Method for making film-coated hard paper double-faced adhesive tape seal fail without damage

A double-sided tape and sealing technology, which is used in the device for opening the bag, heating and unsealing, and the unsealing of objects. Operating time, the effect of improving controllability

Active Publication Date: 2020-03-27

BEIJING HANGXING MACHINERY MFG CO LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the methods to invalidate paper glue include using special component solution to invalidate specific curing glue, ultra-low temperature to invalidate glue, and external heating steam to invalidate glue. In practical applications, paper adhesives with different components often appear, and targeted configuration Solutions of specific components means complex

Ultra-low temperature is difficult to achieve for local sealing to make the glue invalid, and ultra-low temperature is rare

Externally heated steam is difficult to control the standard parameters, and the high humidity of the steam can easily cause excessive deformation of the local seal. The operability and safety of the steam is also the weakness of this method

[0003] At present, the method of making the double-sided adhesive tape of coated hard paper invalid is to use ultra-low temperature to make the glue invalid, and the electric hot shovel shovels the seal to destroy the sealing adhesive layer. In practical applications, the electric hot shovel cannot achieve non-destructive peeling of the double-sided adhesive layer.

It is difficult to achieve ultra-low temperature to make the glue invalid for local sealing, and the ultra-low temperature method is not common

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0034] Choose a courier data envelope with a sealing size of 330mm*10mm. The material of the envelope is 200g of film-coated and waterproof whiteboard paper. The double-sided adhesive on the sealing part is all transferred to the waterproof layer side of the film, and the vibrator is vibrated on the sealing part. After the seal fails, it will open naturally. Film hard paper double-sided adhesive seal adhesive recovery.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Login to View More

Abstract

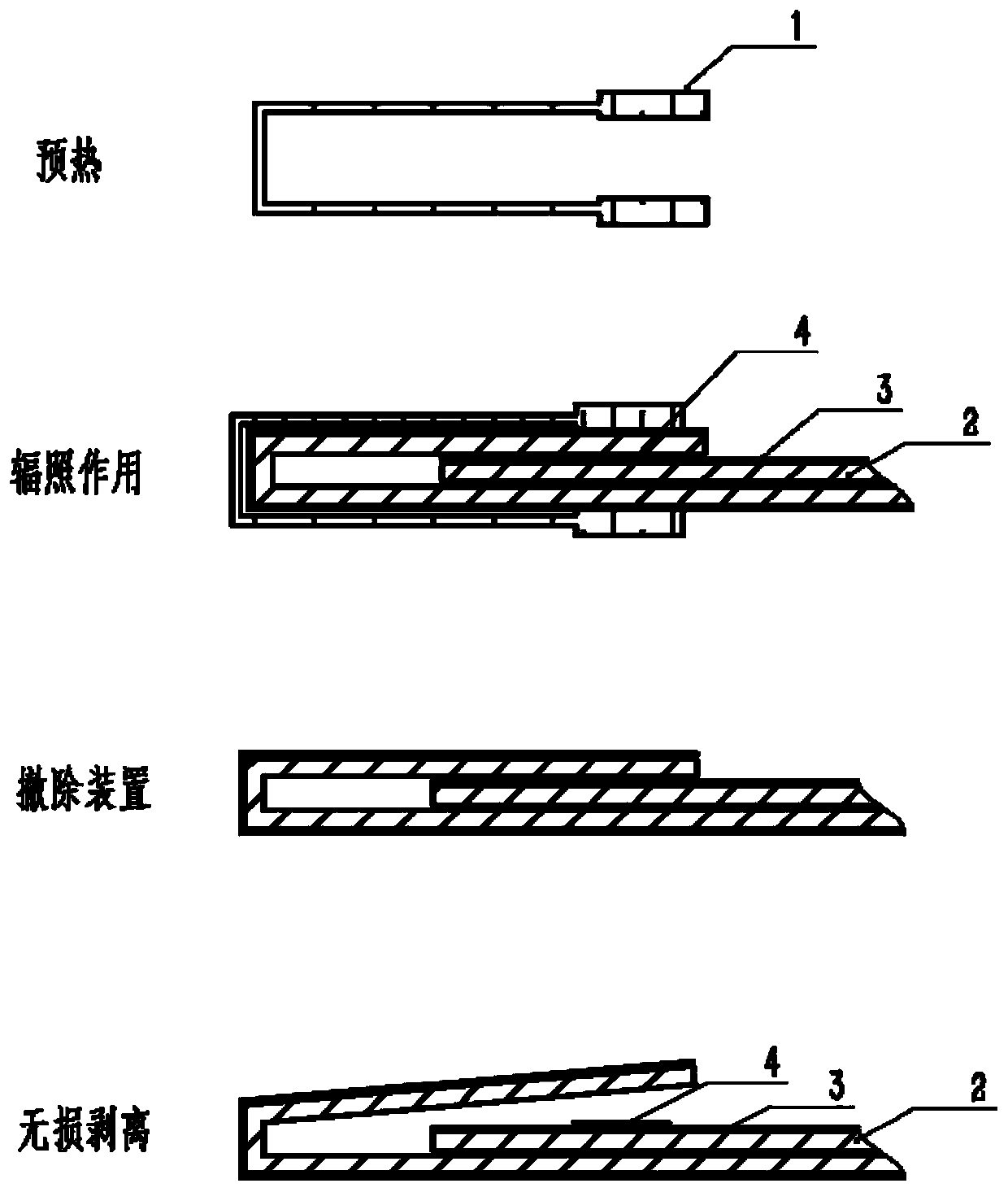

The invention discloses a method for making a film-coated hard paper double-faced adhesive tape seal fail without damage. The method comprises the steps: 1, preheating an acting area of an electromagnetic wave radiation device to 100 DEG C or above; 2, placing the seal in an electromagnetic wave radiation environment, wherein the outside of a parting action area is guaranteed not to be affected bya radiation area; 3, performing heat radiation at the position, close to the glue, of the seal, wherein the temperature of the far glue does not exceed 60% of the irradiation temperature; 4, acting for a certain period of time B under the conditions that the electromagnetic radiation wavelength is 4-18 microns, the output power is 200-900W and the clamping temperature of the radiation device is 100-150 DEG C, removing electromagnetic wave radiation, and then uncovering the seal. The method provided by the invention effectively simplifies the method for making the film-coated hard paper doublefaced adhesive tape fail, shortens the operation time, and improves the controllability of the process.

Description

technical field [0001] The invention relates to a method for invalidating a paper glue seal, in particular to a method for nondestructively invalidating a film-coated hard paper double-sided adhesive seal. Background technique [0002] At present, the methods to invalidate paper glue include using special component solution to invalidate specific curing glue, ultra-low temperature to invalidate glue, and external heating steam to invalidate glue. In practical applications, paper adhesives with different components often appear, and targeted configuration Solutions of specific components means complex. Ultra-low temperature is difficult to achieve partial sealing to make the glue invalid, and ultra-low temperature is rare. Externally heated steam is difficult to control the standard parameters, and the high humidity of the steam can easily cause excessive deformation of the local seal. The operability and safety of the steam is also the weakness of this method. [0003] At ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B43M7/00B65B69/00

CPCB43M7/004B65B69/0066

Inventor 陈炎田顺吉张海涛

Owner BEIJING HANGXING MACHINERY MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com