Penicillin bottle turnover standing method and unpacking bottle straightening method

A technology for vials and upright bottles, which is applied in the field of flipping upright bottles and unpacking and unpacking of vials, which can solve problems such as unreasonable structure, low efficiency of unscrambling bottles, and high labor intensity of workers, so as to improve efficiency and reduce production costs , the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

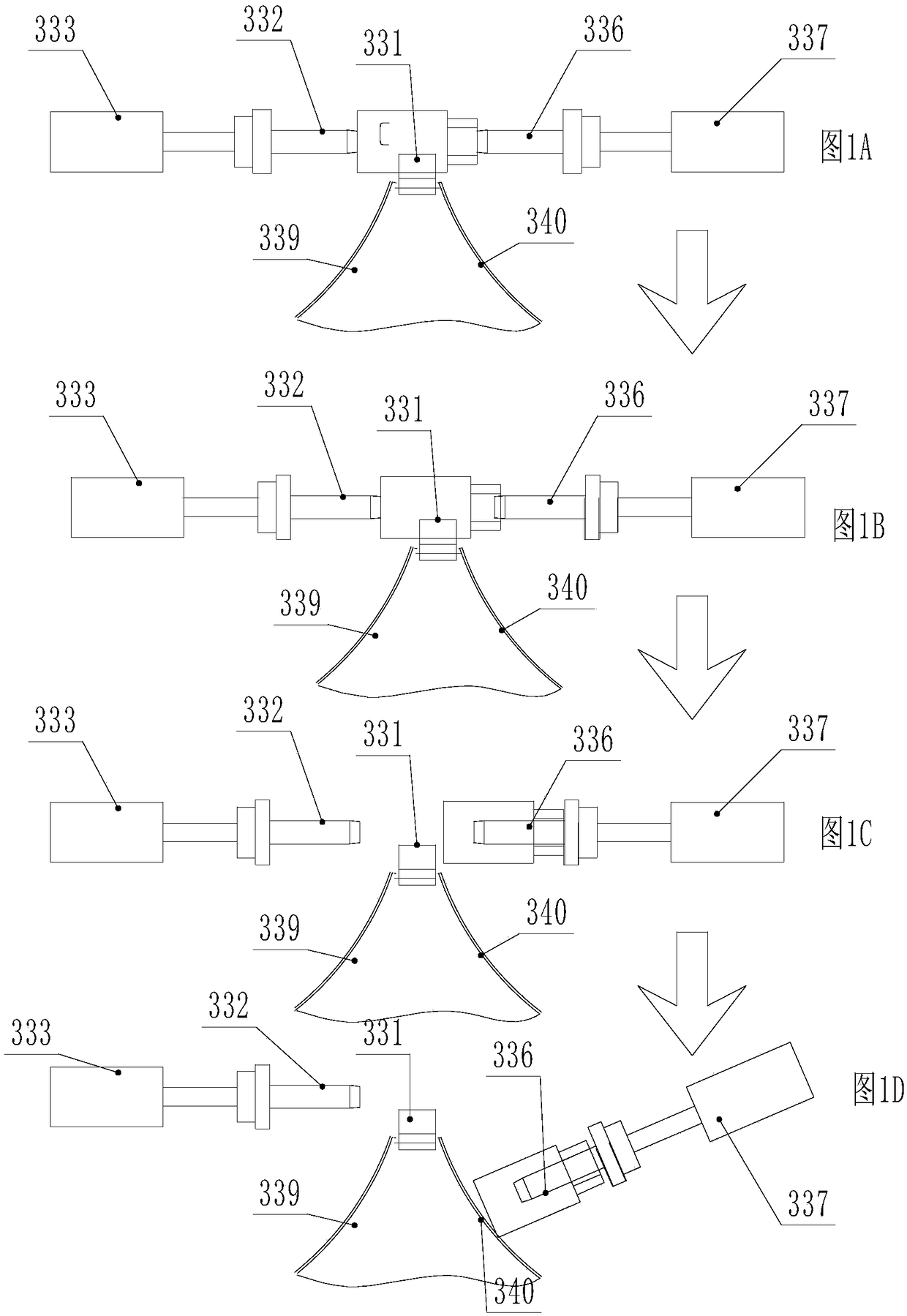

[0046] Such as figure 1 Shown, a kind of vial bottle upside-down vertical bottle method comprises the following steps:

[0047] A1. Provide a bottle support rack with a bottle support slot, and the bottle body of the vial is placed in the bottle support slot horizontally, such as figure 1 As shown in A.

