Patents

Literature

32results about How to "Prevent pull up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

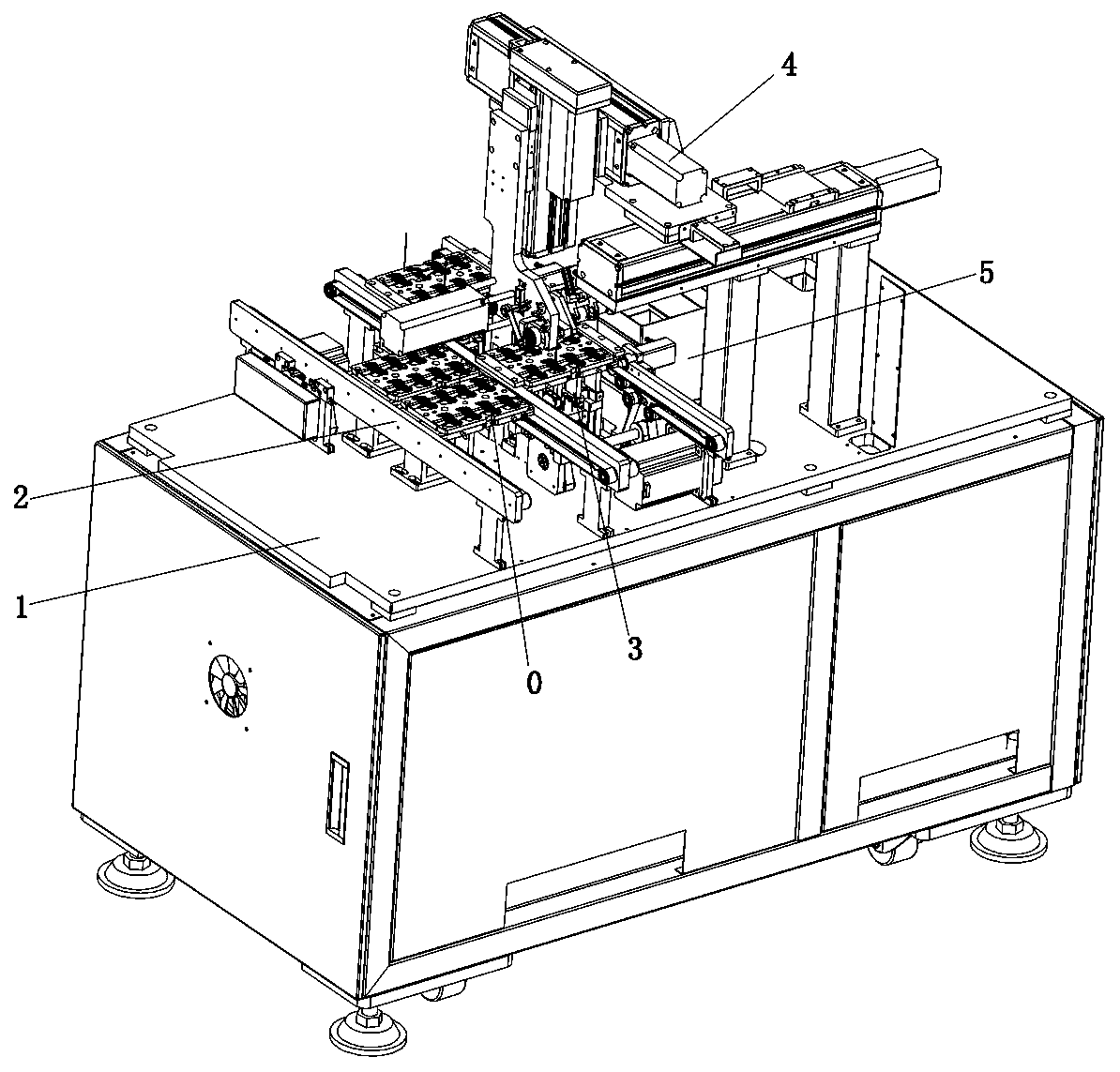

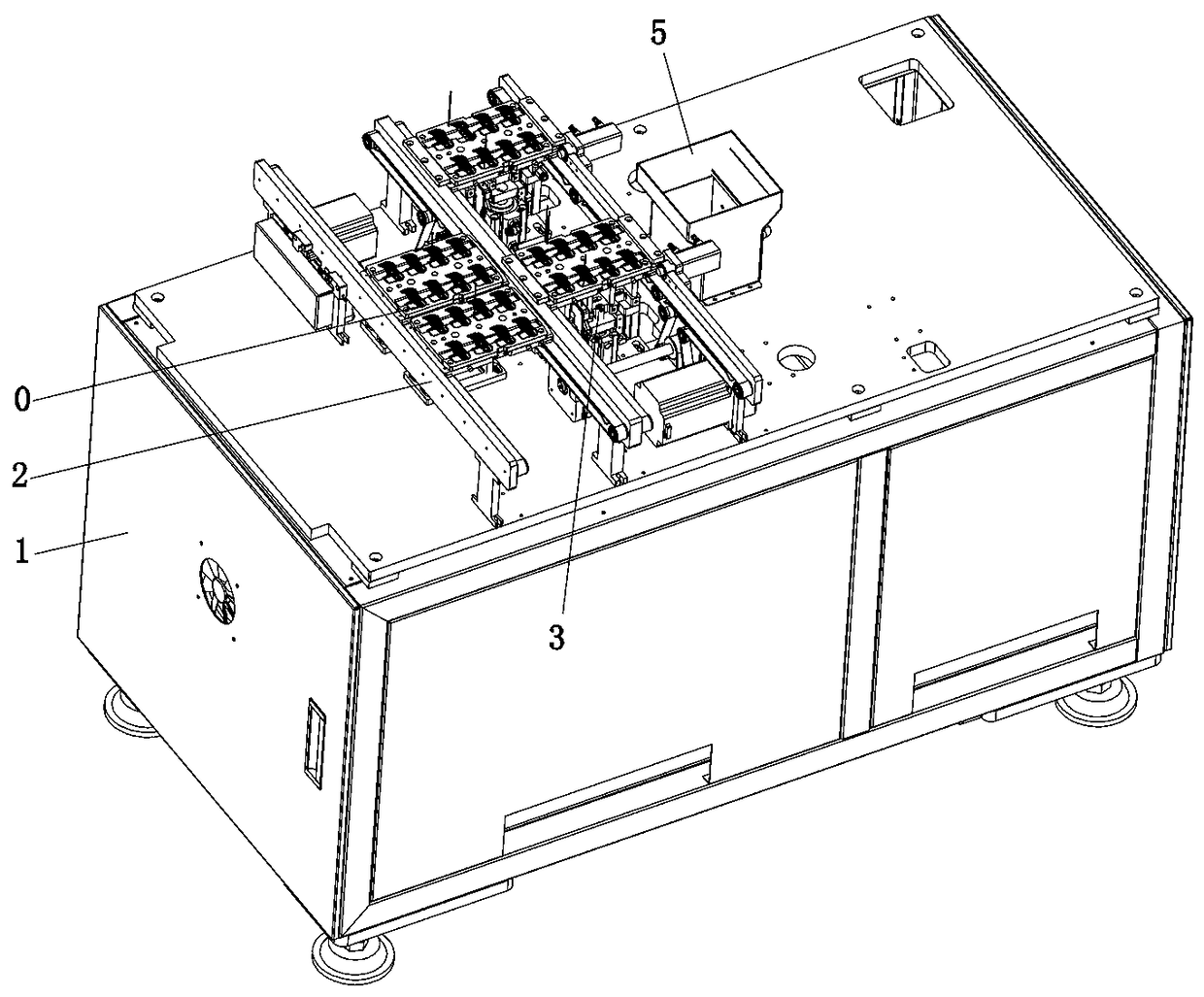

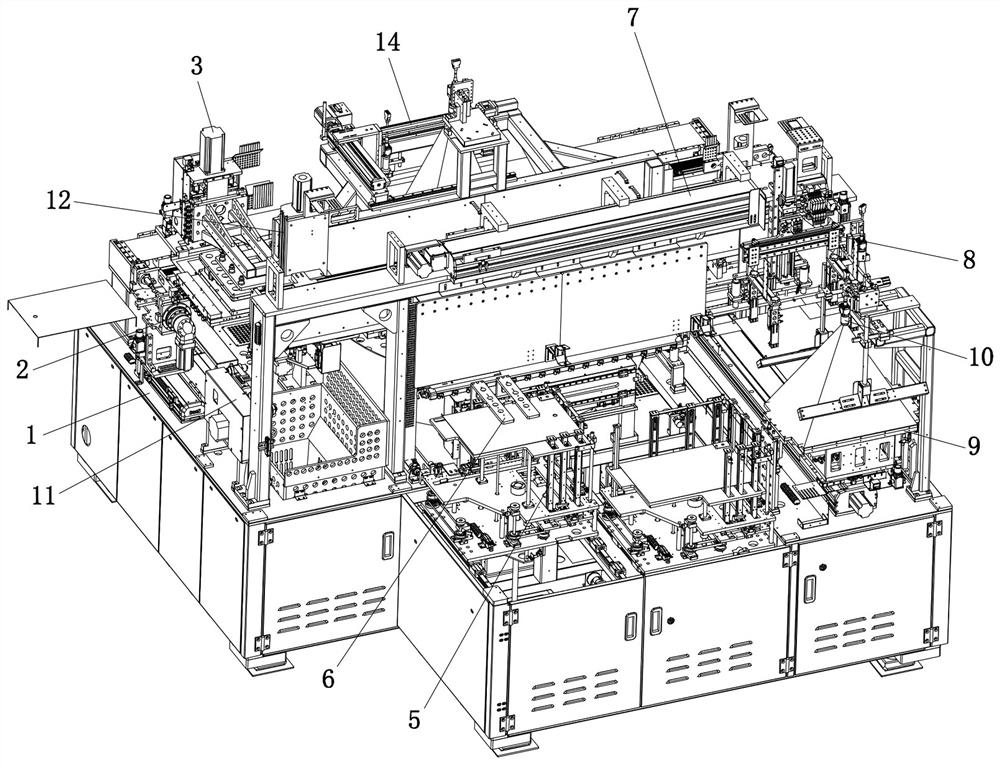

Automatic film tearing machine for accessory assembly

ActiveCN109334215AAvoid position shiftGuaranteed assembly accuracyLamination ancillary operationsLaminationTectorial membraneGlass sheet

The invention discloses an automatic film tearing machine for accessory assembly. The automatic film tearing machine comprises a transmission mechanism, a positioning and supporting mechanism, a filmtearing mechanism and a feed box, wherein the transmission mechanism is horizontally arranged on a rack; the positioning and supporting mechanism is arranged at a film-tearing station; the film tearing mechanism is arranged above the film-tearing station; the film tearing mechanism comprises a rotating component, a film clamping component and a pressing component; the film clamping component and the pressing component are respectively connected to the output end of the rotating component; the film clamping component and the pressing component comprise at least two groups, and every two groupsare arranged at an interval; the output ends of the film clamping component and the pressing component are downwards obliquely arranged opposite to each other; the feed box is arranged below the filmtearing mechanism and has an upward opening; after the protective film on gum is torn out by the film tearing mechanism, the torn protective film is put in the feed box. The automatic film tearing machine for accessory assembly disclosed by the invention is applicable to automatic whole line assembly of accessories, multiple films are torn each time, the film tearing efficiency is effectively improved, position offset of the gum or the glass sheet in the film tearing process is effectively avoided, and the assembling precision and quality are ensured.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

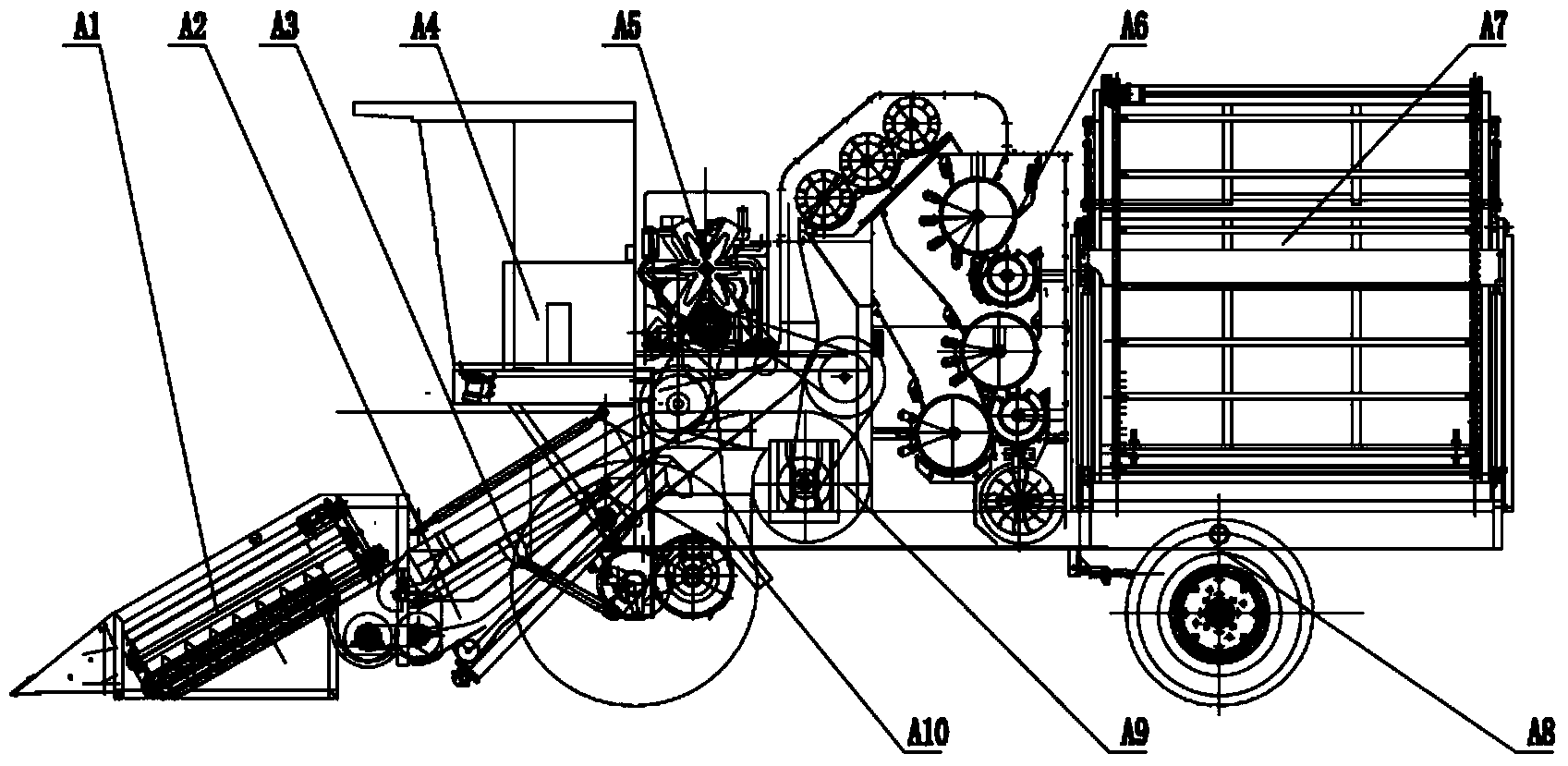

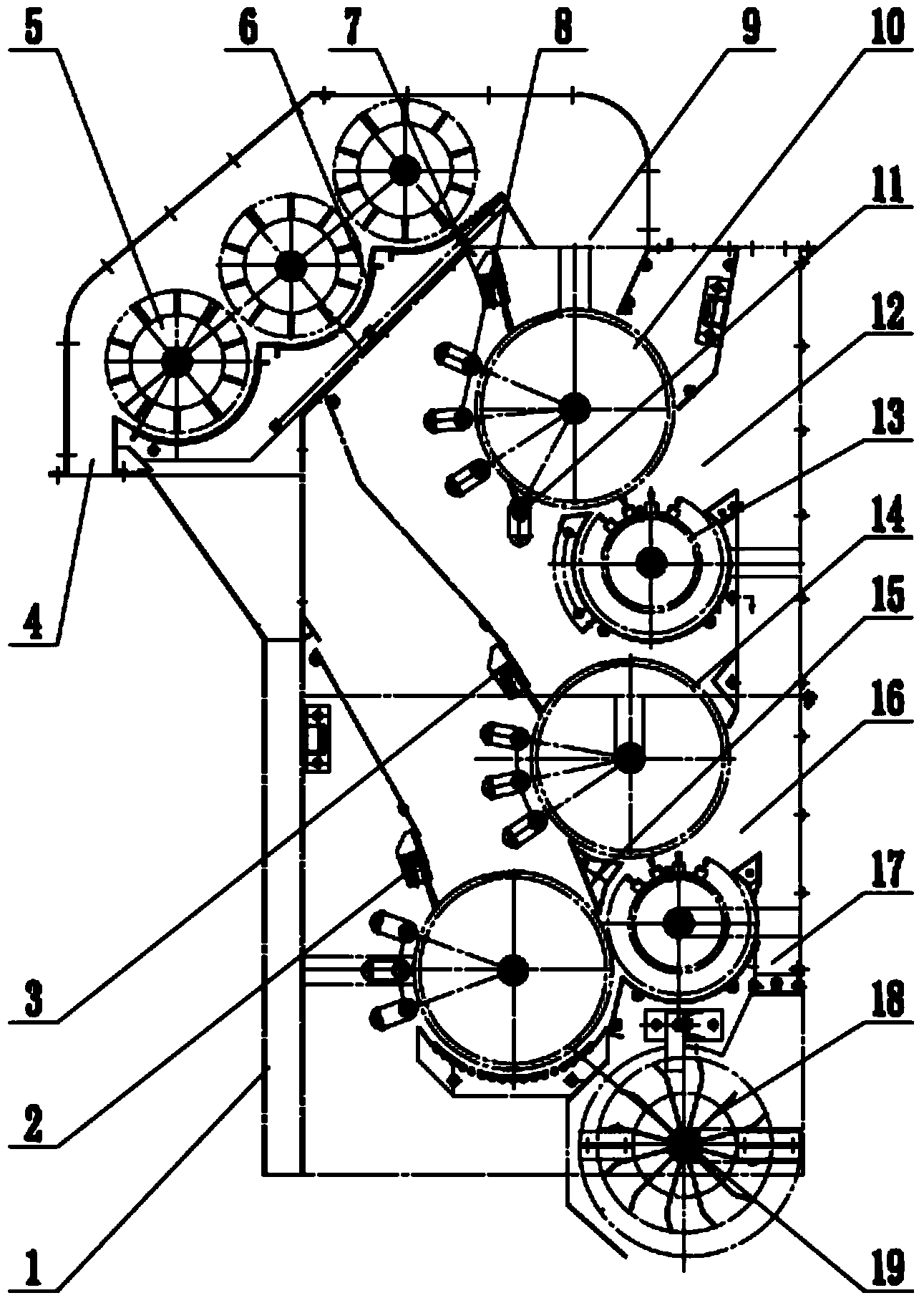

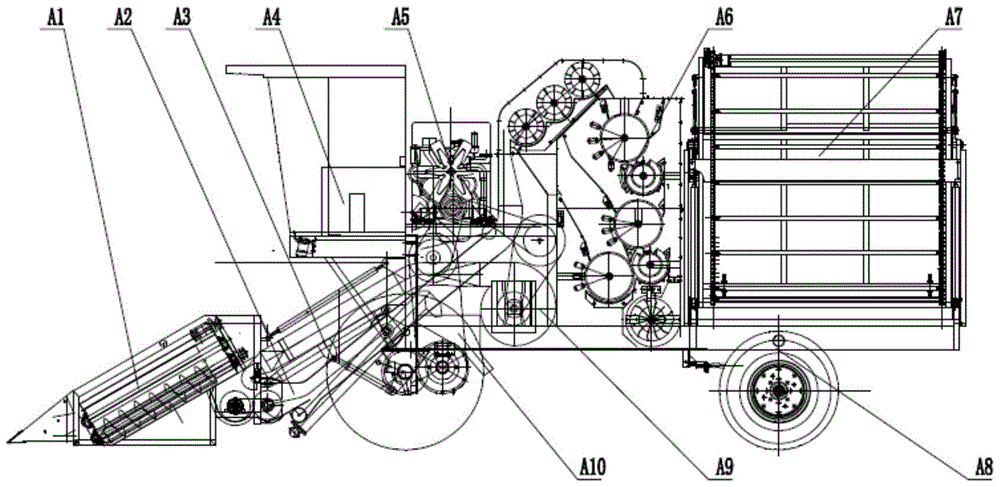

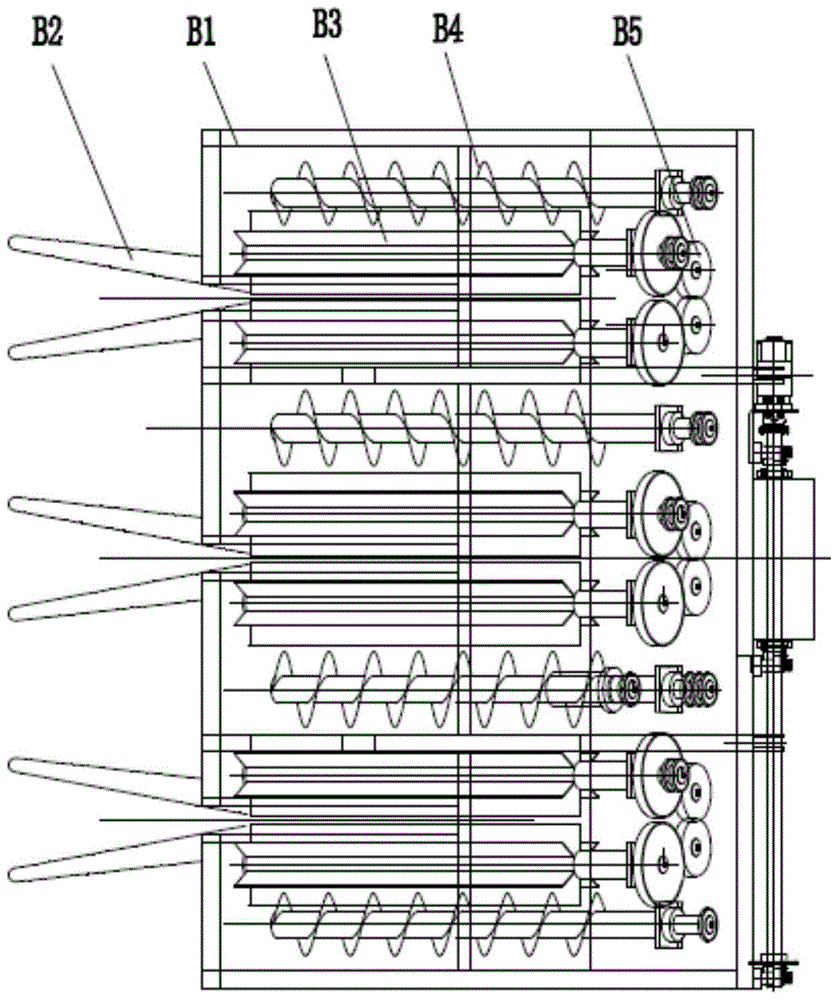

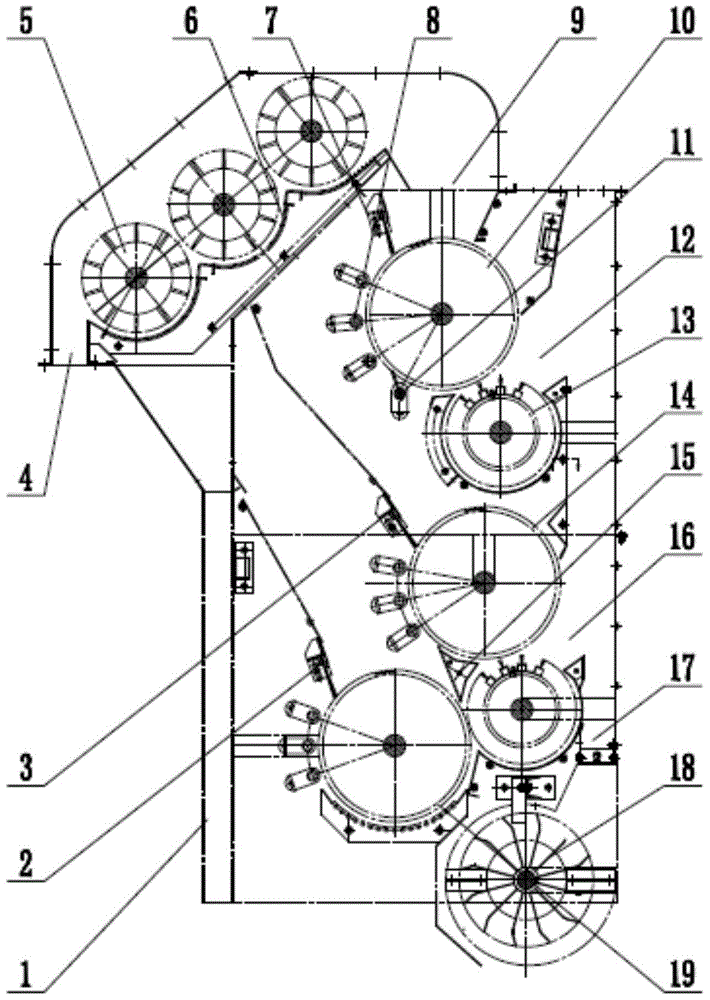

Brush roll cotton picker

The invention relates to a brush roll cotton picker and belongs to the technical field of agricultural machinery. The brush roll cotton picker comprises a picking table, an air conveying device, a cotton boll separating device, an impurity cleaning device and a cotton collecting box which are arranged on a self-walking chassis, the impurity cleaning device comprises primary, secondary and tertiary tooth rollers, one side of the primary tooth roller is provided with an upper brush, one side of the secondary tooth roller is provided with a middle brush, one side of the tertiary tooth roller is provided with a lower brush, sides of the primary, secondary and tertiary tooth rollers are provided with interval arranged beating rods respectively, an upper brush roller is arranged below the primary tooth roller, a lower brush roller with bristles which simultaneously contact with outer circles of the secondary and tertiary tooth rollers is arranged below the secondary tooth roller, an arc barrier is mounted on the lower side of the tertiary tooth roller, one side in a casing, which is far from the beating rods, is provided with a cotton collecting flow channel which conveys air flow from bottom to top, and the cotton collecting flow channel is provided with upper and lower flow suction openings. The bottom of the cotton collecting flow channel is connected with an air outlet of a cotton conveying fan. By means of the brush roll cotton picker, cotton fiber damages can be remarkably reduced, the impurity cleaning effect is improved, the impurity content rate is lower than 10%, meanwhile, the recycling effect is enhanced, and the unginned cotton loss can be greatly reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

