Automatic film tearing machine

A film machine, automatic technology, applied in the direction of layered products, lamination auxiliary operation, lamination, etc., can solve the problems of affecting work efficiency, easy adhesion of dust, waste of tape, etc., to improve production efficiency, reliable effect, and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

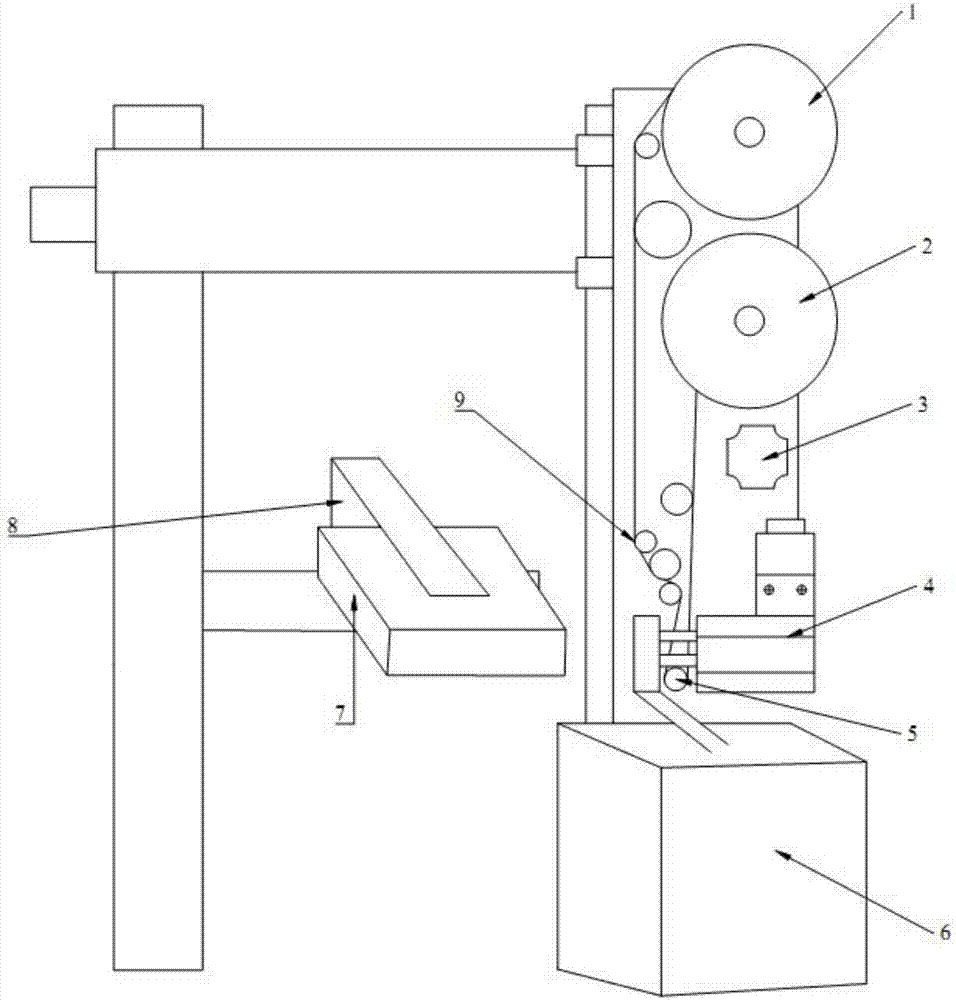

[0014] Such as figure 1 Shown: an automatic film tearing machine, its structure includes: a material receiving device, a feeding device, a roll length control device, a film throwing device, a pressing wheel, a protective film collection box, a throwing product recovery box, a throwing device, Rolling rubber device; the receiving device is a disc type hinged by a rotating shaft, the lower end of the receiving device is equipped with a feeding device, the bottom of the feeding device is equipped with a roll length control device, and the bottom end of the roll length control device is A film throwing device is installed, one side of the film throwing device is provided with a pressing wheel, the bottom of the pressing wheel is provided with a protective film collection box, and the other side of the frame is equipped with a throwing device, so A throwing product recovery box is installed on the throwing device, and the rubber rolling device is arranged at the top of the film th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com