Separation device and separation method thereof

A separation device and separation method technology, applied in the direction of chemical instruments and methods, layered products, lamination auxiliary operations, etc., can solve the problems of reduced efficiency, increased labor costs, printed circuit boards affecting the quality of printed circuit boards, etc., to ensure Quality, the effect of avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above and other objects, features and advantages of the present invention more comprehensible, a preferred embodiment is specifically cited below, together with the accompanying drawings, and is described in detail as follows:

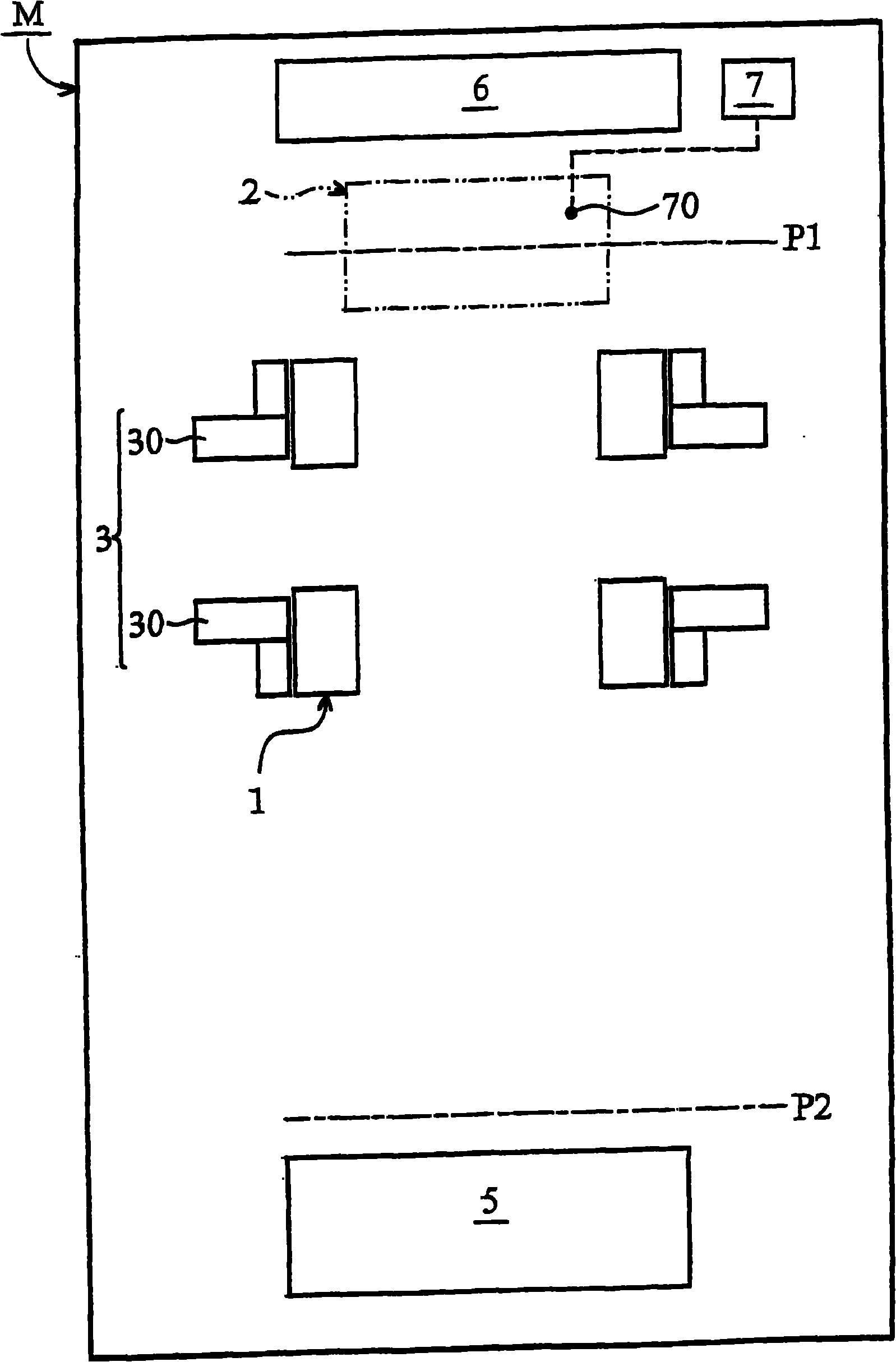

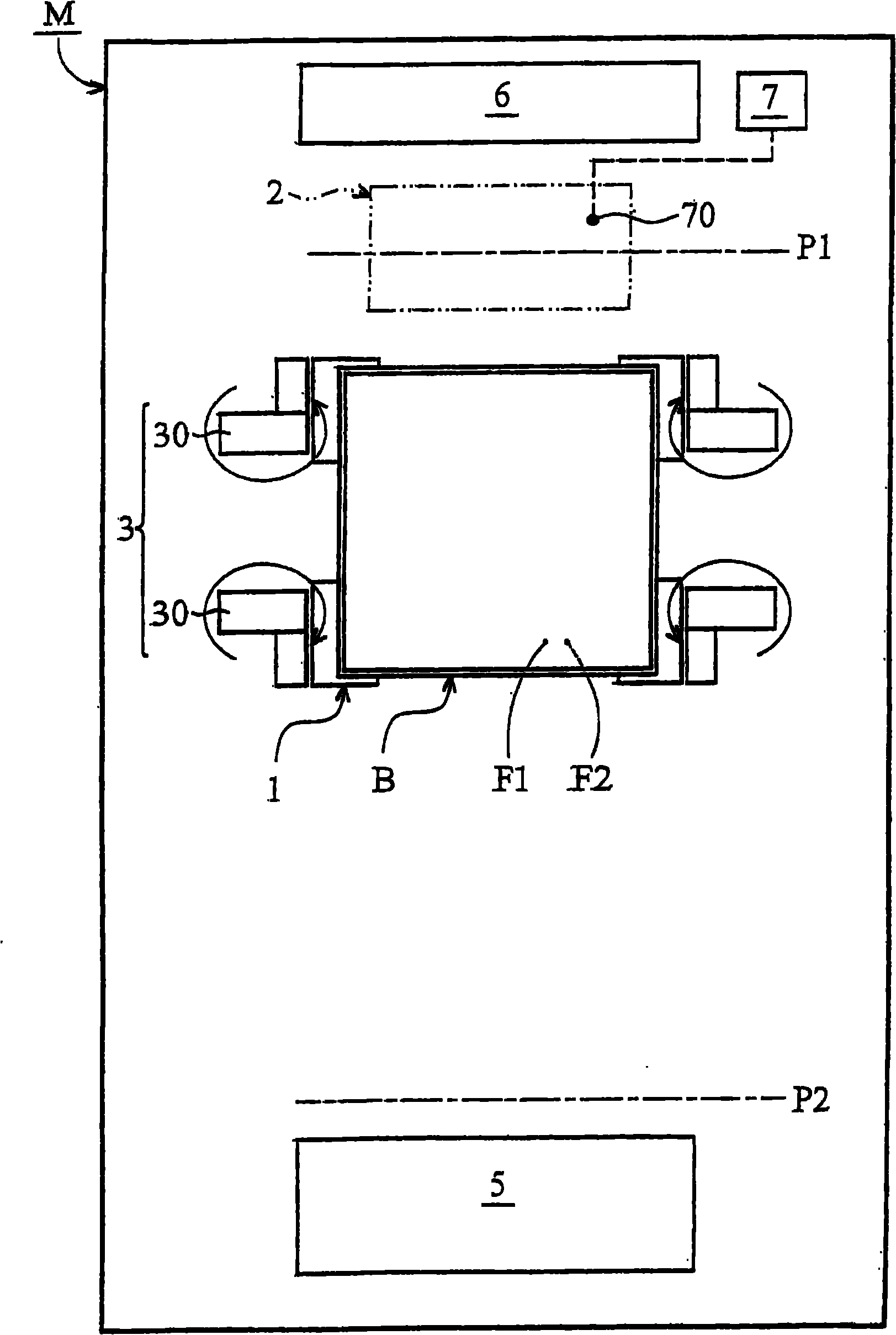

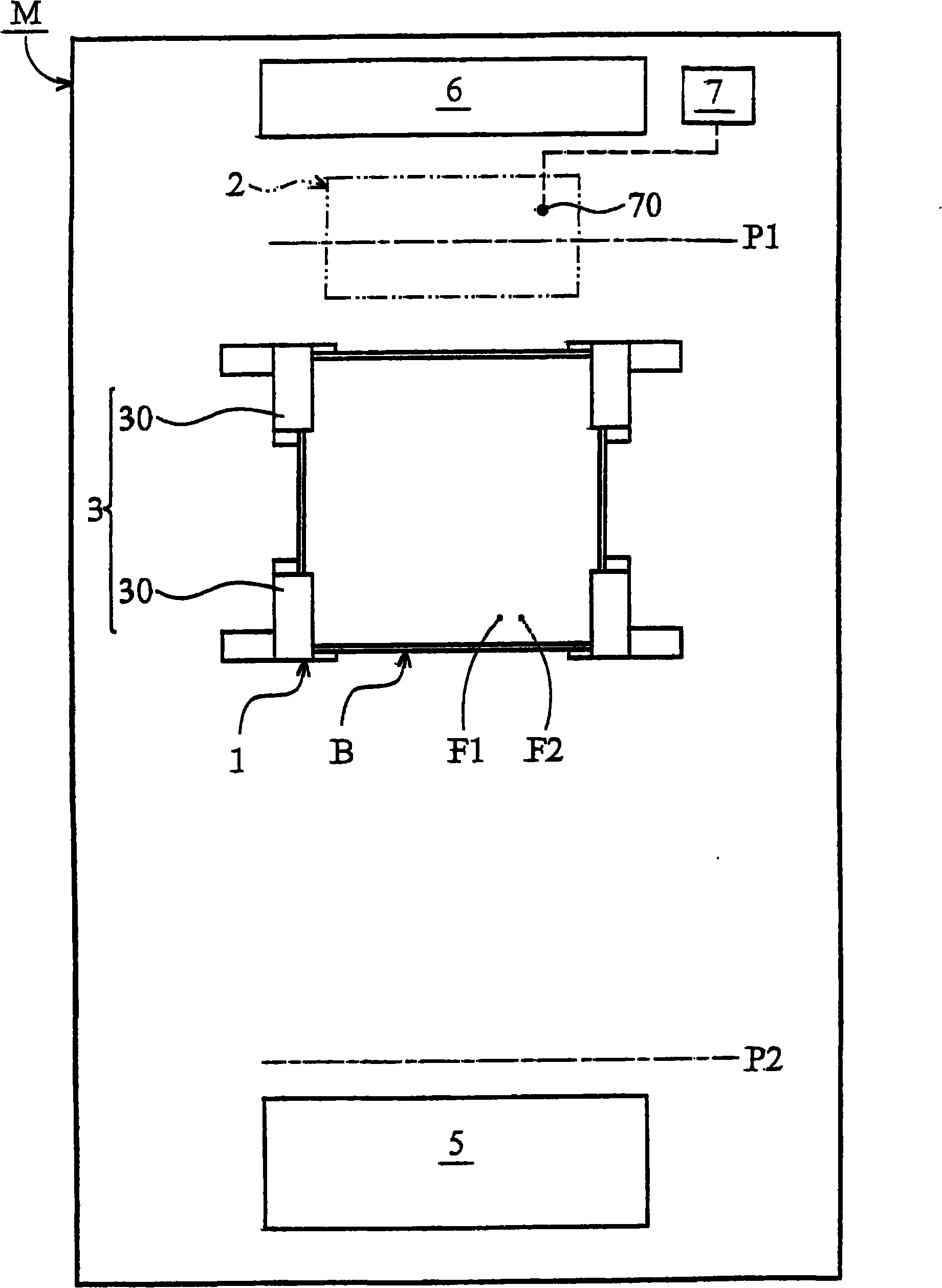

[0036] Figure 1A , Figure 1B , Figure 1C , Figure 1D , Figure 1E , Figure 1F A schematic diagram showing the operating procedure for separating a first base material B and a second base material F1, F2 connected to each other by using the separation device M of the present invention, Figure 2A , Figure 2B , Figure 2C , Figure 2D , Figure 2E , Figure 2F means corresponding to Figure 1A , Figure 1B , Figure 1C , Figure 1D , Figure 1E , Figure 1F A schematic side view of the operation procedure for separating the interconnected first substrate B and the second substrates F1 and F2 using the separation device of the present invention.

[0037] Please also see Figure 1A / 2A, Figure 1B / 2B, Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com