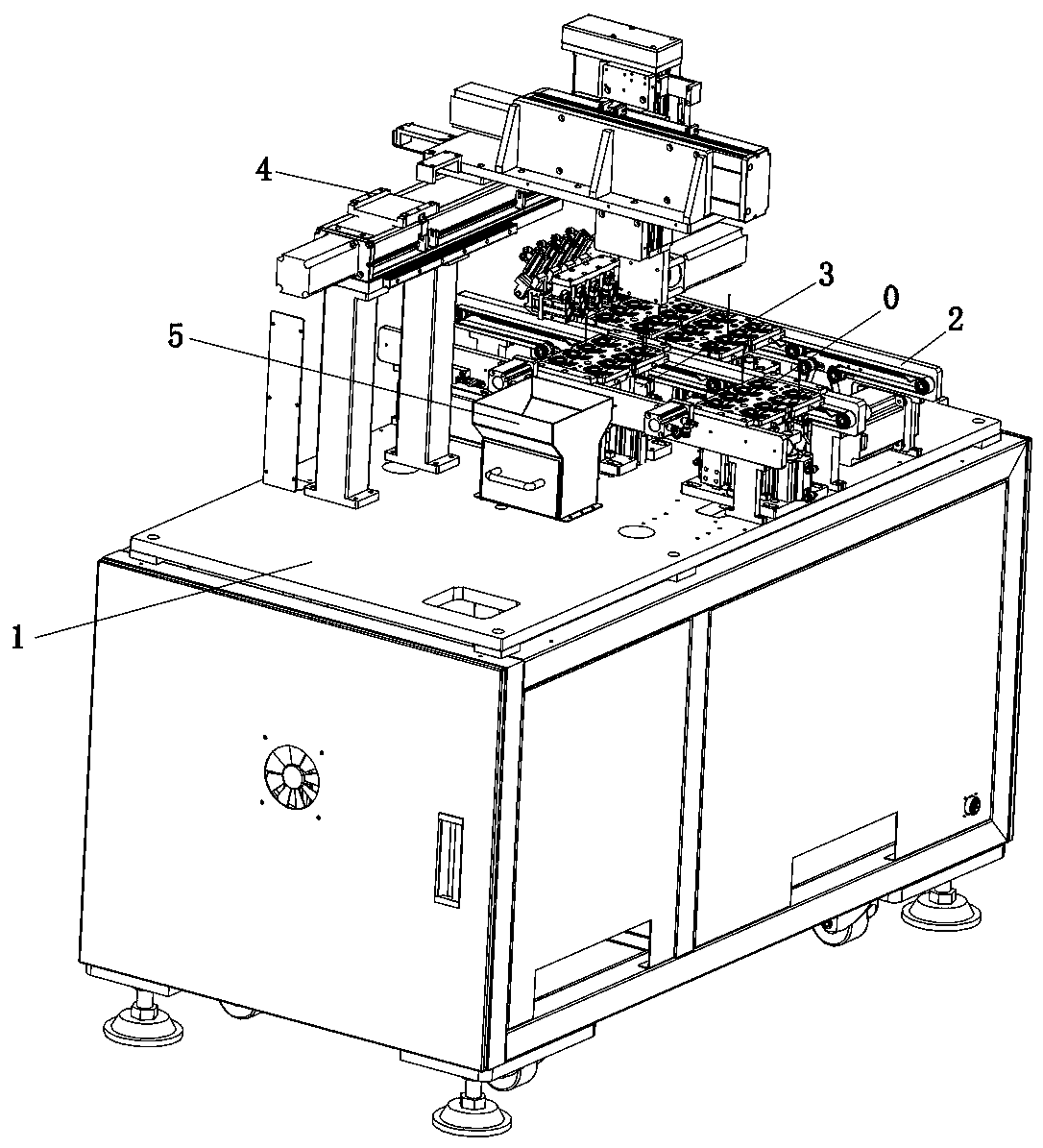

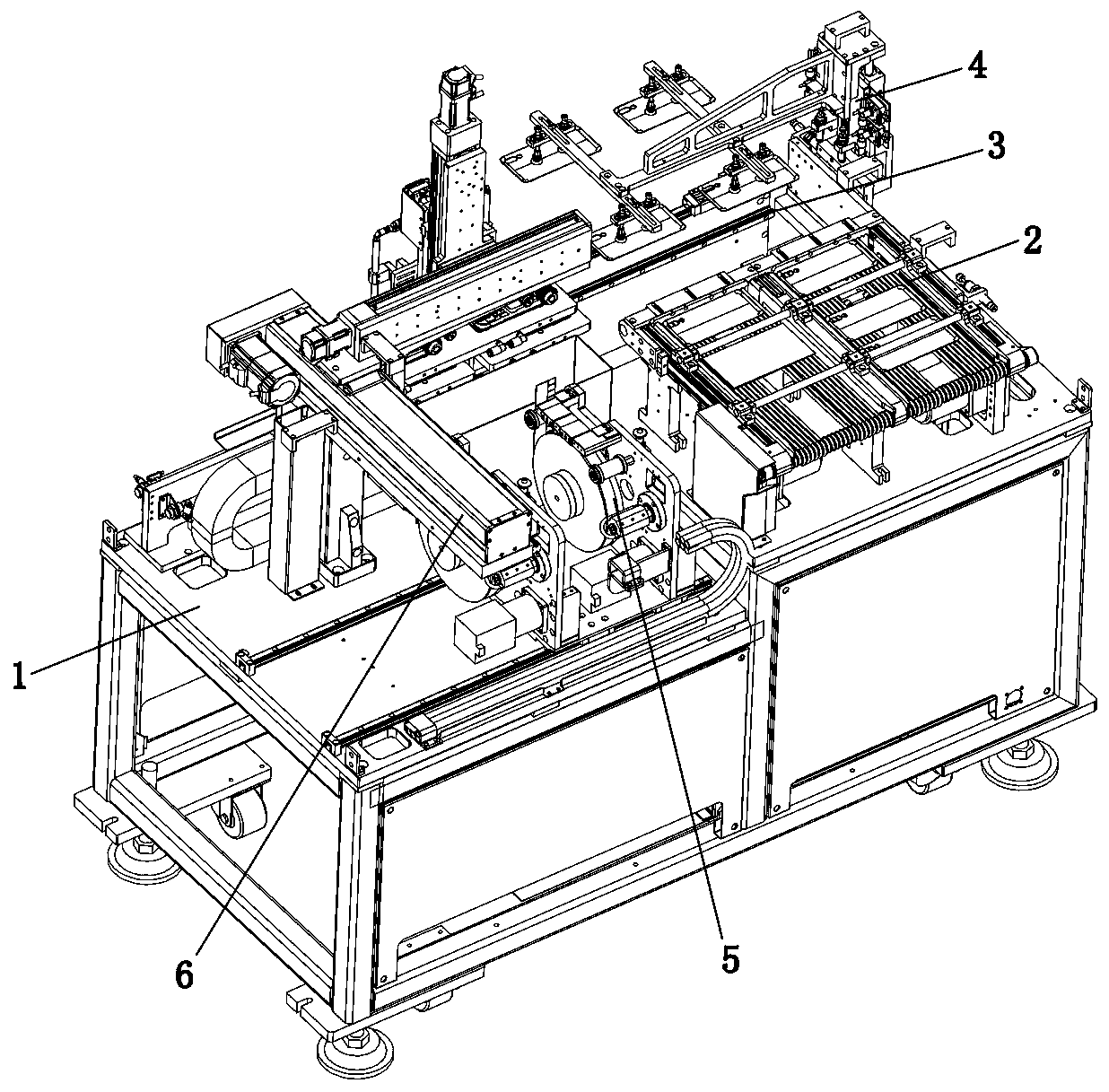

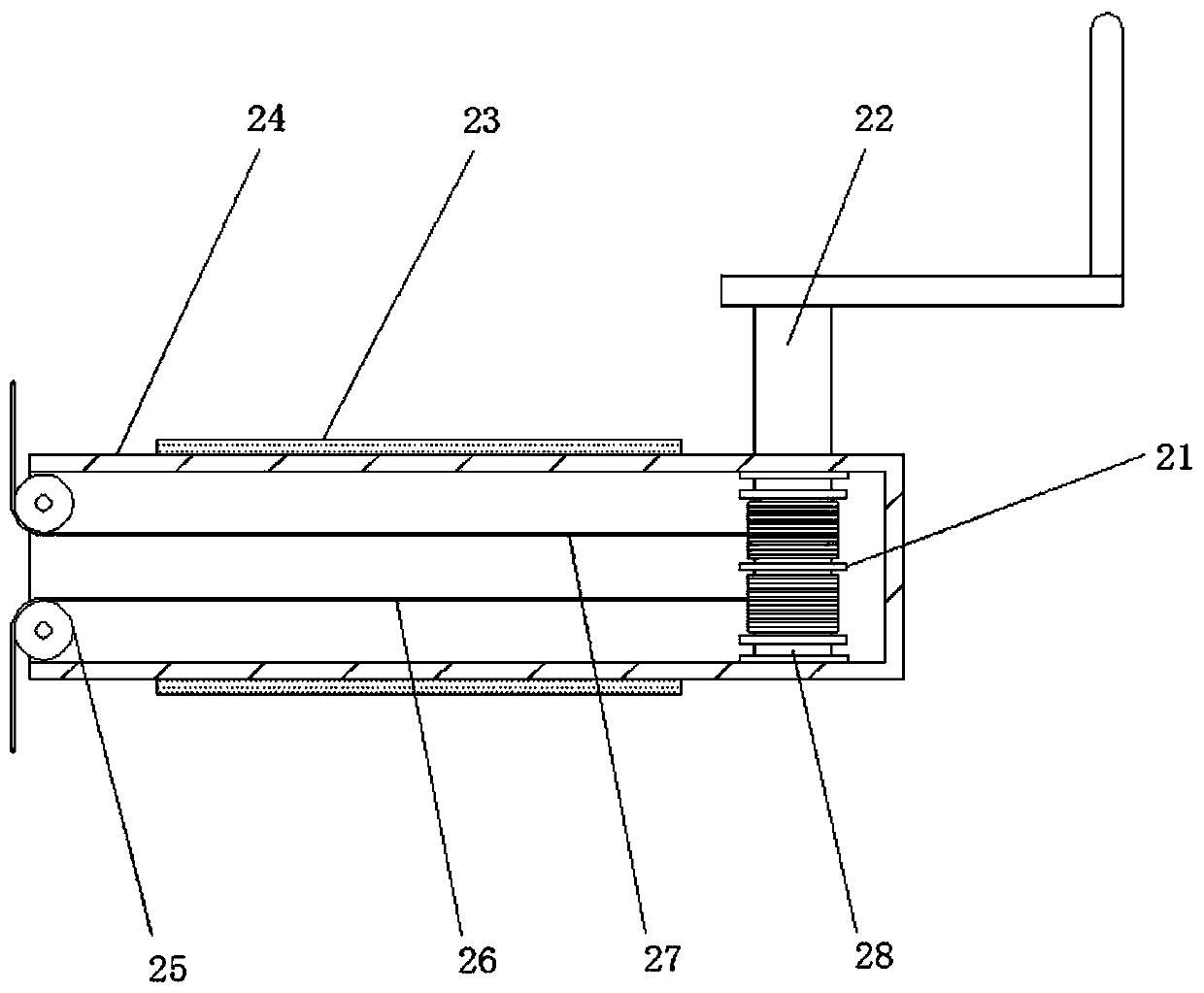

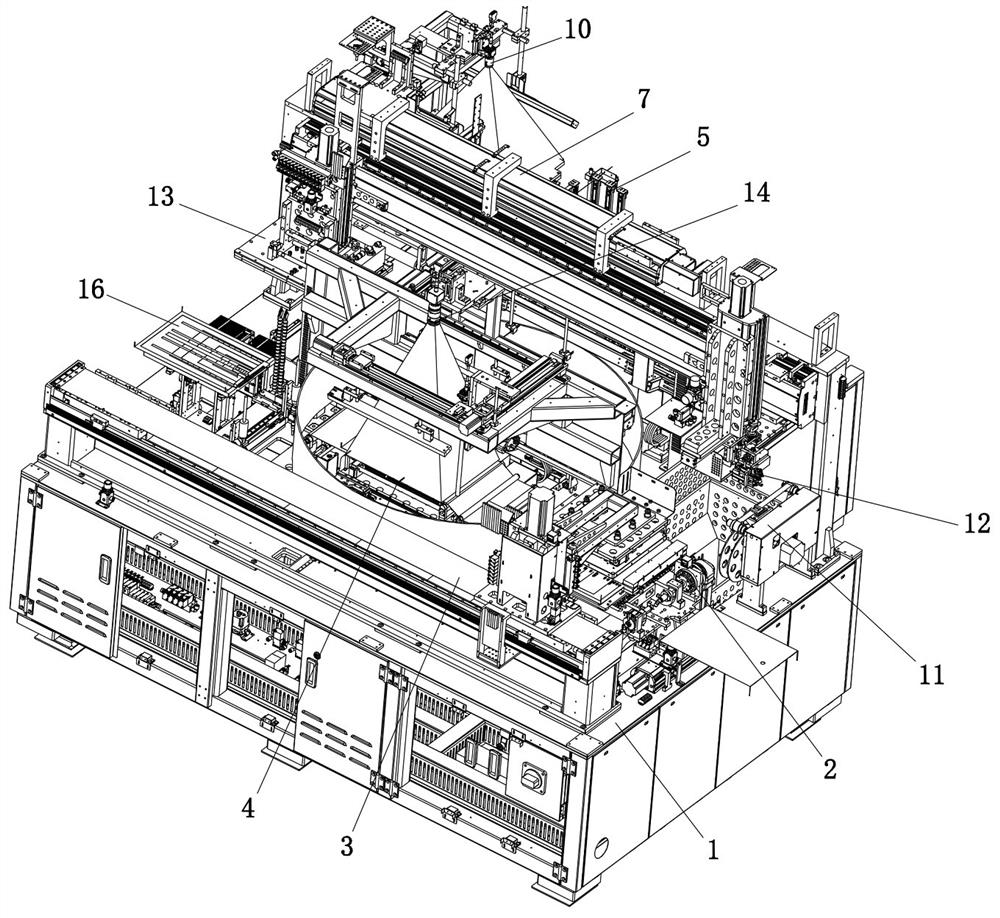

Automatic film tearing machine and film tearing process thereof

PendingCN109353112AReduce the difficulty of tearing the filmReduces substrate damageLamination ancillary operationsLaminationManipulatorEngineering

The invention discloses an automatic film tearing machine and a film tearing process thereof. The automatic film tearing machine comprises a conveying belt, a lifting and sliding platform, a picking manipulator, an easy-to-tear guide-out mechanism and a film tearing mechanism. The conveying belt is horizontally arranged on a frame; the lifting and sliding platform is arranged at the discharging end of the conveying belt; the picking manipulator is arranged on the other side of the conveying belt and the lifting and sliding platform; the easy-to-tear guide-out mechanism is arranged on one sideof the conveying belt, and the film tearing mechanism is arranged above the lifting and sliding platform and the easy-to-tear guide-out mechanism; the film tearing mechanism comprises a rotating component and two film tearing components, and the film tearing components are respectively arranged on two sides of the rotating component. The automatic film tearing machine and the film tearing processthereof have the advantages that the film tearing difficulty is lowered effectively, and damage to base materials is reduced; alternate feeding and discharging of the base materials are realized, andlinkage between feeding and discharging of the base materials and the film tearing mechanism is effectively improved; the film tearing components are driven synchronously in the same direction to rotationally tear films, and accordingly, the film tearing efficiency is improved greatly.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

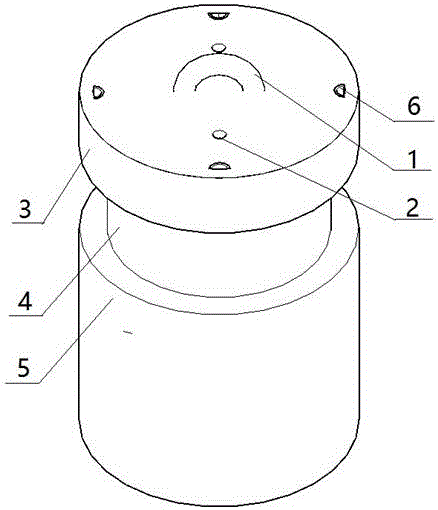

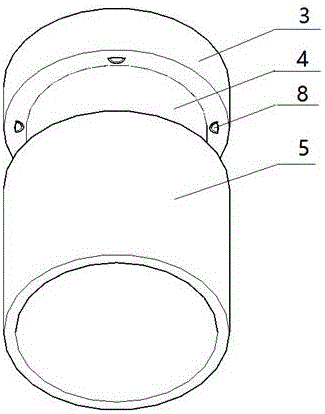

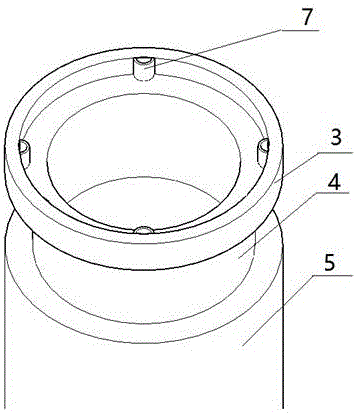

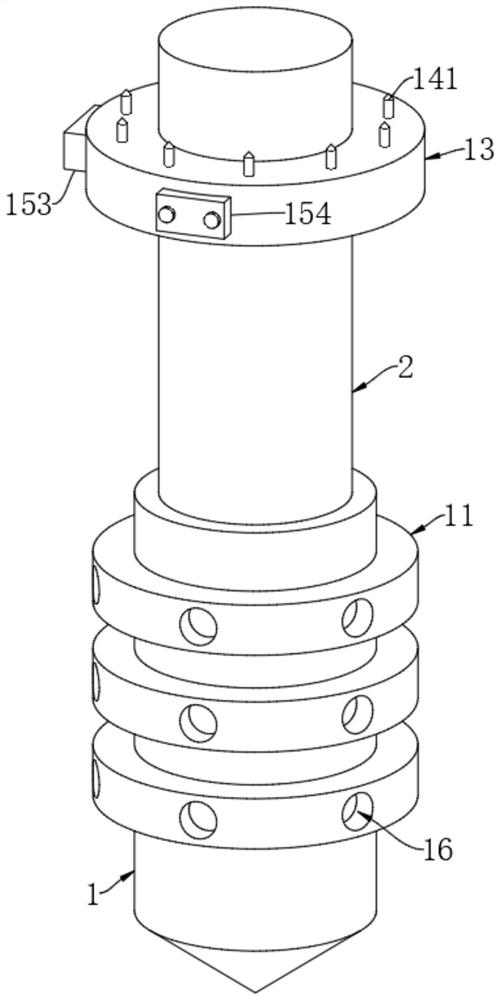

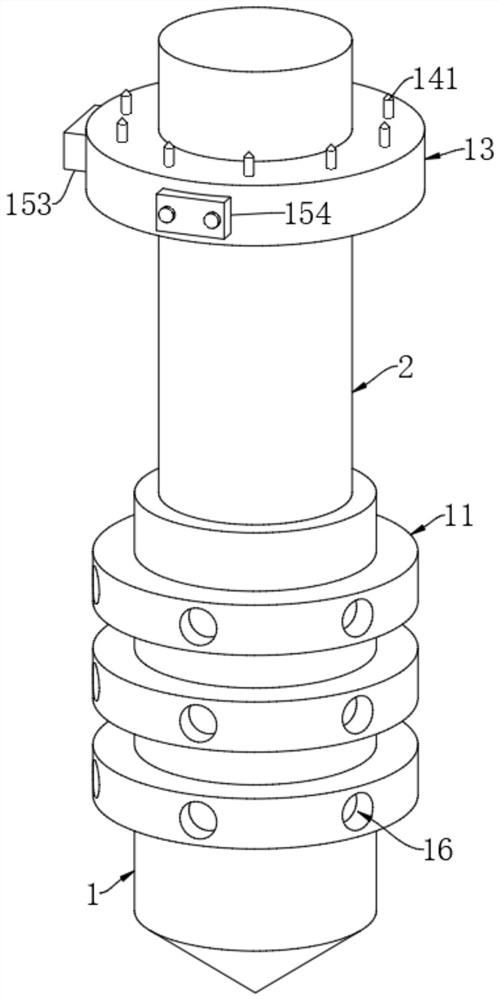

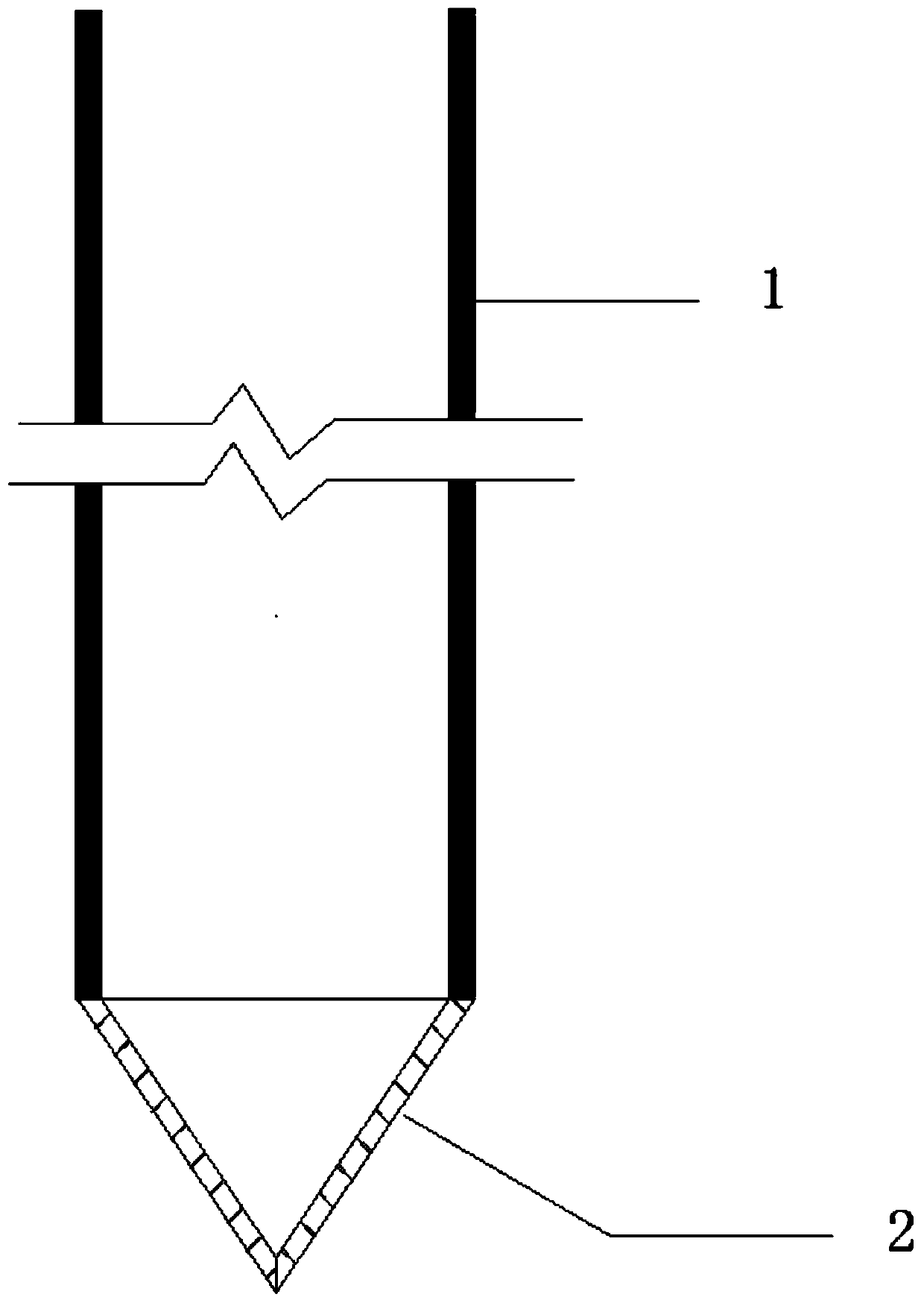

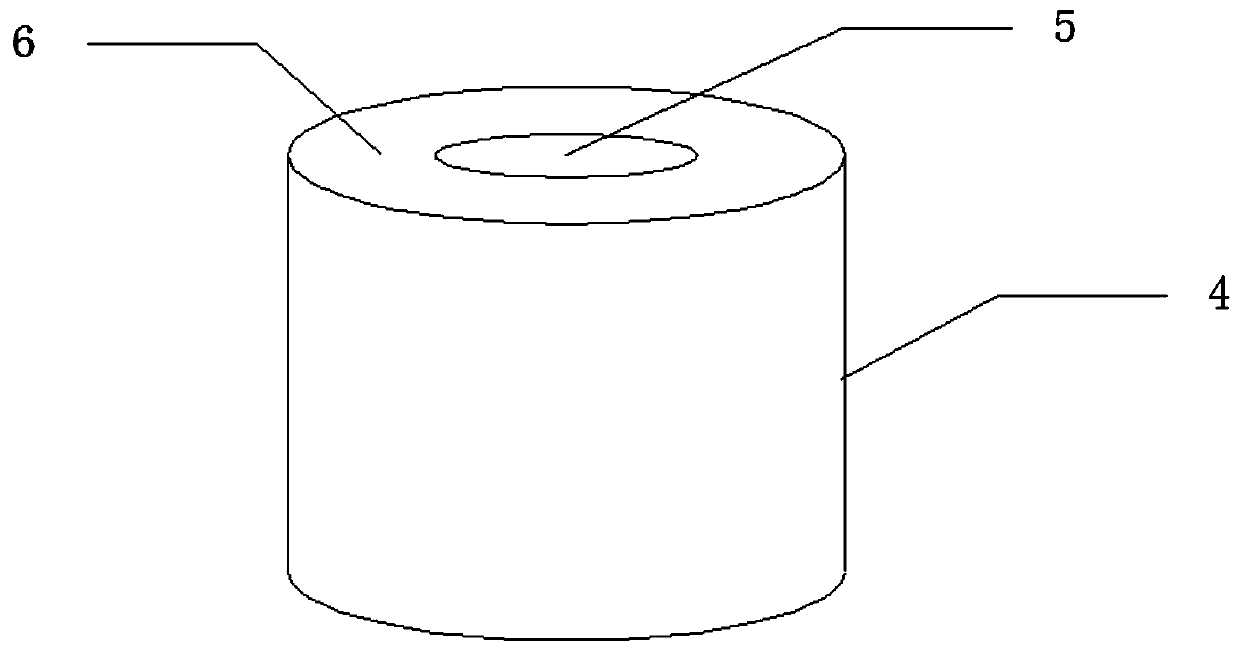

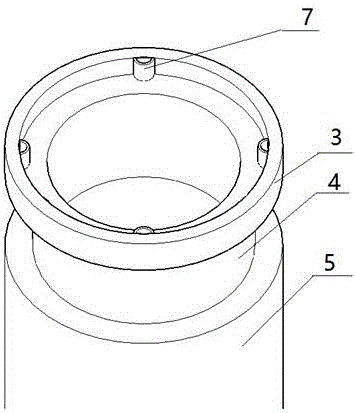

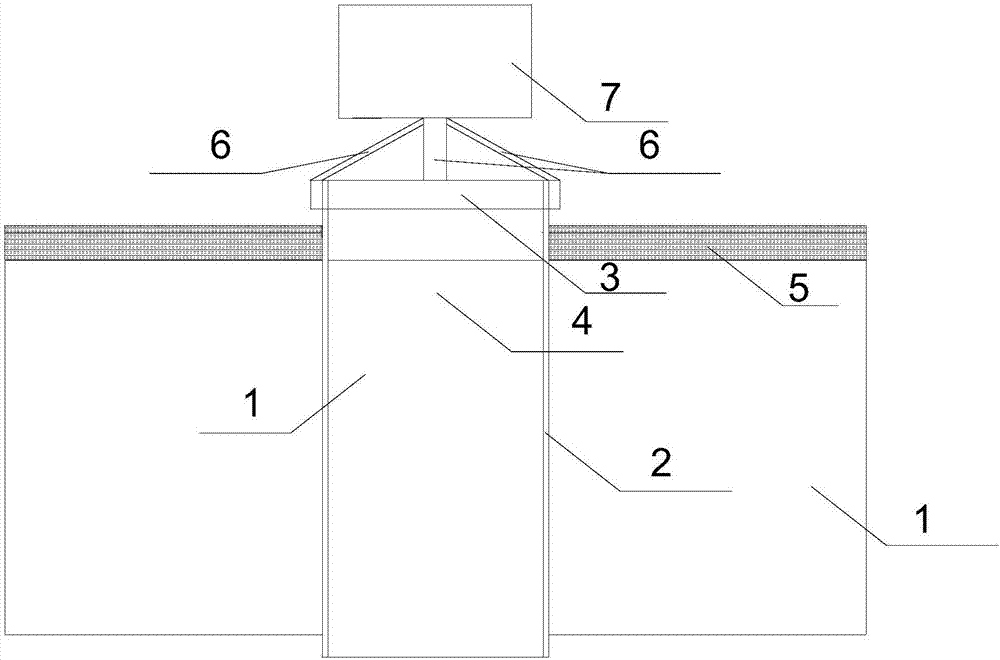

Grouting suction anchor and installation method thereof

InactiveCN106240749APrevent pull upImprove ultimate pull-out capacityAnchorsBulkheads/pilesEngineeringCement mortar

The invention discloses a grouting suction anchor comprising a cylinder body; the cylinder body has an integral structure comprising an upper part, an intermediate part and a lower part; the diameter of the upper cylinder body is identical to that of the lower cylinder body; the diameter of the intermediate cylinder body is less than those of the upper cylinder body and the lower cylinder body; the upper, the intermediate and the lower cylinder body share a same center line; a top part of the upper cylinder body is provided with multiple grouting inlets and scuppers; the grouting inlets are communicated with a grouting channel inside a side wall of the upper cylinder body; the grouting channel extends downwards to a lower end surface of the upper cylinder body; an outlet of a lower end of the grouting channel is positioned between the outer lateral surface of the upper cylinder body and the outer lateral surface of the intermediate cylinder body; the grouting channel and the cylinder body inner chamber are separated from each other. The invention also discloses an installation method of the suction anchor. After downward penetration of the suction anchor is completed, the intermediate cylinder body and soil body interspace are filled with cement mortar which can improve the lateral bearing capacity of the suction anchor. After the cement mortar is solidified, the friction coefficient between surrounding soil body and anchor cylinder contact surface is increased and the limit bearing capacity of the suction anchor is increased.