[0048] A2. The left pin and the right pin that can move horizontally and vertically flip 90° are set on both sides of the bottle holder. The left pin and the right pin are respectively facing the bottle mouth and bottle Bottom horizontal movement; such as figure 1 Shown in B.

[0049] A3. When any one of the left pin and the right pin comes into contact with the bottom of the vial, the left pin and the right pin will continue to move horizontally for a distance from the top of the bottle, and then stop moving horizontally. The needle pushes the vial to move horizontally during the distance of pushing the bottle so that the mouth of the vial fits on the right or left pin, ...

Embodiment 2

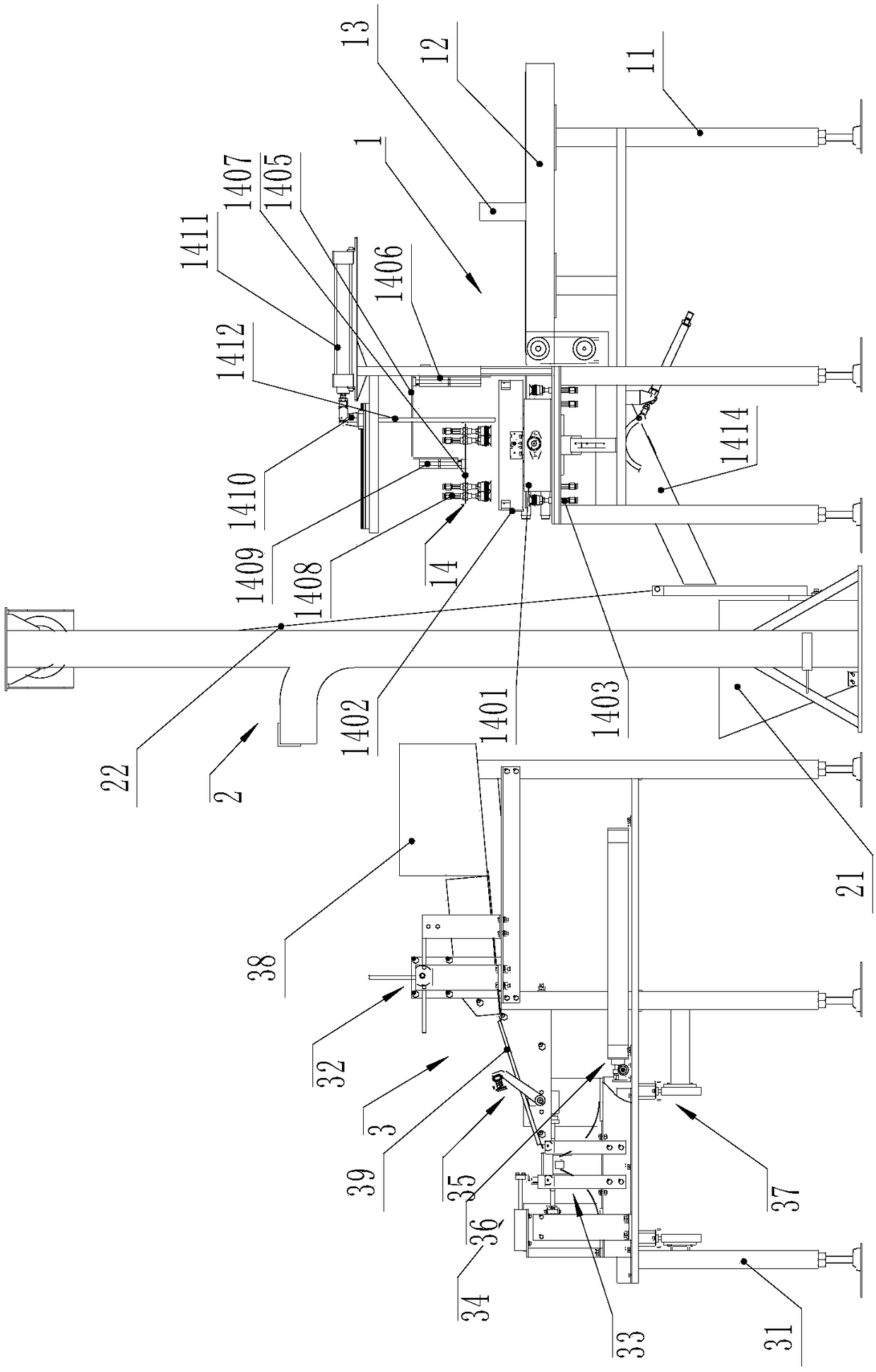

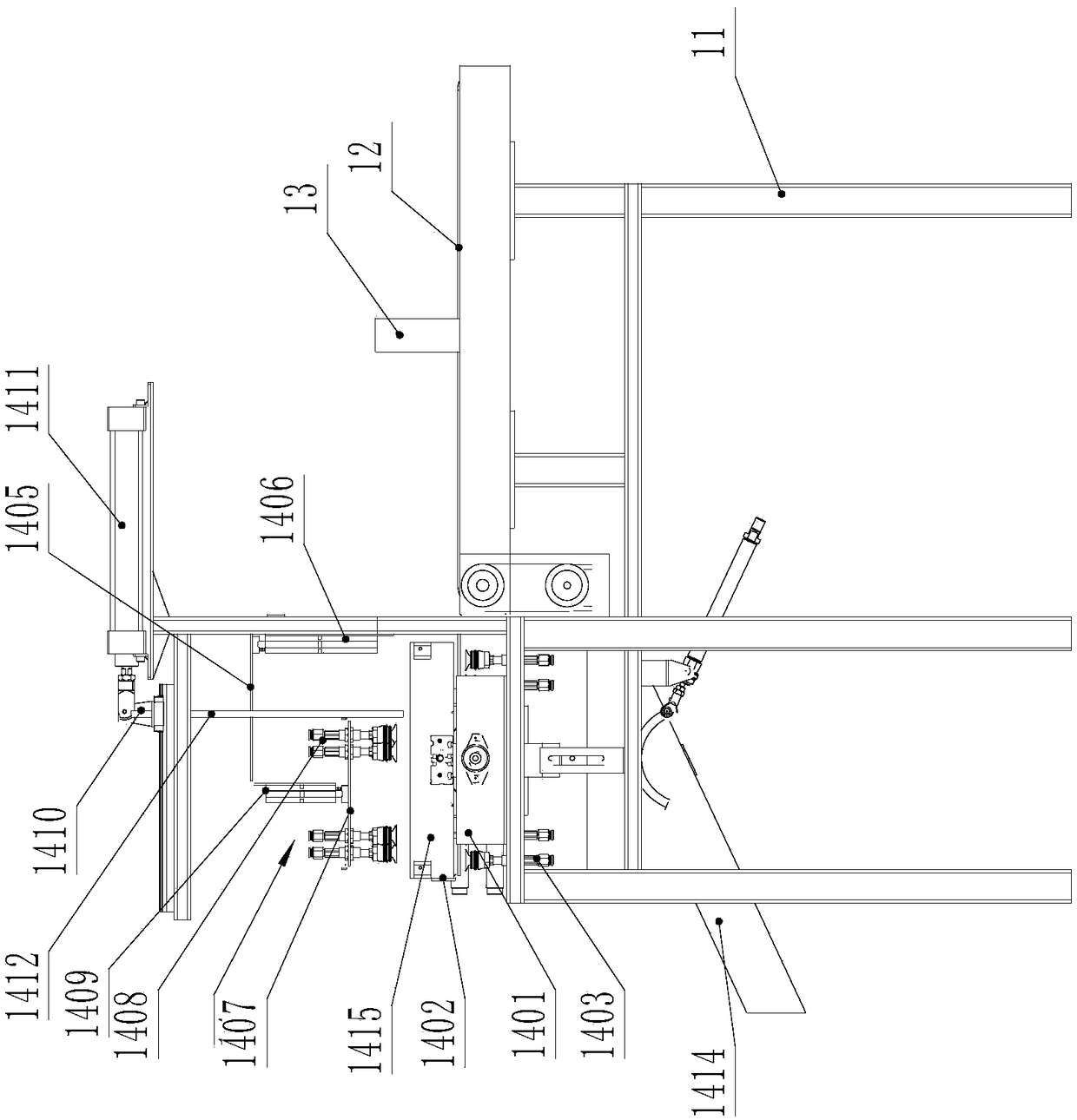

[0053] A method for unpacking and sorting vials, comprising the following steps:

[0054] B1. Unpack the vial set and pour it into the receiving hopper;

[0055] B2. The vials in the receiving hopper enter the carding conveying trough and then lie flat and arrange in a single row for transportation;

[0056] B3. Use the transition conveying trough to transport the carded vials to the bottle holder; the transition conveying trough and the combing and conveying trough are placed obliquely and transported by the weight of the vials;

[0057] B4. Utilize the flipping upright bottle method in claim 1 to arrange the vials to make the vials stand;

[0058] B5, the standing cillin bottle vertically falls into the output trough and releases it.

[0059] Wherein, the unpacking method of step B1 is: place the vial set with packaging film on the unpacking platform, use the lower suction cup assembly to continuously suck the lower mold of the packaging film from the bottom, and use the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com