Film-tearing apparatus

A film device and film roller technology, applied in the field of machinery, can solve problems such as relatively high requirements for parts matching, increased consumption of consumables, and increased costs, and achieve the effects of complete and simple tearing process, improved tearing efficiency, and mechanized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The purpose of the present invention is to provide a film tearing device, which can realize the film tearing process machine is complete and simple, the operation is mechanized, the failure rate is low, the loss can be reduced, and the film tearing efficiency can be improved.

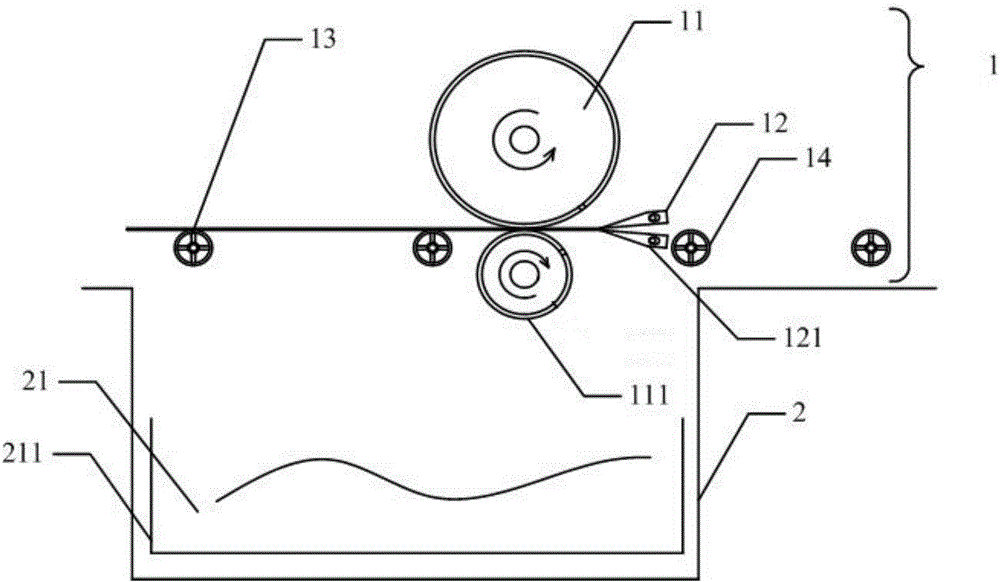

[0036] see below figure 1 , a kind of film tearing device embodiment in the present invention is described:

[0037] An embodiment of a film tearing device of the present invention includes a film tearing part 1 and a film closing part 2. The film tearing part 1 includes: a film closing roller 11 and an edge lifter 12; the edge lifter 12 can be lifted from the circuit board to protect film; the film collecting roller 11 is used to tear off the protective film lifted by the edge lifter 12; the film collecting roller 11 and the edge lifter 12 are located on the same side of the circuit board.

[0038] In this embodiment, the edge lifter 12 of the film tearing part 1 and the film take-up roller 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com