Owner:OCEAN UNIV OF CHINA

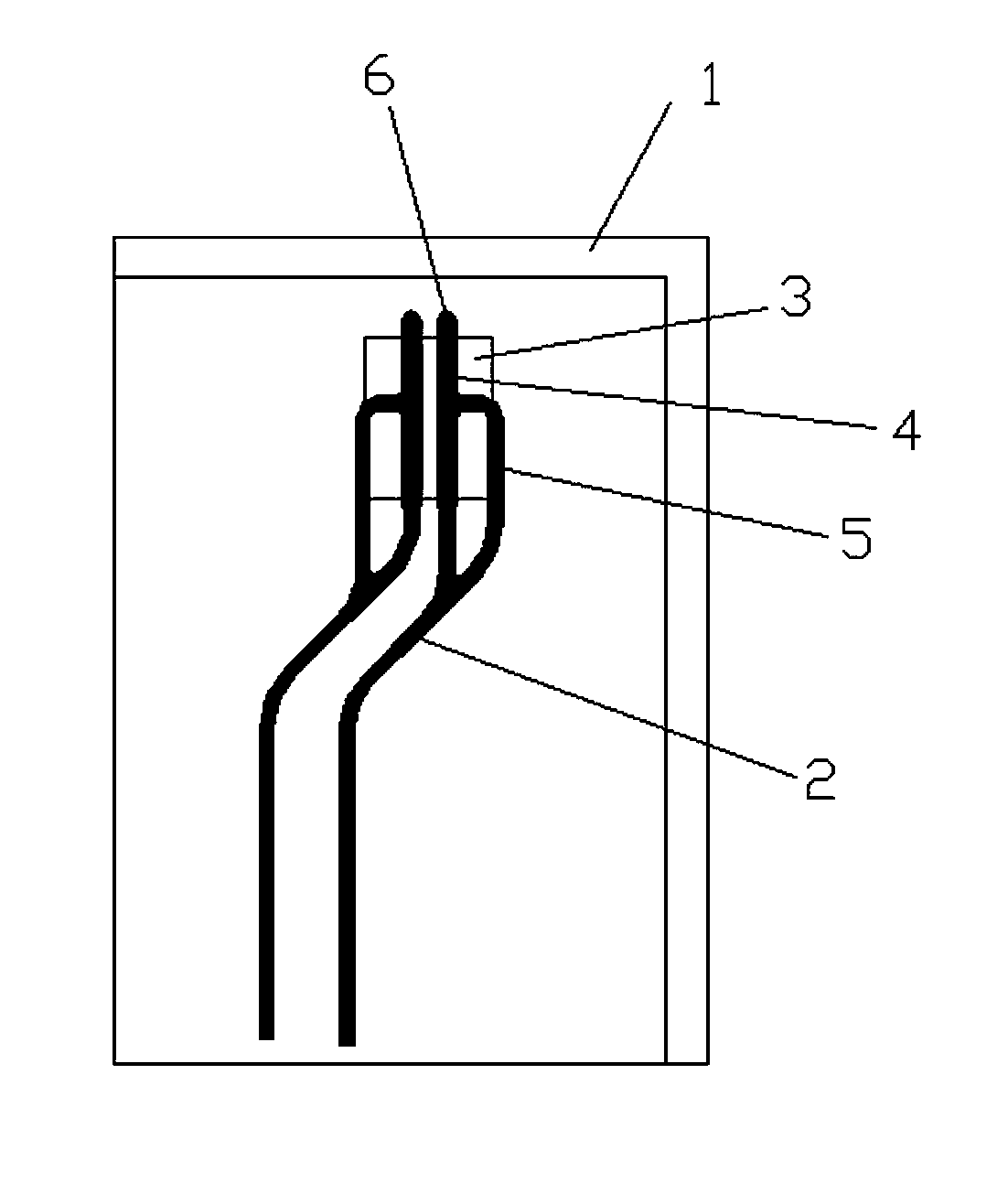

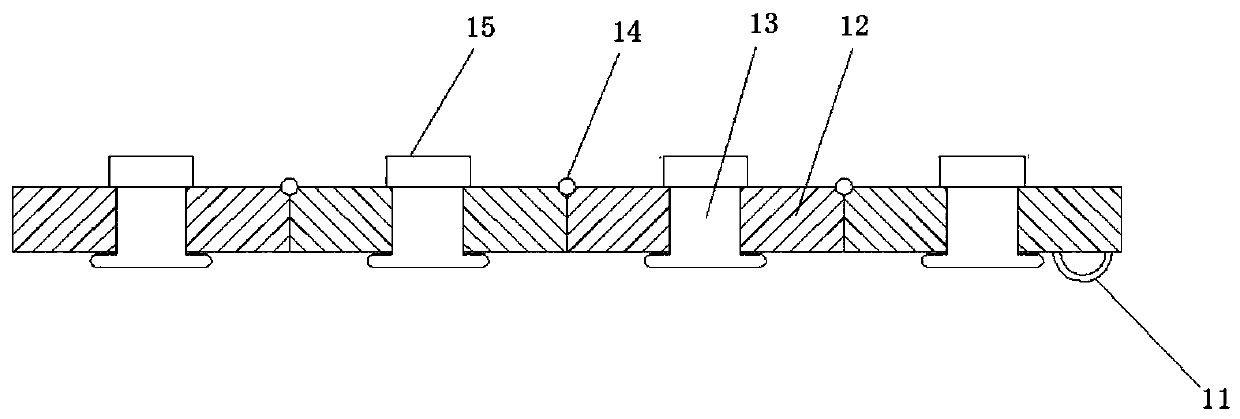

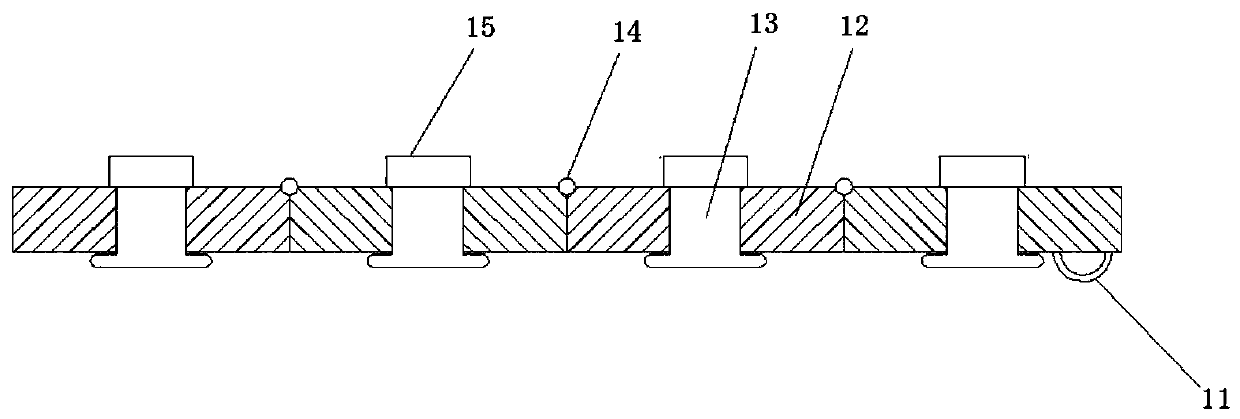

FPC (flexible printed circuit) welding disc

InactiveCN103458612APrevent pull upImprove adhesionElectrical connection printed elementsAgricultural engineeringCopper foil

The invention discloses an FPC (flexible printed circuit) welding disc which comprises a substrate and walking lines arranged on the substrate. An upper covering film is arranged on the walking lines, copper foil on each walking line is exposed by forming a window at one end of the walking line by the upper covering film to form a welding disc body, and a second walking line is led out at the public end of each welding disc walking line to be connected in the middle of the welding disc walking line. The FPC welding disc is firmer and capable of lowering product reject rate.

Owner:昆山凌达光电科技有限公司

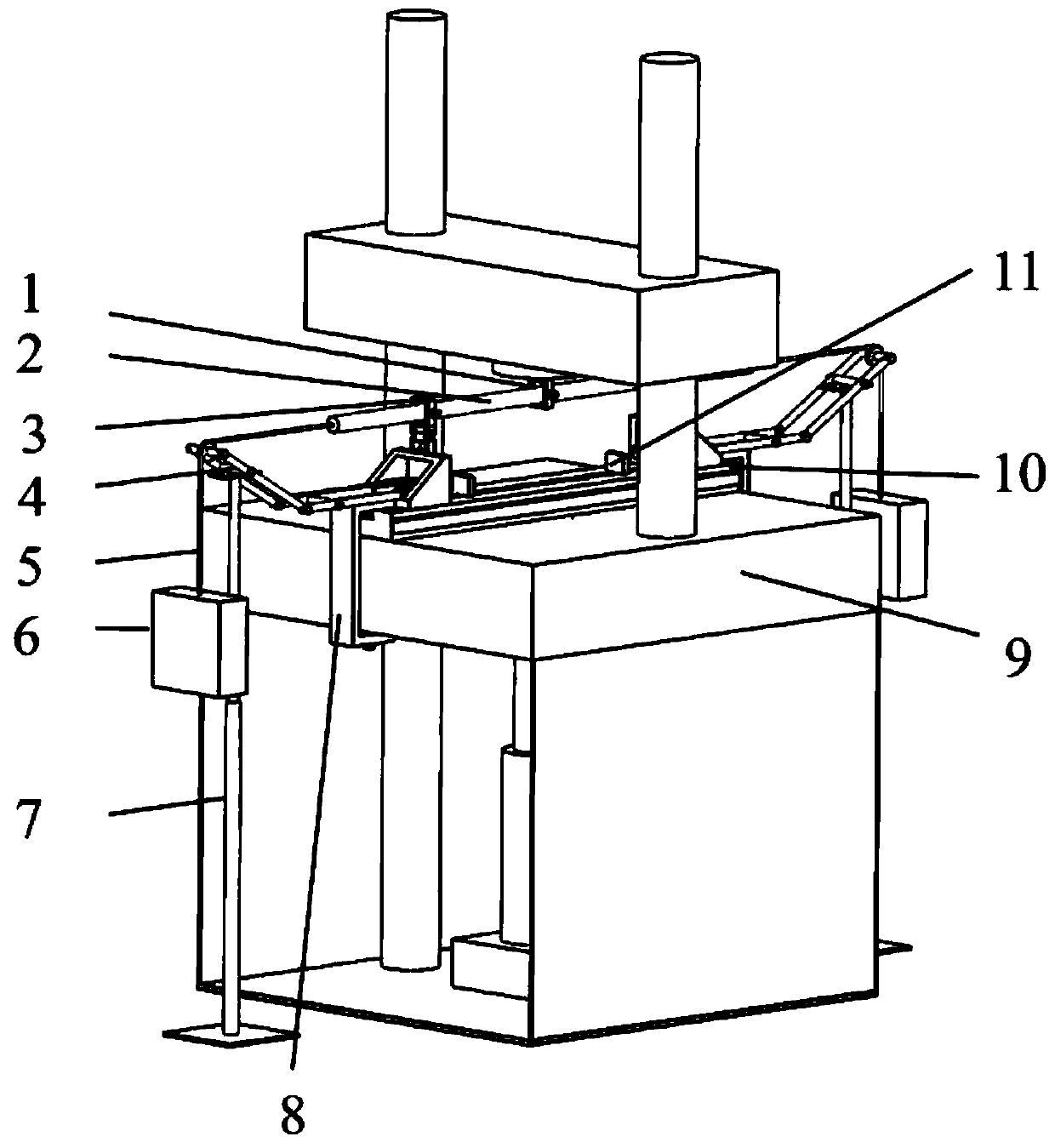

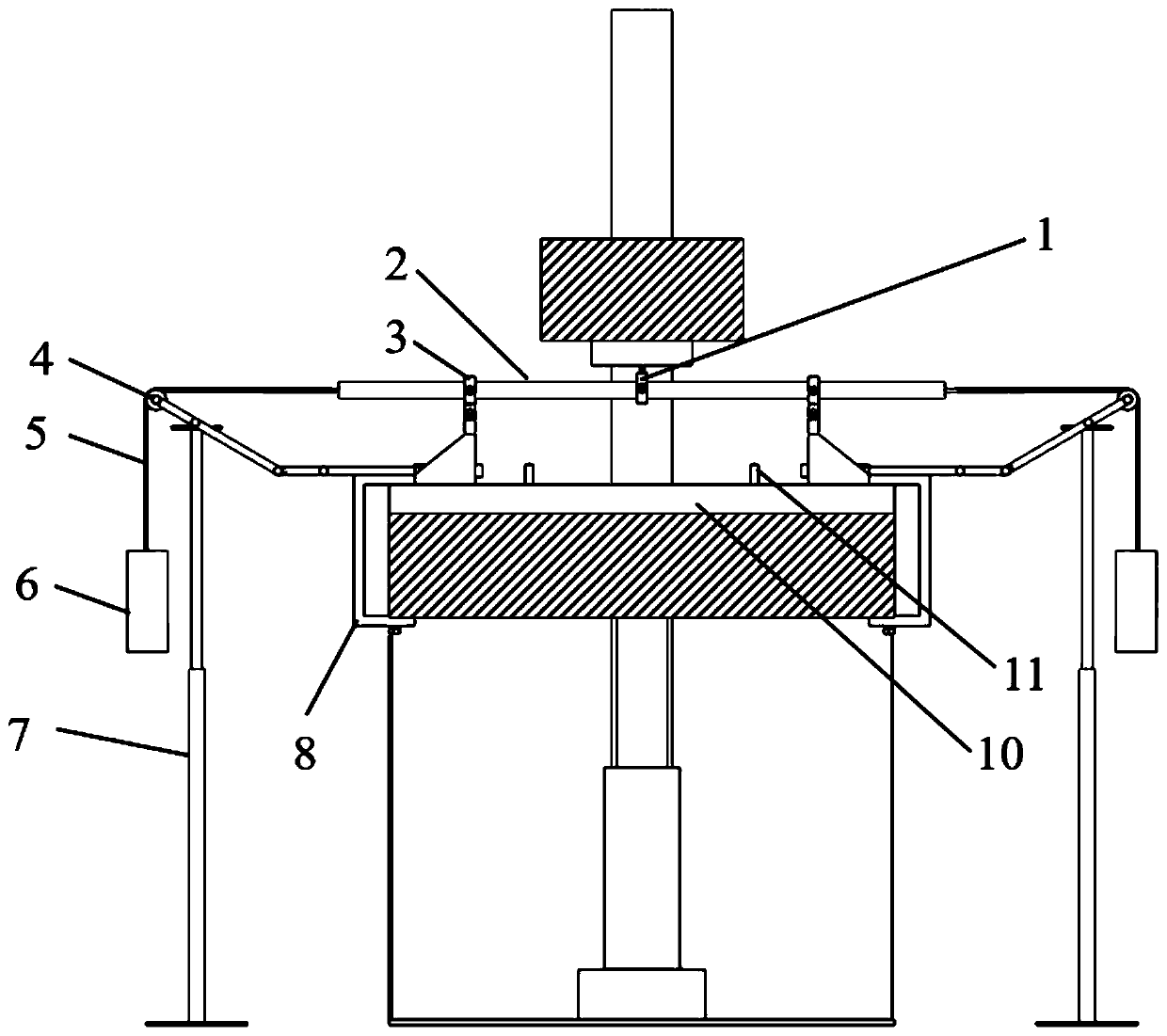

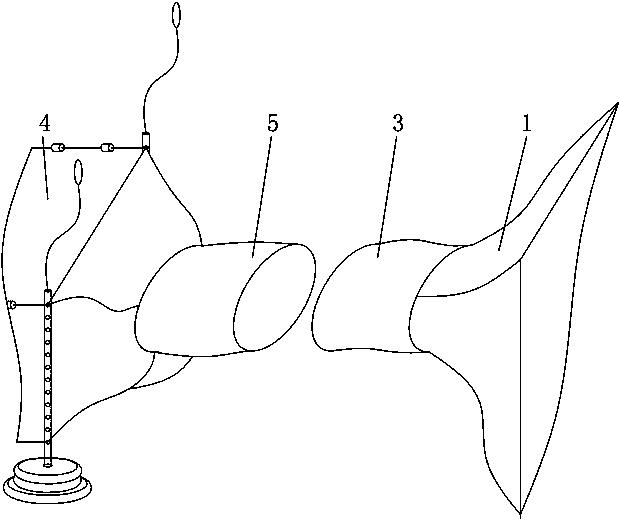

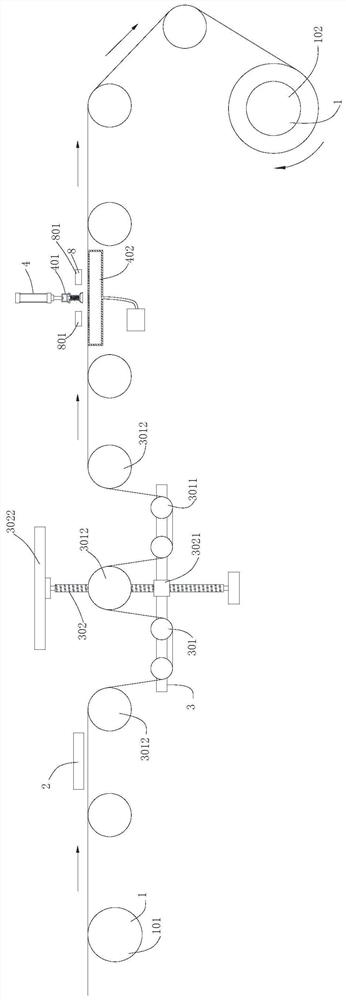

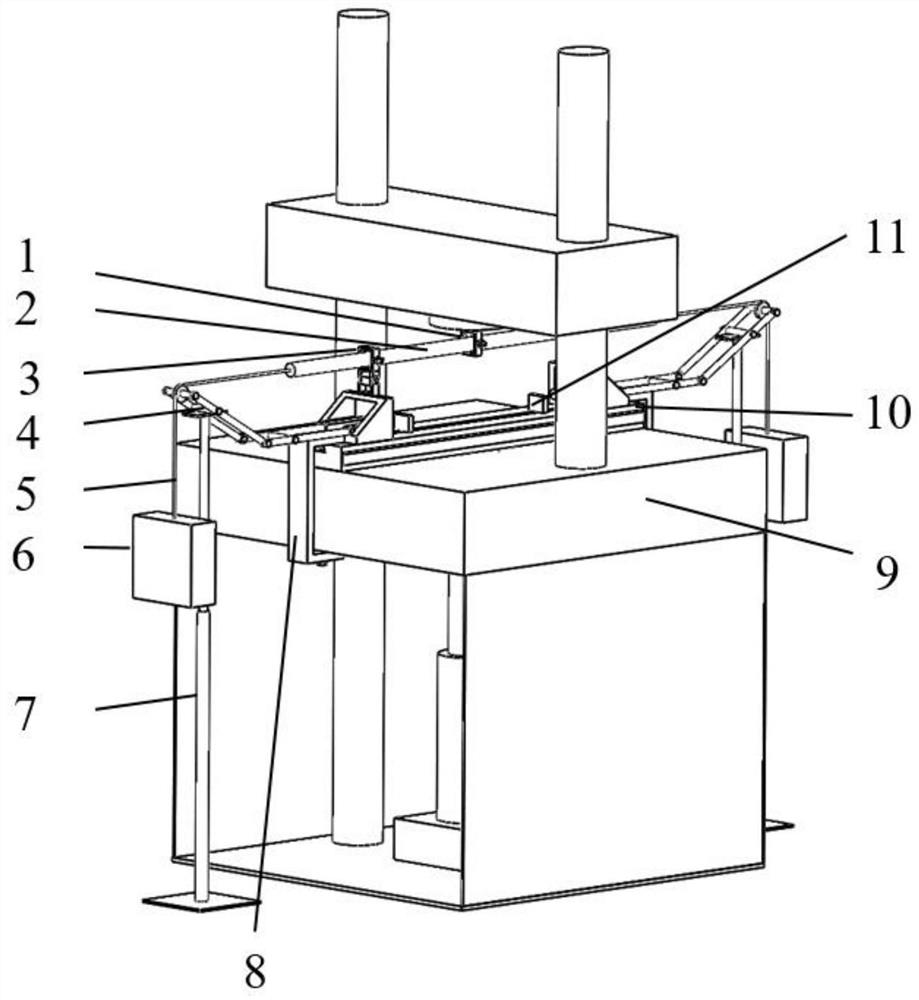

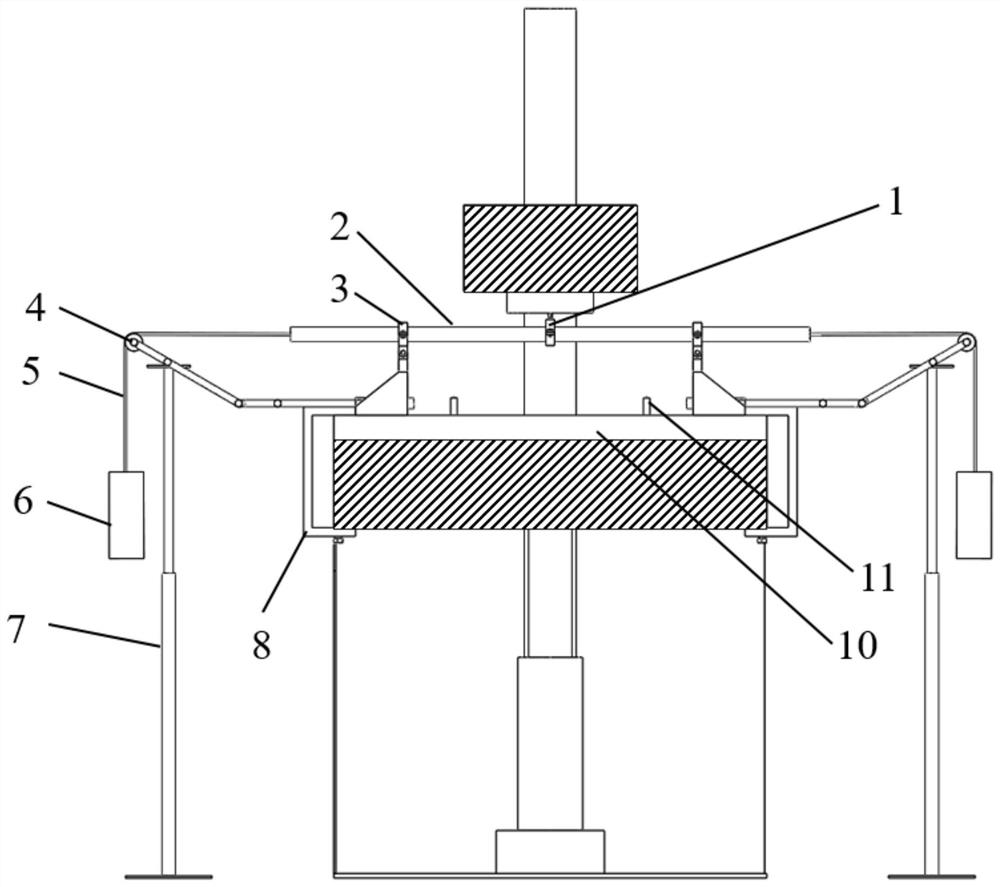

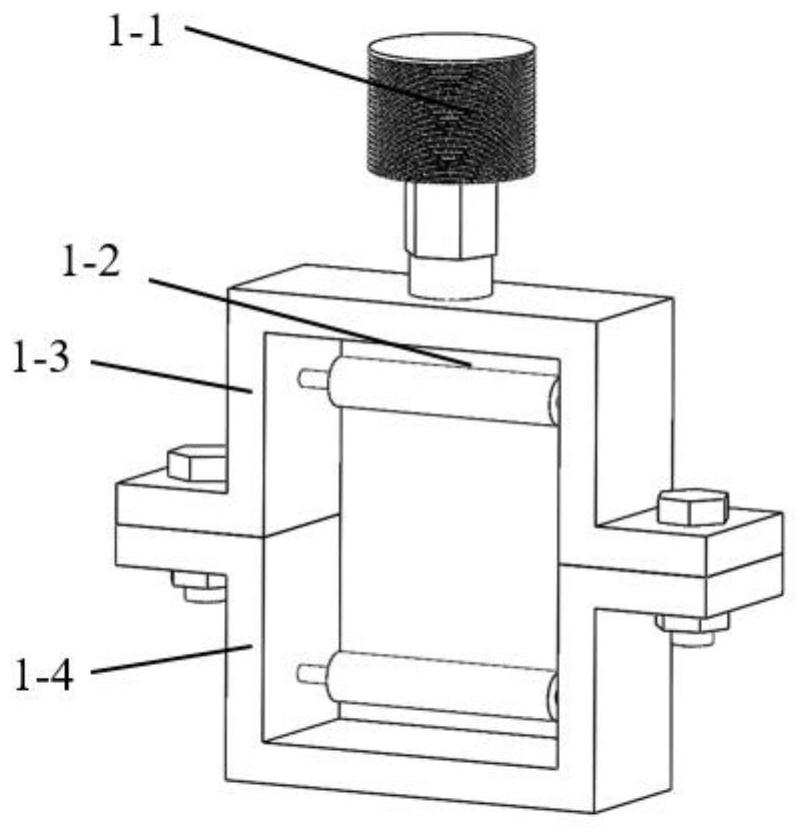

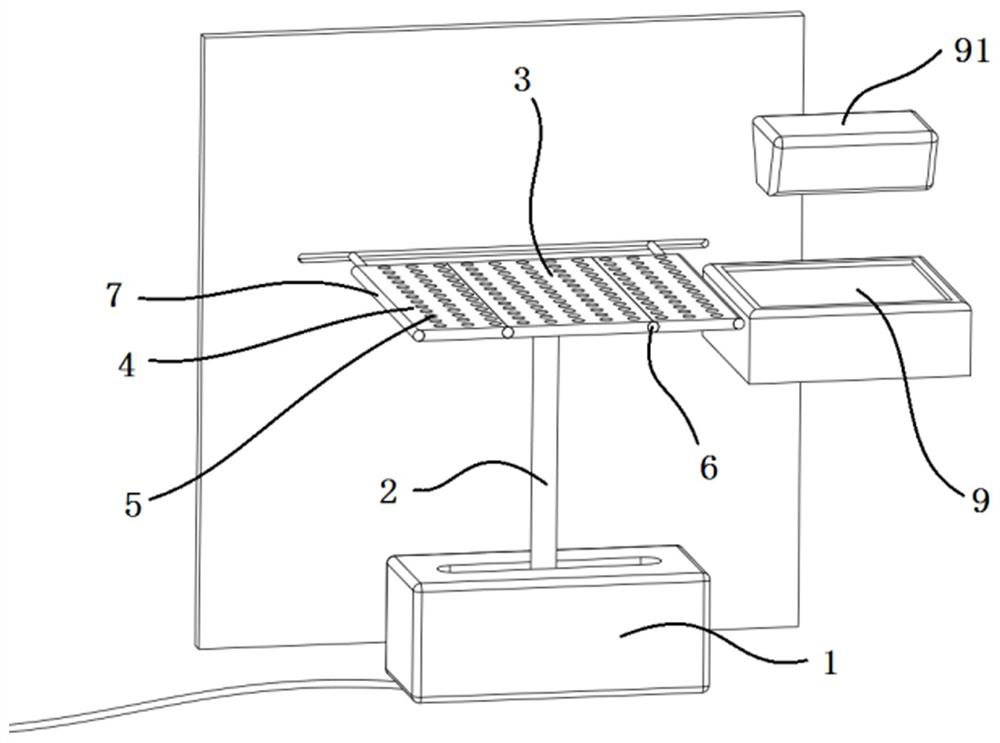

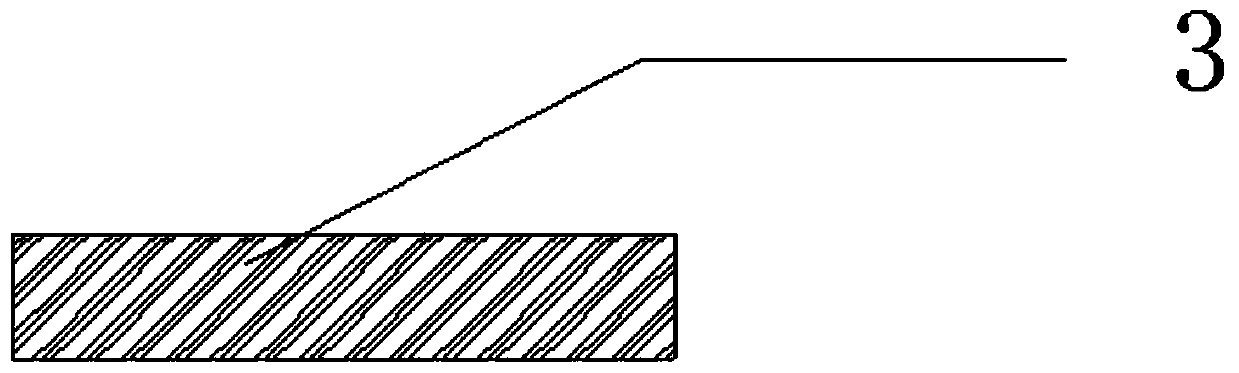

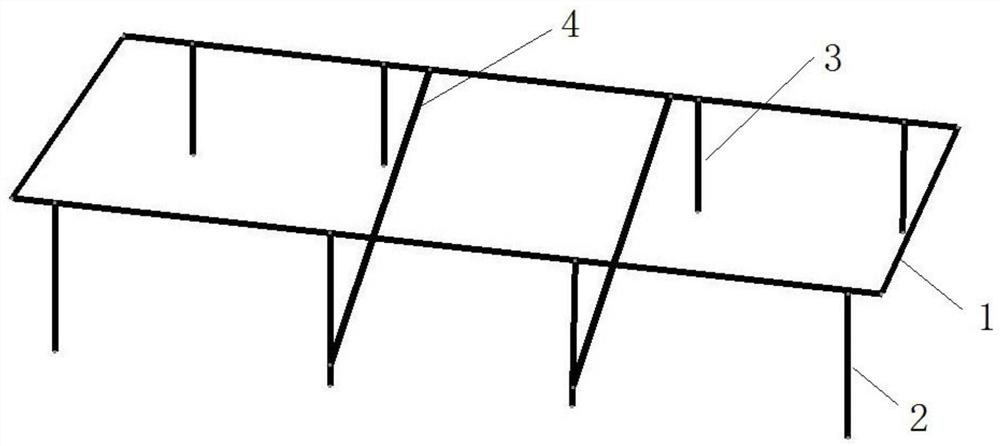

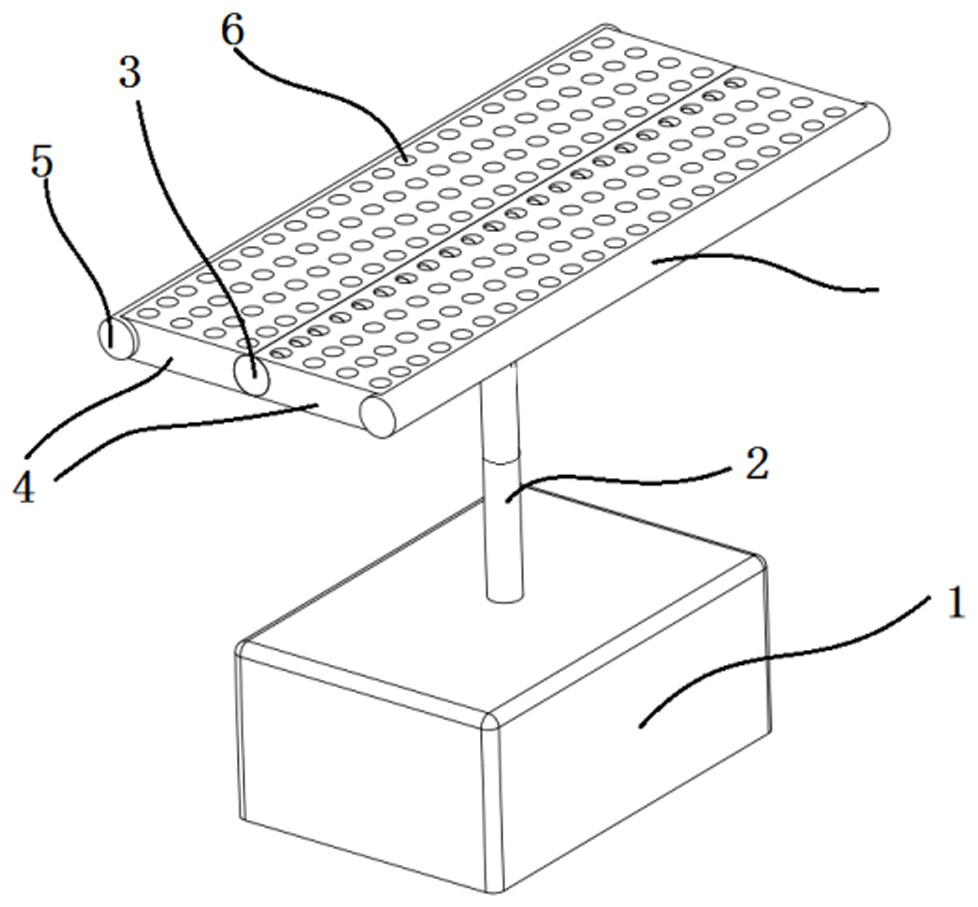

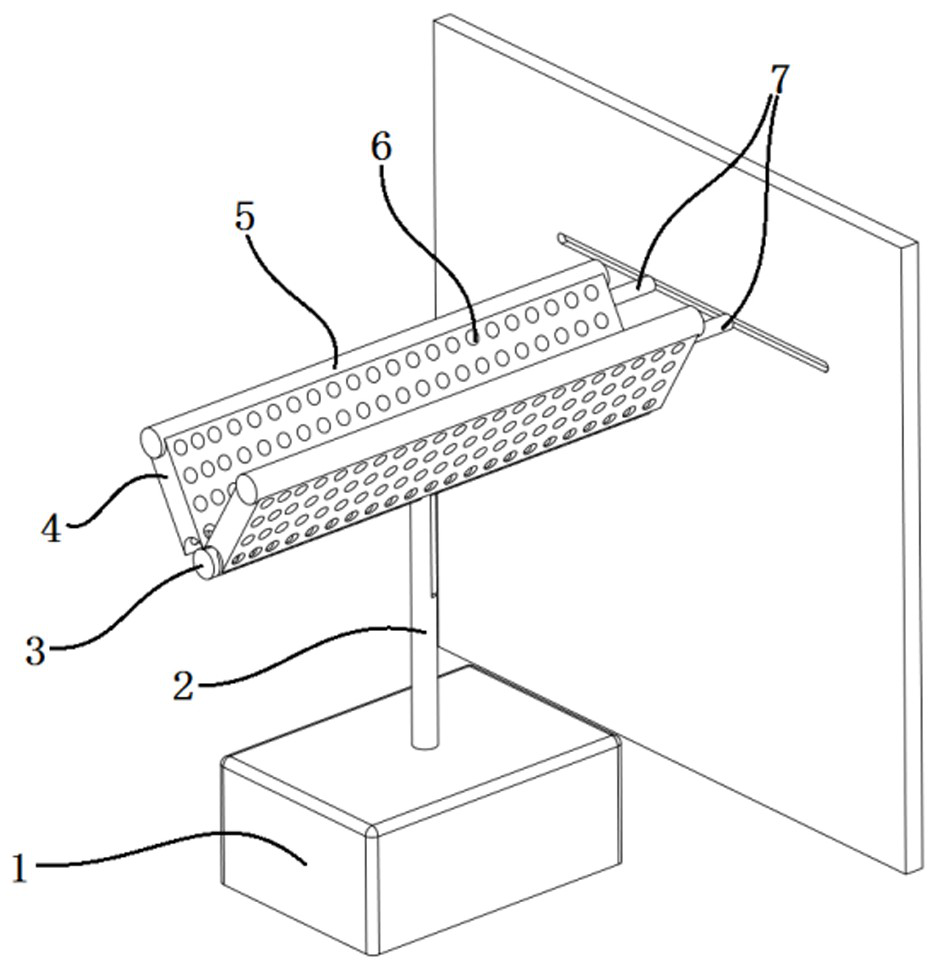

Aerial cable bending rigidity experiment method and device under stretching and bending combination

