Fully-automatic PET cover film peel-off machine

A cover film, fully automatic technology, applied in the direction of packaging, transportation and packaging, unsealing of objects, etc., to reduce labor costs and improve tearing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

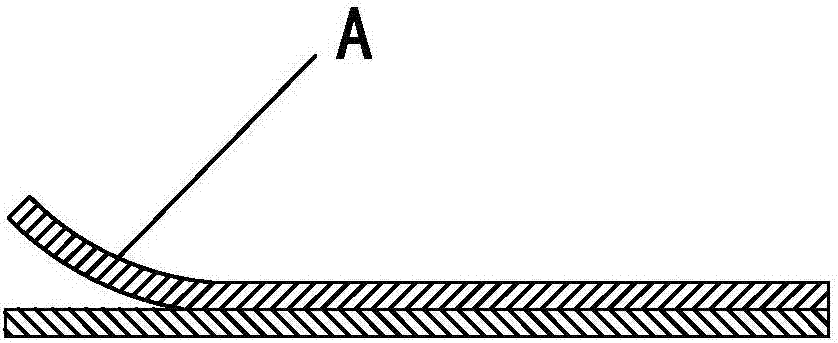

[0018] Such as figure 1 As shown, the cover film A covered on the product should be pre-teared at one corner before tearing off.

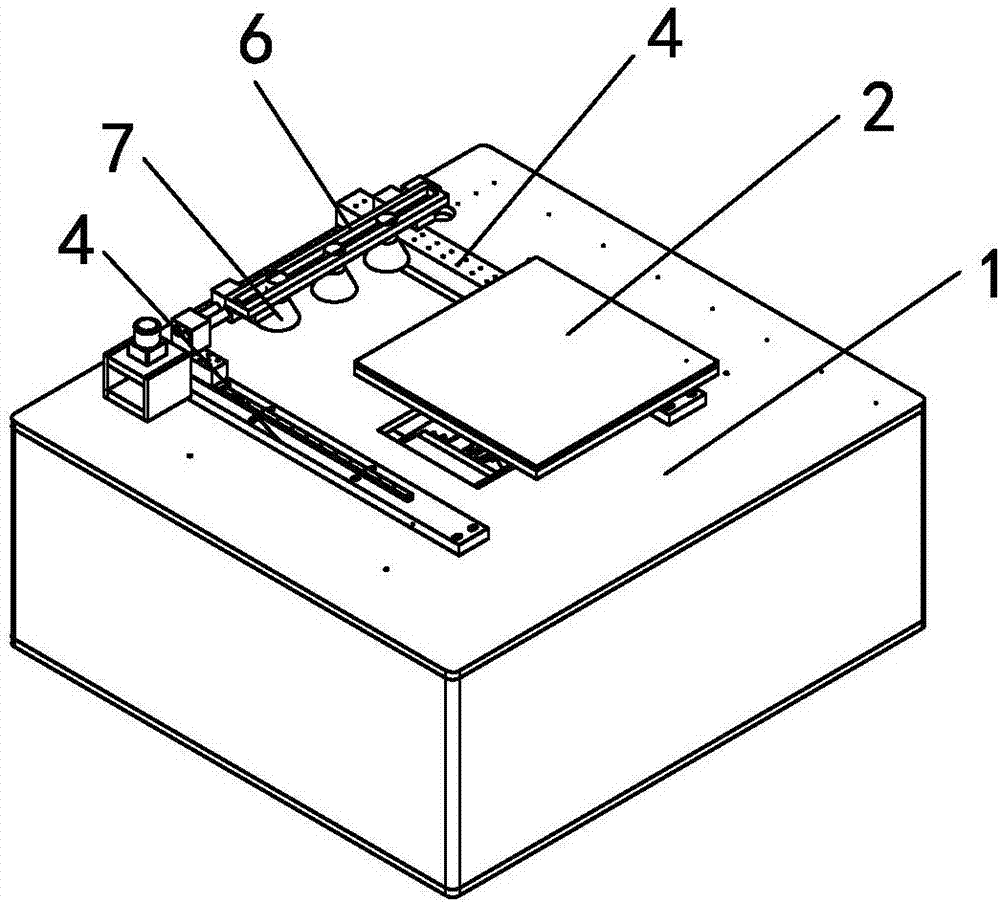

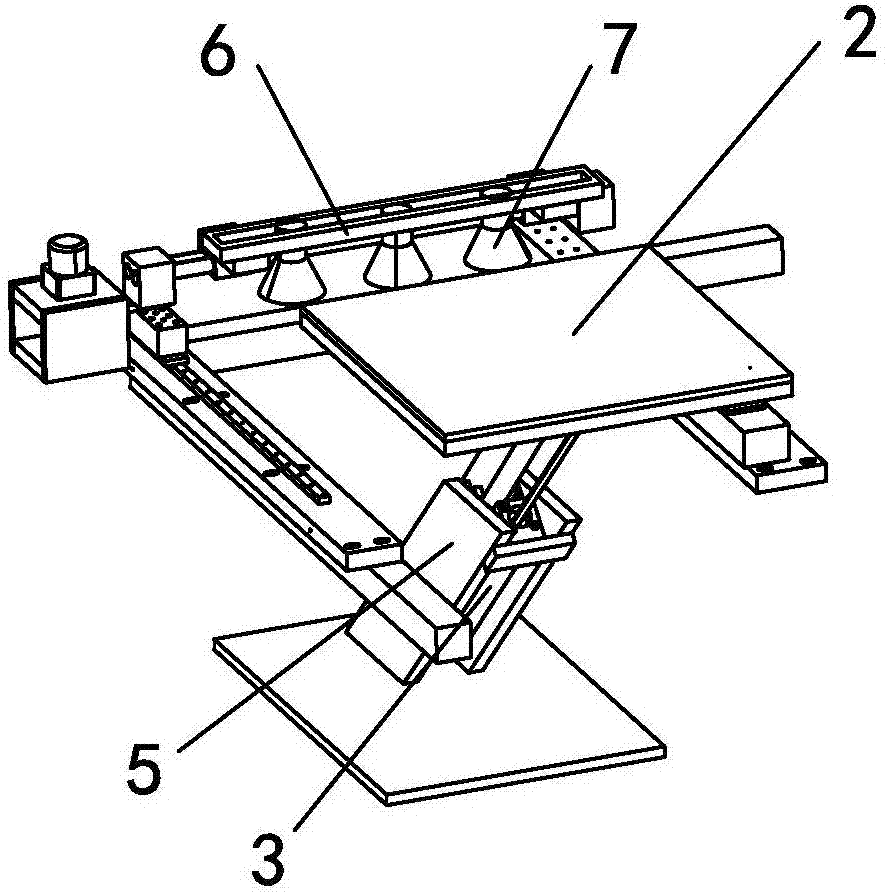

[0019] see figure 2 with 3 , a fully automatic PET cover film tearing machine, including a table top 1, a liftable platform 2 for placing products is arranged on the top of the table, an inclined cylinder 3 is placed under the table, and a cylinder is inclined The inclined slide rail 4 with the same angle, the slide block in the slide rail is connected with the bottom of the stage, and the pneumatically driven slide block moves in the slide rail, thereby controlling the lifting of the stage. A slider-type slide rail 5 is respectively arranged on both sides of the platform on the table top, and a mounting rod 6 is arranged on the sliders of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com