Automobile instrument curved glass cover plate film tearing equipment

A technology for automotive instrumentation and curved glass, applied in chemical instruments and methods, lamination auxiliary operations, packaging, etc., can solve problems such as removal of protective film, and achieve the effect of reducing installation difficulty, convenient disassembly and assembly, and adjustable film tearing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

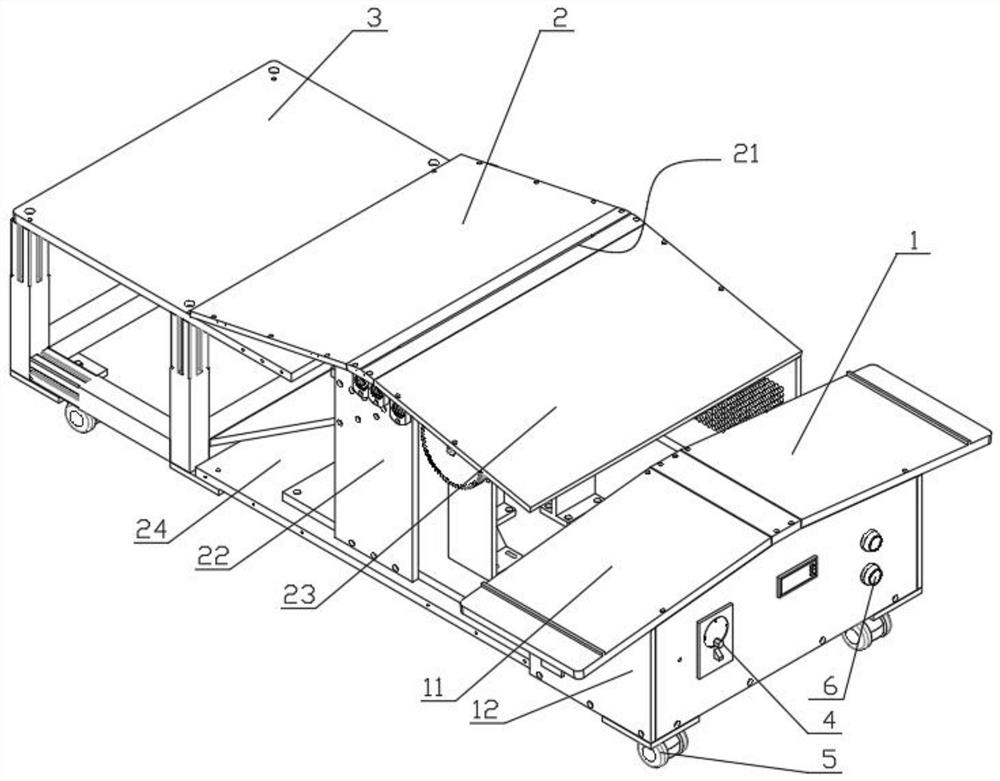

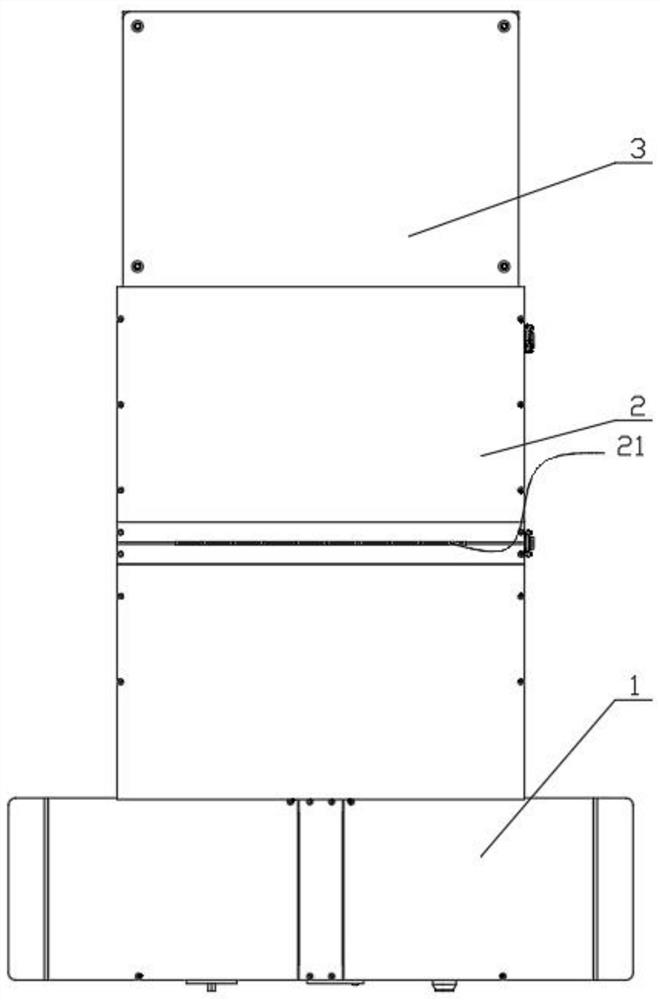

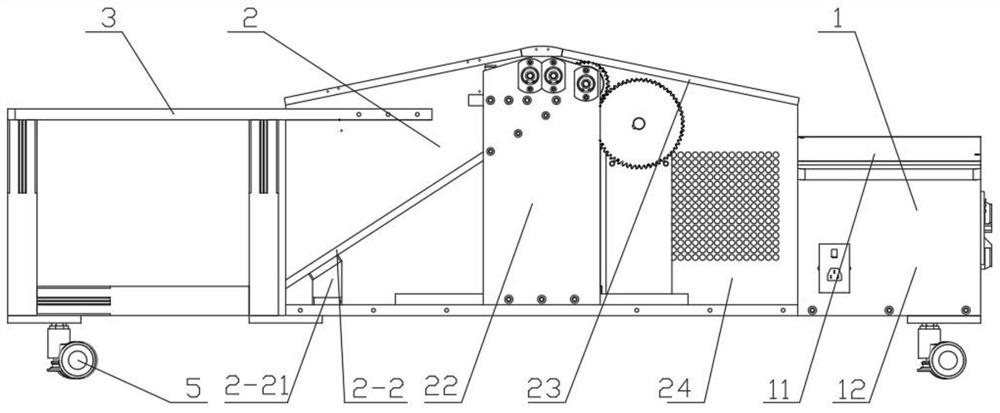

[0058] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, a kind of equipment for tearing film on the curved surface glass cover plate of automobile instrument in this embodiment, including preheating device 1, tearing film device 2 and collecting device 3, the two sides of tearing film device 2 are respectively fixedly installed with preheating device 1 and collecting device 3, the film tearing device 2 has a film inlet 21 on the top of the device, and the film tearing device 2 has a mold tearing device 22 inside, and the preheating device 1 preheats the glass cover of the car instrument panel with the tearing film , the protective film is softened, and the tearing film device 2 tears off the heated and softened explosion-proof film, and the explosion-proof film enters the inside of the tearing film device 2 from the film inlet 21, and the torn off explosion-proof film falls into the collection device 3 inside.

specific Embodiment approach 2

