Unpacking device for penicillin bottle sets

A technology of a vial set and packaging device, which is applied in the field of unpacking devices for a vial set, which can solve the problems of high labor intensity, difficult unpacking assembly, intelligent and simple assembly, and complicated operation, and achieve a reasonable auxiliary clamping state, Realize the effect of unpacking automation and avoid hard collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below through specific examples.

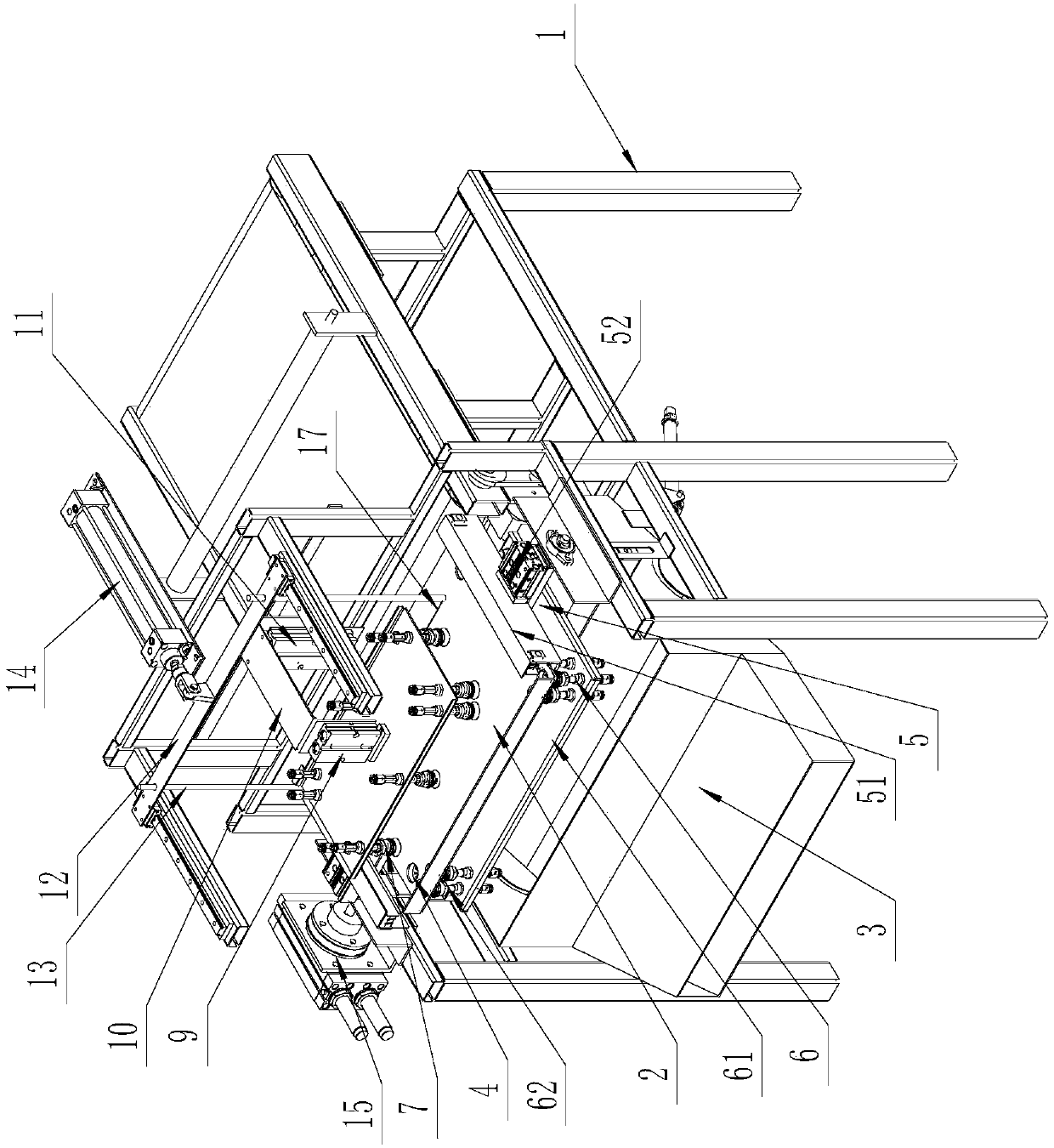

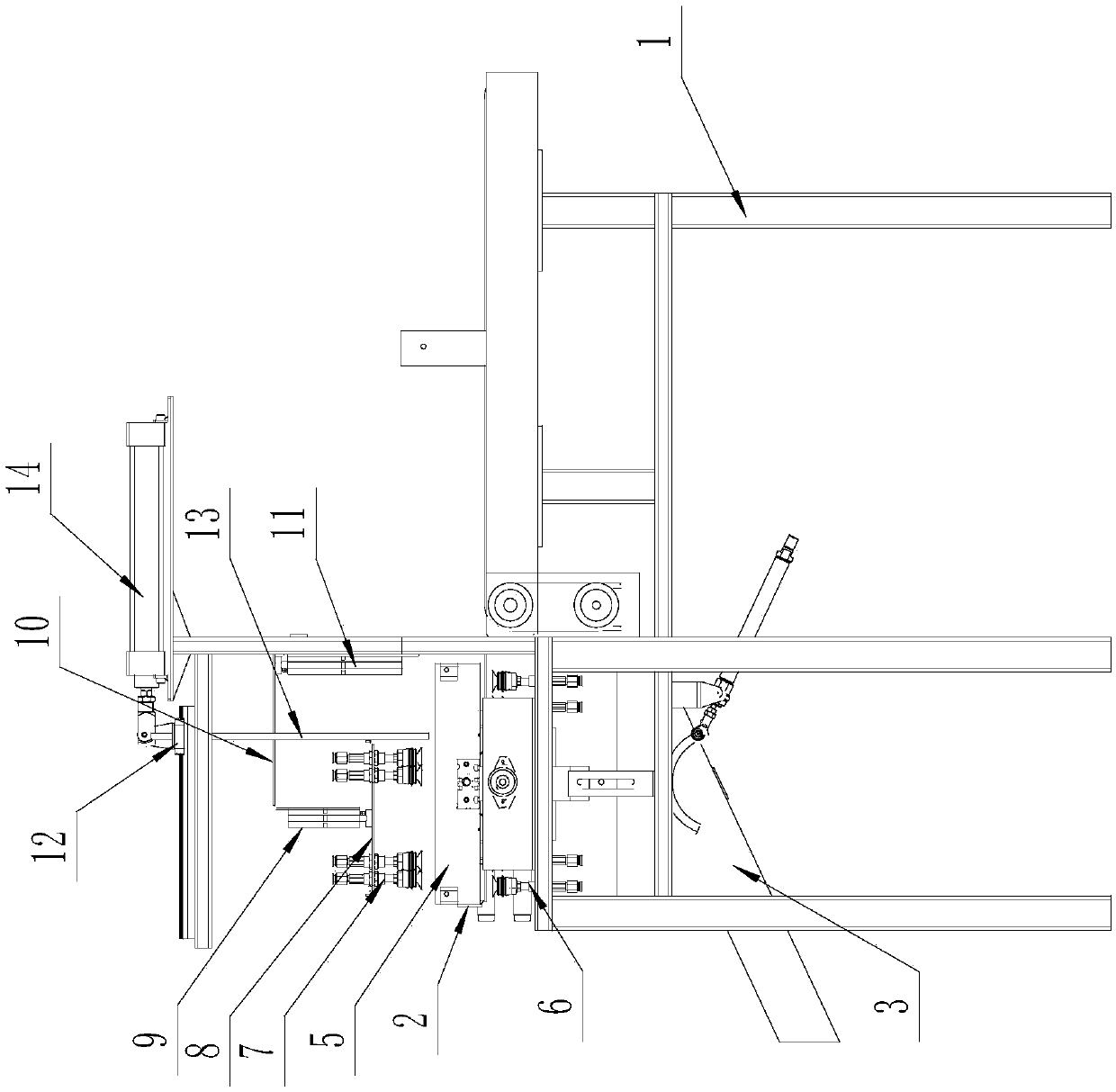

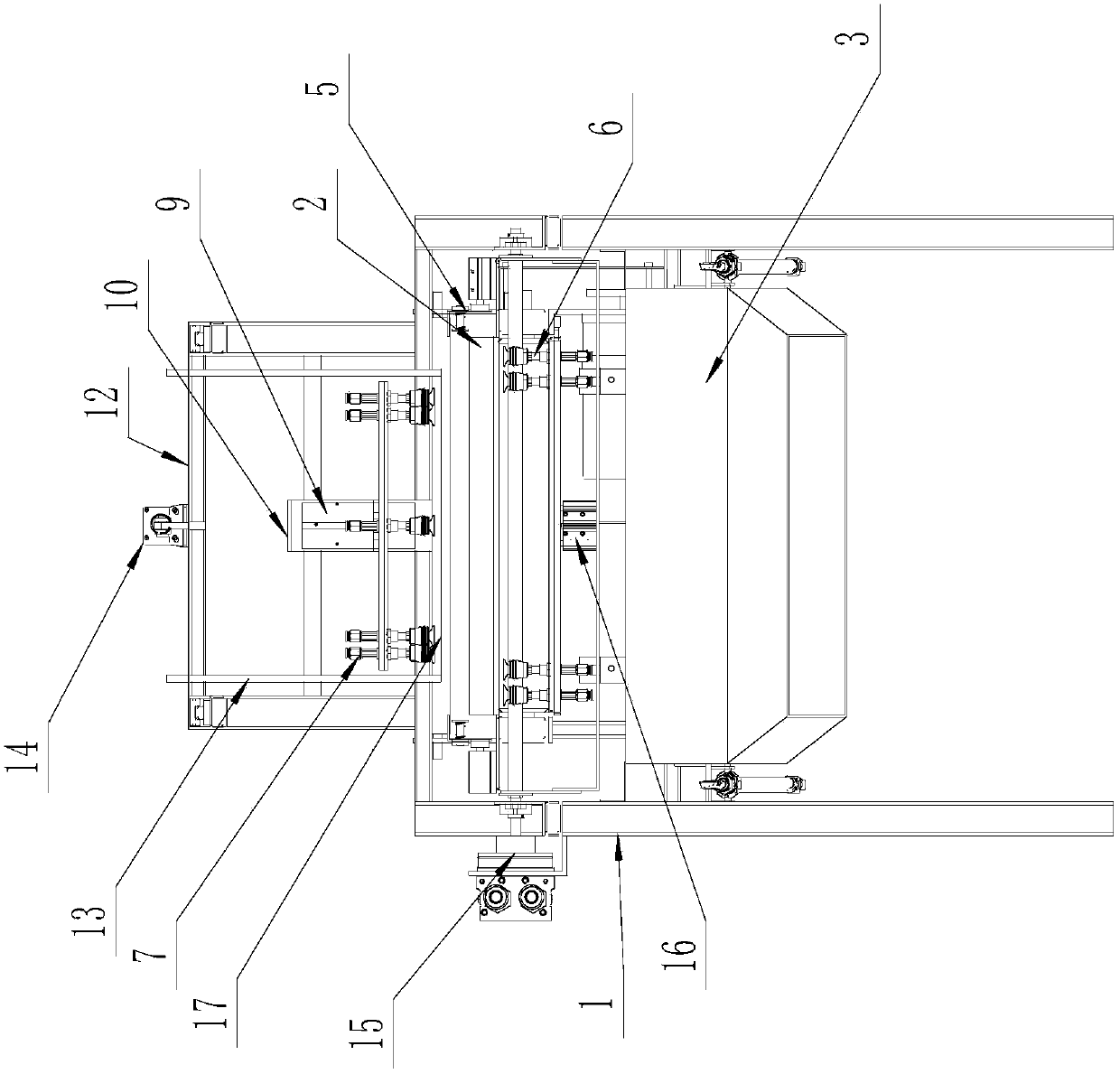

[0035] Such as Figures 1 to 11 As shown, an unpacking device of a vial set 8 includes a frame 1, an unpacking platform 2 is installed on the frame 1, and a placement area for placing the vial set 8 is provided on the unpacking platform 2 , the lower suction cup assembly 6 is vertically slidably installed on the frame 1, the lower suction cup assembly 6 is located below the unpacking platform 2 and is driven up and down by the lower lifting power device, and the unpacking platform 2 is provided with a convenient lower The avoidance through hole 4 exposed by the suction cup assembly 6; the upper lift frame 10 is vertically slidably installed above the unpacking platform 2 on the frame 1, and the upper lift frame 10 is driven and lowered by the upper lift power device. On the upper lifting frame 10, the upper suction cup assembly 7 is vertically slidably installed, and the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com