Automatic PCB (Printed Circuit Board) high-temperature adhesive tearing device and adhesive tearing process thereof

A technology of PCB board and high temperature glue, applied in the field of automation, can solve the problems of high labor cost, low glue tearing efficiency, and difficulty in tearing high temperature glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with accompanying drawing:

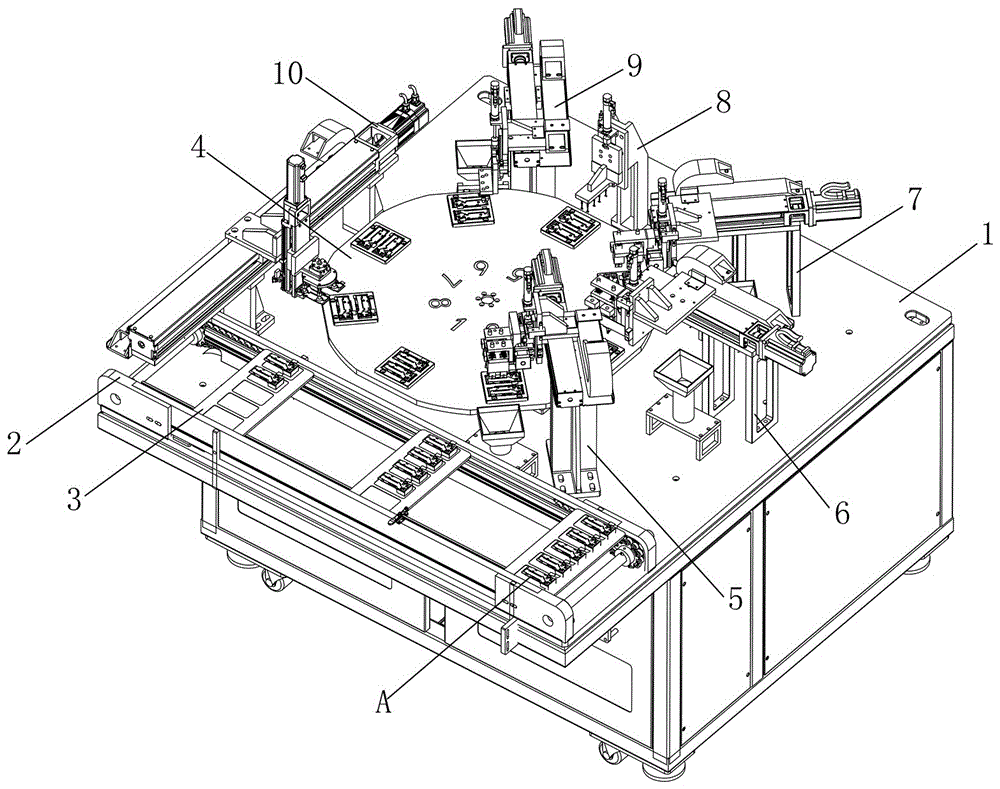

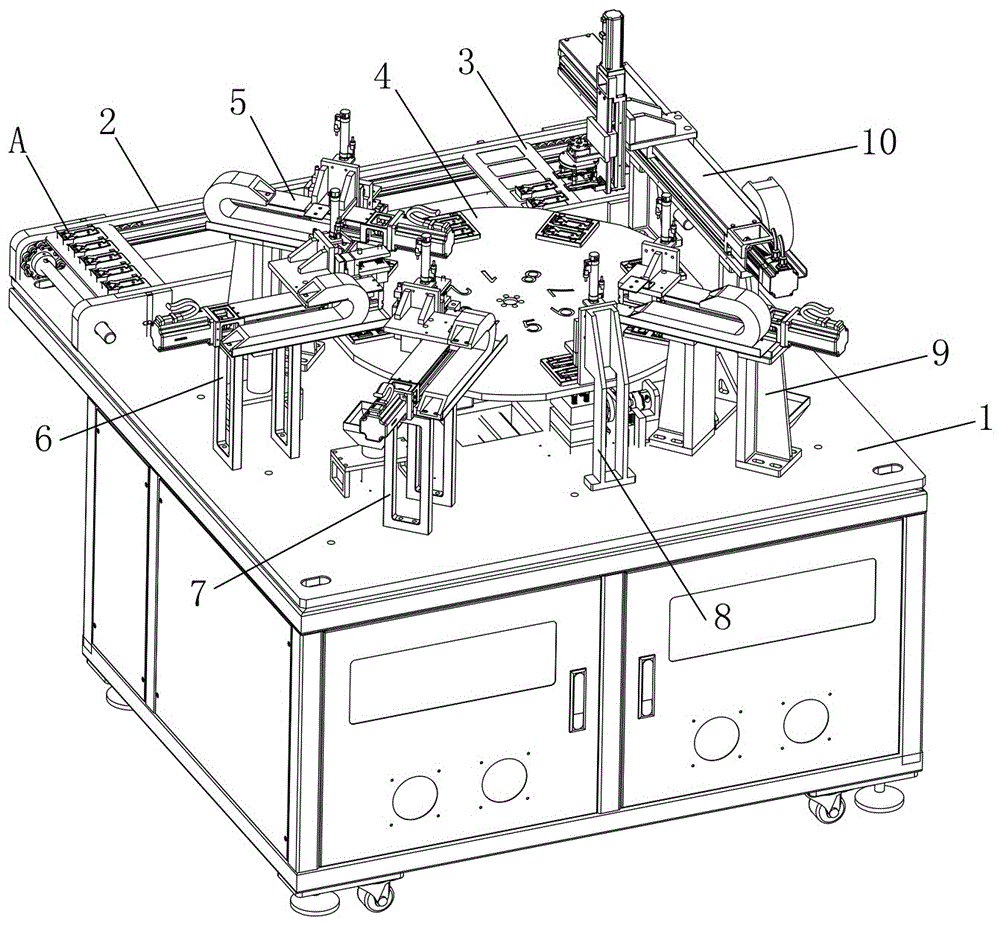

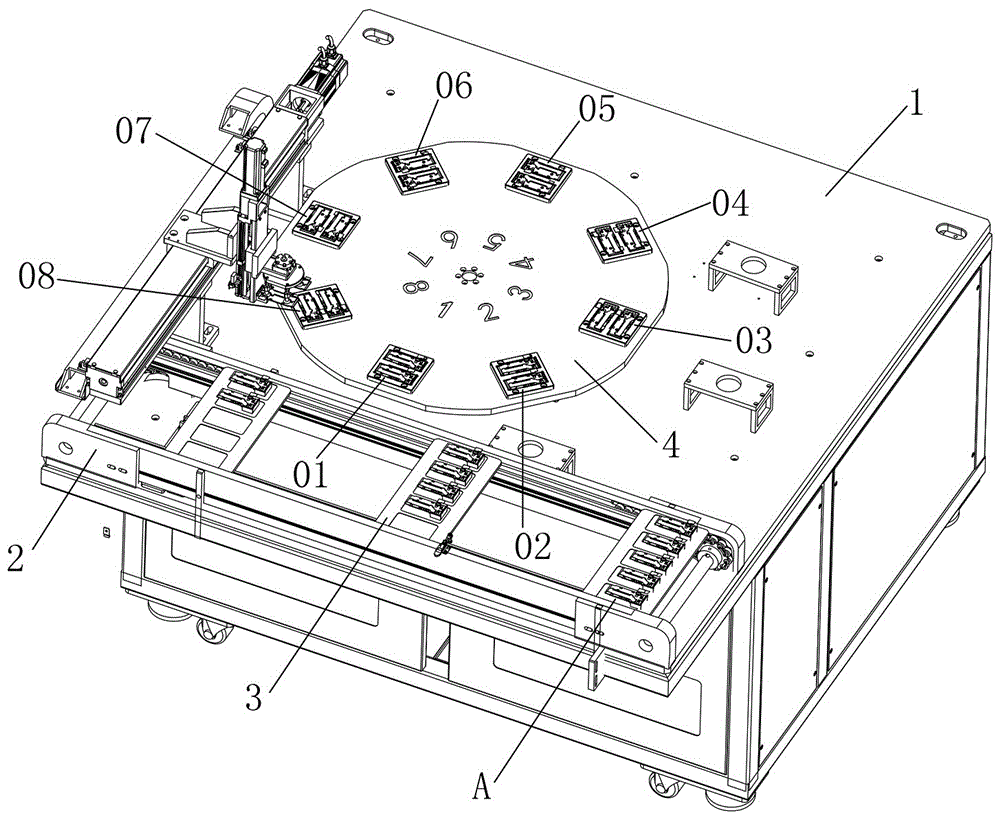

[0064] Such as Figure 1 to Figure 17 As shown, the technical scheme adopted by the present invention is as follows: a device for automatically tearing PCB board high-temperature glue, including a working platform 1 and a material belt 2, and the material belt 2 is arranged on the side of the working platform 1, so that the product A is transported in a straight line, and the working There is a turntable 4 on the platform 1, and the product A on the material belt 2 is transferred to the turntable 4, so as to tear off the high-temperature glue on the product A. It also includes a double-sheet adhesive tearing mechanism 5 and a first tearing mechanism arranged along the outer edge of the turntable 4. Single-sheet glue mechanism 6, the second single-sheet glue tearing mechanism 7, the back glue tearing mechanism 8, the disc glue tearing mechanism 9 and the loading and unloadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com