ActiveCN110849563ASimple structurePrecise applicationMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesAerial cableEngineering

The invention belongs to the field of aerial cable testing, and relates to an aerial cable bending rigidity experiment method and device under stretching and bending combination; a traditional three-point bending test cannot measure the response of an aerial cable under the action of a stretching and bending combination load, and the scheme provides the aerial cable bending rigidity experiment device and an experiment method. According to actual working conditions, a load equivalence method is adopted. The three-point bending test is improved; a set of experiment support composed of a base support, an extension frame and a vertical supporting frame is designed; radial tension is applied by using a universal testing machine; weights are suspended at two ends of a sample cable to apply axialtension to the sample cable; the tension output from the universal testing machine and displacement data of the middle point of the cable body are combined with data of the two laser sensors symmetrical to the middle point, and a hysteretic curve of bending moment and curvature of the aerial cable under repeated reciprocating stretching and bending combination is calculated and analyzed, so thatthe change of bending rigidity is studied.

Owner:DALIAN UNIV OF TECH

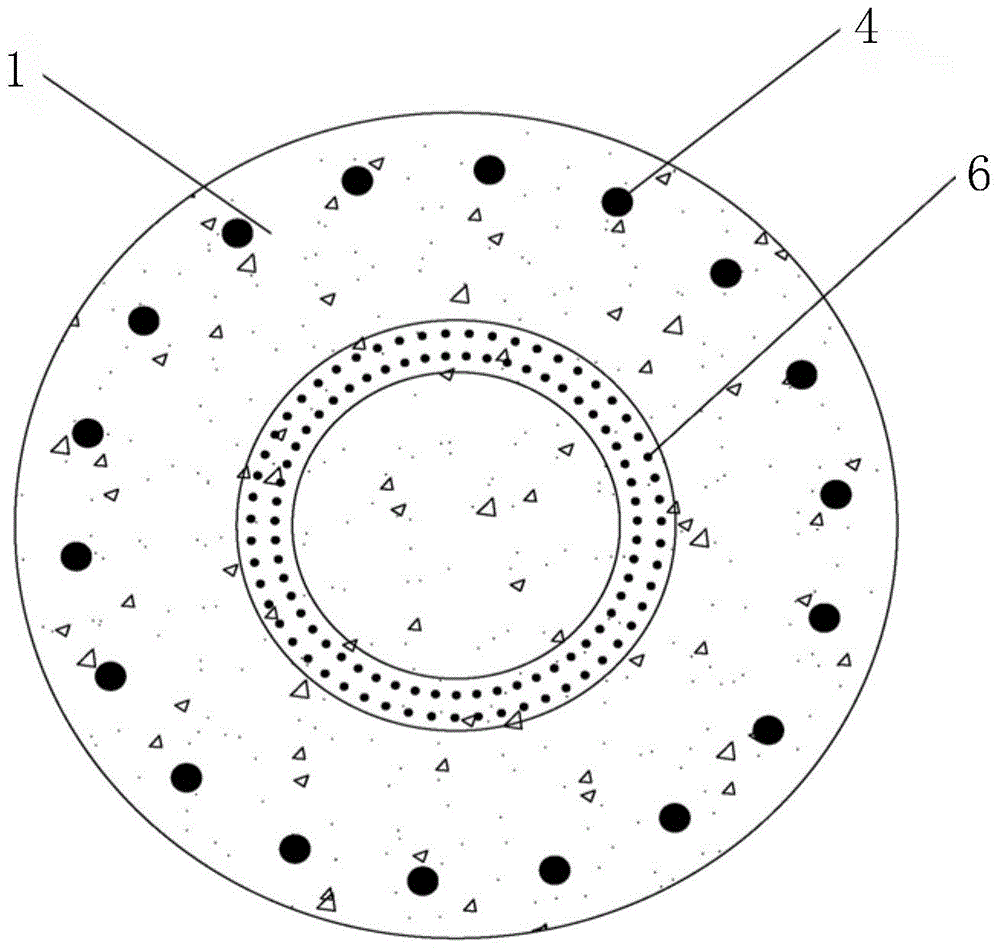

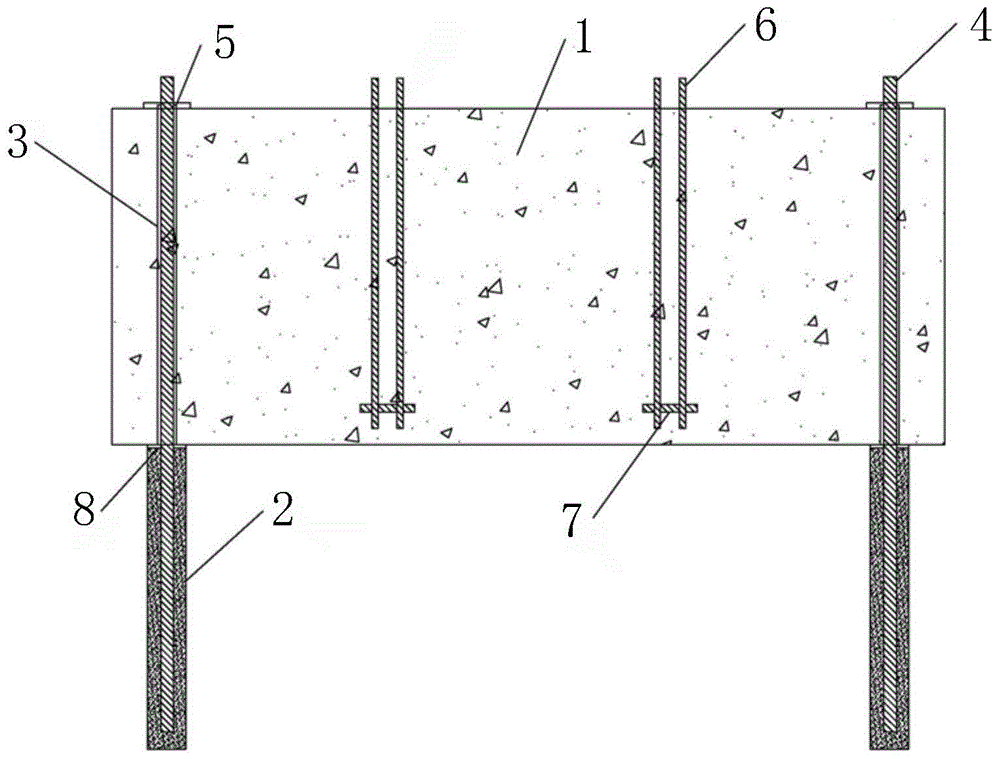

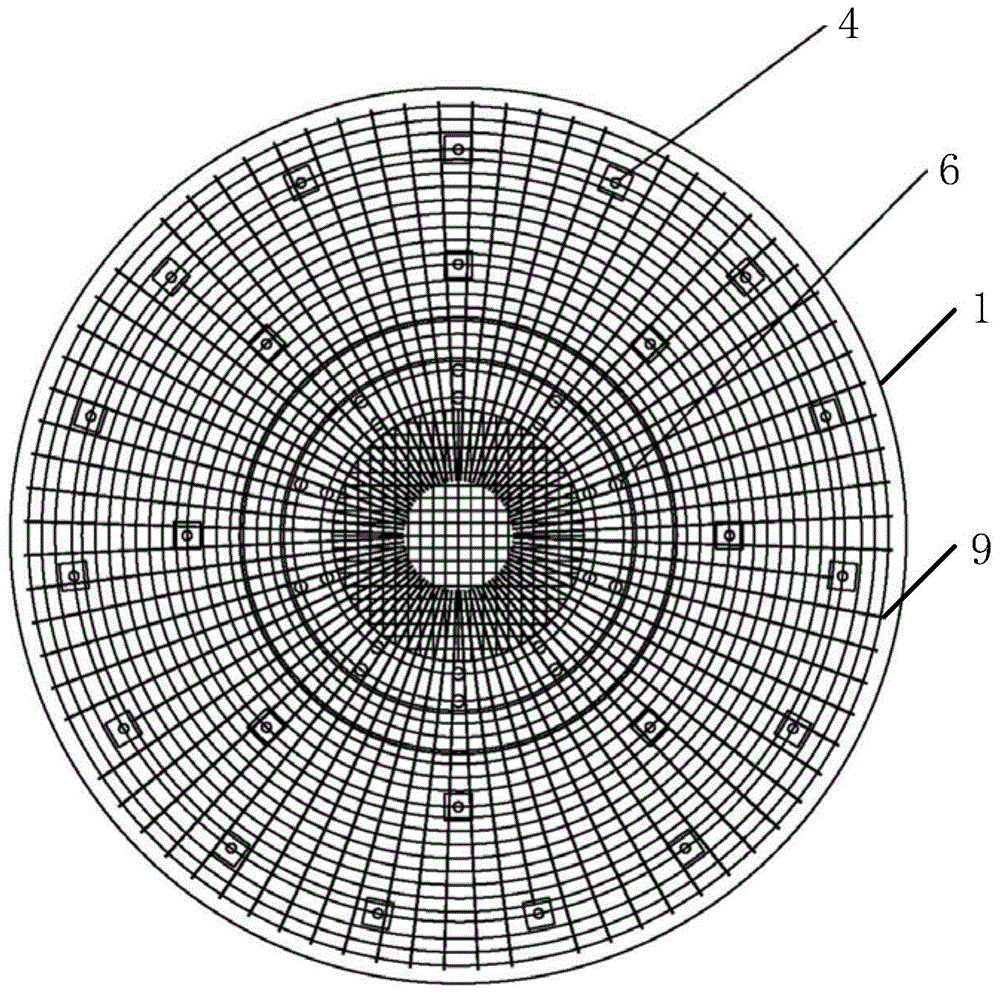

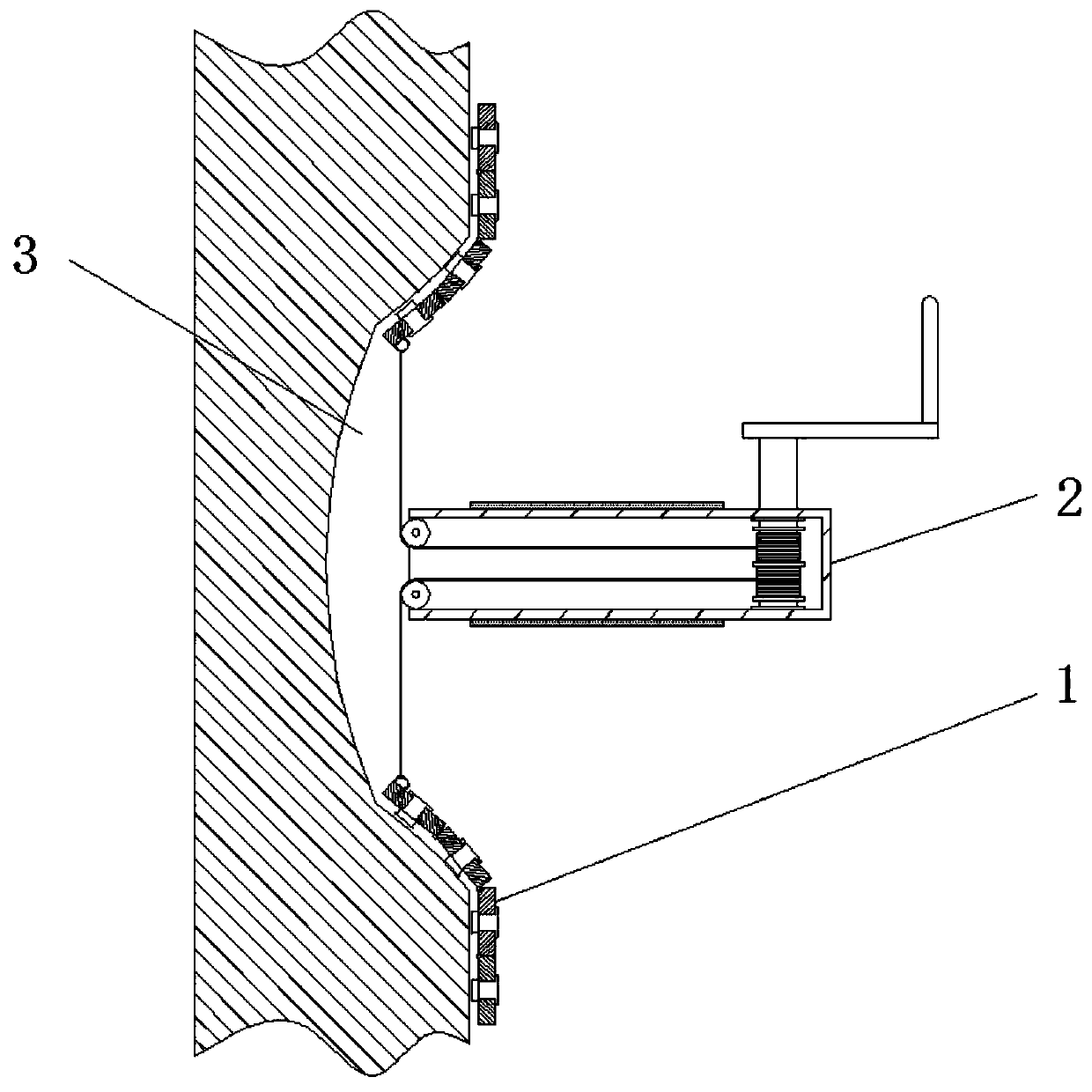

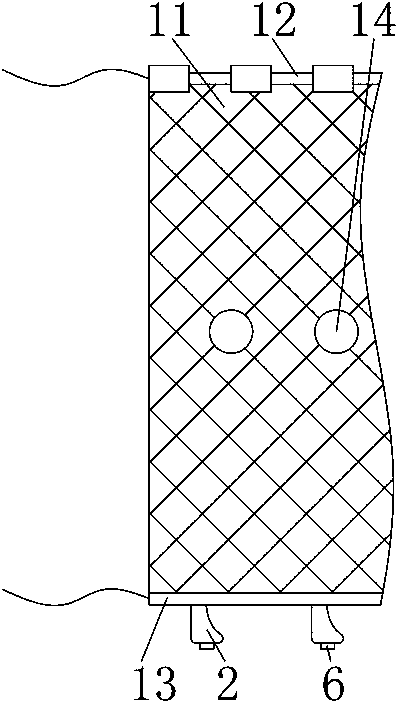

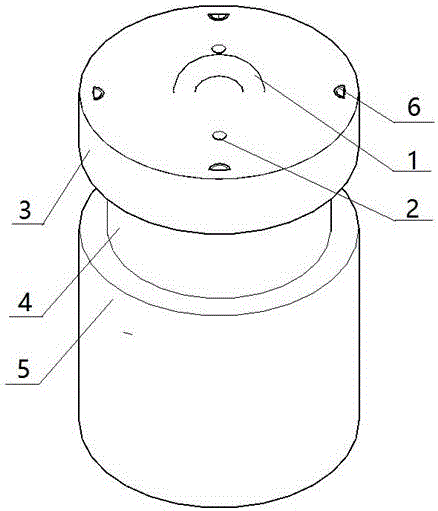

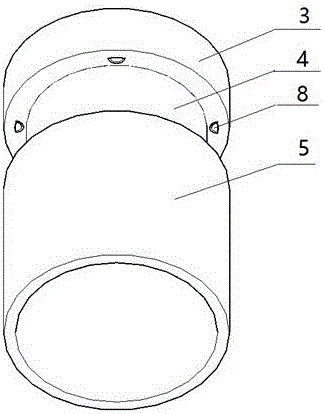

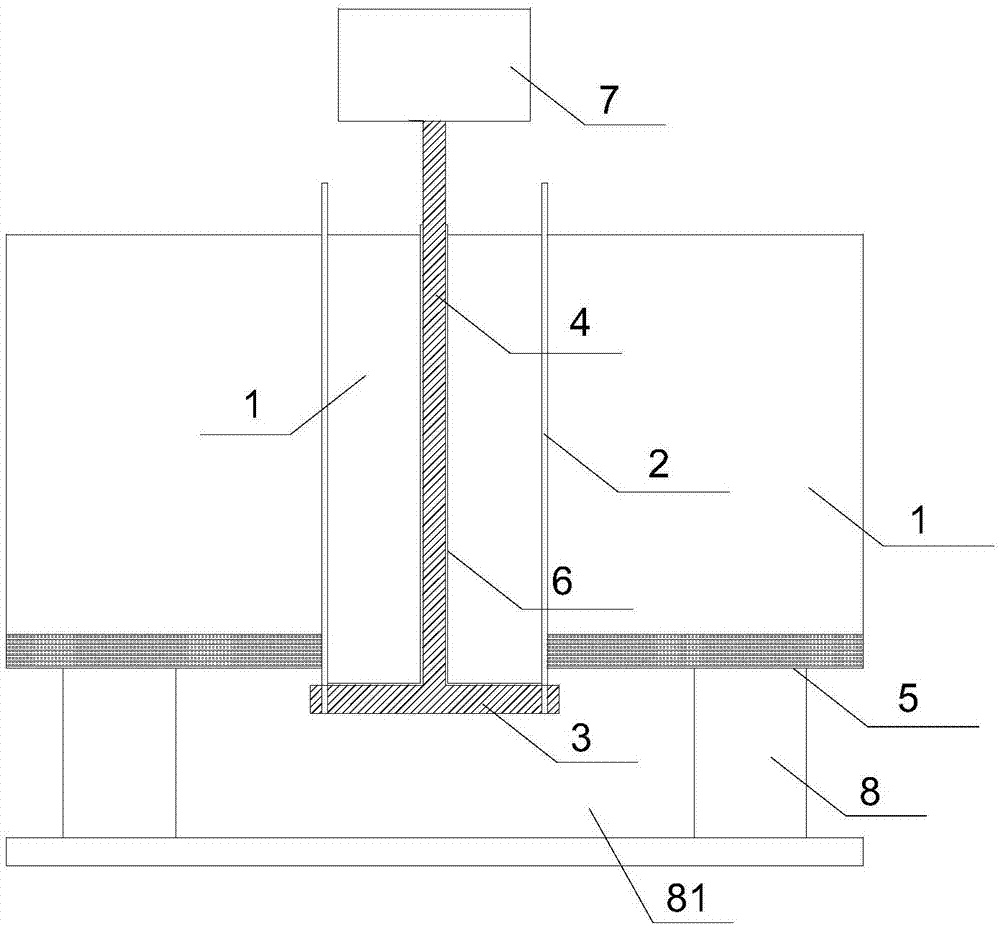

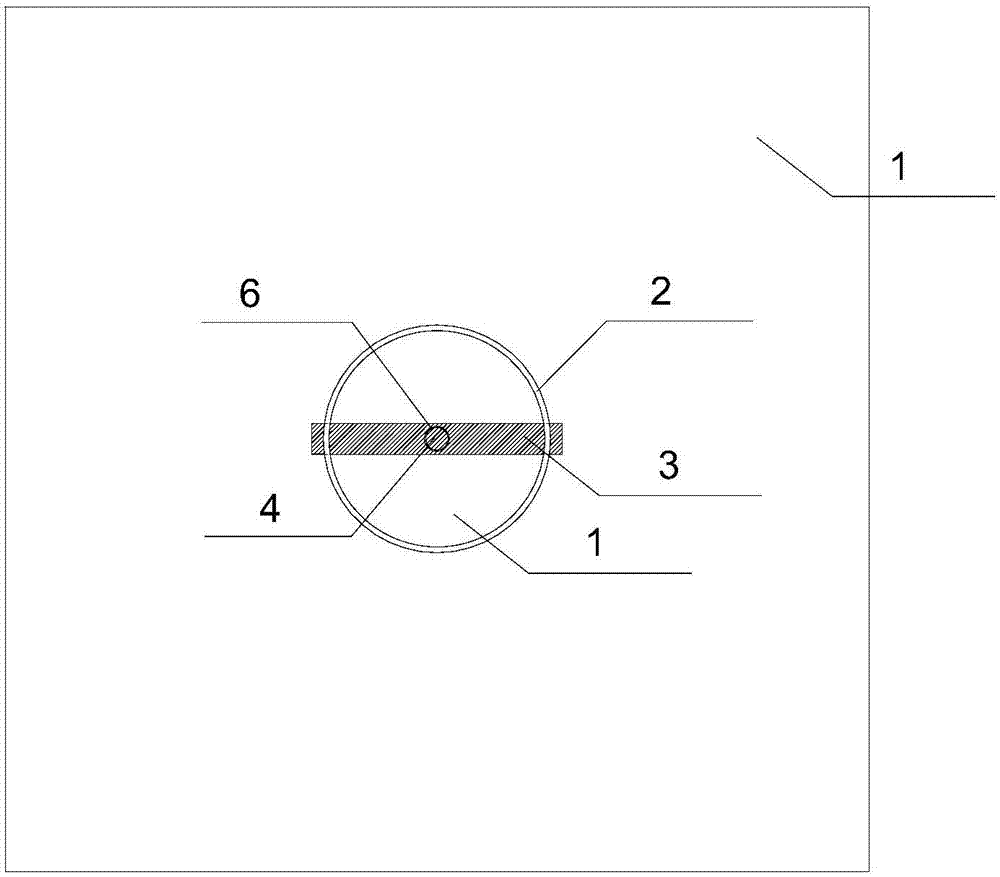

Rock anchor rod foundation structure

InactiveCN104532873AImproved ability to resist bending moment loadsPlay a supporting roleBulkheads/pilesEngineeringRock bolt

The invention discloses a rock anchor rod foundation structure. According to the rock anchor rod foundation structure, at least one circle of anchor rod sleeves (3) are evenly distributed on the outer edge of a foundation platform (1); a foundation pile (2) is vertically arranged under each anchor rod sleeve (3); an anchor rod (4) is vertically fixed to each foundation pile (2), and the upper portion of each anchor rod (4) penetrates through the foundation platform (1) through the corresponding anchor rod sleeve (3) and is fixed to the top of the foundation platform (1) through an anchor rod nut (5); at least one circle of screws (6) are evenly distributed at the center of the foundation platform (1); a plurality of reinforcing rods (9) penetrate through gaps between the screws (6) and connect the center of the foundation platform (1) with the outer edge of the foundation platform (1) in a reinforcing mode. The bending moment load resisting capacity of the foundation piles is greatly enhanced, building materials consumed for the foundation platform are saved, the problems of an existing foundation ring are solved, the bending moment load resisting capacity of a whole foundation is enhanced, and material cost is lowered.

