Fixing device for cable laying

A fixing device and cable laying technology, applied in the direction of cable laying equipment, cable installation, cable accessories, etc., can solve the problems of reducing performance, high frequency vibration, affecting the service life, etc., to reduce the current magnetic effect, improve the use of performance, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

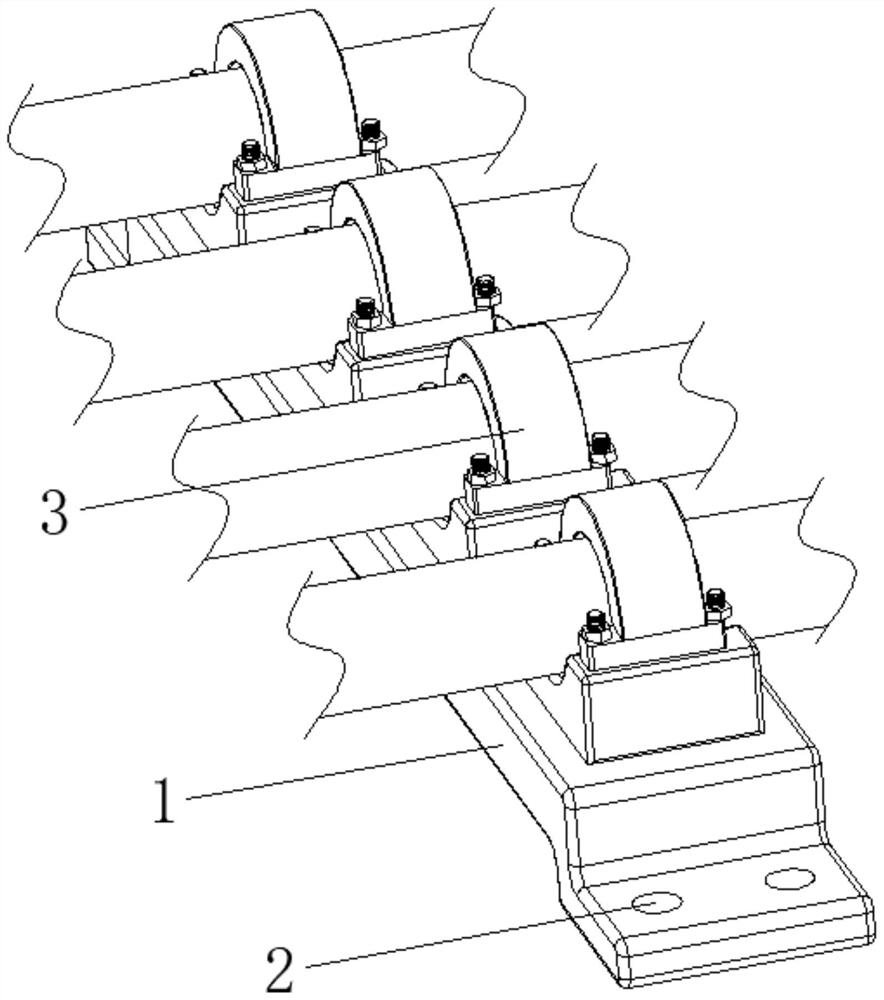

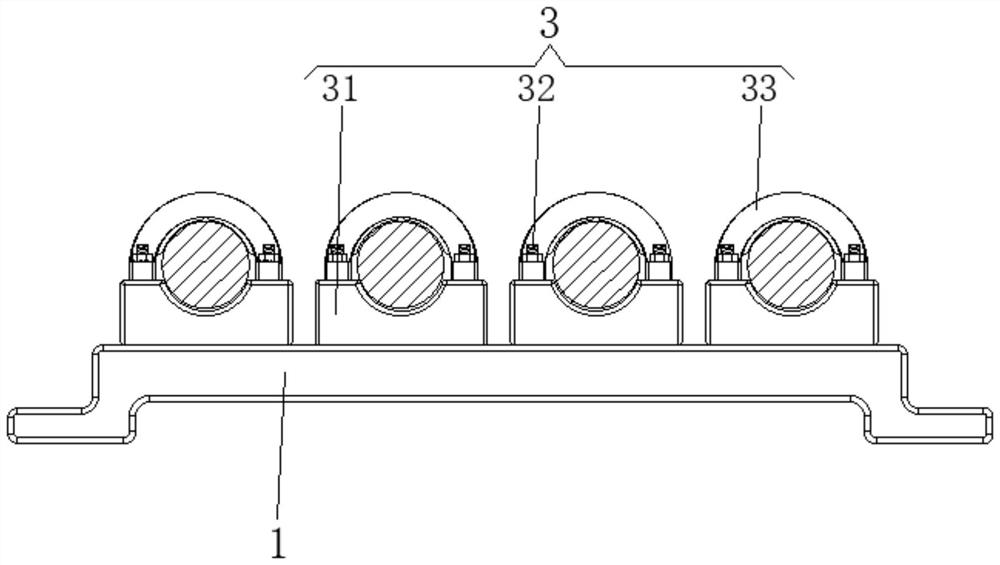

[0030] see Figure 1-6 , the present invention provides a technical solution: a fixing device for cable laying, comprising a mounting base 1, a fixing hole 2, and a line clamp device 3, the fixing holes 2 are set on the two sides corresponding to the bottom edge of the surface of the mounting base 1, The line card device 3 is arranged on the top of the installation base 1, and the line card devices 3 are evenly distributed on the top of the installation base 1;

[0031] The line card device 3 is provided with a limiting device 31, a connecting stud 32, and a pressing device 33. The bottom of the limiting device 31 is fixedly connected to the top of the installation base 1, and the bottom end of the connecting stud 32 is connected to the inside of the limiting device 31. And the position close to the end is fixedly connected, the pressing device 33 is matched and connected on the top of the limit device 31, the pressing device 33 is connected with the connecting stud 32 and fix...

