Automatic assembling machine for inlaid ceramic chips

An automatic assembly machine and ceramic chip technology, applied in packaging, transportation and packaging, heating and unsealing, etc., can solve the problems of difficult control of precision, unqualified product quality, heavy workload, etc., to improve automation level and production efficiency, meet Automated production line, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

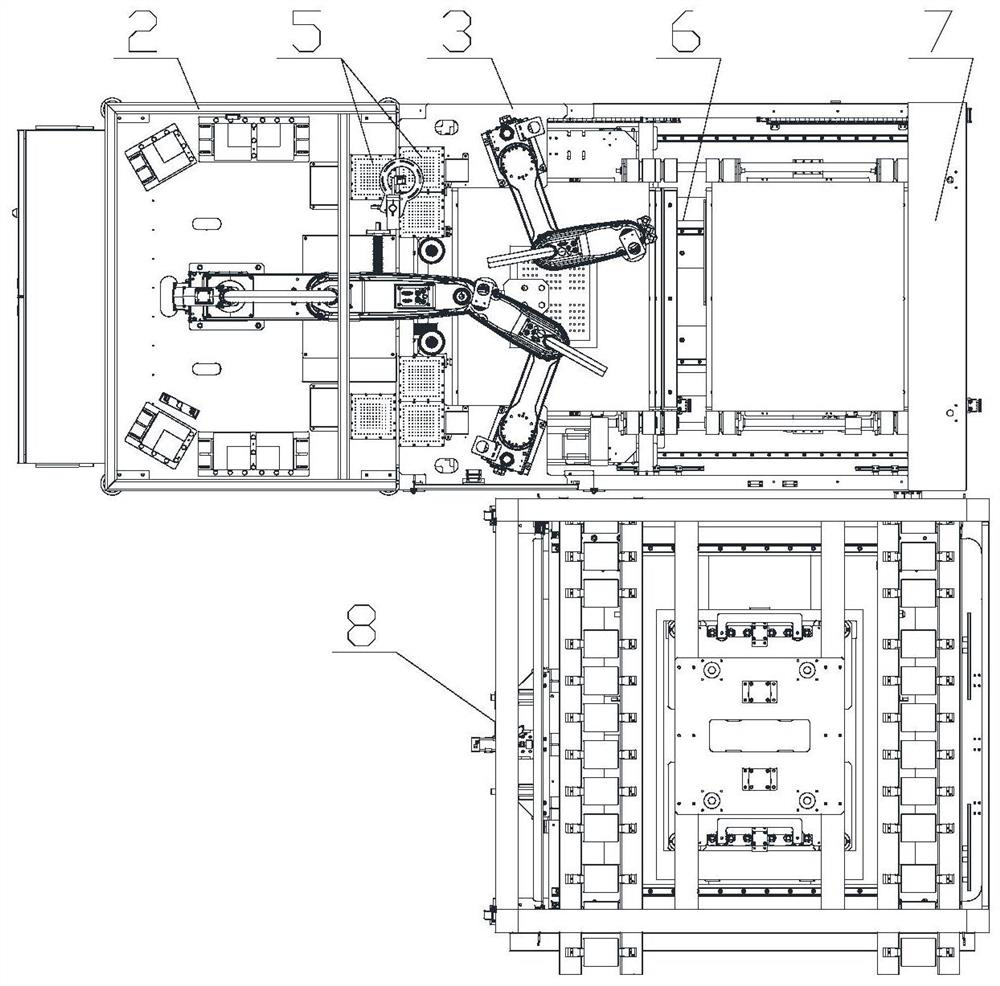

[0051] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

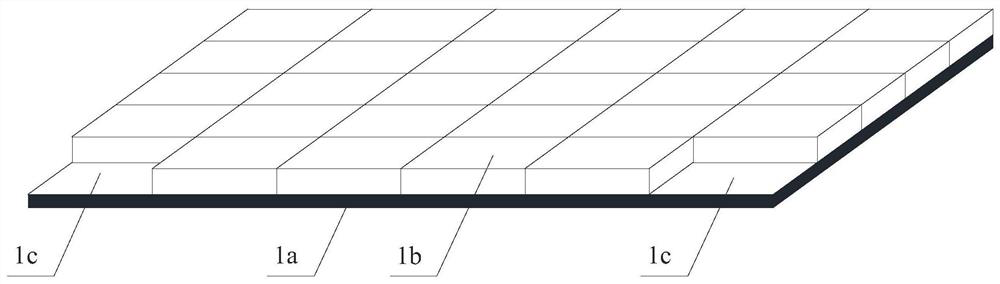

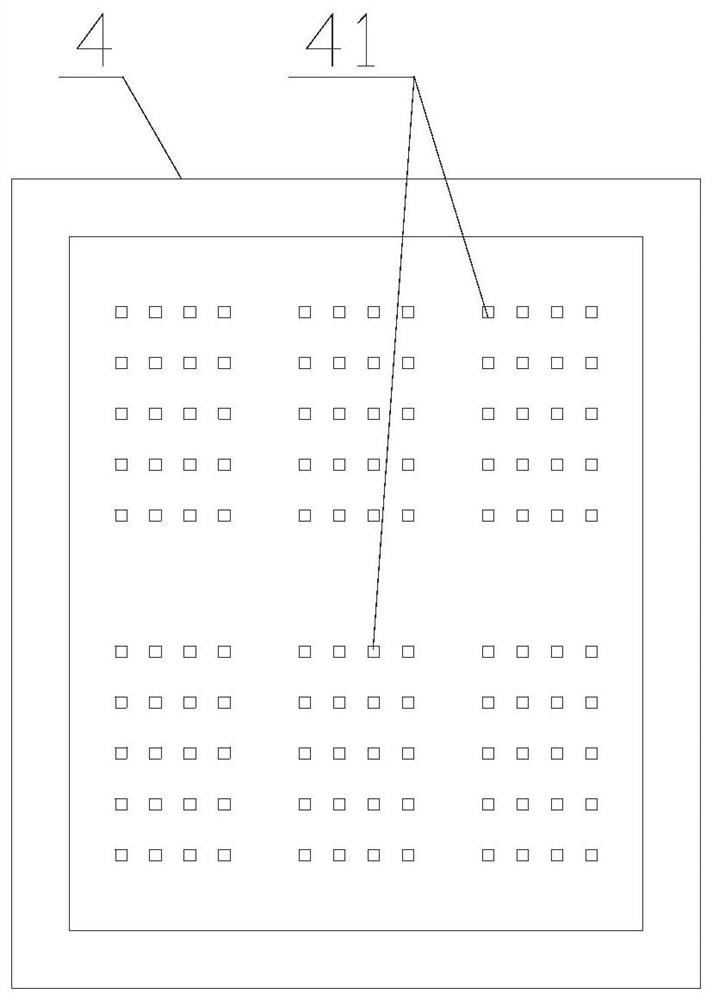

[0052] Such as image 3 As shown, an automatic assembly machine for inlaid ceramic sheets of the present invention includes a ceramic sheet debonding and film tearing mechanism 2, a ceramic sheet visual inserting mechanism 3, a substrate exchange and replacement mechanism 6, and a substrate stacking mechanism arranged in sequence along the process 8. Among them, the ceramic sheet degumming and film tearing mechanism 2 is used for degumming and tearing off the adhesive film 1a on the back of the ceramic sheet slice 1, and is used for feeding and feeding the ceramic sheet visual inserting mechanism 3; The feeding mechanism 3 is used to embed the ceramic sheet 1b after the adhesiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com