Method for making paper adhesive seal lose efficacy in lossless manner

A rubber seal and paper-based technology, which is applied in the field of non-destructive failure of paper-based glue seals, can solve problems such as excessive deformation of local seals, complicated solution methods, and difficulty in controlling specification parameters, so as to simplify failure methods, shorten operation time, and improve The effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

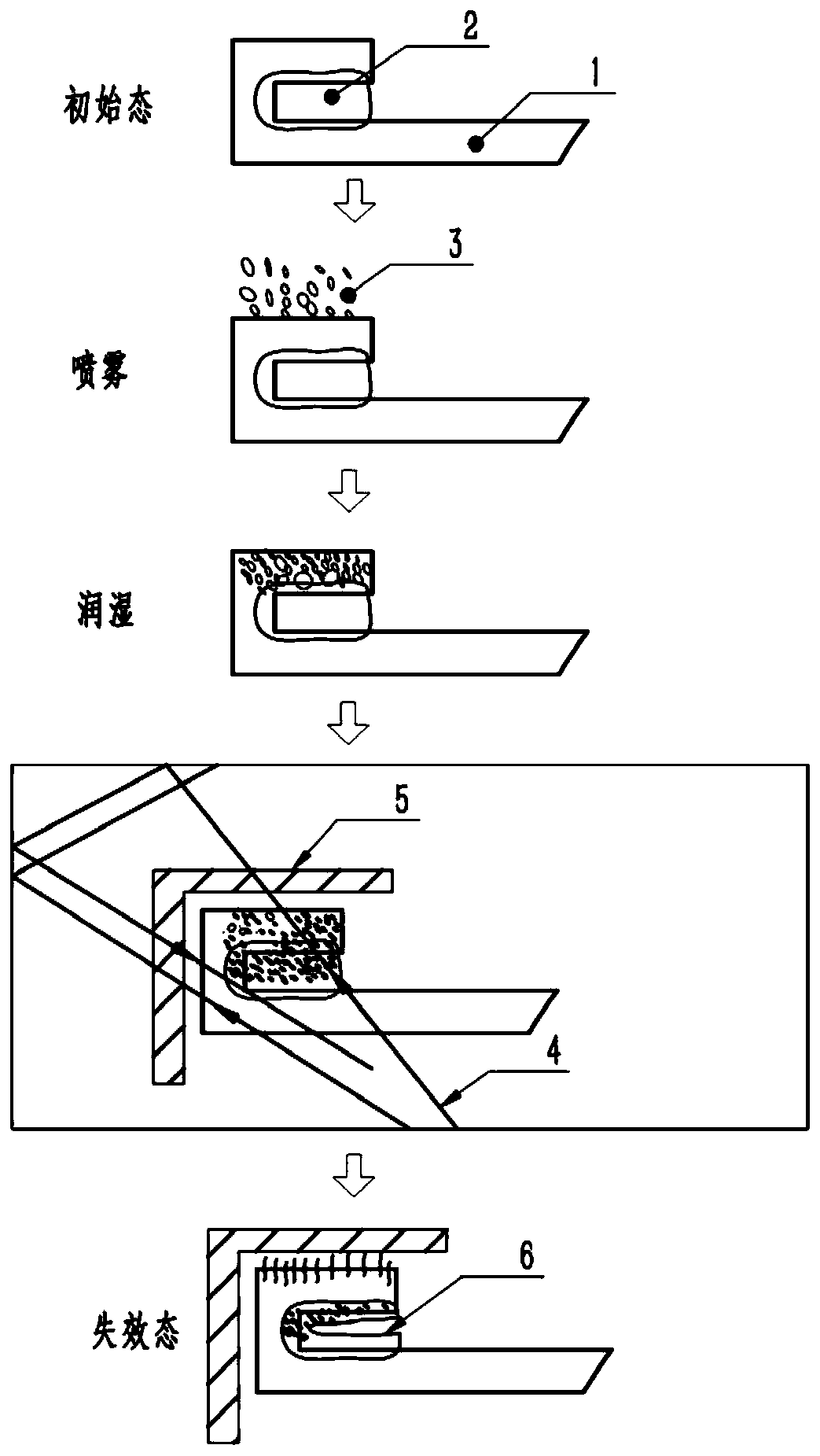

[0029] Choose an envelope with a sealing size of 120mm*18mm, the envelope material is 80g double-adhesive paper, the unit water injection volume is 0.5ml / cm2, cover it with a polyvinyl chloride film, the microwave frequency is 2.45GHz, the output power is 300W, and the action time is 30s. The cured glue at the sealing can be transformed into a wet glue state. After vibrating the vibrator at the sealing, the sealing will fail and open naturally. After the failure, there will be no obvious deformation and water stains on the paper glue sealing, and the paper glue sealing can still be glued after folding. Then restore.

[0030] Traditional water vapor makes the paper glue seal invalid, the process is dangerous, and the dismantling process cannot be quantitatively controlled, but the method of the present invention can complete the non-destructive disassembly with quantitative, constant power and fixed time; the method of the present invention effectively simplifies the paper quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com