Unartificial material mechanical agitator for manufacturing industry

A mechanical stirring, non-artificial technology, applied to mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., can solve the problems of untimely mixing, high labor intensity, low production efficiency, etc., and meet the needs of modern production , Reduced labor intensity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

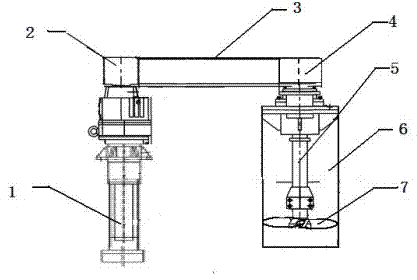

[0013] This embodiment provides a non-artificial material mechanical agitator for manufacturing, characterized in that: the non-artificial material mechanical agitator for manufacturing includes a drive cylinder (1), a driving wheel (2), Conveyor belt (3), driven wheel (4), rotating shaft (5), mixer (6), stirring blade (7);

[0014] Wherein: the mixer (6) is provided with a rotating shaft (5), the rotating shaft (5) is provided with a stirring blade (7), and the rotating shaft (5) is connected with a driving mechanism through a transmission mechanism.

[0015] In the transmission mechanism, the driving wheel (2) drives the driven wheel (4) through the conveyor belt (3), the driving wheel (2) and the driven wheel (4) are in a horizontal position, and the driven wheel (4) is connected The rotating shaft (5) in the device (6) is connected, and the driving wheel (2) is connected with the driving mechanism through a connecting rod.

[0016] The driving mechanism is a driving cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com