FPC (flexible printed circuit) welding disc

A pad and base material technology, applied in the direction of electrical connection of printed components, printed circuit components, etc., can solve problems such as easy to break, backlight is not bright, affect product display function and product yield, increase adhesion, prevent The effect of being pulled up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

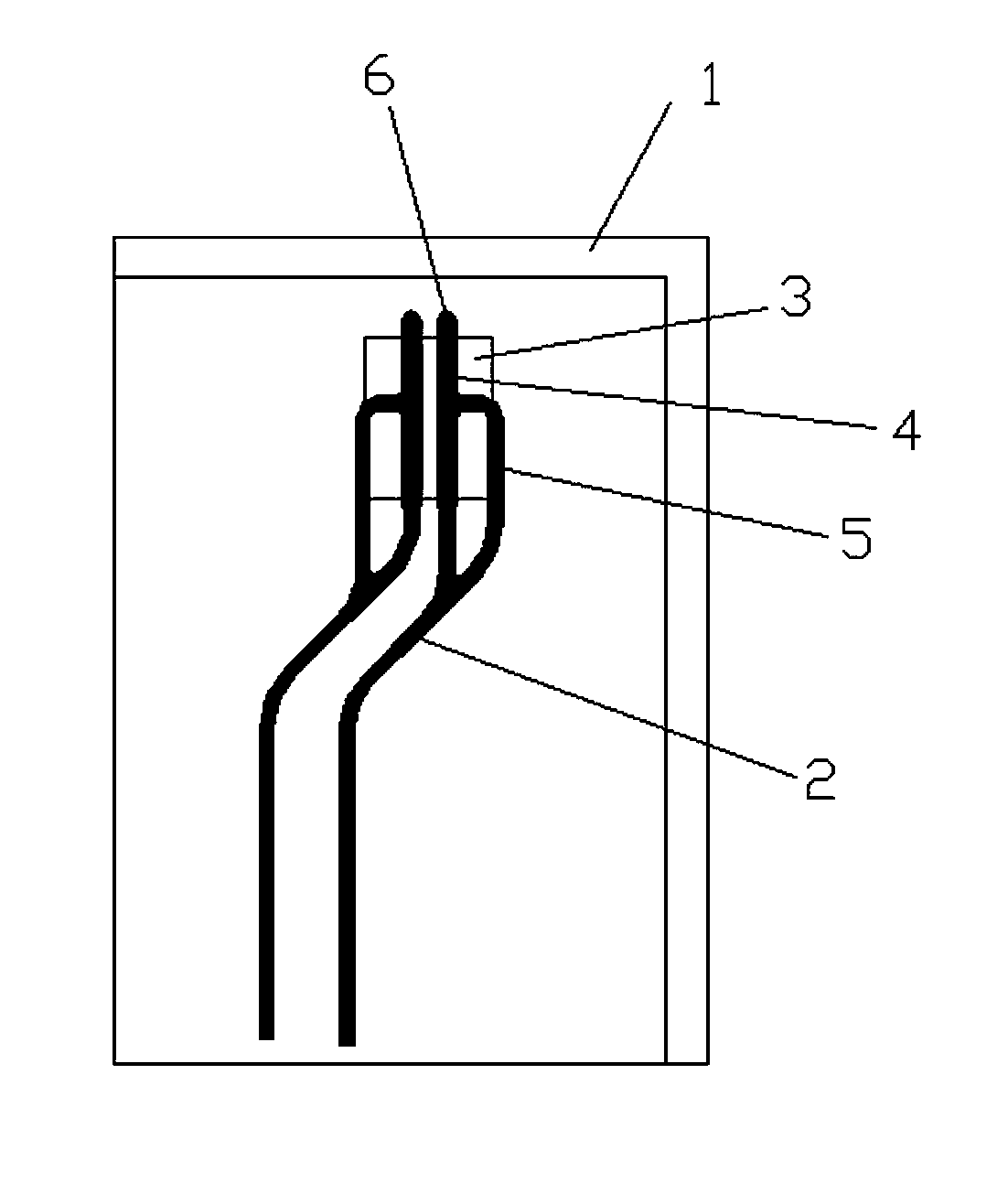

[0013] An FPC pad, comprising a base material 1 and a wiring 2 arranged on the base material, an upper coating film 3 is arranged on the wiring, and the upper coating film is exposed on the wiring by opening a window at one end of the wiring The copper foil forms the pad 4, and the second wire 5 is drawn out from the common end of the wire on the pad to connect to the middle of the wire on the pad. In this way, the second wiring opening can play a better reinforcing role, prevent the pad from being pulled up, and increase the adhesion of the entire pad; when the wiring breaks at the edge of the pad, the second wiring can also It plays a conduction role and will not affect the normal use of the FPC.

[0014] Preferably, an extension part 6 is provided at one end of the pad trace, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com