[0059] Specific implementation mode two: combination Figure 1-Figure 6 Describe this embodiment, based on the specific embodiment one, a kind of film tearing equipment for the curved glass cover plate of automobile instrument in this embodiment, the preheating device 1 includes a preheating plate 11 and a first mounting frame 12, and the preheating plate 11 is installed On the top of the first installation frame 12, the preheating plate 11 has a radian, and its radian can be designed according to the curved glass cover plate of the automobile instrument to be removed;

[0060] Two baffle plates 23 are installed on the top of the second installation frame 24, and a film inlet 21 is arranged between the two baffle plates 23, and the angle between the two baffle plates 23 is the same as that of the curved glass cover plate of the automobile instrument. Compatible with surface angles.

specific Embodiment approach 3

[0061] Specific implementation mode three: combination Figure 1-Figure 6 Describe this embodiment, based on the specific embodiment one, a kind of film tearing equipment for the curved glass cover plate of automobile instrument in this embodiment, the preheating plate 11 is electrically connected with the thermostat 4, and the thermostat 4 can control and adjust the preheating. The temperature of the heating plate 11 meets the heating requirements of protective films with different thicknesses. There are two protrusions on both sides of the upper end surface of the preheating plate 11 to prevent the curved glass cover plate of the automobile instrument from slipping during preheating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com