Owner:霍宏斌

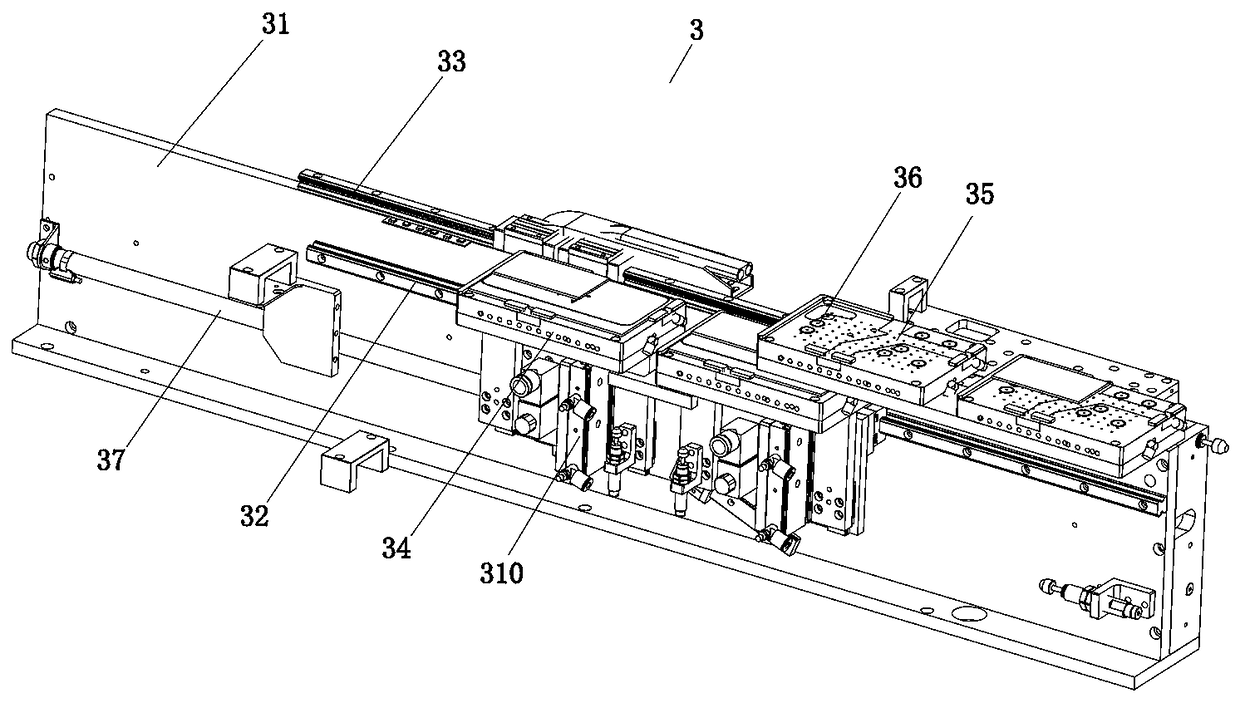

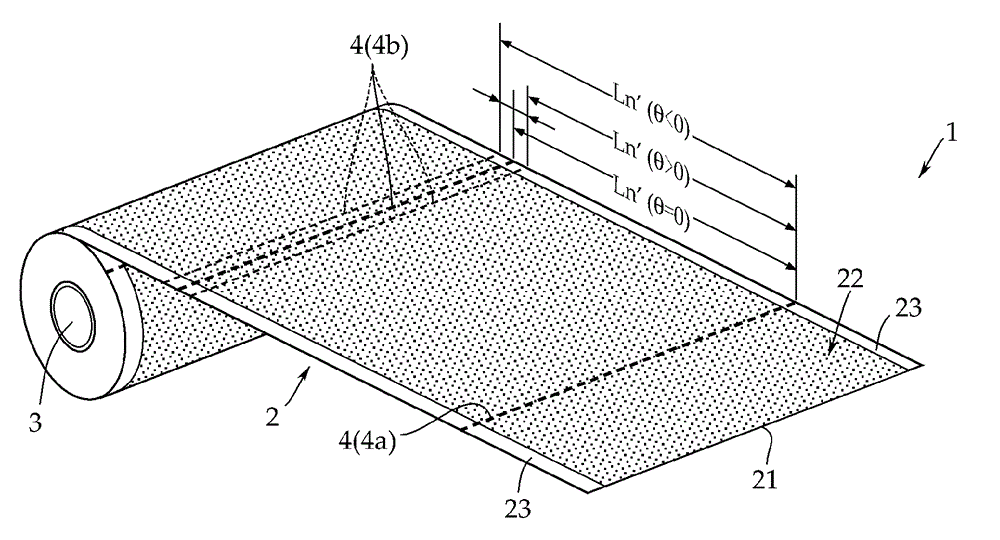

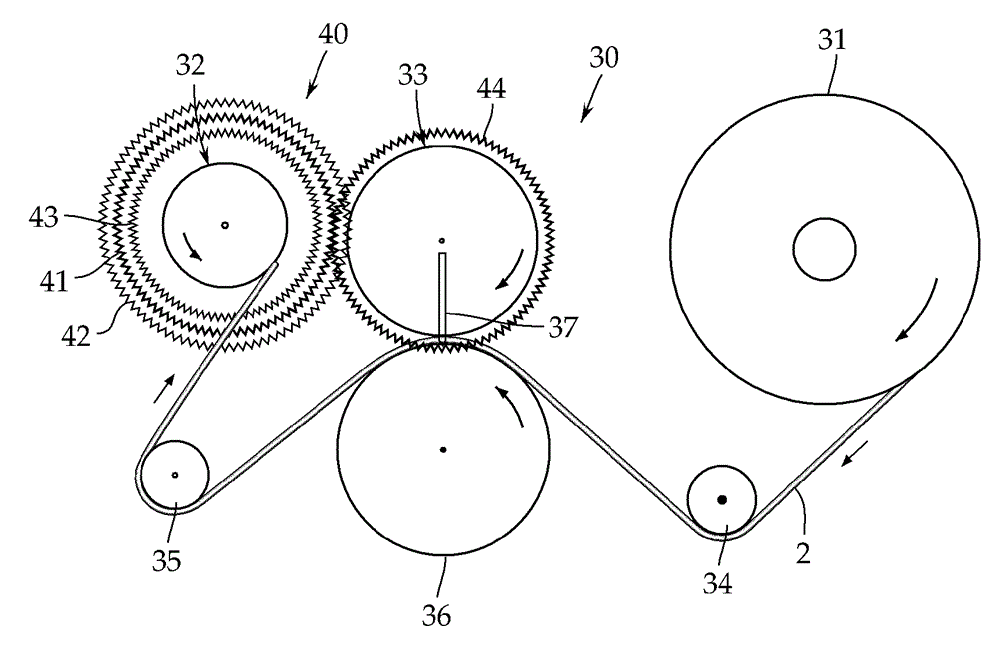

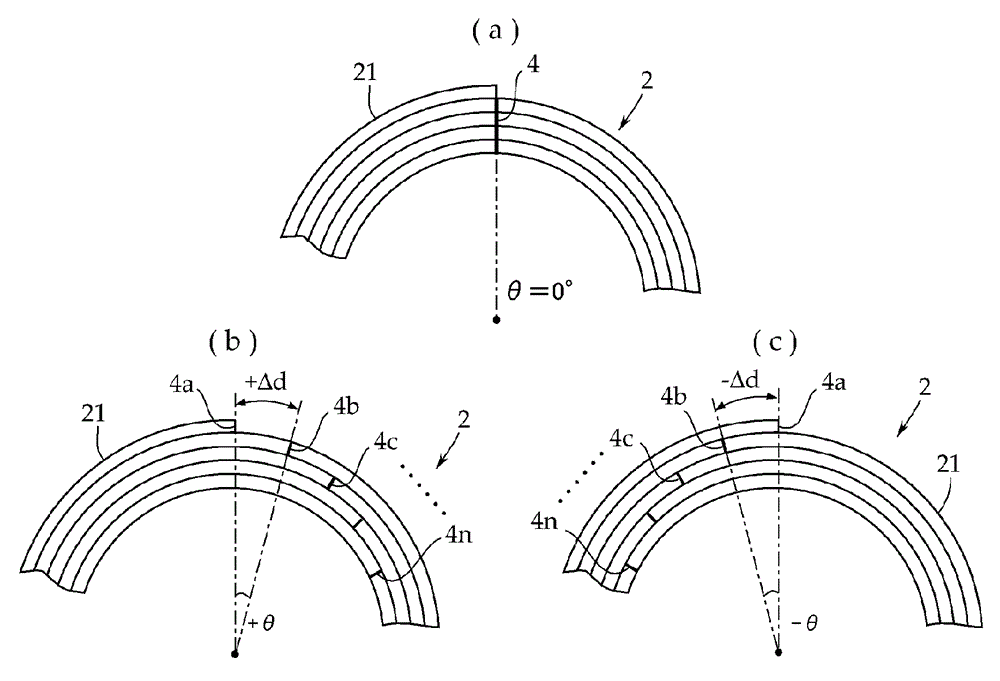

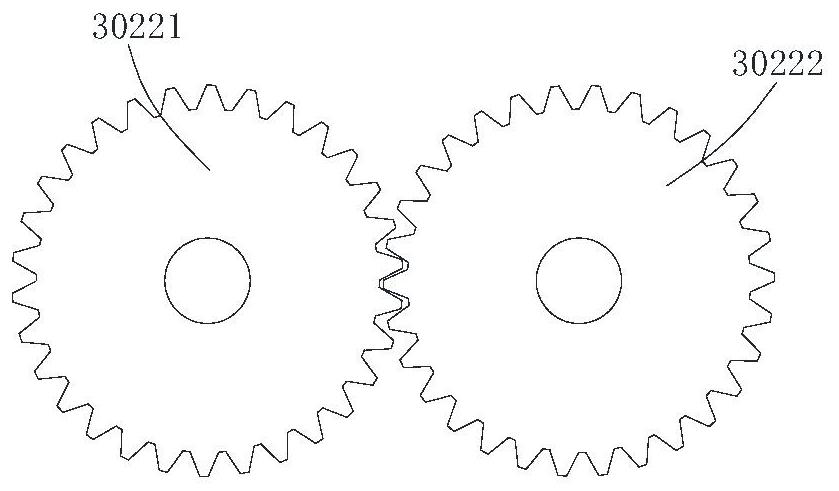

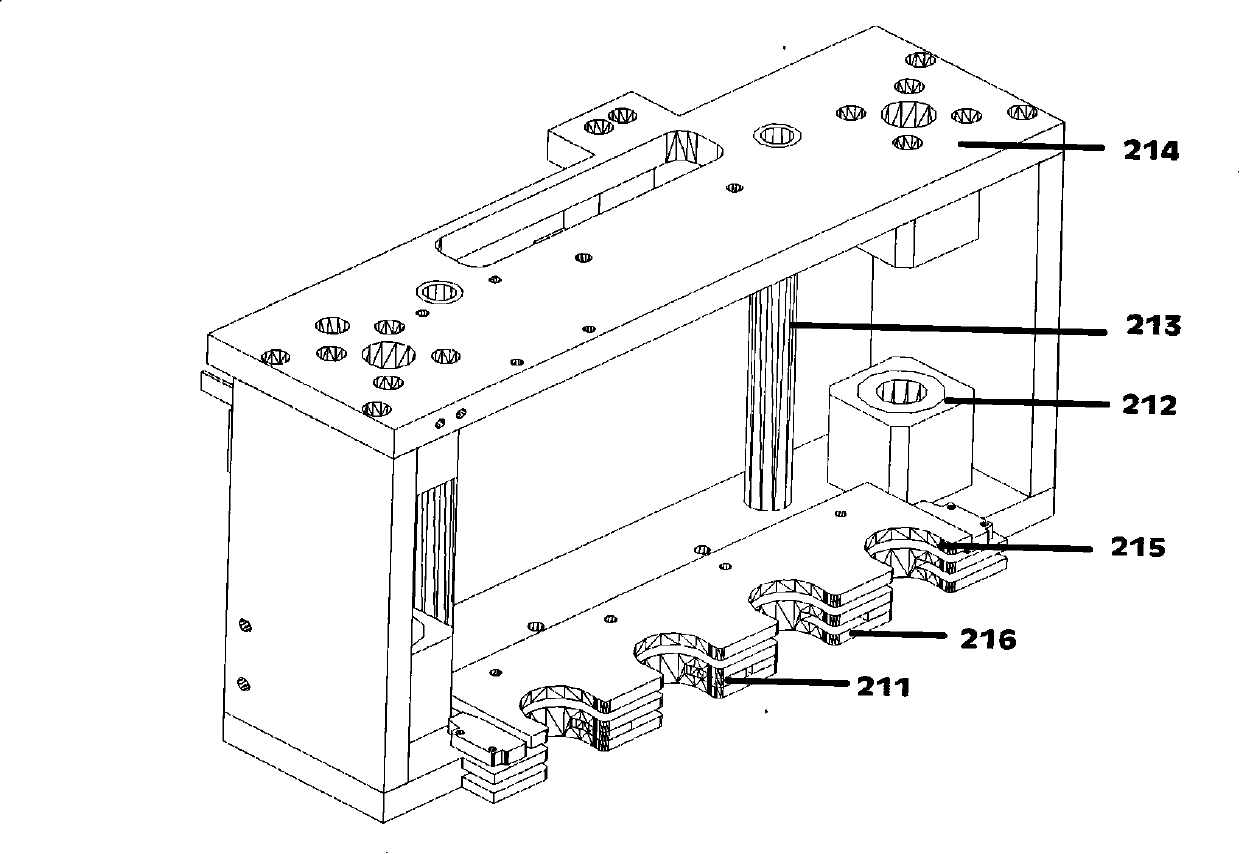

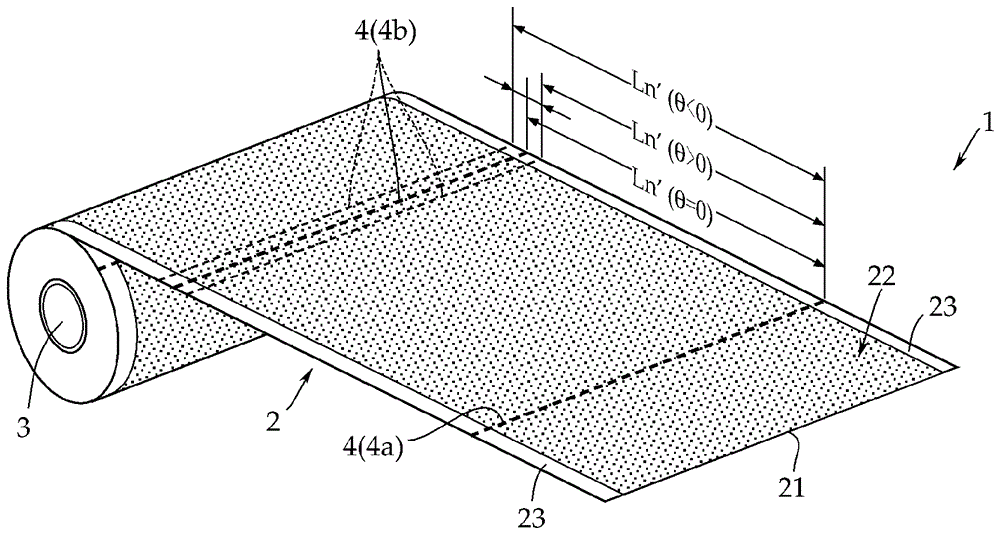

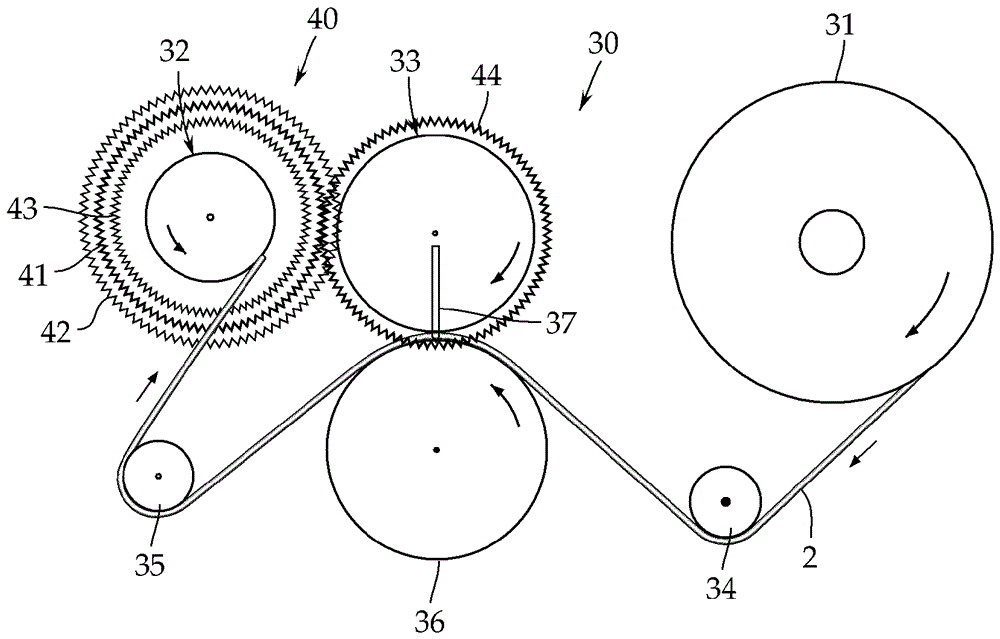

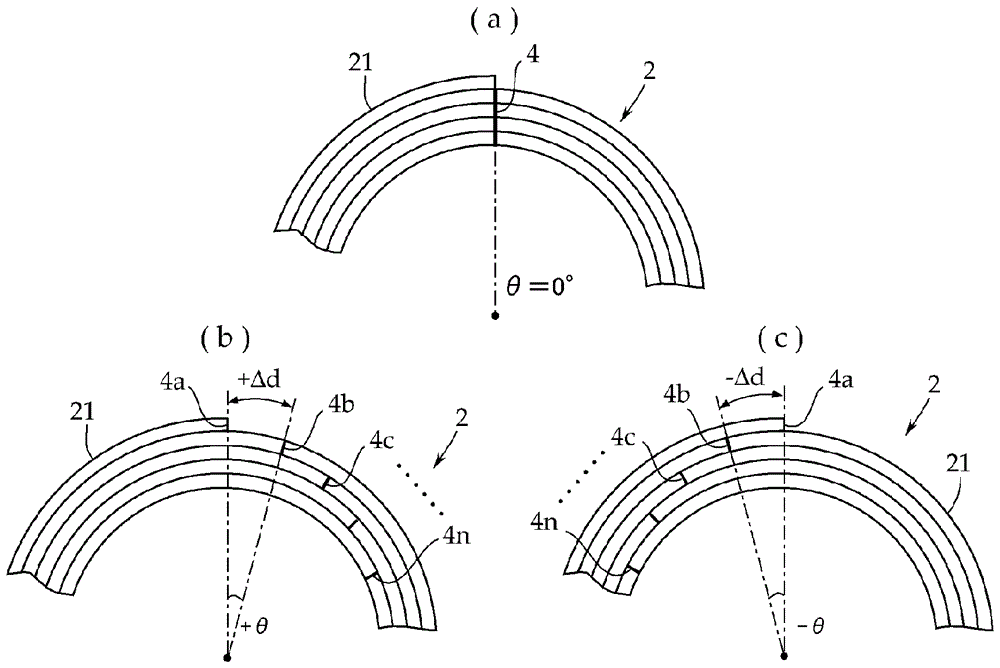

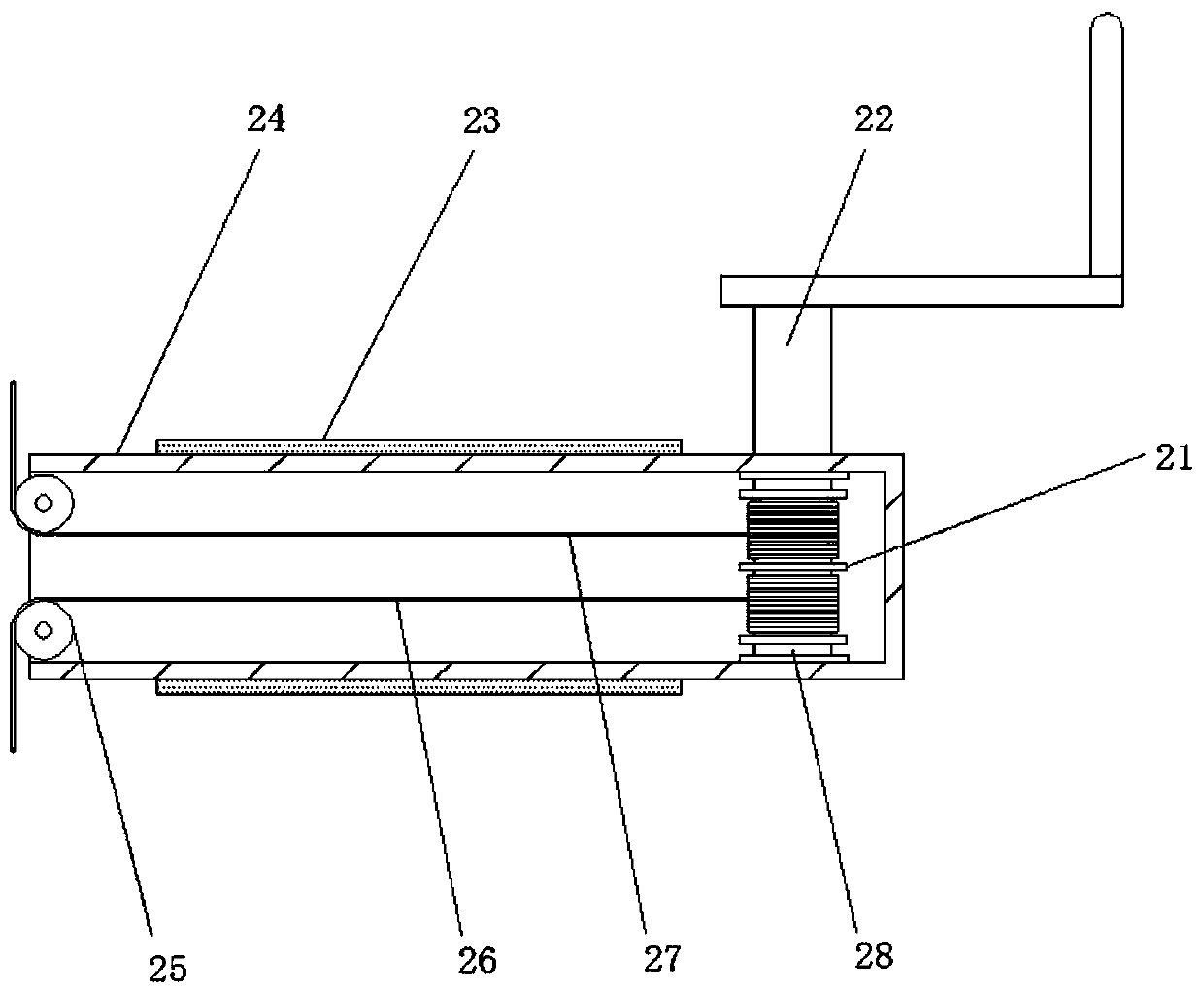

Manufacturing device for splicing tape roller

ActiveCN104055477AAvoid deformationPrevent pull upHousehold cleanersManufacturing technologyGear wheel

The invention provides a manufacturing technique for a splicing tape roller which enables a cutting wire to cut off a splicing tape all the time to form the splicing tape roller at a certain position. The splicing tape roller comprises a reeling roller (32) and a cutting wire forming roller (33); the reeling roller (32) reels up the splicing tape (2) extracted from a female roller (31); the cutting wire forming roller (33) is arranged between the female roller (31) and the reeling roller (32), and forms the cutting wire (4) at a specified interval on the splicing tape (2); the reeling roller (32) and the cutting wire forming roller (33) can rotate synchronously through specified gears (40).

Owner:NITOMS INC

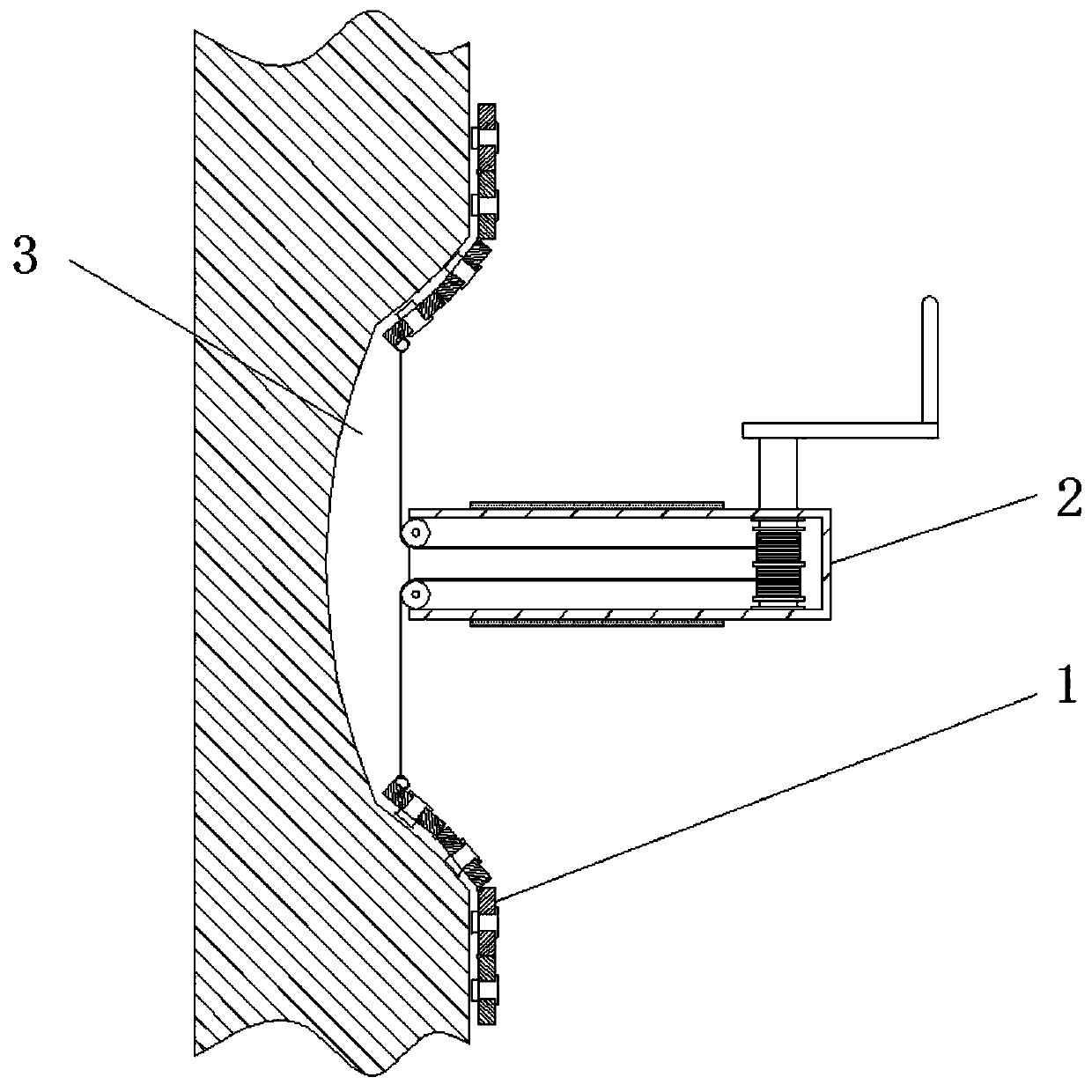

Automobile sag repairing tool

The invention discloses an automobile sag repairing tool. The automobile sag repairing tool comprises a pulling force part and a pair of adsorption chains; each adsorption chain is formed in the modethat at least four rectangular hinge blocks are hinged to one another, and the bottoms of the side faces, in the same direction, of the opposite faces of the rectangular hinge blocks are provided withhinge points used for allowing the adjacent rectangular hinge blocks to be hinged; hooks are arranged on the rectangular hinge blocks located at the corresponding ends of the sides, far away from thehinge points, of the adsorption chains; and the rectangular hinge blocks are provided with T-shaped fixing rods in a penetrating mode in the width direction, and suction cups are arranged at the ends, close to the hinge points, of the T-shaped fixing rods. According to the automobile sag repairing tool, in the repairing process, a pair of the adsorption chains are symmetrically adsorbed to the two sides of an automobile sag, a rotating handle is rotated to enable a rotating shaft to wind a first connecting rope and a second connecting rope, the first connecting rope and the second connectingrope pull the adsorption chains to rotate to repair the sag, no supporting point is needed in the repairing process, the condition that in the repairing process, counter-acting force is generated to act on an automobile to generate an adverse effect is avoided, labor is saved, operation is easy, and the automobile sag repairing tool is suitable for a green hand.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

