Tube-sinking cast-in-situ pile device suitable for expansive soil region and construction method

A technique for sinking cast-in-situ piles and expansive soil, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as construction difficulties of cast-in-place piles, achieve high construction efficiency, flexible layout, and reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

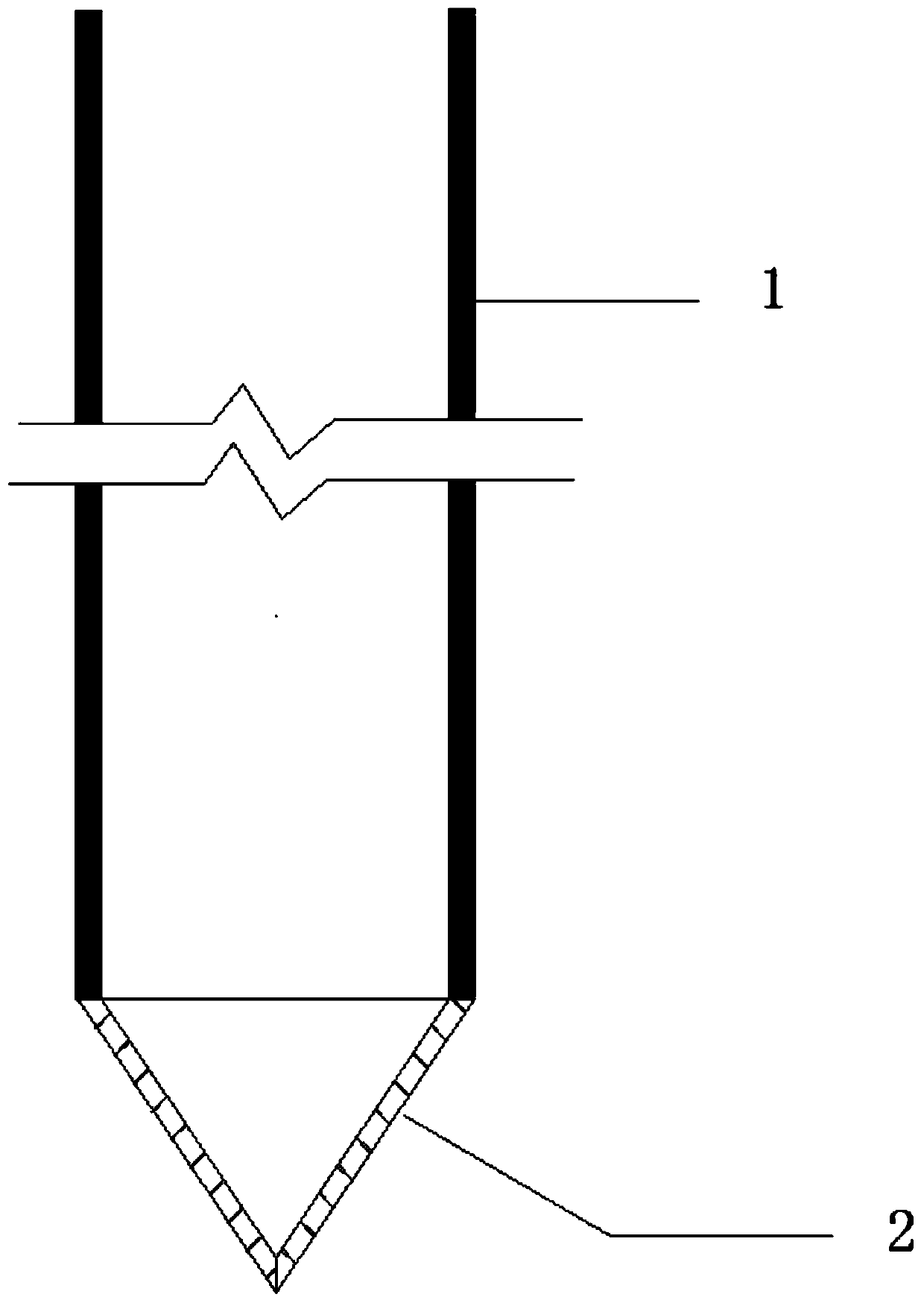

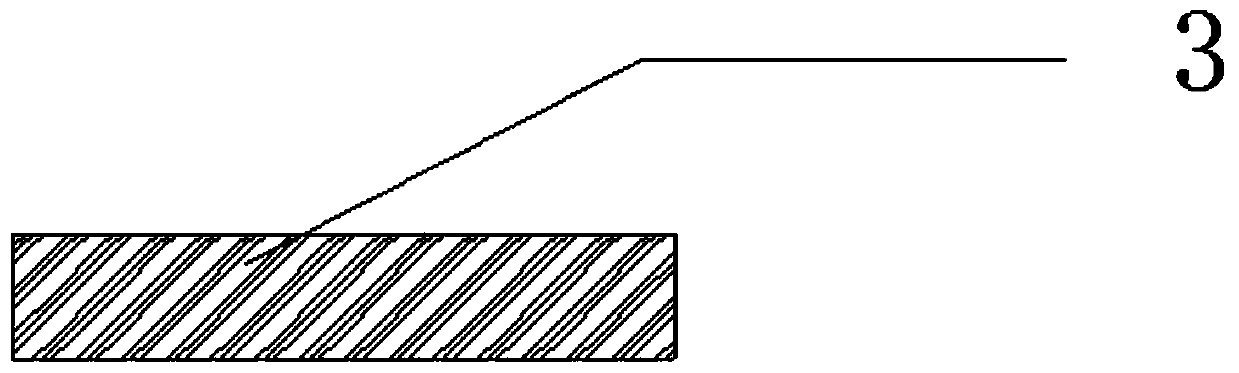

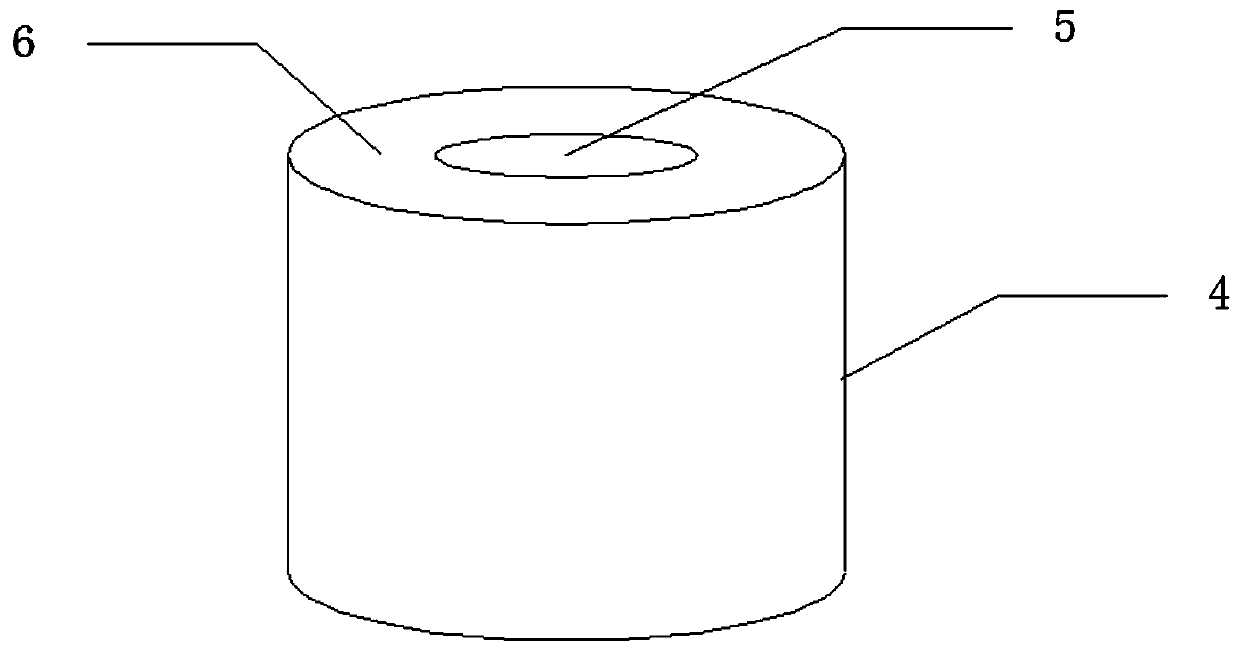

[0033] Such as Figures 1 to 6 As shown, a sinking tube cast-in-situ pile device suitable for expansive soil areas includes a valve pile tip 2, a plug 3, and a retaining ring 4, and the valve pile tip 2 is arranged at the end of the immersed tube 1; the plug 3 is A cylindrical steel block, the plug 3 is placed at the bottom of the immersed tube 1; the retaining ring 4 is a hollow cylindrical structure, the retaining ring 4 is installed on the outside of the cast-in-place pile, and the height of the retaining ring 4 is not less than the atmospheric influence depth; A cover plate 6 is welded on the top of the ring 4, and a circular opening 5 is opened on the cover plate 6, and the diameter of the circular opening 5 is not smaller than the diameter of the cast-in-situ pile.

[0034] Wherein, the materials of the immersed tube 1, the valve pile tip 2, the plug 3 and the retaining ring 4 can all be made of stainless steel.

[0035] In one embodiment, the height of the retaining ri...

Embodiment 2

[0038] Such as Figure 7-11 Shown, another aspect of the present invention also provides a kind of construction method that is applicable to the immersed pipe grouting pile of expansive soil area, comprises the following steps:

[0039] Step 1: Set the valve pile tip 2 at the end of the immersed tube 1, use the static pressure or dynamic immersed tube method for construction, and construct the immersed tube 1 to the design elevation;

[0040] Step 2: Place the plug 3 at the bottom of the immersed tube 1;

[0041] Step 3: placing steel bars 7 in the immersed tube 1, then pouring concrete to form cast-in-place piles, and then pulling out the tubes;

[0042] Step 4: After the tube is pulled out, the retaining ring 4 is sunk into the soil around the pile by static force or dynamic pile pressing.

[0043] The method can provide safety guarantee for the construction operation of the immersed pipe grouting pile in the expansive soil area, and prevent the pile body from being affect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com