Penicillin bottle automatic bale breaker

A technology of vials and unpacking machines, which is applied in packaging, transportation and packaging, and unsealing of objects, etc. It can solve the problems of complex unpacking operations, high process precision requirements, and the inability to realize intelligent and simple unpacking and assembly. Achieve the effect of realizing unpacking automation and improving the efficiency of unpacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below through specific examples.

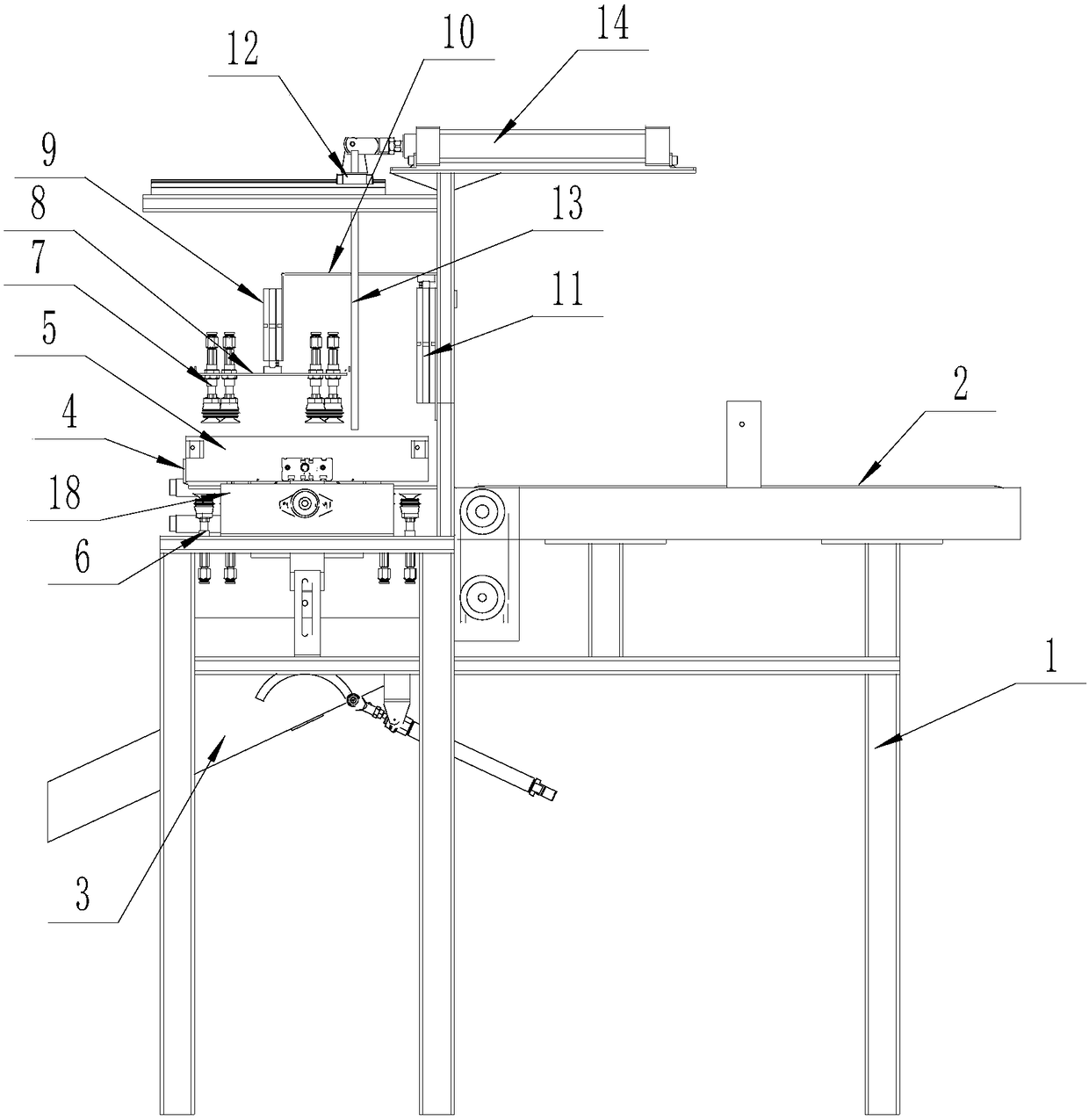

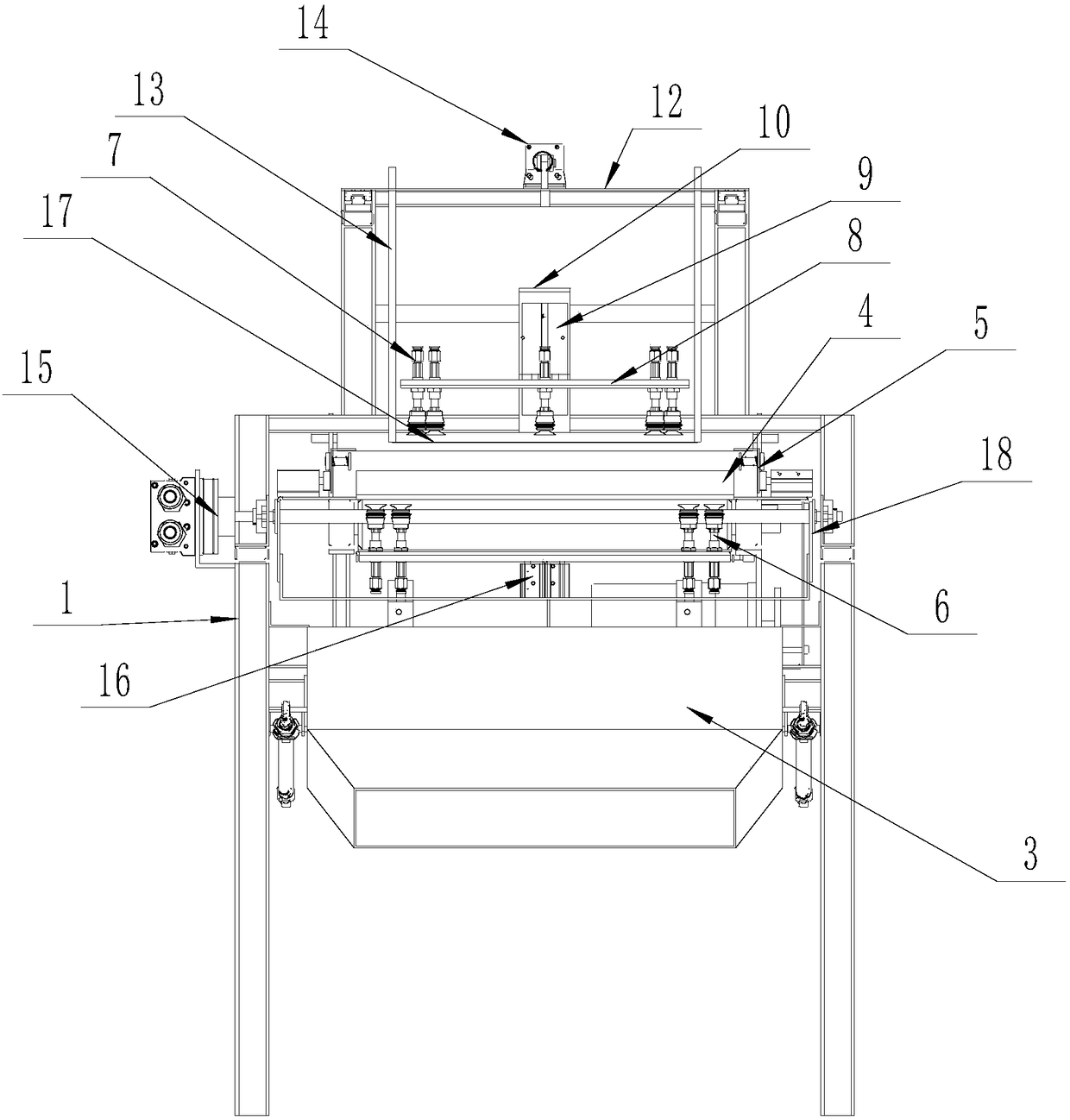

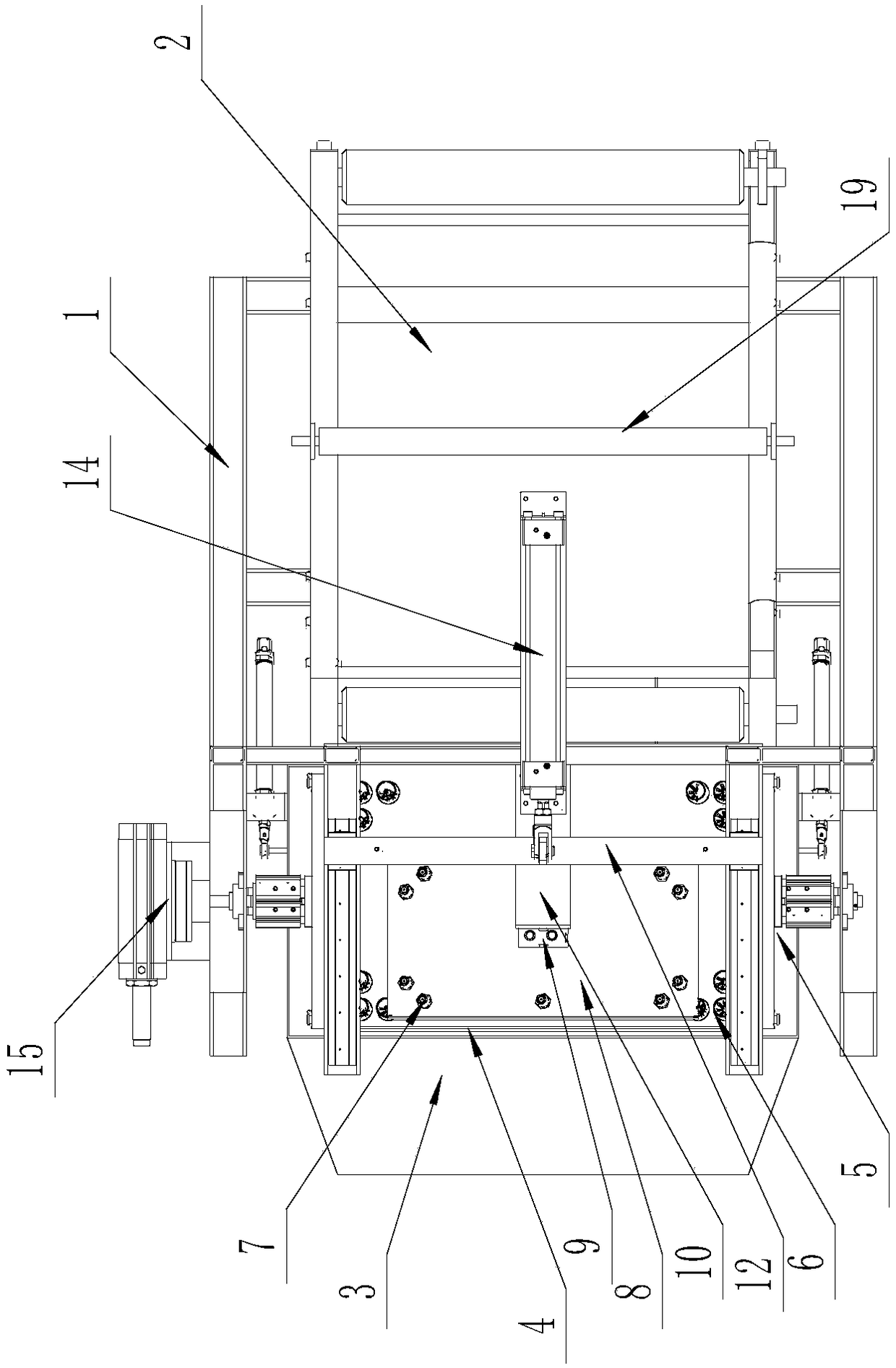

[0042] Such as Figure 1 to Figure 14 Shown, the automatic unpacking machine of a kind of vial comprises frame 1, and the conveyer belt 2 driven by conveying power device is installed on described frame 1; The roller 19 is positioned above the conveyor belt 2 and matches with the upper end of the vial group 20 .

[0043] The frame 1 is used for installing and supporting other components, and the frame 1 is made by welding profiled bars.

[0044] Turning material turning frame 18 is rotated on described frame 1, and described material turning frame 18 is driven to turn over by material turning power device, and this material turning frame 18 is installed on the frame 1 by rotating shaft rotation, and described material turning power device adopts The rotary cylinder 15 realizes that the turning pallet 4 for placing the vial group 20 is fixed on the turning rack 18, the turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com