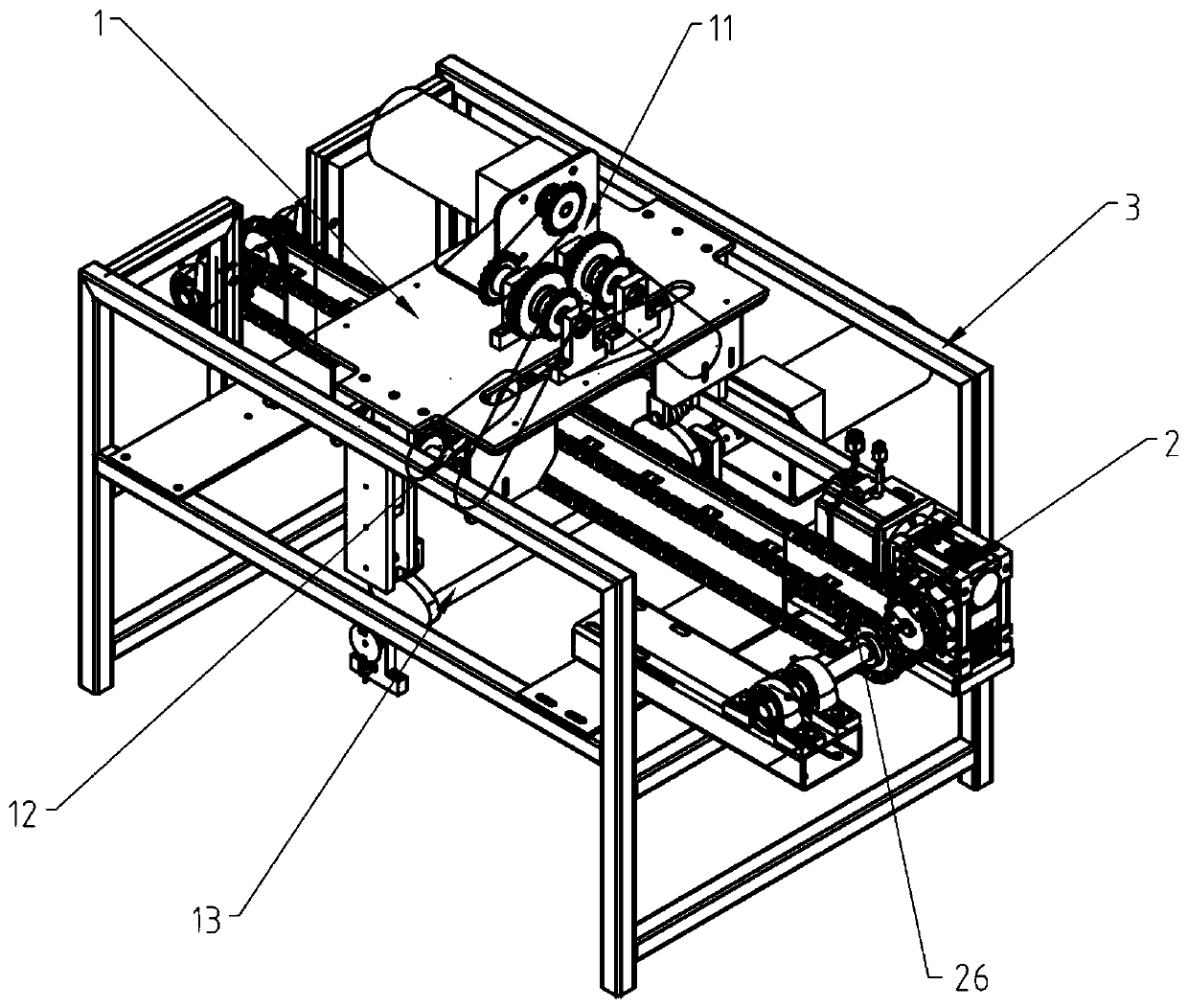

[0042] see figure 1 , figure 1 It is a kind of poultry gizzard surface cleaning equipment in this embodiment, including a scraping assembly 1, a transmission assembly 2 and a frame 3, the scraping assembly 1 is assembled on the upper half of the frame 3, and the transmission assembly 2 includes a transmission chain 26 , the transmission chain 26 passes through the middle of the scraping assembly 1, on which poultry gizzards are placed, and the two ends of the transmission assembly 2 are respectively assembled on the frame 3 through the bracket plate. Preferably, the conveying direction of the conveying chain 26 is perpendicular to the action direction of the scraping assembly 1 .

