Ton bag unpacking device

A large-ton bag and heater technology is applied in the field of unpacking devices, which can solve the problems of high consumption of cutting tools, occupational hazards of personnel, and low production efficiency, so as to avoid dust pollution, material leakage, and unloading. The effect of smooth feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

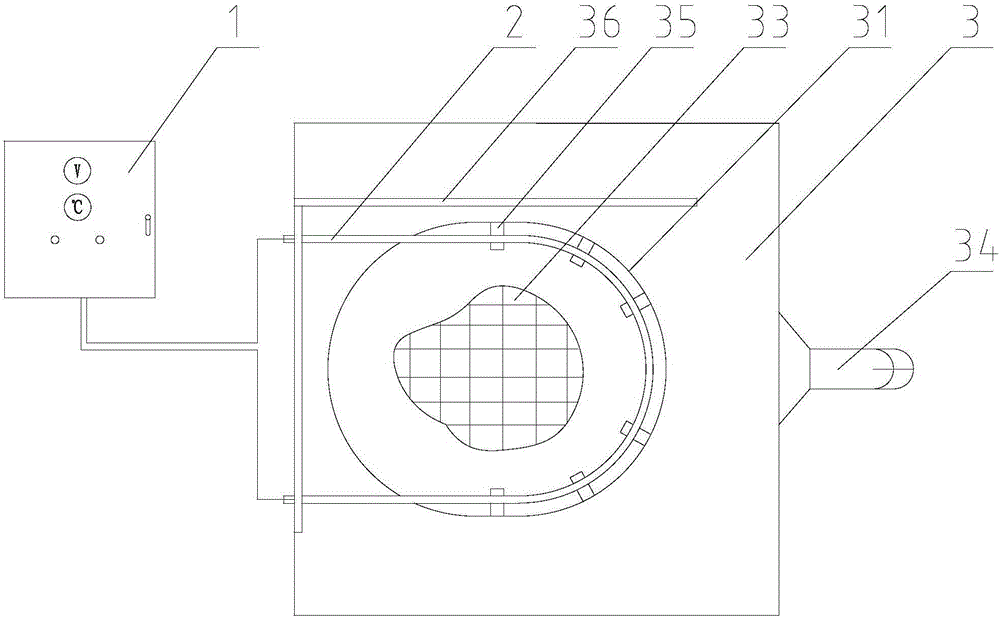

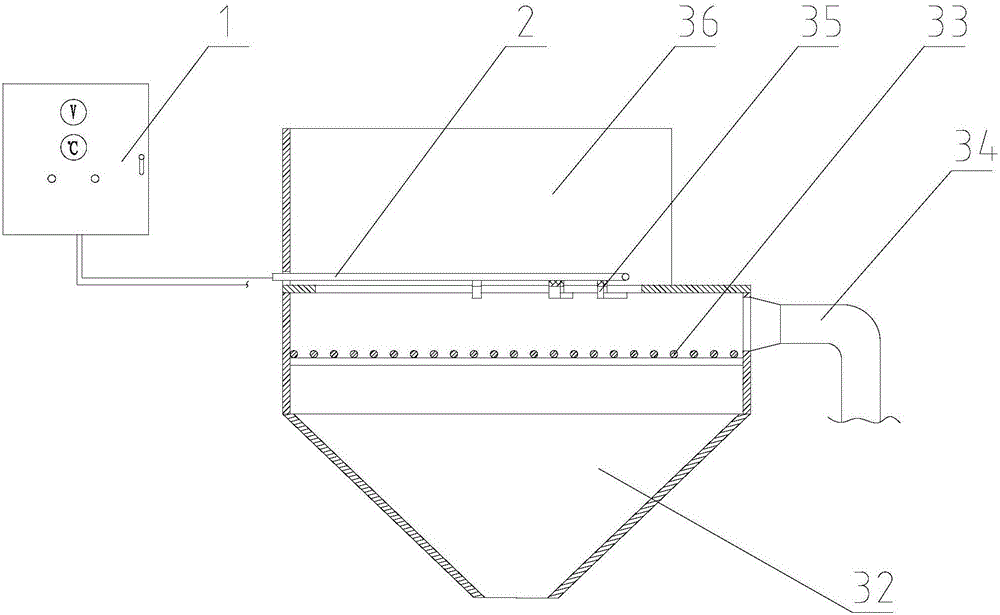

[0028] like figure 1 , figure 2 As shown, the present invention includes an electrical control box 1, a heater 2 and a blanking platform 3; the electrical control box 1 is electrically connected to the heater 2, and the heater 2 heats up under the heating of the electrical control box 1 to melt the big bag; The blanking platform 3 is provided with a blanking port 31, which is arranged in parallel directly below the heater 2. The area of the blanking port 31 should be larger than that of the heater 2, so that the gap area melted out of the big bag can be smaller than the blanking port The area of 31 makes the materials all enter the discharge port 31, which will not cause bulk material and dust leakage; the bottom of the discharge platform 3 is connected to the discharge funnel 32. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com