Full-automatic packing machine

A fully automatic packaging machine and fuselage technology, applied in packaging and other directions, can solve the problems of complex structure and high manufacturing cost, and achieve the effects of high unpacking efficiency, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

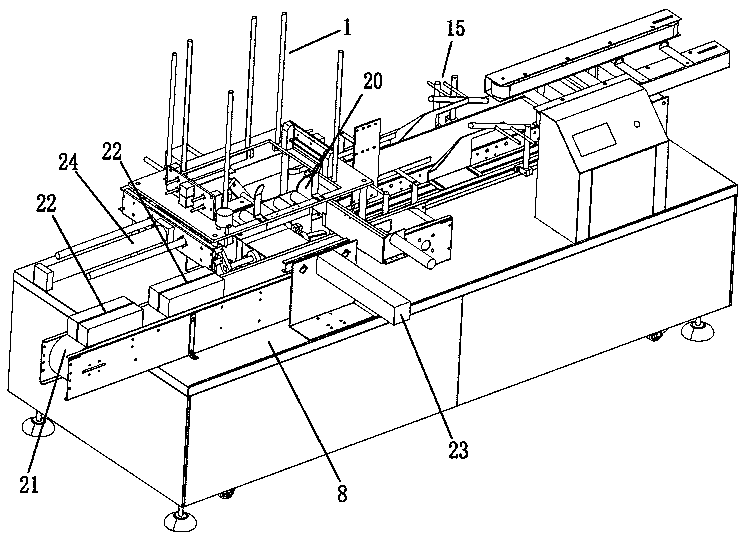

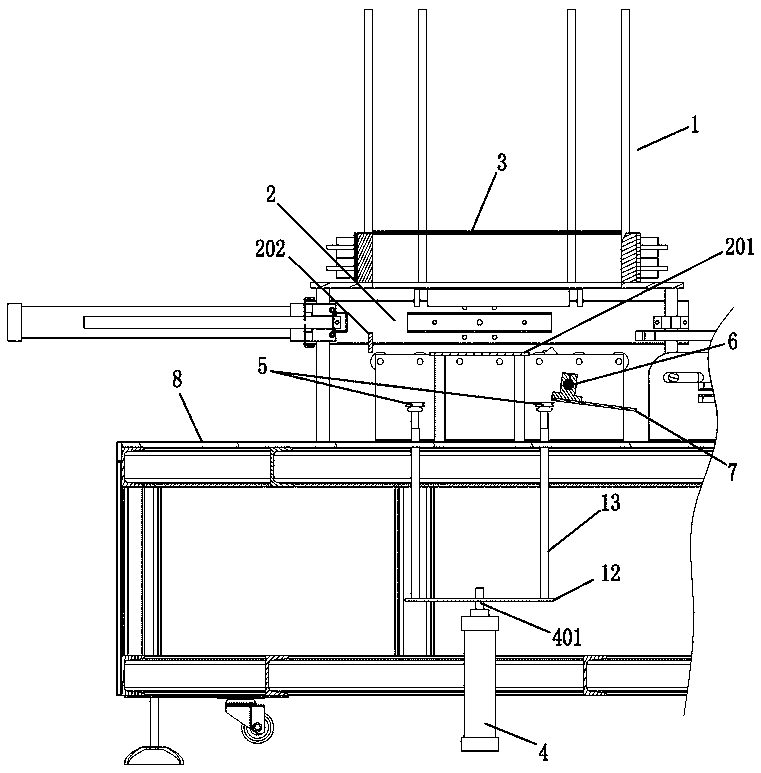

[0042] Such as Figure 1 to Figure 16 As shown, a fully automatic packaging machine includes a discharge rack 1 installed on the fuselage 8, an unpacking molding cavity 2 is provided below the discharge rack 1, and it is characterized in that the discharge rack 1 is horizontally placed with folding Shaped carton 3, the two sides of the folded carton 3 form a positioning folding edge 301 and an unpacking folding edge 302;

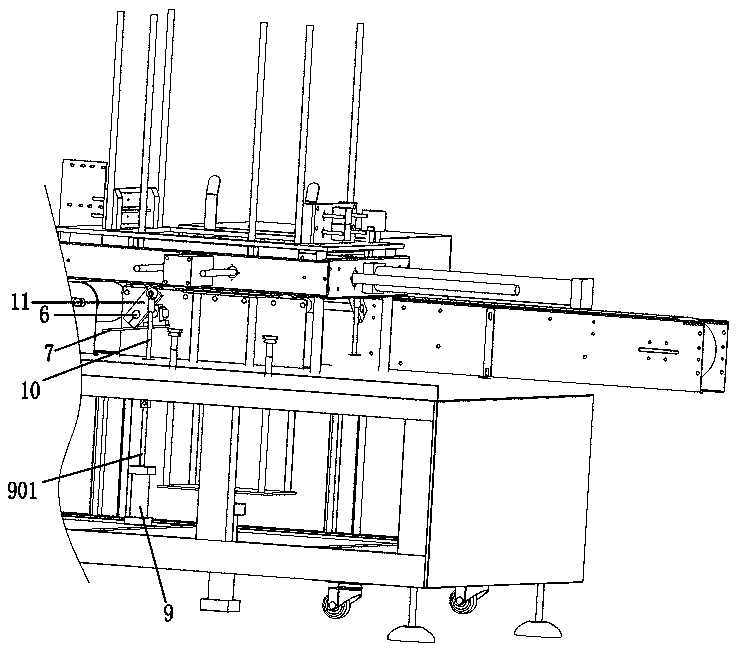

[0043] A supporting plate 201 is fixed on the said out-of-box forming cavity 2, and a suction cup 5 is vertically installed under the supporting plate 201 through a driver 4, and the suction cup 5 is driven up and down by the driver 4, so that the suction cup 5 will lift the folded carton 3 from the discharge rack 1 transferred to the supporting plate 201 of the unpacking molding cavity 2 for positioning;

[0044] One side of the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com