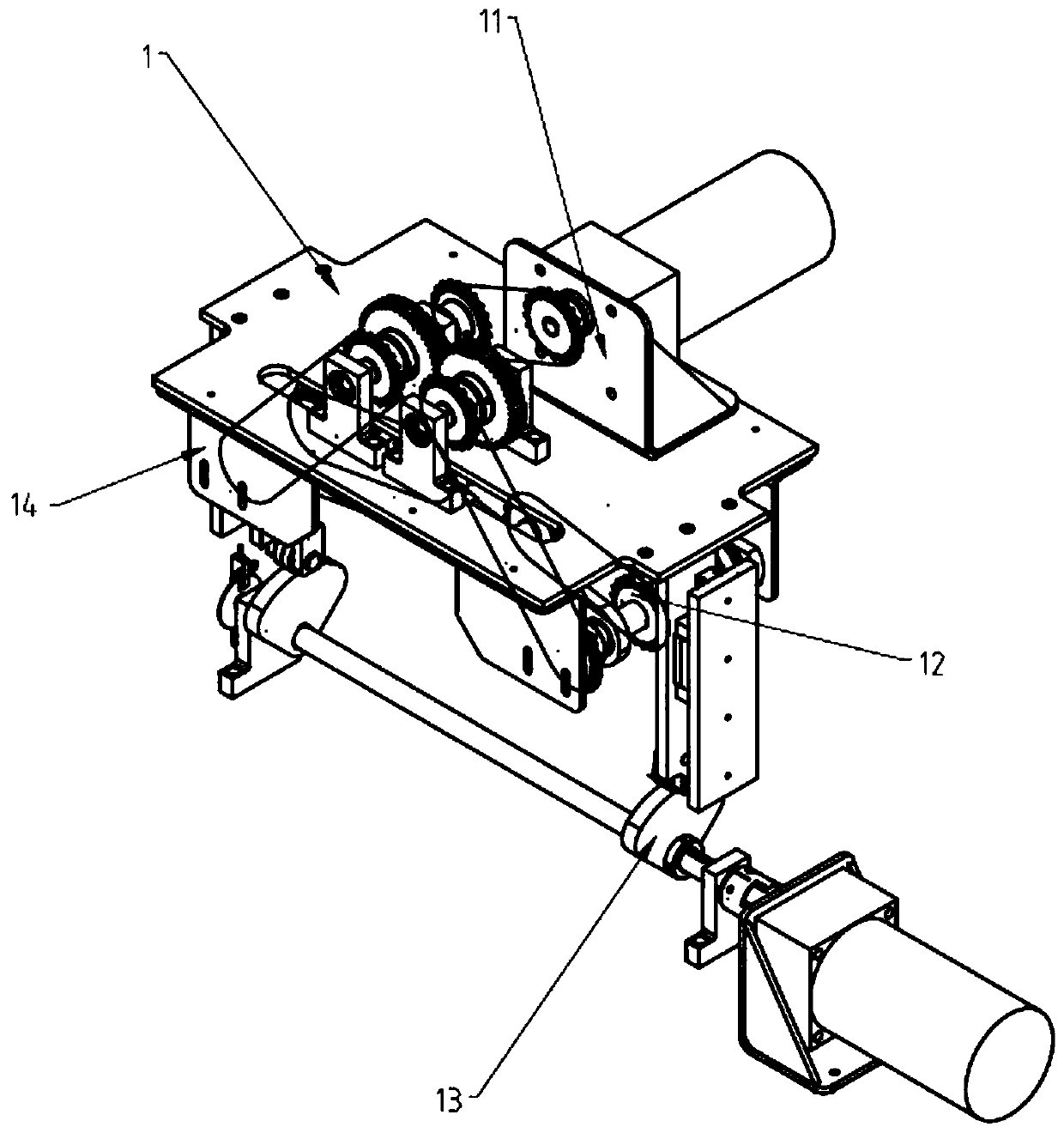

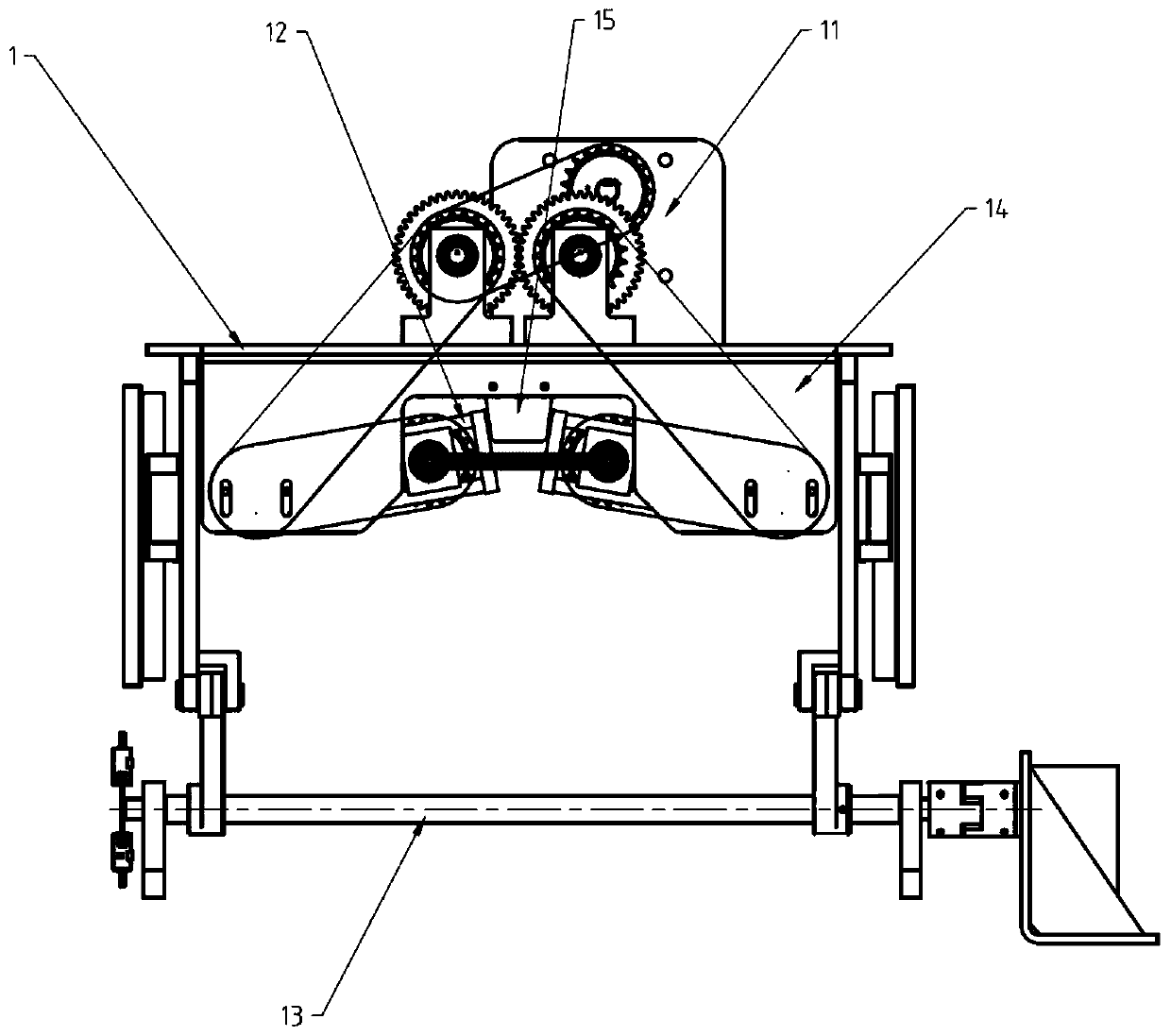

[0043] Combine below Figure 2-Figure 4 , the scraping assembly 1 includes a power transmission mechanism 11, an actuator 12, and a lifting mechanism 13, and the power transmission mechanism 11 includes a first motor 113 and a related transmission shaft, and is connected to the actuator 12 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com