Film tearing device

A film device and film clip technology, applied in the directions of layered products, lamination auxiliary operations, lamination, etc., can solve the problems of low film tearing efficiency and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

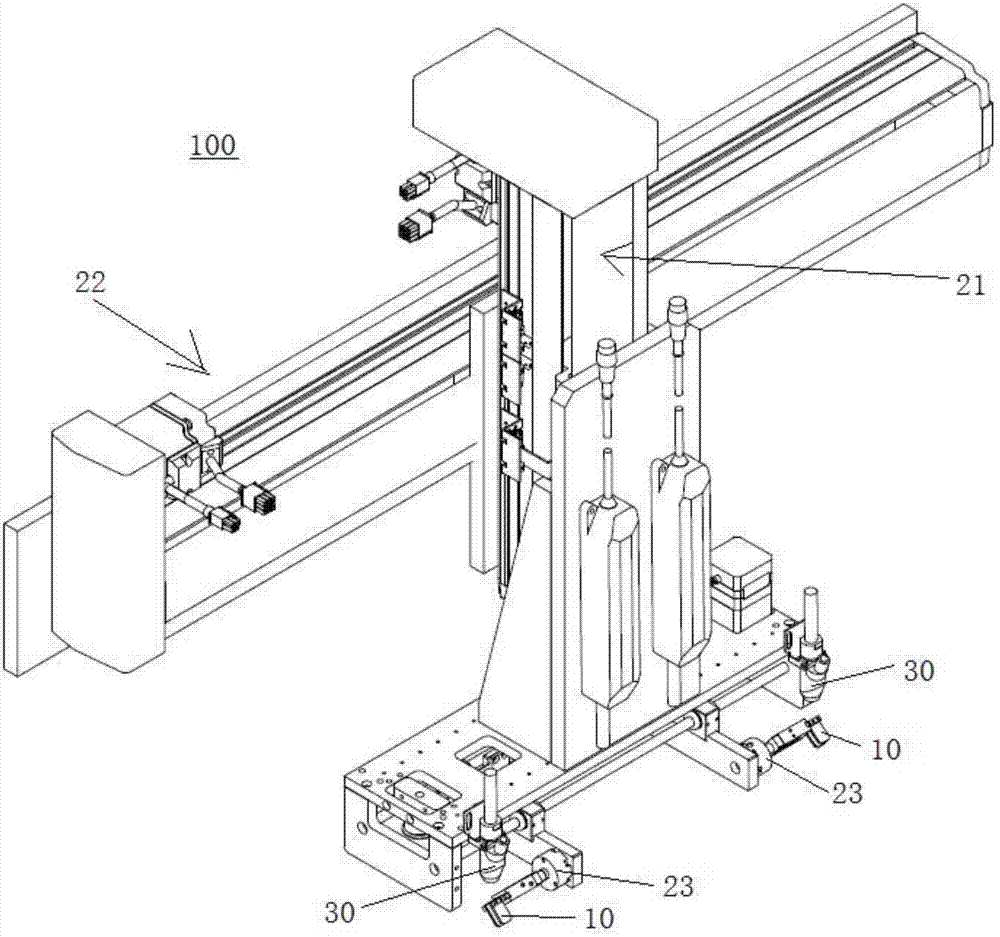

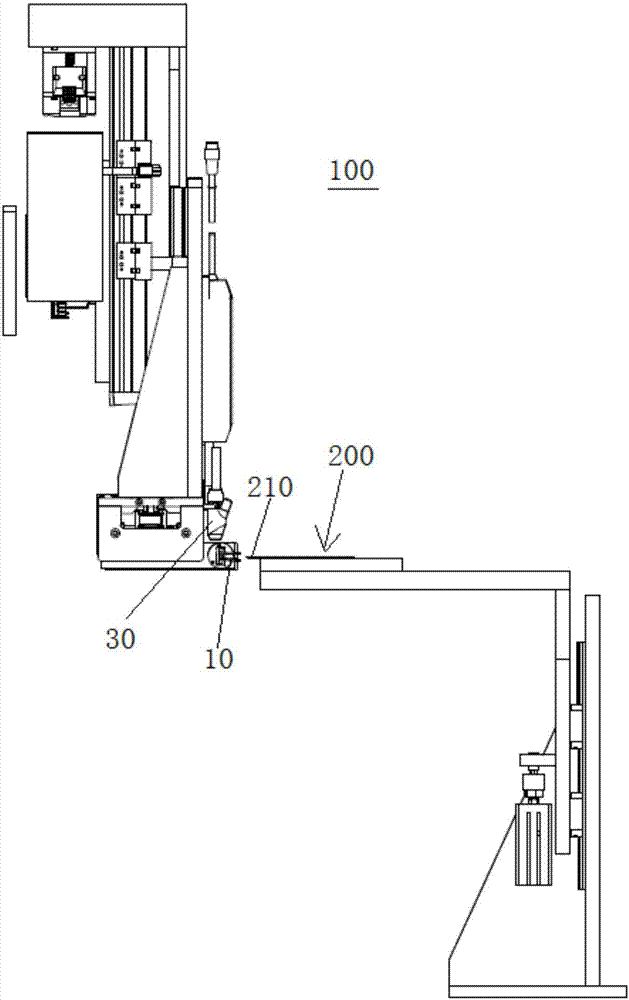

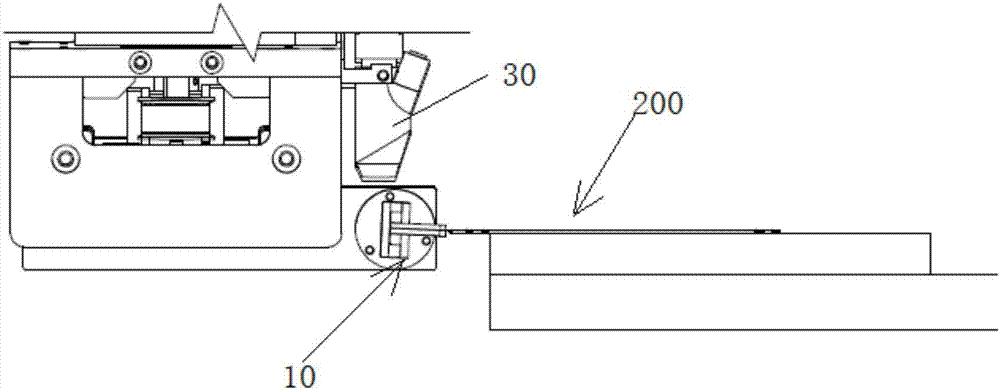

[0012] Please refer to figure 1 , figure 2 , figure 1 Is a schematic diagram of a film tearing device according to an embodiment of the present invention; figure 2 It is a side view of a film tearing device according to an embodiment of the present invention. The tearing device 100 of the present invention is used to tear off the protective film 220 with the tearing handle 210 on the product 200. The tearing device 100 includes a tearing clamp 10 and a positioning linkage unit for clamping the tearing film by using pneumatic power Handle 210; a positioning linkage unit for driving the film tearing fixture 10 to tear off the protective film 220 along an arc-shaped path. The positioning linkage unit specifically includes a Z-axis drive unit 21, a Y-axis drive unit 22, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com