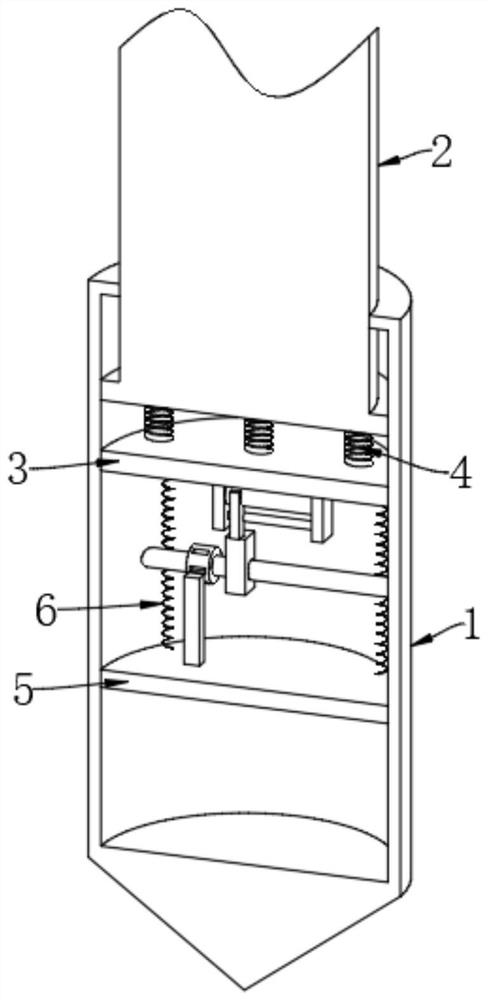

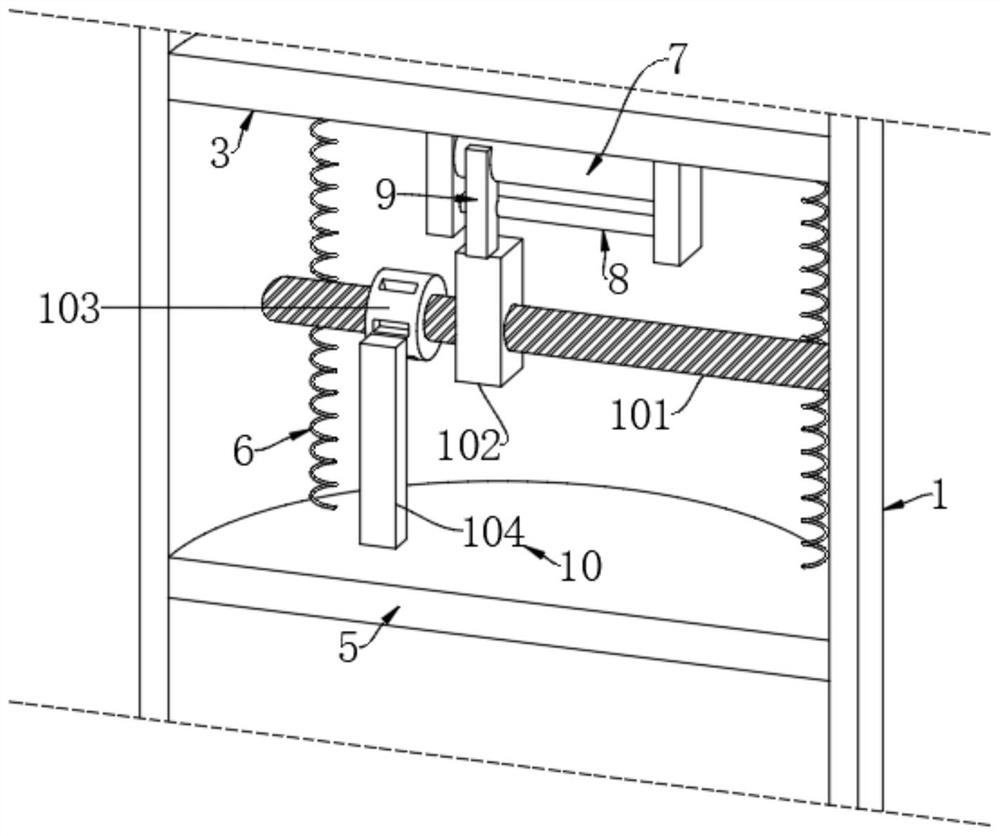

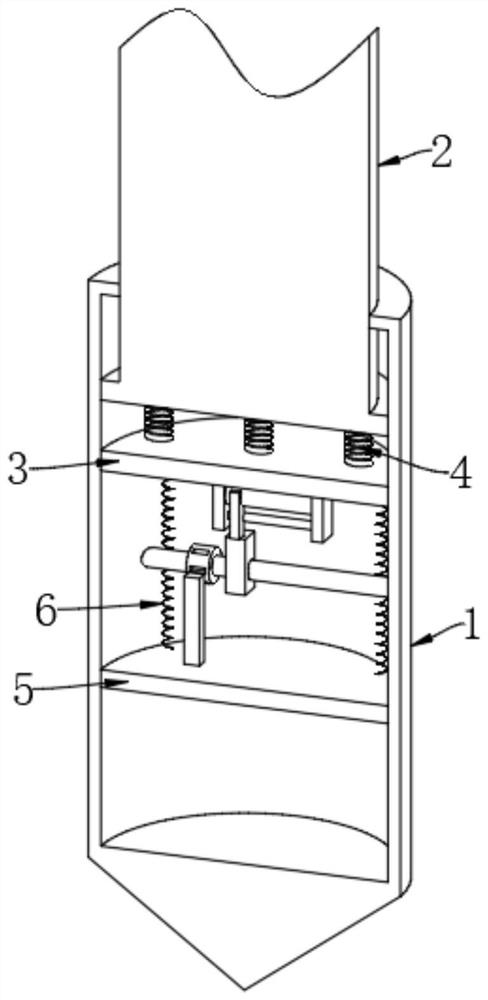

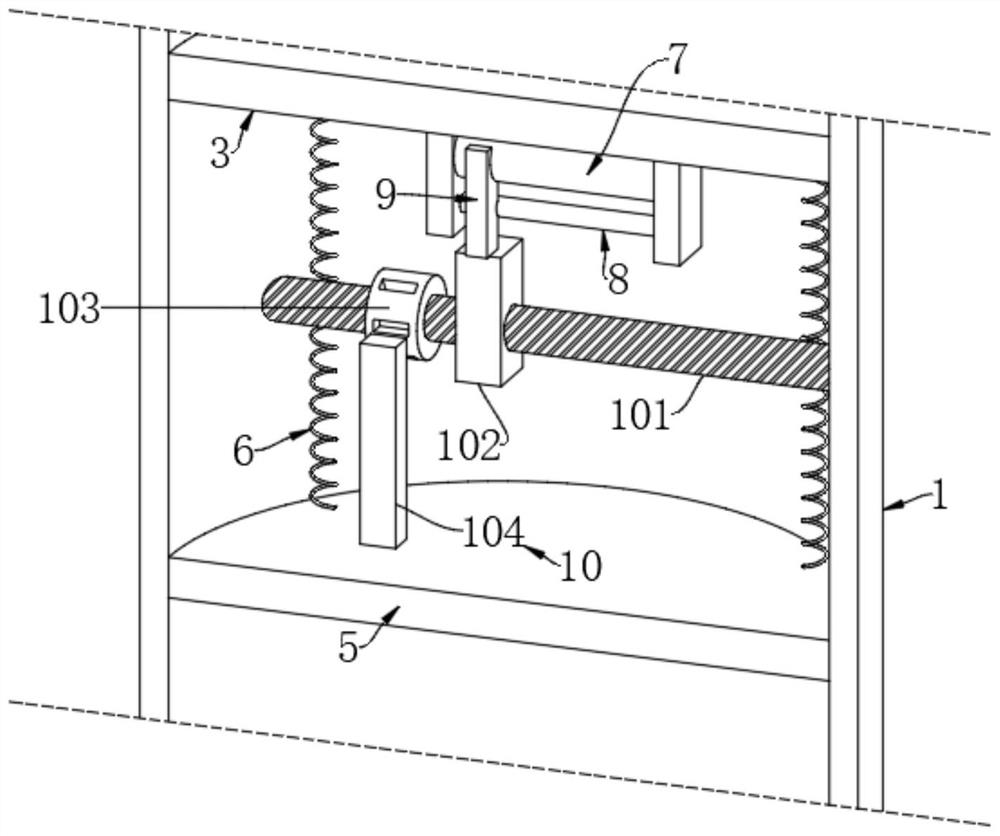

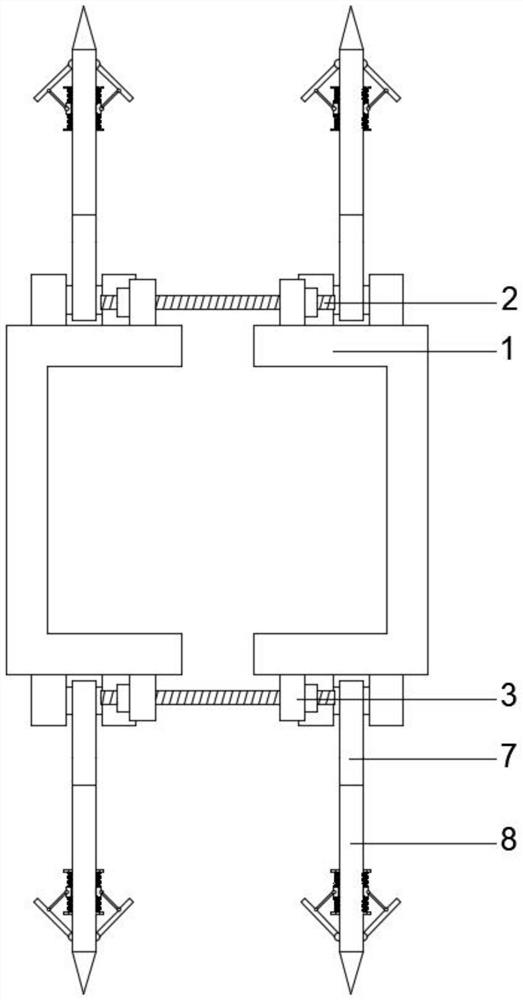

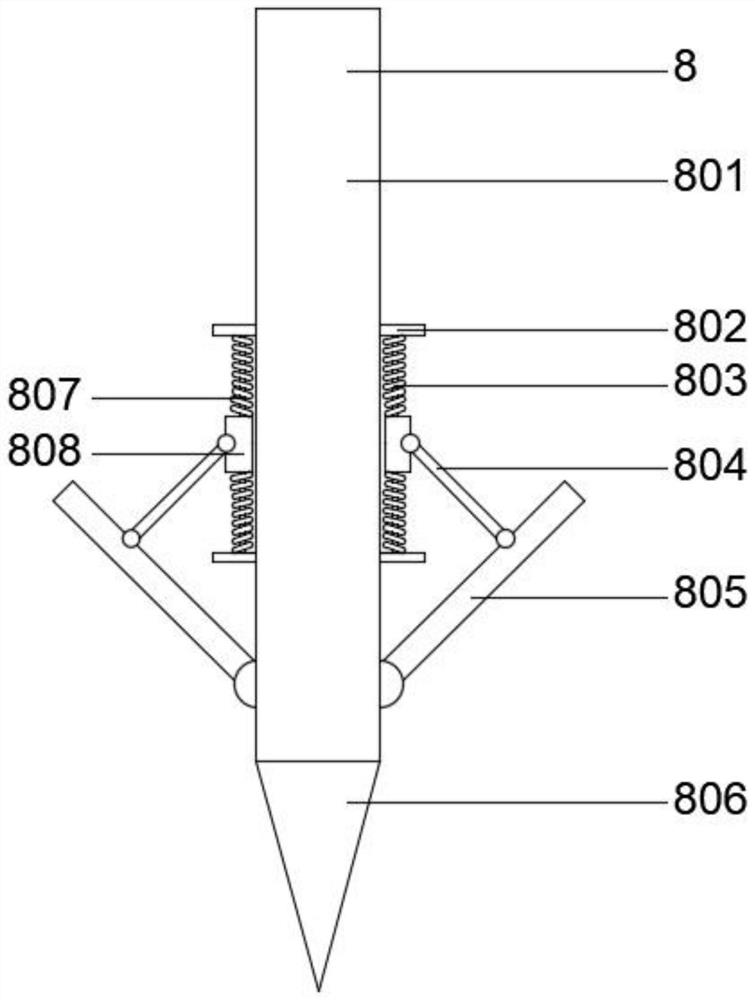

Civil engineering building composite pile

ActiveCN113356184APrevent pull upAvoid pullingProtective foundationPhotovoltaic energy generationArchitectural engineeringStructural engineering

The invention belongs to the field of composite piles, and particularly relates to a civil engineering building composite pile. The pile comprises an insertion pile and a supporting pile, the insertion pile is in hollow design, the supporting pile is slidably arranged in the insertion pile, a buffer plate is fixedly connected in the insertion pile, and a plurality of buffer springs are fixedly connected between the buffer plate and the supporting pile. A partition plate is slidably connected into the insertion pile, water is injected into the lower side of the partition plate, a plurality of extension springs are fixedly connected between the buffer plate and the partition plate, a rheostat is fixedly connected to the lower end of the buffer plate, a metal guide rod is fixedly connected to the rheostat, a sliding piece is slidably connected to the metal guide rod, and the sliding piece is in contact connection with the rheostat. The partition plate is provided with an adjusting mechanism matched with the sliding piece. The composite pile can automatically regulate and control the resistance between the composite pile and soil according to the change of the air temperature, and the situation that the composite pile is pulled up, and the stability of the whole structure is affected is avoided.

Owner:黑龙江省建筑安装集团有限公司

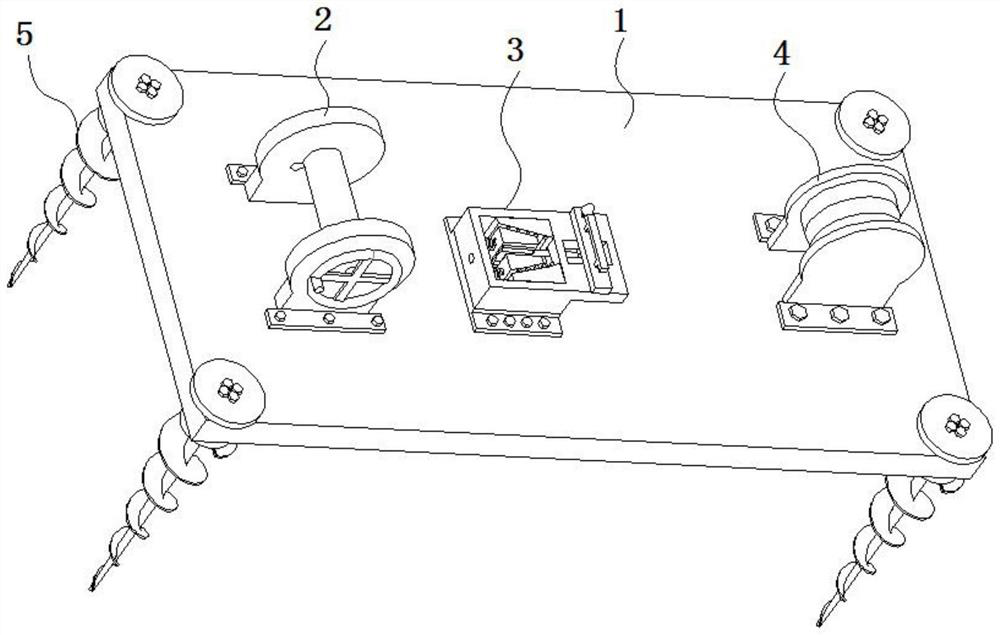

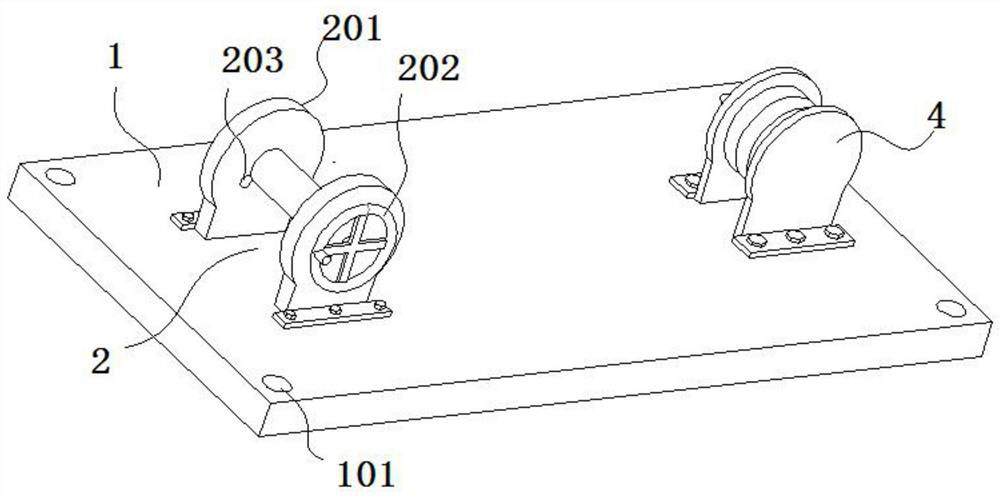

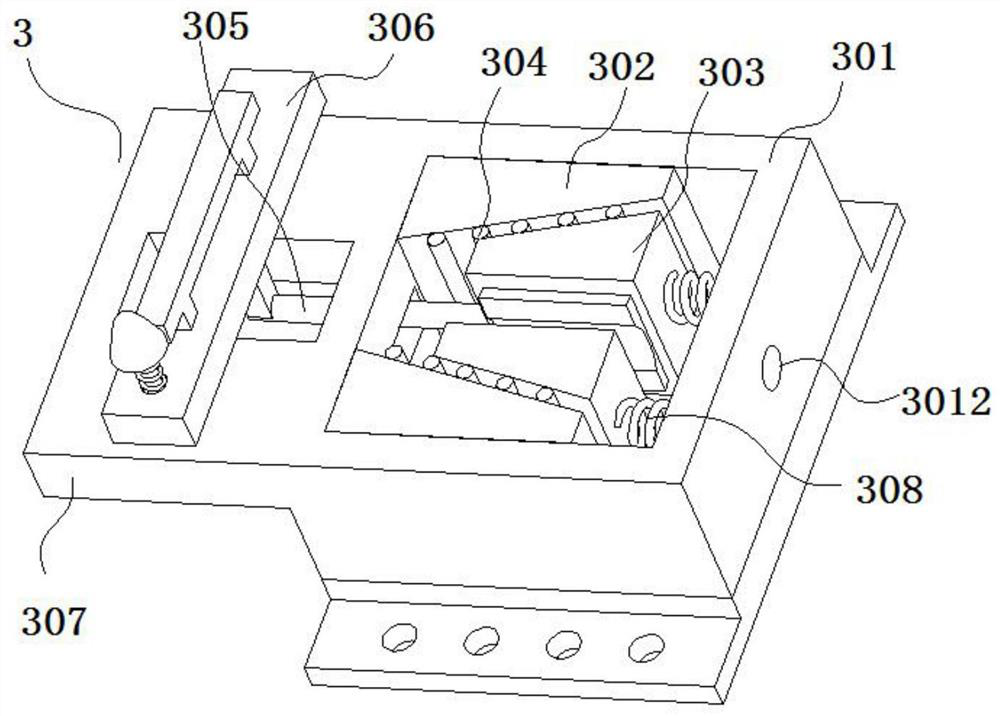

Steel wire rope clamping device for drilling crane

InactiveCN112158750ATighten upStep up and be effectiveWinding mechanismsMarine engineeringRight trapezoid

The invention discloses a steel wire rope clamping device for a drilling crane, and relates to the technical field of drilling and workover equipment in the petroleum industry. The steel wire rope clamping device comprises a base, an adjusting assembly, a fastening assembly, a guide wheel and ground anchor assemblies arranged at the four corners of the base in a sleeving mode; the adjusting assembly is fixedly installed on the upper surface of the base; the adjusting assembly comprises a wire spool fixedly installed on the upper surface of the base; a wire winding handle is fixedly installed on one side surface of the wire spool; the fastening assembly is fixedly installed on the upper surface of the base and located on one side of the adjusting assembly; and the guide wheel is fixedly installed on the upper surface of the base and located on the side, away from the adjusting assembly, of the fastening assembly. According to the steel wire rope clamping device for the drilling crane, after the length of a guy rope is adjusted through the adjusting assembly, a main clamp block and an auxiliary clamp block of a right trapezoid structure in the fastening assembly are matched with eachother, so that a brake pad of an arc-shaped structure can stably tighten the guy rope, the structure is simple, it can be guaranteed that gaps between the two sides of a main clamp and the two sidesof an auxiliary clamp are uniform, meanwhile the guy rope can be effectively tightened in the fixing assembly, and the stability of a derrick is improved.

Owner:合肥星研科技有限公司

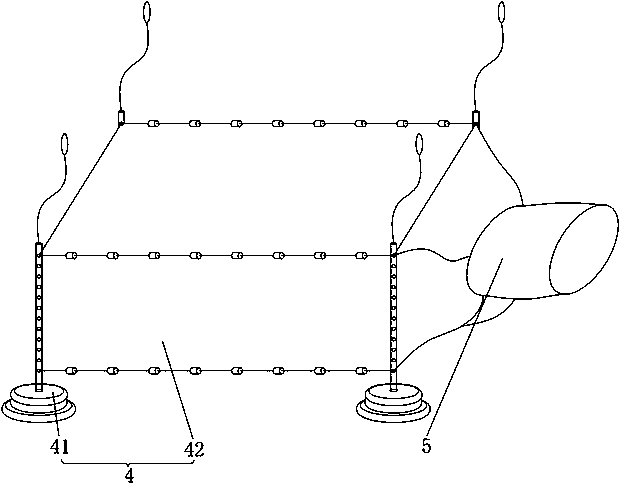

Net-hauling fish collection method for pond with base membrane laid

The invention discloses a net-hauling fish collection method for a pond with a base membrane laid. The method is characterized by comprising following steps: S1, a hauling net is arranged in the pondwith the laid base membrane, a shovel-shaped pendant is arranged at the bottom of the hauling net, and a first net cuff is arranged on the outer side of the hauling net; S2, shoals of fish are drivento gather by the hauling net; S3, a net cage is arranged beside the outer side of the hauling net, and a second net cuff corresponding to the first net cuff is arranged on one side of the net cage; S4, the first net cuff and the second net cuff are butted; S5, the hauling net is closed and the shoals of fish are driven to the first net cuff and the second net cuff to enter the net cage; S6, the first net cuff and the second net cuff are removed, and the second net cuff is tightened. The bottom of the hauling net is prevented from being pulled up, the shoals of fish are prevented from escapingfrom the bottom of the hauling net, so that the fish collection efficiency is improved, the operation cost is reduced, all that is required is to drive the shoals of fish to enter the first net cuff when the shoals of fish are driven to enter the net cage, measures such as fishing and the like causing damage to the shoals of fish are not needed, and the shoals of fish are prevented from being damaged in the fish collection process.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Full-automatic detection and label changing device for graphene RFID label

ActiveCN112345857AImprove accuracyGuaranteed data communicationLayered productsLaminationEngineeringGraphite

The invention discloses a graphene RFID label full-automatic detection label changing device. The device comprises a power mechanism, a detection mechanism, a buffer temporary storage mechanism and alabel changing mechanism, wherein the power mechanism comprises a first power roller and a second power roller; the detection mechanism is used for detecting the graphene RFID tag; the buffer temporary storage mechanism is arranged between the detection mechanism and the second power roller and comprises a speed reduction roller and an adjusting piece so as to increase or decrease the conveying stroke of the bottom film between the movable roller and the fixed roller; the label changing mechanism is arranged between the buffer temporary storage mechanism and the second power roller, the labelchanging mechanism comprises a label changing piece and a label changing platform, the label changing platform is used for bearing a bottom film, and the label changing piece can replace detected unqualified graphene RFID labels with qualified graphene RFID labels. According to the device, accumulation of the bottom film attached with the graphene RFID tag during tag replacement can be prevented,and tag replacement efficiency is high.

Owner:SHANDONG HUAGUAN SMART CARD

A civil engineering building composite pile

ActiveCN113356184BPrevent pull upAvoid pullingProtective foundationPhotovoltaic energy generationArchitectural engineeringStructural engineering

The present invention belongs to the field of combination piles, especially involving a kind of civil engineering building combination pile, including piles and support piles.There are multiple buffer springs between the buffer board and the fixed connection between the buffer board and the support pile. There is a partition of the sliding connection in the inserting pile, and the lower side of the partition is injected with water.There are multiple stretching springs in a fixed connection. The lower end of the buffer plate is fixed with a variable resistor, and a metal guide rod is fixed on the resistor.There is a adjustment mechanism that cooperates with the slide sheet on the partition.The present invention allows the combined pile to automatically regulate the resistance between itself and the soil according to the changes in temperature, to avoid the combination piles from being pulled up, affecting the stability of the overall structure.

Owner:黑龙江省建筑安装集团有限公司

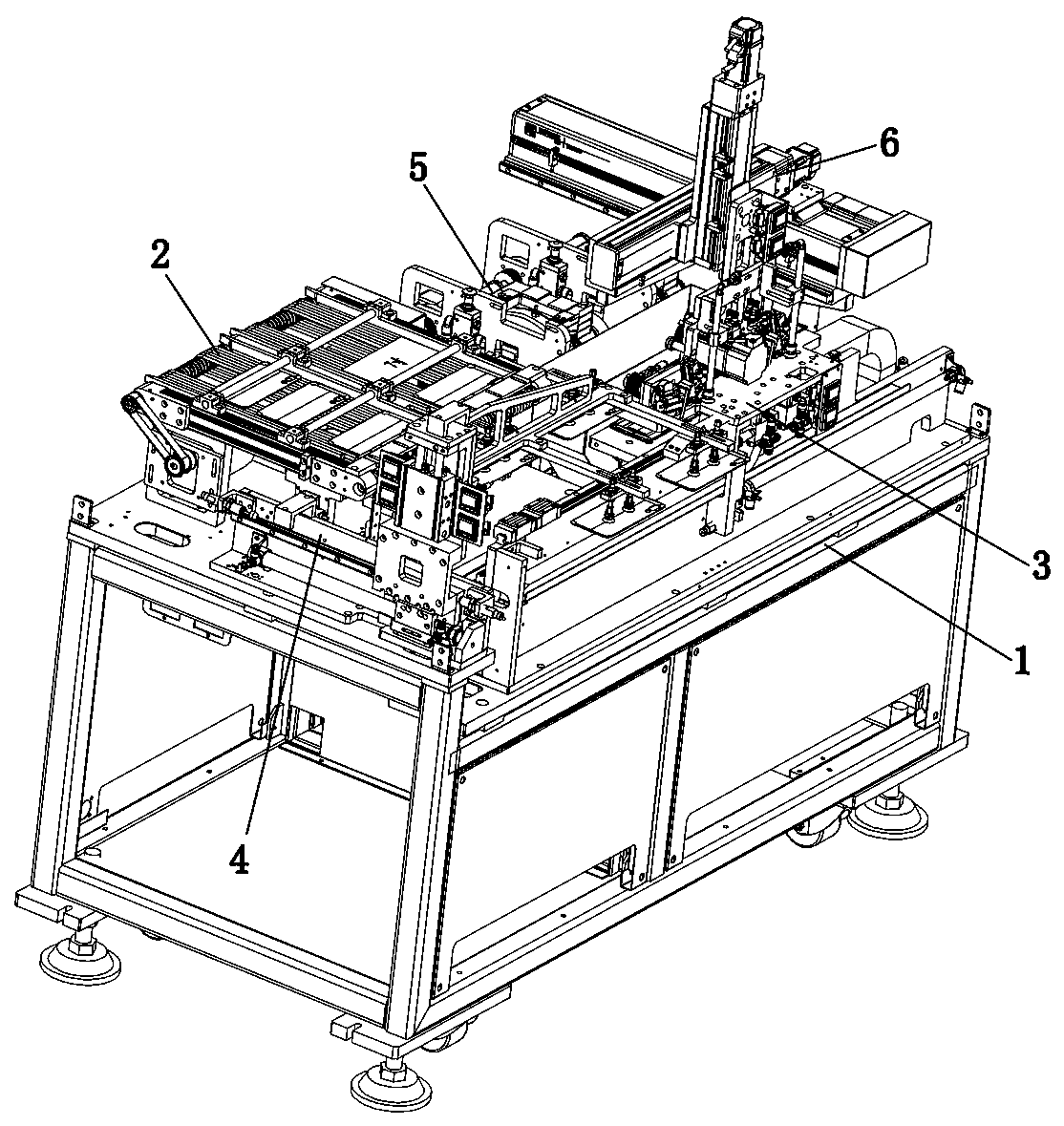

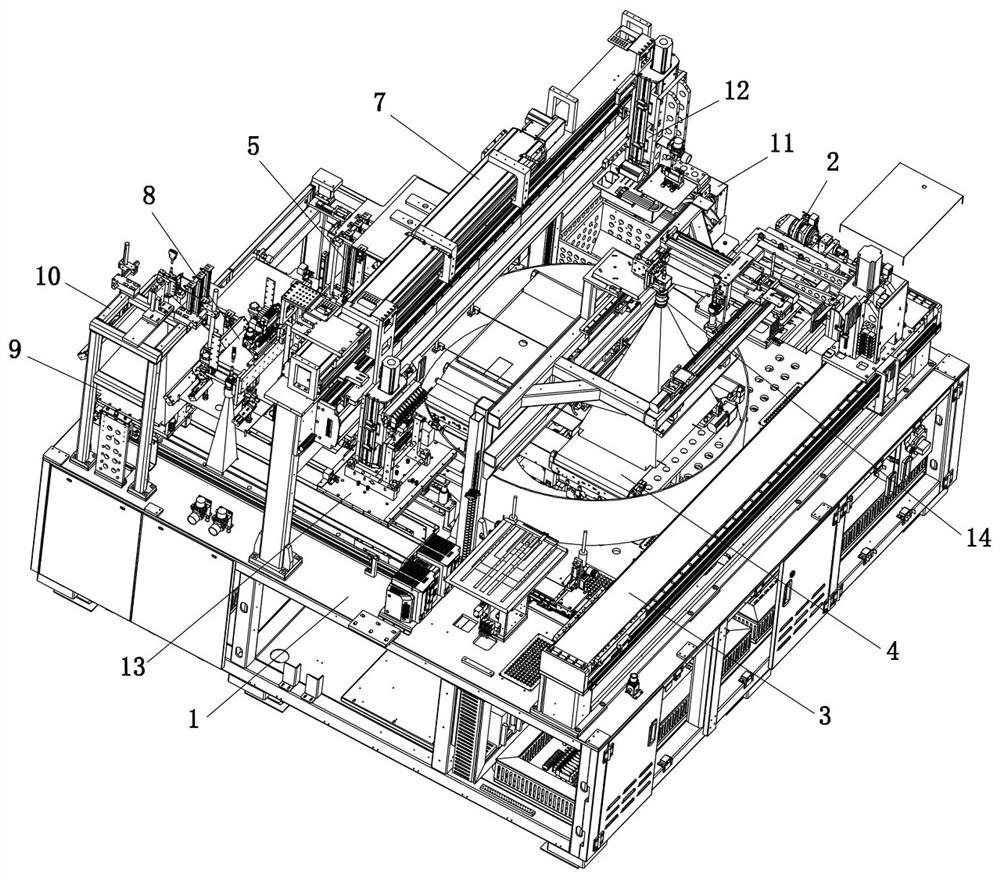

Full-automatic special-shaped polaroid laminating machine and laminating process thereof

PendingCN114093267AReduce sticking air bubblesReduce waiting timePolarising elementsIdentification meansSurface mountingFully automated

The invention discloses a full-automatic special-shaped polaroid laminating machine and a laminating process thereof. The full-automatic special-shaped polaroid laminating machine comprises a material receiving turnover mechanism, a feeding carrying arm, an alternate patching mechanism, a polaroid feeding mechanism, a material taking, film tearing and patching mechanism and a detection mechanism, and the material receiving turnover mechanism is arranged on a machine table; the feeding carrying arm is horizontally arranged on one side of the material receiving turnover mechanism; the alternate patching mechanism is arranged at the side part of the feeding carrying arm; the polaroid feeding mechanism is arranged on the other side edge of the machine table; the material taking, film tearing and patching mechanism is arranged between the alternate patching mechanism and the polaroid feeding mechanism; and the detection mechanism is erected above the alternate patching mechanism and is used for carrying out surface detection. According to the invention, the attachment surface of a glass substrate is aligned, a lower mounting belt and an upper surface mounting suction plate cooperate to realize automatic attachment of the back surface of a polaroid, the attachment bubbles are effectively reduced through linear contact type surface mounting, the production efficiency is effectively improved by adopting the alternate polaroid and surface mounting, the point detection and surface detection modes are combined, and automatic detection of irregular surfaces is effectively realized.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

An experimental method and device for bending stiffness of overhead cables under tension-bending combination

ActiveCN110849563BSimple structurePrecise applicationMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesAerial cablePull force

The invention belongs to the field of overhead cable testing, and relates to an experimental method and device for bending stiffness of an overhead cable under tension-bending combination. The traditional three-point bending test cannot measure the response of overhead cables under combined tension and bending loads. This proposal provides a measurement device and experimental method for the bending stiffness of overhead cables. According to the actual working conditions, the load equivalent method is adopted. By improving the three-point bending test, design a set of experimental support consisting of base support, extension frame and vertical support frame, and use a universal testing machine to apply radial tension, and hang weights at both ends of the sample cable to exert force on the sample cable. Axial tensile force, the tensile force output from the universal testing machine and the displacement data of the middle point of the cable body, combined with the data of two laser sensors symmetrical to the middle point, the bending of the overhead cable under the combination of multiple reciprocating stretching and bending is calculated and analyzed. The hysteresis curve of moment and curvature can be used to study the change of bending stiffness.

