An experimental method and device for bending stiffness of overhead cables under tension-bending combination

A technology of bending stiffness and overhead cables, which is applied in the direction of testing material strength, measuring devices, and strength characteristics by applying a stable bending force. It can solve problems such as insufficient accuracy, inability to apply tension to the sample cable, and inability to perform multiple bendings, etc., to achieve The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail with reference to the accompanying drawings and implementation procedures as follows.

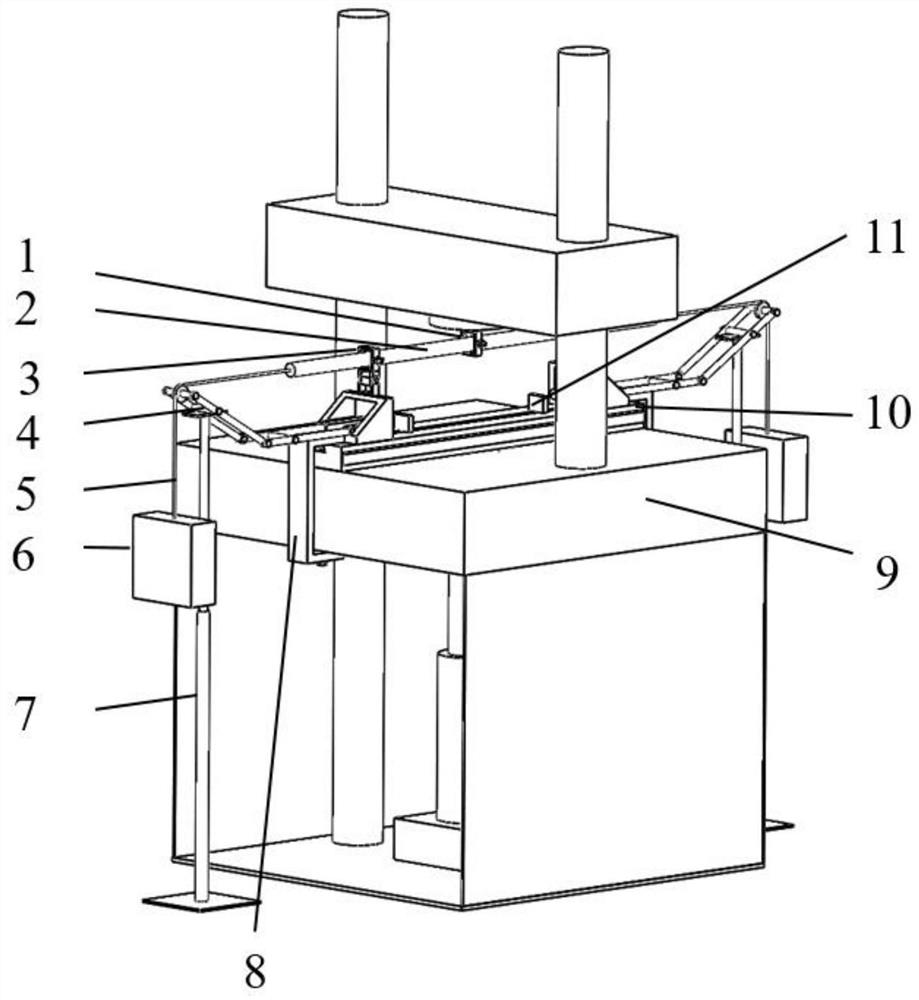

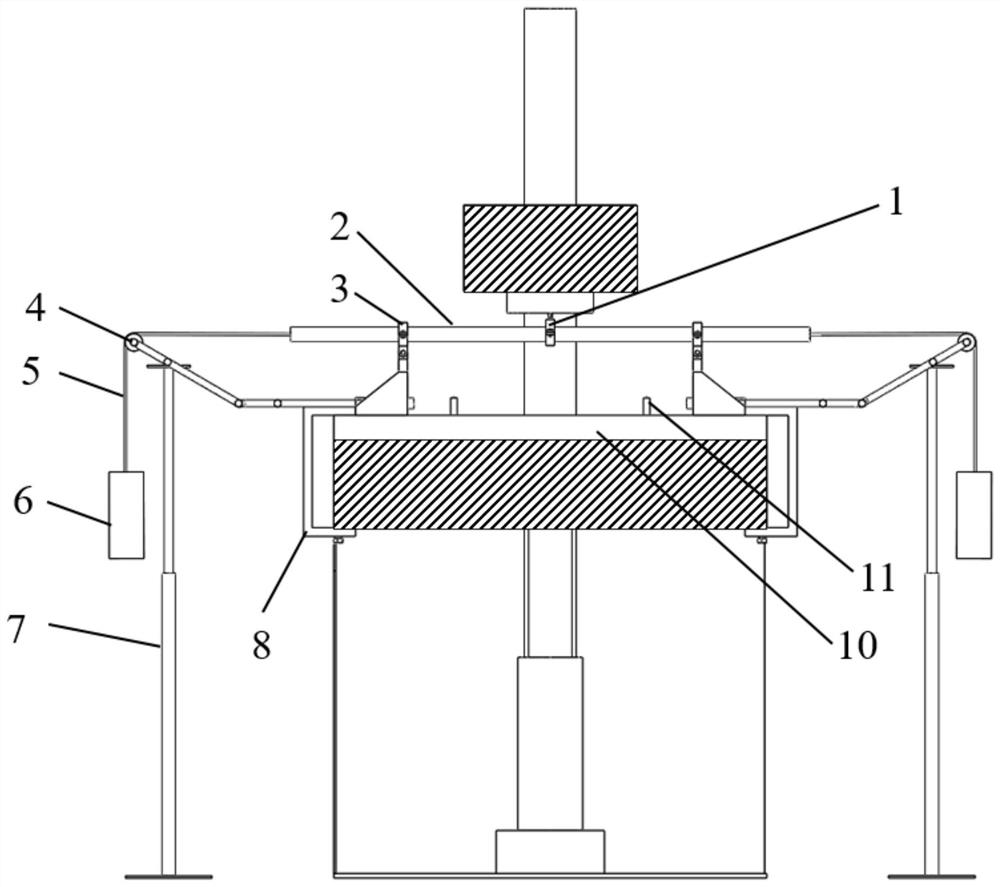

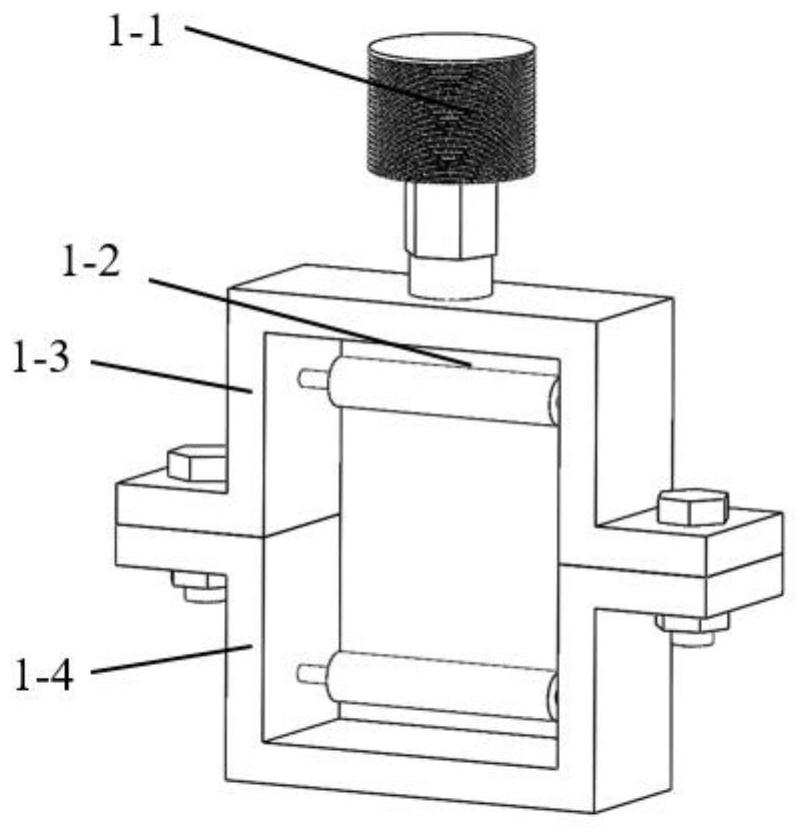

[0045] like Figure 1 to Figure 10 , an experimental device for bending stiffness under a combination of tension and bending of an overhead cable, comprising an intermediate twist bracket 1, a side twist bracket 2, an extension bracket 4, a weight 6, a vertical support bracket 7, a U-shaped buckle 8, a universal testing machine 9, The base bracket 10 and the laser rangefinder 11 .

[0046]The moving platen 9-2 and the moving base 9-4 of the universal testing machine 9 are connected with the guide post 9-1, and the force sensor 9-3 is connected with the moving platen. When the sample cable 2 is installed, the moving platen 9-2 remains fixed. The hydraulic cylinder 9-5 is connected with the movable base, and the movable base 9-4 moves up and down through the expansion and contraction of the hydraulic cylinder 9-5, resulting in tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com