Film tearing equipment for sequentially tearing bottom films and top films of OLED materials

A technology of bottom film and top film, which is applied in transportation and packaging, unsealing of objects, chemical instruments and methods, etc. It can solve the problems of OLED material bending, wear and tear film success rate, etc., and achieve smooth operation, high degree of automation, The effect of improving the tearing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

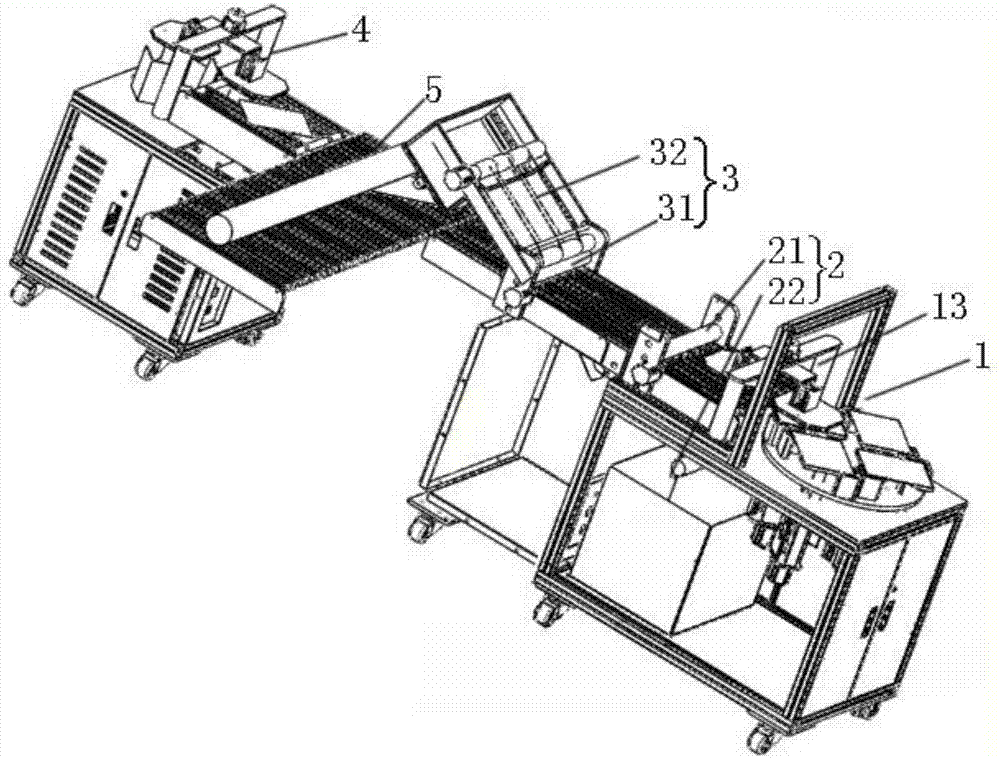

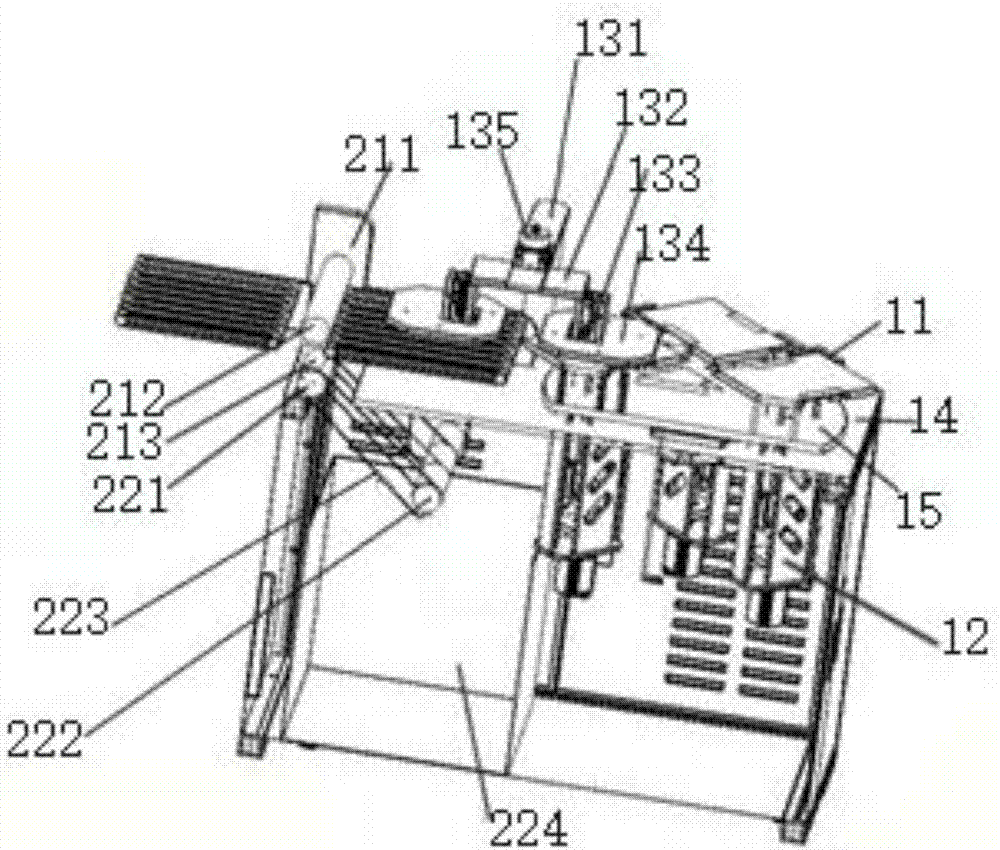

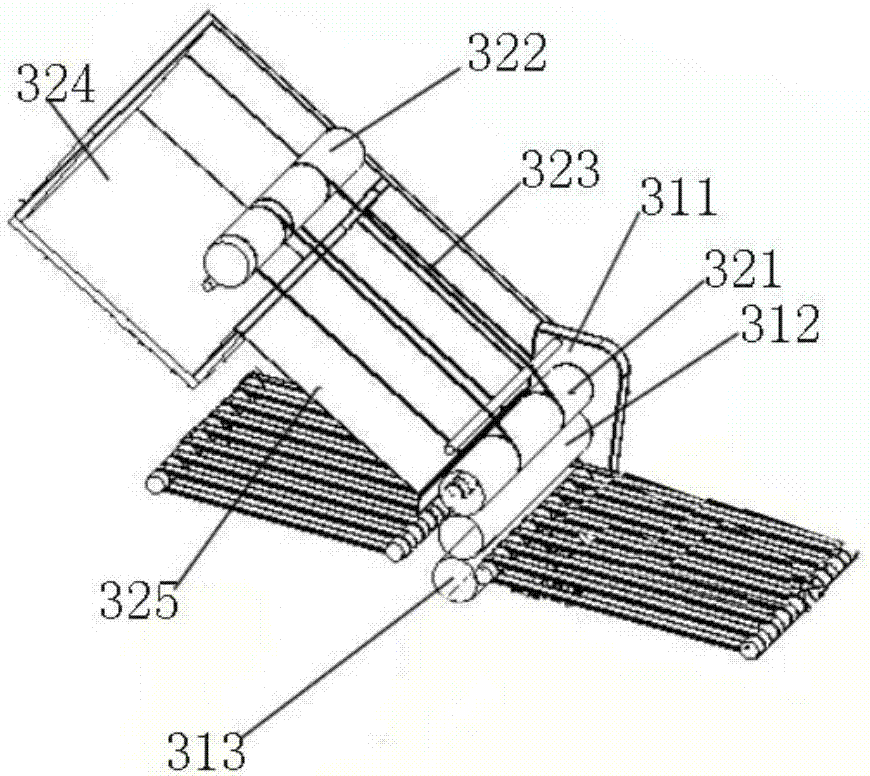

[0033] This embodiment provides a film tearing device that successively tears the bottom film and the top film of the OLED material, such as figure 1 with figure 2 As shown, it includes a feeding device 1, a front tearing device 2, a rear tearing device 3, a dust removal device 5, a receiving device 4, and the OLED material is placed on the feeding device 1, the front tearing device 2, and the rear tearing device 3 , the dust removal device 5, the horizontal transmission device (specifically a belt conveyor) for transmission between the dust removal device 5 and the receiving device 4; the feeding device 1 is used to place the OLED material without tearing the film on the horizontal transmission device, including for placing A discharge tray 11 for OLED materials, a lifting drive mechanism 12 for driving the discharge tray 11 up and down, a rotary conveying assembly 13 for the feeding section, and a workbench 14 for the feeding device;

[0034] Preferably, the discharge tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com