Owner:DALIAN UNIV OF TECH

A brush roller cotton picker

The invention relates to a brush roll cotton picker and belongs to the technical field of agricultural machinery. The brush roll cotton picker comprises a picking table, an air conveying device, a cotton boll separating device, an impurity cleaning device and a cotton collecting box which are arranged on a self-walking chassis, the impurity cleaning device comprises primary, secondary and tertiary tooth rollers, one side of the primary tooth roller is provided with an upper brush, one side of the secondary tooth roller is provided with a middle brush, one side of the tertiary tooth roller is provided with a lower brush, sides of the primary, secondary and tertiary tooth rollers are provided with interval arranged beating rods respectively, an upper brush roller is arranged below the primary tooth roller, a lower brush roller with bristles which simultaneously contact with outer circles of the secondary and tertiary tooth rollers is arranged below the secondary tooth roller, an arc barrier is mounted on the lower side of the tertiary tooth roller, one side in a casing, which is far from the beating rods, is provided with a cotton collecting flow channel which conveys air flow from bottom to top, and the cotton collecting flow channel is provided with upper and lower flow suction openings. The bottom of the cotton collecting flow channel is connected with an air outlet of a cotton conveying fan. By means of the brush roll cotton picker, cotton fiber damages can be remarkably reduced, the impurity cleaning effect is improved, the impurity content rate is lower than 10%, meanwhile, the recycling effect is enhanced, and the unginned cotton loss can be greatly reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

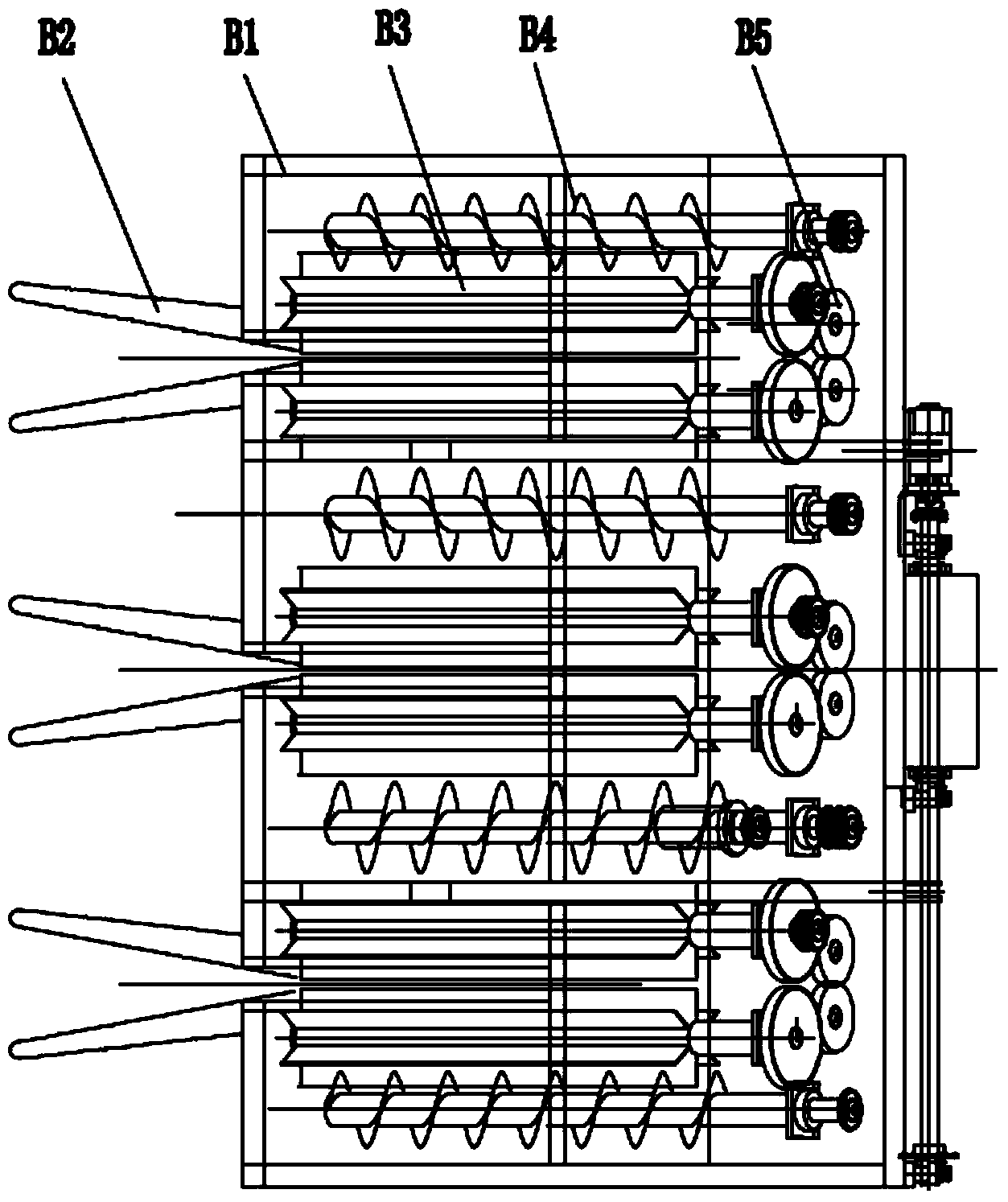

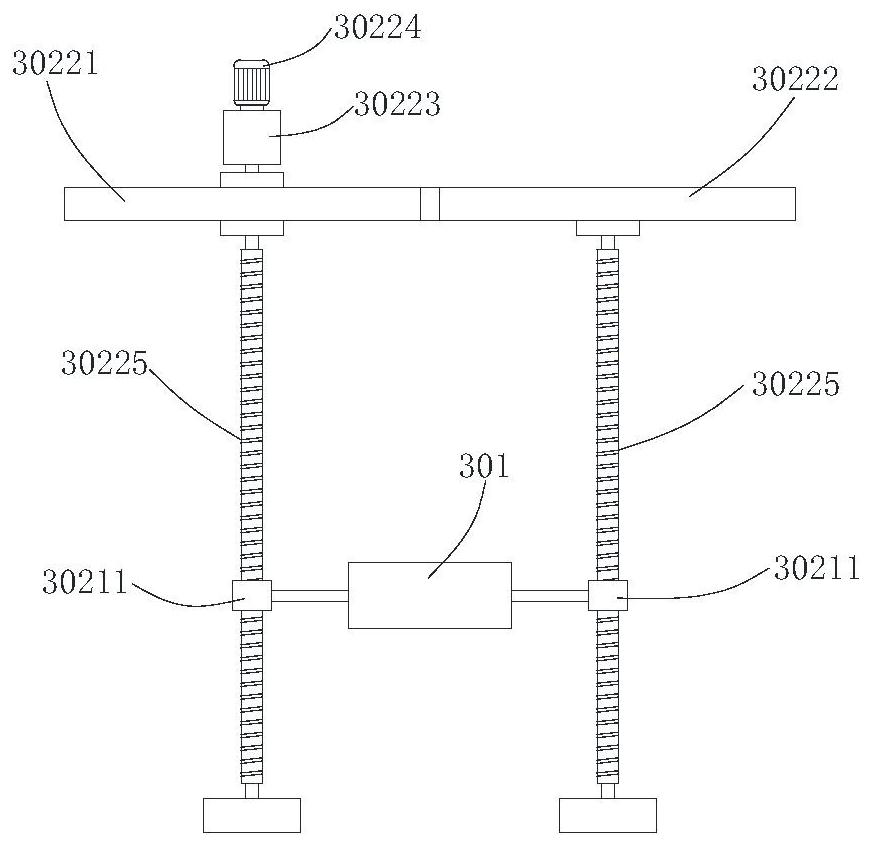

A bidirectional pleated fabric preparation device and its debugging method

ActiveCN112144267BRealize three-dimensional mechanized processingReduce labor costsHeating/cooling textile fabricsTransmissivity measurementsStructural engineeringMechanical engineering

Owner:SUZHOU JINGJIEWEI FABRIC TECH CO LTD

Tube-sinking cast-in-situ pile device suitable for expansive soil region and construction method

InactiveCN111236222AFully consider engineering characteristicsNot affected by atmospheric rainfallBulkheads/pilesSoil scienceRebar

The invention relates to the technical field of engineering pile construction, in particular to a tube-sinking cast-in-situ pile device suitable for an expansive soil region. The device comprises a valve pile tip, a plug and a retaining ring, wherein the valve pile tip is arranged at the end part of an sunken tube; the plug is placed at the bottom of the sunken tube; the retaining ring is mountedon the outer side of the cast-in-place pile and the height is not lower than the atmospheric influence depth; a cover plate is arranged at the top of the retaining ring and is provided with a circularopening with the diameter not smaller than that of the cast-in-situ pile. The invention also relates to a construction method, which comprises the following steps of: constructing the sunken tube toa designed elevation by adopting a static pressure or power sunken tube method; placing the plug at the bottom of the sunken tube; placing steel bars in the sunken tube, then pouring the concrete to form a cast-in-situ pile, and then pulling out the tube; and sinking the retaining ring into the soil around the pile by adopting the static or dynamic pile pressing method. By sufficiently consideringthe engineering characteristics of expansive soil, the construction efficiency is high, and arrangement is flexible, the method is suitable for cast-in-situ pile construction of various expansive soil layers, and the influence of soil expansion and shrinkage on a pile body can be greatly reduced.

Owner:CHANGZHOU INST OF TECH

Grouting suction anchor and its installation method

InactiveCN106240749BImprove lateral bearing capacityIncrease ultimate bearing capacityAnchorsBulkheads/pilesEngineeringCement mortar

The invention discloses a grouting suction anchor comprising a cylinder body; the cylinder body has an integral structure comprising an upper part, an intermediate part and a lower part; the diameter of the upper cylinder body is identical to that of the lower cylinder body; the diameter of the intermediate cylinder body is less than those of the upper cylinder body and the lower cylinder body; the upper, the intermediate and the lower cylinder body share a same center line; a top part of the upper cylinder body is provided with multiple grouting inlets and scuppers; the grouting inlets are communicated with a grouting channel inside a side wall of the upper cylinder body; the grouting channel extends downwards to a lower end surface of the upper cylinder body; an outlet of a lower end of the grouting channel is positioned between the outer lateral surface of the upper cylinder body and the outer lateral surface of the intermediate cylinder body; the grouting channel and the cylinder body inner chamber are separated from each other. The invention also discloses an installation method of the suction anchor. After downward penetration of the suction anchor is completed, the intermediate cylinder body and soil body interspace are filled with cement mortar which can improve the lateral bearing capacity of the suction anchor. After the cement mortar is solidified, the friction coefficient between surrounding soil body and anchor cylinder contact surface is increased and the limit bearing capacity of the suction anchor is increased.

Owner:OCEAN UNIV OF CHINA

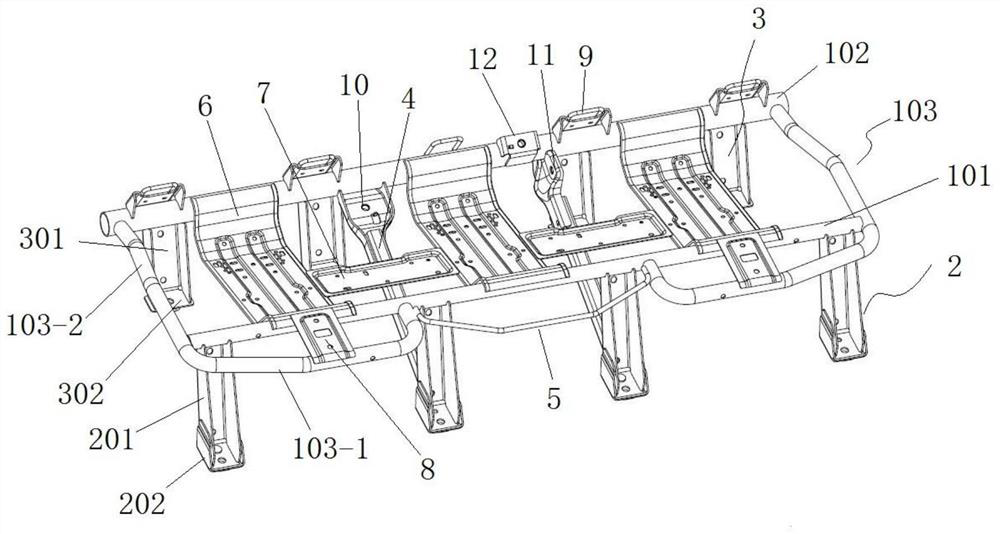

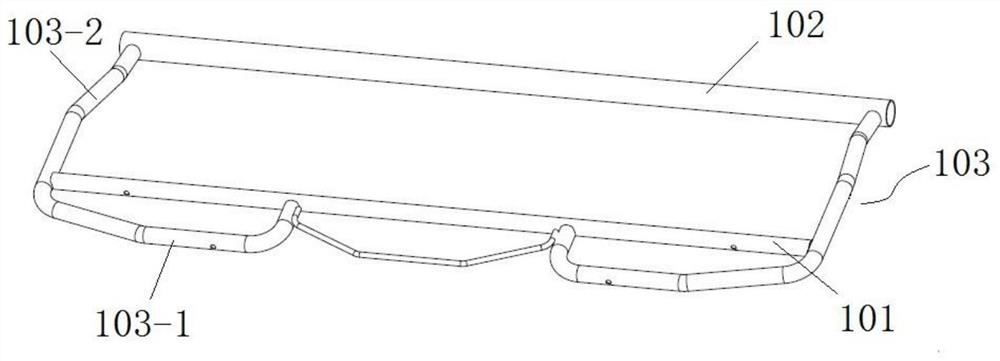

High-strength automobile rear-row seat framework

Owner:上海国琻汽车科技有限公司

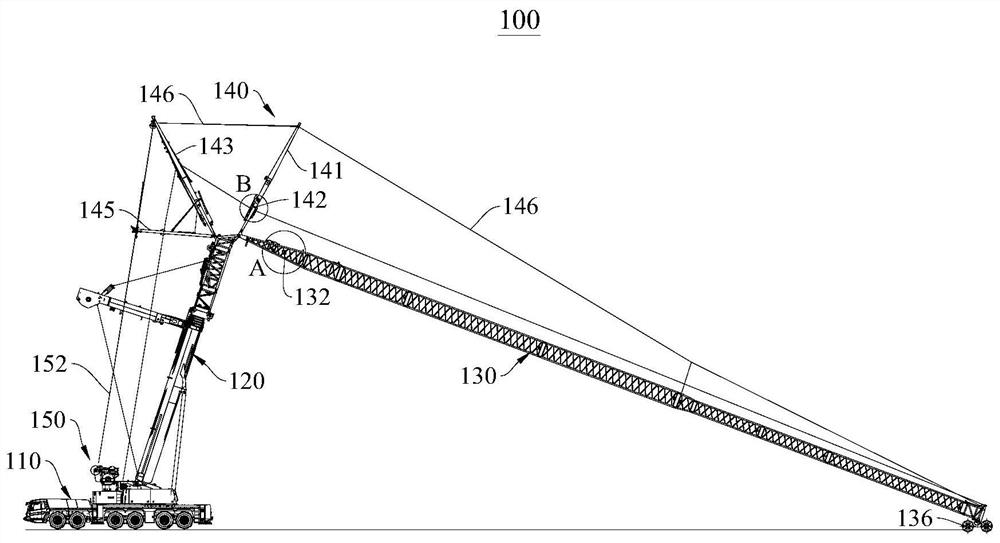

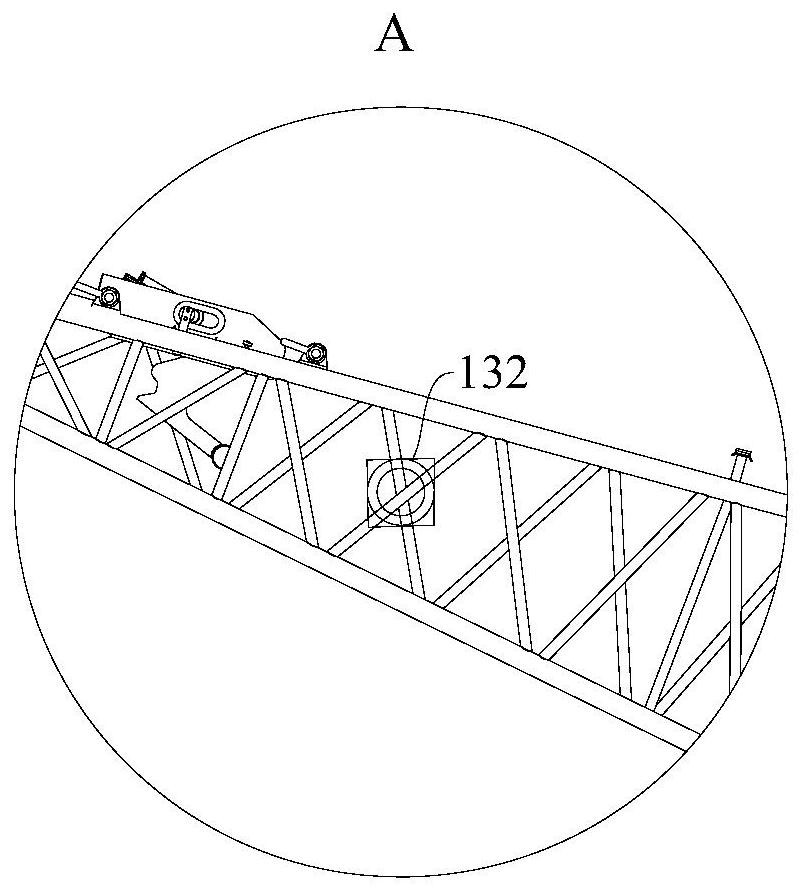

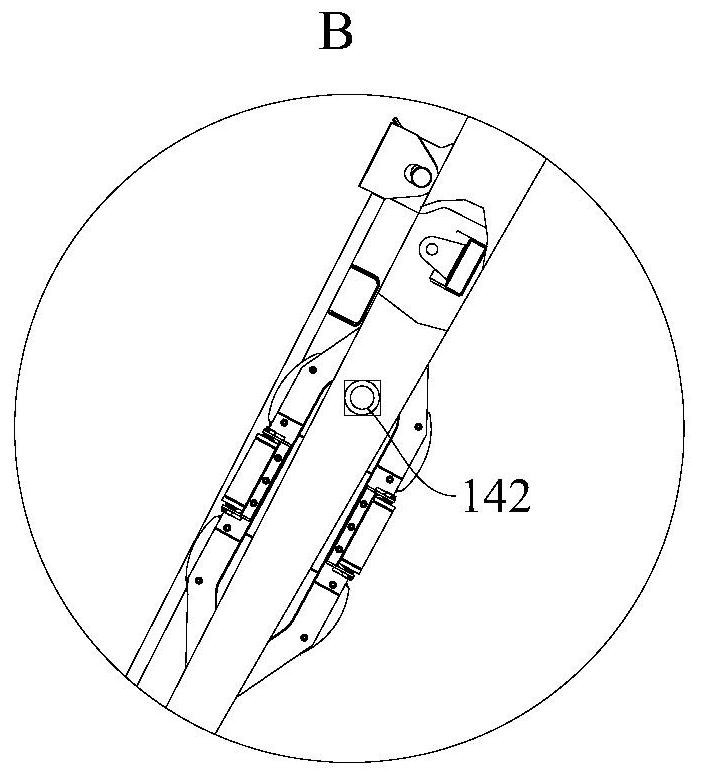

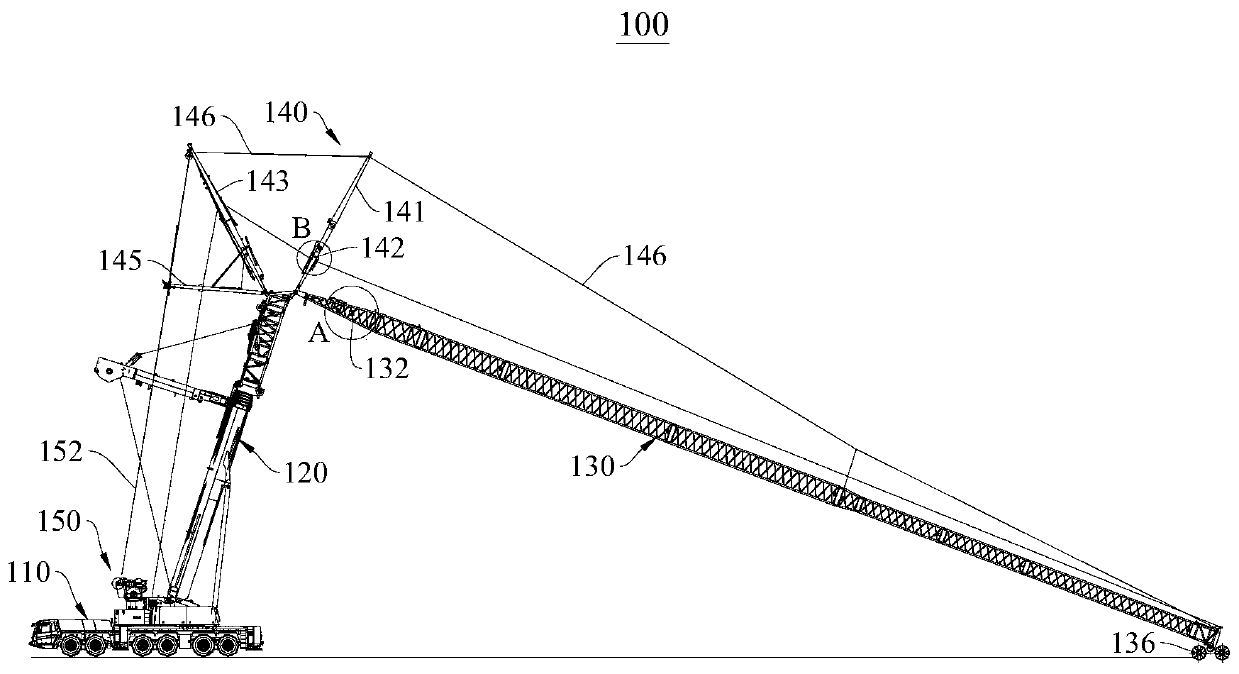

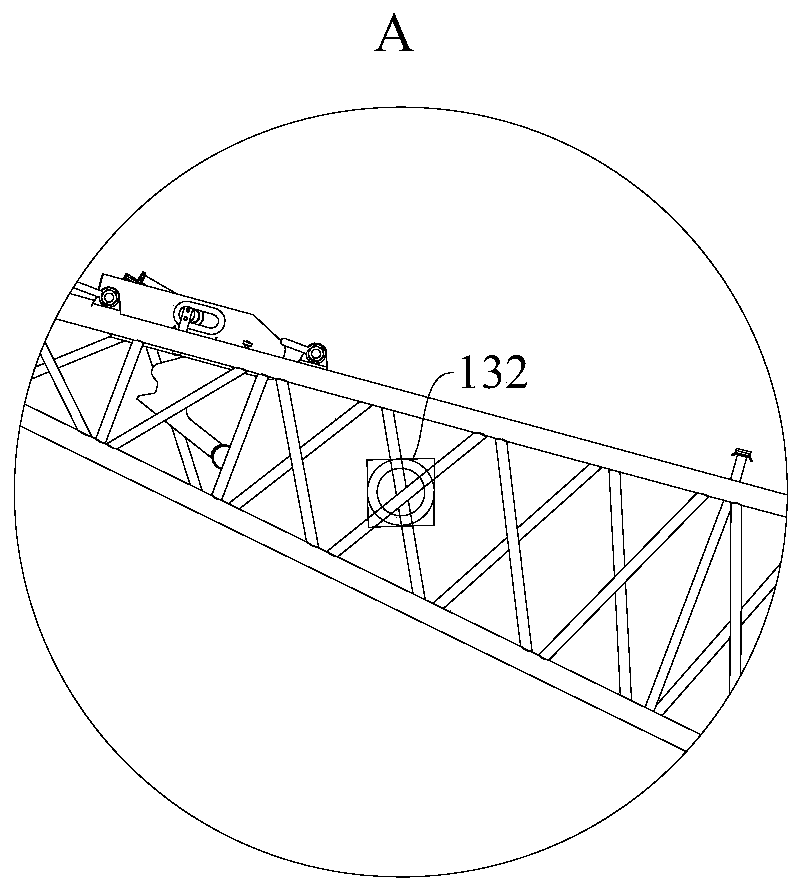

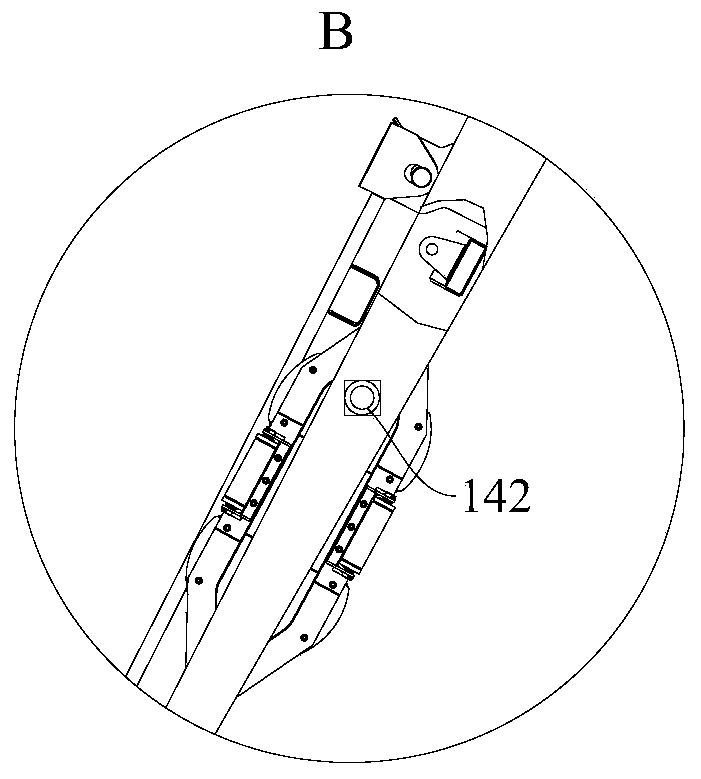

Crane, tower jib control method and tower jib control device

ActiveCN111017740BGuaranteed touchdownPrevent leaning forwardCargo handling apparatusPassenger handling apparatusControl engineeringTower