Embodiment example 2

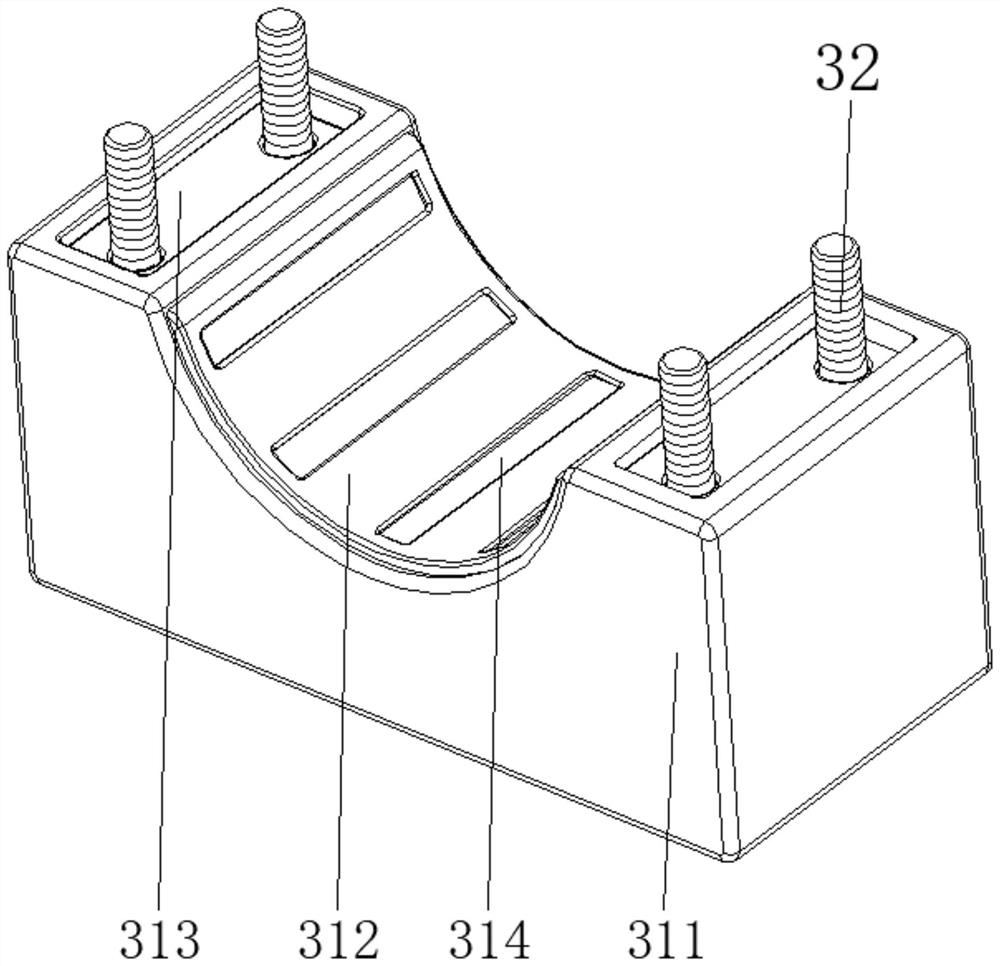

[0033] The limiting device 31 is provided with an arc groove limiting block 311, an anti-skid pad 312, a slide plate 313, and a flexible support device 314. fixed on the surface of the arcuate groove limiting block 311 and located at the groove position, the slide plate 313 is slidably connected inside the arcuate groove limiting block 311 and close to the top position, and the sliding plate 313 is connected with the connecting stud 32, The flexible supporting device 314 is arranged inside the arc groove limiting block 311 and is positioned at the position of the anti-skid pad 312. The bit block 311 cooperates to limit the cable, and at the same time, it is connected by the connecting stud 32 and locked by a nut. At this time, the anti-skid pad 312 has an anti-skid effect on the cable, and it is difficult to move at will. At the same time, the slide plate 313 It will be moved downward by the pressure of the pressing device 33, and then the pressure will be applied to the flexi...

Embodiment example 3

[0036] The pressing device 33 is provided with an arc-shaped pressing plate 331, a pressing key bar 332, and a pressurizing device 333. The pressing key bar 332 is fixed on the bottom end of the arc-shaped pressing plate 331. The booster device 333 is arranged on the inner wall of the arc-shaped pressure plate 331, and is stuck on the cable by the arc-shaped pressure plate 331, and cooperates with the arc-shaped groove limit block 311 through the key bar 332. After locking, the pressure The key bar 332 will press the slide plate 313, so that the cable is supported flexibly, and at the same time, according to the action force and reaction force, the pressure will also be applied to the booster device 333 at this time, which further helps to fix the cable without loosening Case.

[0037] The booster device 333 is provided with an arc panel 3331, a capsule body 3332, and a rubber layer 3333. One end of the arc panel 3331 is rotatably connected to the inner wall of the arc-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com