Owner:SANY AUTOMOBILE HOISTING MACHINERY

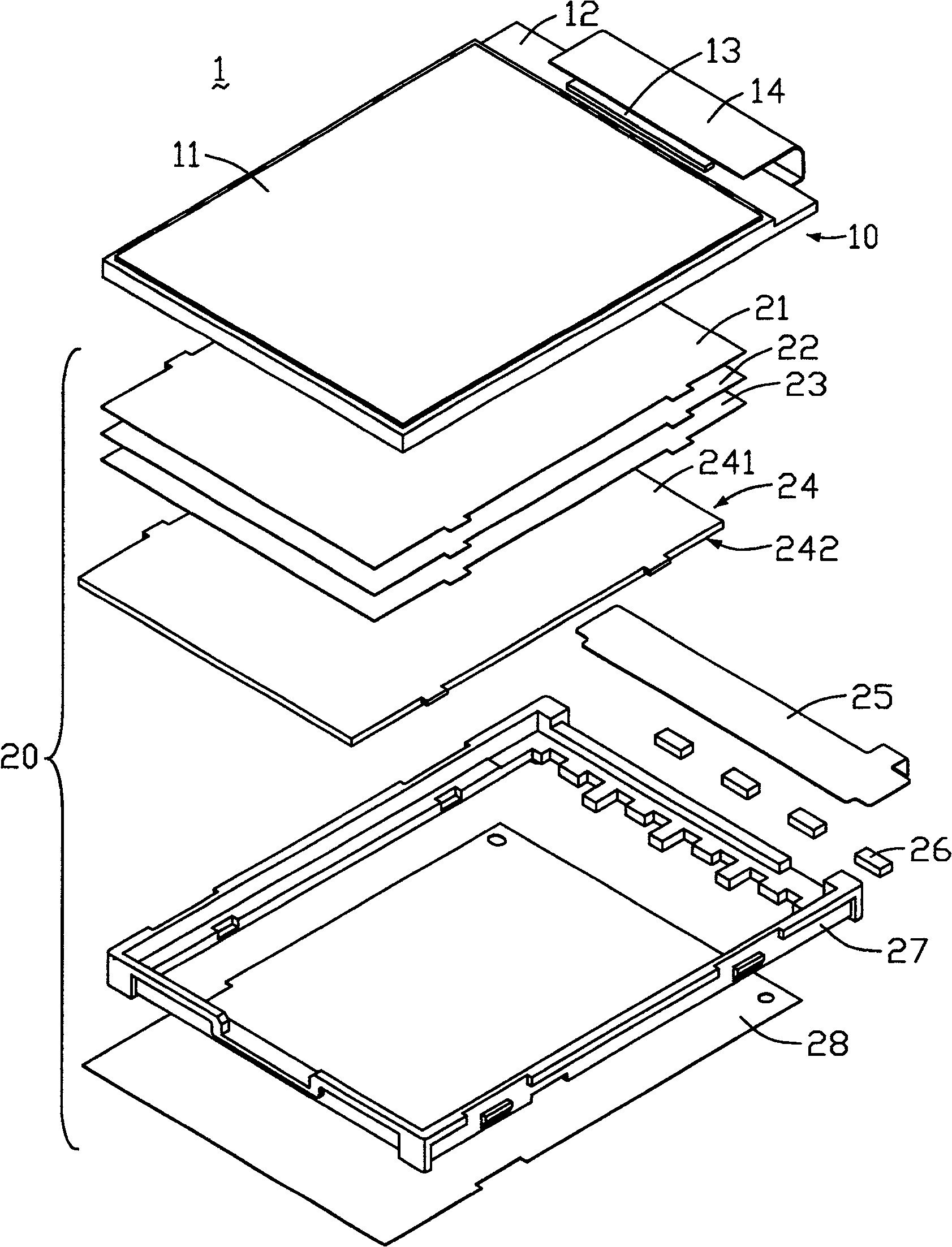

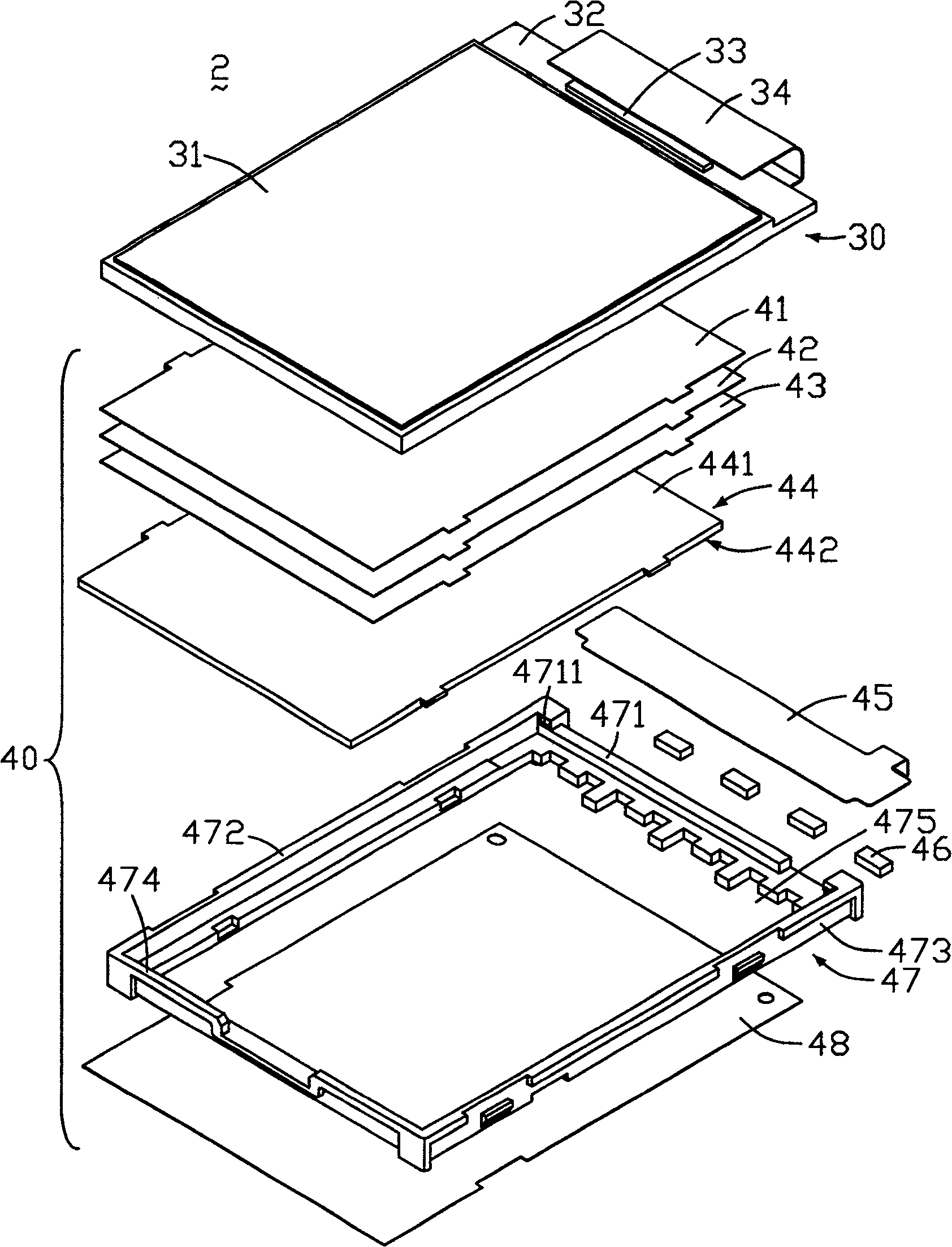

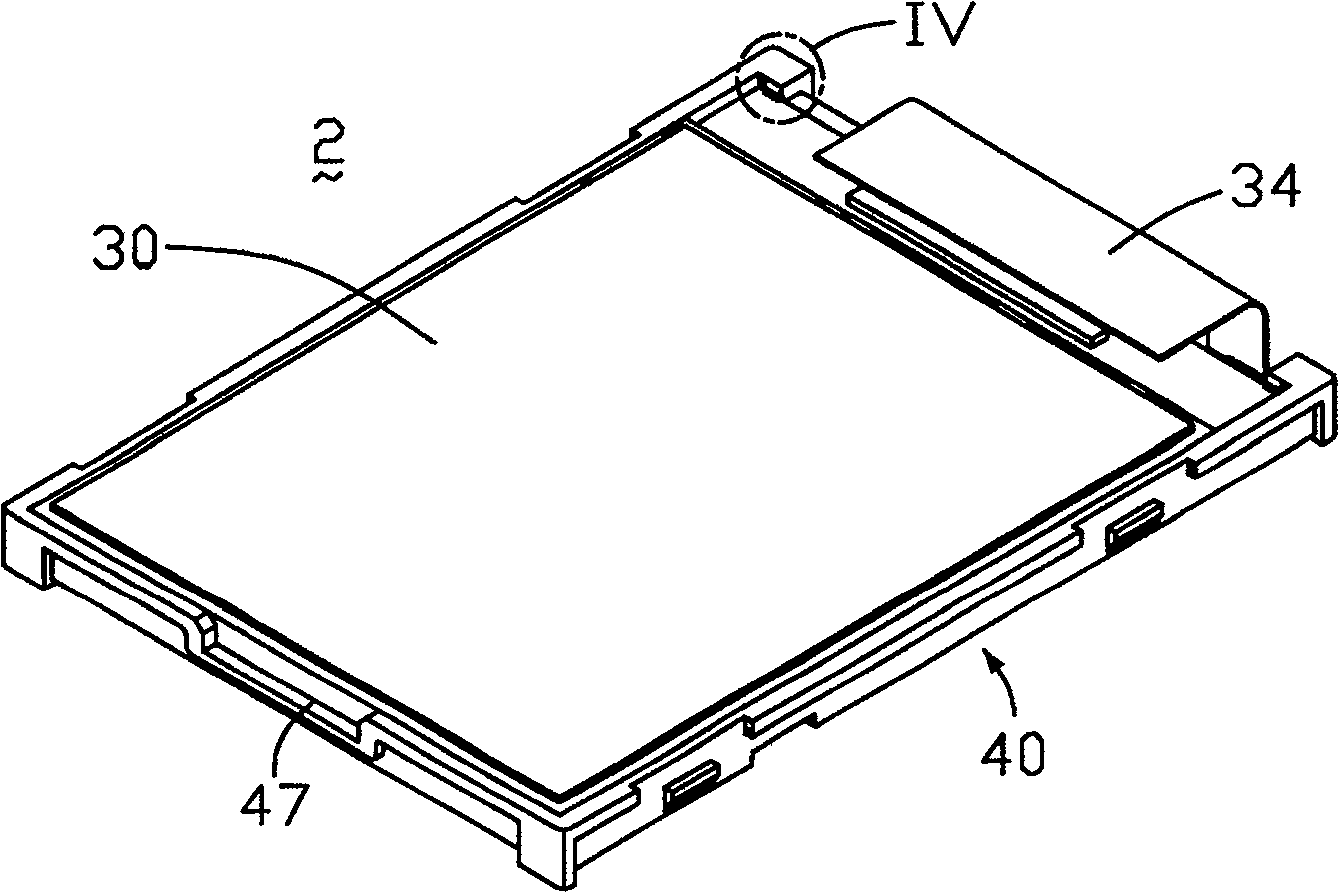

Liquid crystal display

InactiveCN100414385CImprove display qualityPrevent pull upStatic indicating devicesNon-linear opticsLiquid-crystal displayFlexible circuits

This invention relates to one LCD device, which comprises one LCD panel and one aphototropism module set, wherein, the LCD panel comprises one display area, one non-display area and flexible circuit; the display area is near to non-display area; one end of flexible circuit board is connected to non-display area; the aphototropism set comprises one frame composed of four side walls to form one container space to contain the LCD panel; the frame rack is relative to LCD panel at least one side wall of the non-display area set with at least one protruding part.

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

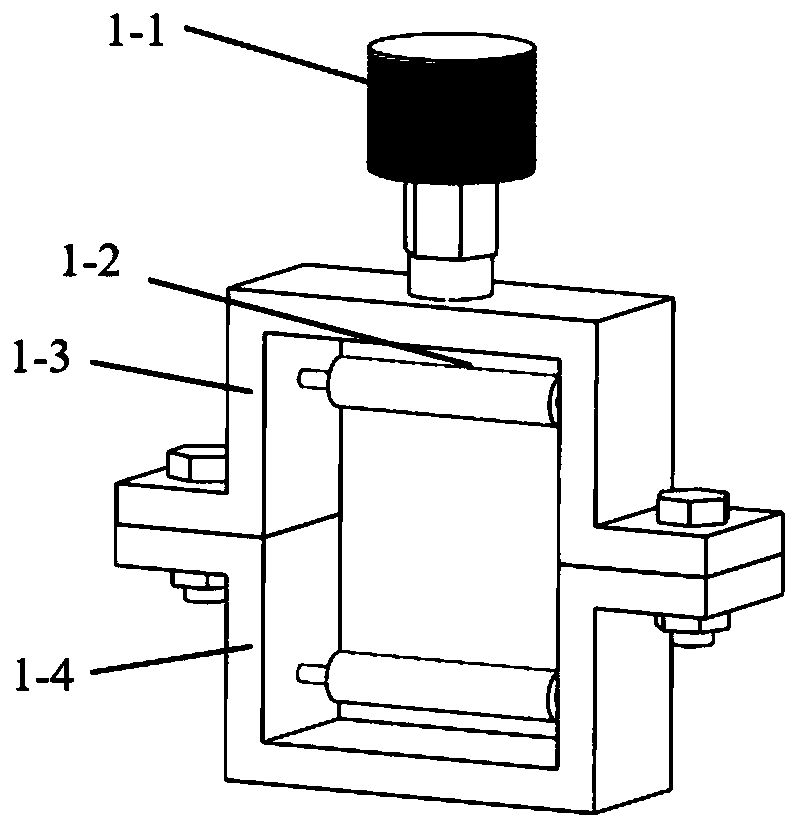

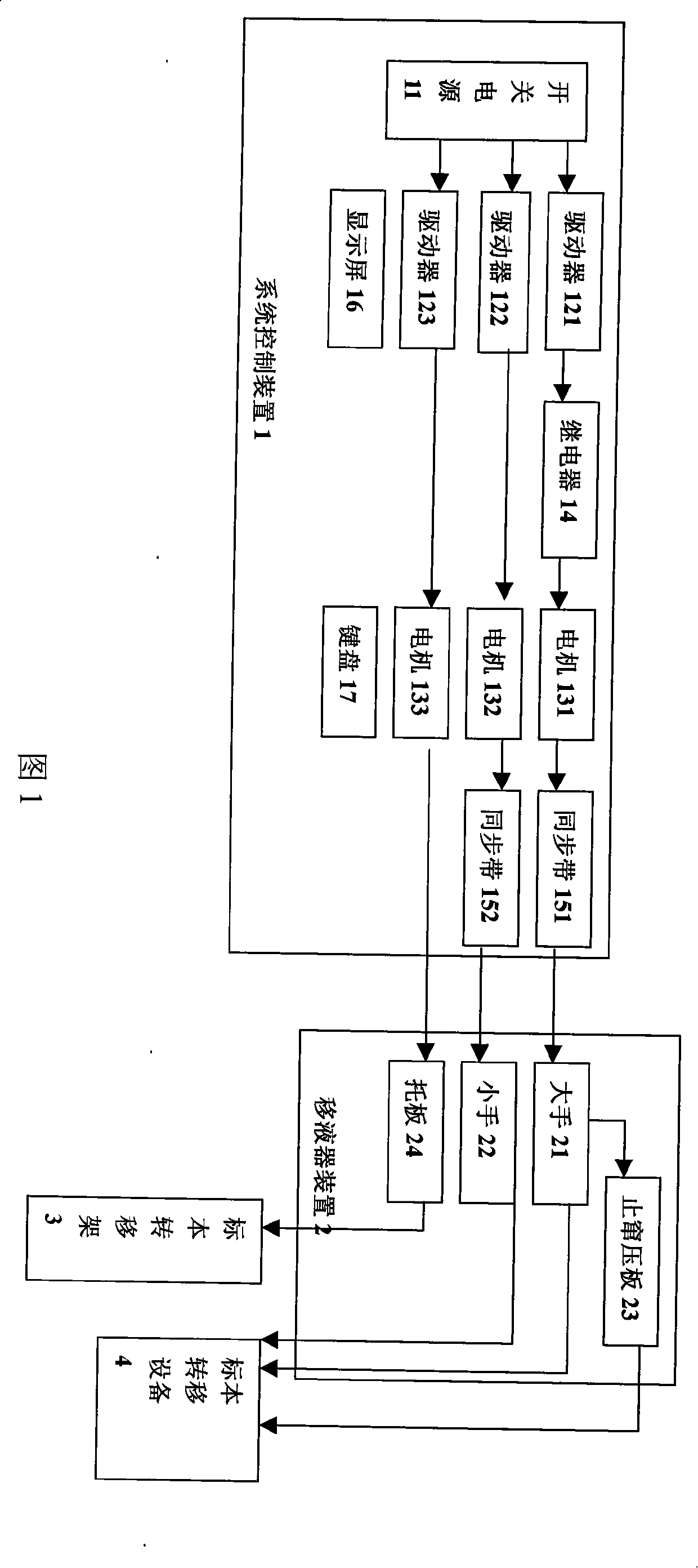

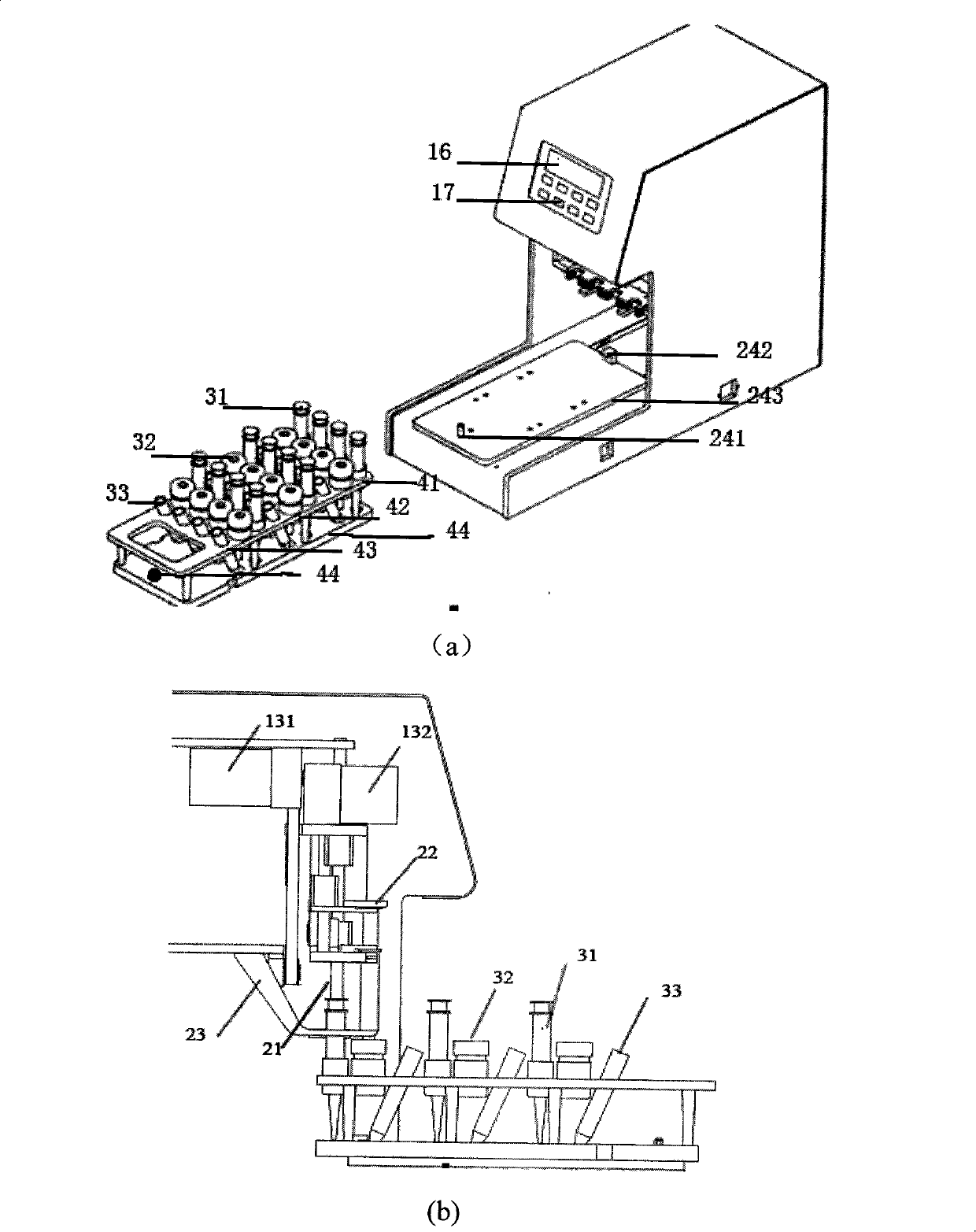

Intelligent sample processor

ActiveCN101625369BPrevent pull upImprove layering effectLaboratory glasswaresMaterial analysisPipetteBottle

The invention discloses an intelligent sample processor, and in particular relates to a medical instrument capable of helping doctors to finish certain mechanical work. The intelligent sample processor comprises a system control device, a pipette device, sample transfer equipment and a sample transfer frame, wherein a user drives the pipette device to perform related operation through a command input through the system control device; the pipette device comprises a large hand, a small hand, a supporting plate and two fleeing prevention pressing plates, wherein the large hand, the small hand and the supporting plate cooperate with each other to finish the pipetting operation; the sample transfer equipment comprises a pipette, a sample bottle and a centrifuge tube; and the sample transfer frame comprises a pipette limit hole, a sample bottle limit hole, a centrifuge tube limit hole and a transfer frame limit hole. The intelligent sample processor is suitable to be used in large hospitals when sampled liquid of patients is transferred so as to avoid excessive personnel input in the mechanical work.

Owner:GUANGZHOU LBP MEDICINE SCI & TECH

Hoist, tower arm control method and tower arm control device

ActiveCN111017740AGuaranteed touchdownPrevent leaning forwardCargo handling apparatusPassenger handling apparatusControl engineeringTower

The invention provides a hoist, a tower arm control method and a tower arm control device, and relates to the technical field of engineering machinery. When a main arm extends or retracts, an actual included angle between the tower arm and a mast structure is obtained through a controller; the retraction and extension speed of the hoist is regulated according to the comparison result between the actual included angle and a preset safe included angle range so that the actual included angle is stabilized in the preset safe included angle range. In the tower arm control device, an acquisition module is used for acquiring the actual included angle between the tower arm and a mast structure; and a control module is used for regulating the retraction and extension speed of the hoist according tothe comparison result between the actual included angle and the preset safe included angle range. The hoist, the tower arm control method and the tower arm control device can facilitate coordinated control over the hoist and the main arm; in the retraction and extension process of the main arm, the mast structure can be prevented from inclining forwards due to excessive extension of the hoist, and the risk that the tower arm is lifted off the ground due to excessive retraction of the hoist and consequently a complete vehicle is overturned can be avoided effectively; and the operation is convenient, and the reliability is high.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

Manufacturing equipment for adhesive tape rolls

ActiveCN104055477BAvoid deformationPrevent pull upHousehold cleanersManufacturing technologyManufacturing line

To provide a manufacturing technique of an adhesive tape roll capable of always forming a cutting line for cutting an adhesive tape at a fixed position. There is a take-up roller (32) for winding the adhesive tape (2) drawn out from the mother roller (31), and it is arranged between the mother roller (31) and the take-up roller (32), and the adhesive tape (2) The cutting line forming rollers (33) on which the cutting lines (4) are formed at predetermined intervals make the take-up roller (32) and the cutting line forming rollers (33) rotate synchronously via predetermined gears (40).

Owner:NITOMS INC

A car dent repair tool

The invention discloses an automobile sag repairing tool. The automobile sag repairing tool comprises a pulling force part and a pair of adsorption chains; each adsorption chain is formed in the modethat at least four rectangular hinge blocks are hinged to one another, and the bottoms of the side faces, in the same direction, of the opposite faces of the rectangular hinge blocks are provided withhinge points used for allowing the adjacent rectangular hinge blocks to be hinged; hooks are arranged on the rectangular hinge blocks located at the corresponding ends of the sides, far away from thehinge points, of the adsorption chains; and the rectangular hinge blocks are provided with T-shaped fixing rods in a penetrating mode in the width direction, and suction cups are arranged at the ends, close to the hinge points, of the T-shaped fixing rods. According to the automobile sag repairing tool, in the repairing process, a pair of the adsorption chains are symmetrically adsorbed to the two sides of an automobile sag, a rotating handle is rotated to enable a rotating shaft to wind a first connecting rope and a second connecting rope, the first connecting rope and the second connectingrope pull the adsorption chains to rotate to repair the sag, no supporting point is needed in the repairing process, the condition that in the repairing process, counter-acting force is generated to act on an automobile to generate an adverse effect is avoided, labor is saved, operation is easy, and the automobile sag repairing tool is suitable for a green hand.

Owner:ANHUI POLYTECHNIC UNIV

Experiment model structure related to adhering feature between concrete and steel pile casting

PendingCN107966405APrevent bonding surface from changingGuaranteed tensionUsing mechanical meansMaterial analysisRelative displacementPull force

The invention discloses an experiment model structure related to an adhering feature between concrete and a steel pile casting. The experiment model structure comprises the steel pile casting and a loading module and is characterized in that the concrete is poured inside and outside the steel pile casting, the loading module is connected with the steel pile casting, the loading module provides pulling force for pulling the steel pile casting away from the concrete, and two ends of the steel pile casting are located outside the concrete. The experiment module structure has the advantages that force is applied to a loading column and transmitted to the steel pile casting to allow the steel pile casting to be in a pulled state instead of a pressed state, and accordingly data inaccuracy causedby steel pile casting deformation due to excessively large pressure is avoided; two ends of the steel pile casting are located outside the concrete to prevent adhering face change after relative displacement between the steel pile casting and the concrete occurs.

Owner:HEFEI UNIV OF TECH

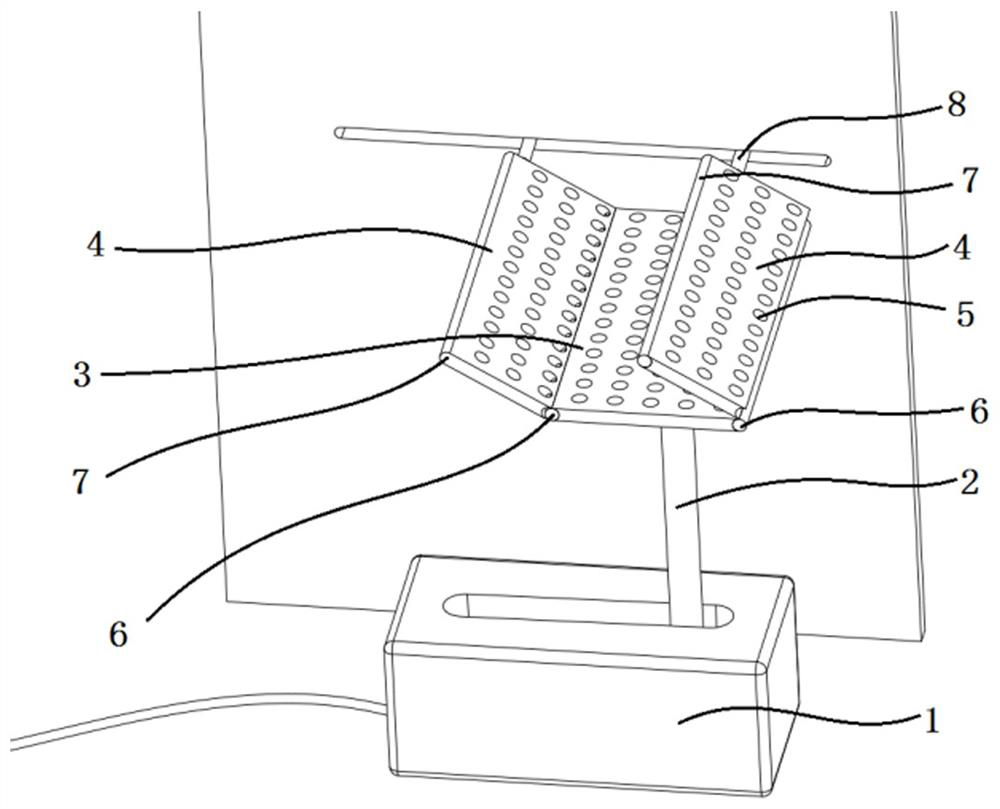

One-way wrinkle fabric preparation device and use method thereof

ActiveCN112195643AReduce labor costsSmooth preparation processTransmissivity measurementsTextile shapingStructural engineeringPower apparatus

The invention discloses a one-way wrinkle fabric preparation device and a use method thereof. The one-way wrinkle fabric preparation device comprises a clamping mechanism and a traction mechanism connected with the clamping mechanism; the clamping mechanism comprises two clamping plates, the clamping plates are movably connected with a traction shaft, and the two clamping plates are symmetricallyarranged at the two sides of the traction shaft in the axial direction; the clamping plates can rotate around the traction shaft, the outer side edges, away from the traction shaft, of the clamping plates are semi-fixedly connected with the outside, the outer side edges can only move on a straight line, and the traction shaft is fixedly connected with the traction mechanism; and the traction mechanism comprises a traction column and a base box, the traction column is fixedly connected with the traction shaft, the base box is located at the end, away from the traction shaft, of the traction column, and a power device is arranged in the base box. According to the one-way wrinkle fabric preparation device, the traction mechanism is in movable fit with the clamping mechanism, so that uninterrupted wrinkling can be carried out on a whole fabric, and compared with manual manufacturing, the time cost is greatly saved.

Owner:苏州睿帛源纺织科技有限公司

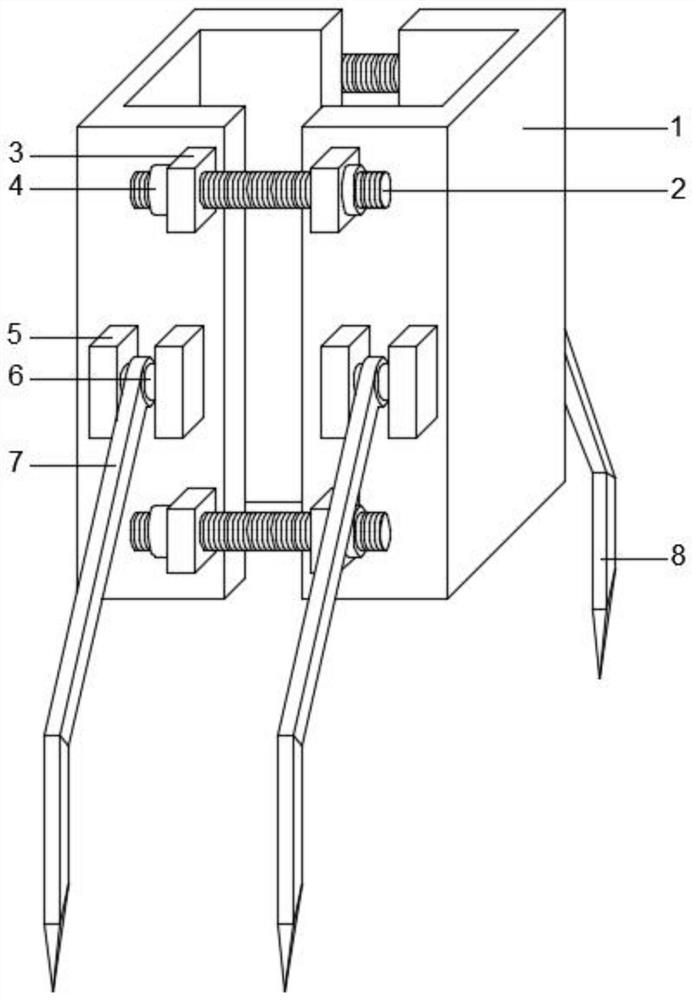

Foundation pile hole reinforcement device for building construction with double reinforcement effect

ActiveCN113047273BNot easy to cause deviationDouble reinforcement effectFoundation repairBulkheads/pilesArchitectural engineeringScrew thread

The invention discloses a foundation pile hole reinforcement device for building construction with double reinforcement effects, which includes a reinforcement device body, which includes: two symmetrically arranged fixing plates, and bolt fixing blocks are symmetrically installed up and down on the outer sides of the two fixing plates The internal thread of the bolt fixing block is connected with bolts, and the left and right sides of the bolt are threaded with fixing nuts, and the two symmetrically arranged fixing plates are connected through the bolts and fixing nuts; the two opposite outer sides of the fixing plates are symmetrically arranged with fixing devices; The foundation is fixed in two symmetrically installed fixed plates, and the foundation piles are fixed on the ground under the cooperation of the fixed plates, so that it is not easy to cause deviation. At the same time, the fixing device fixes the fixed plates so that the fixed plates can be fixed on the ground, so that The foundation is further stabilized, which has a double reinforcement effect on the foundation piles, improves the structural reinforcement effect, improves the stability of the foundation of the building or ground engineering, and plays a reinforcing role in the building or the stratum.

Owner:GUANGZHOU SHENGTE BUILDING TECH DEVCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com