Clean technology for enriching unsaturated fatty acid methyl ester

A fatty acid methyl ester and unsaturated technology, which is applied in the field of enriching unsaturated fatty acid methyl ester, can solve the problems of urea wastewater that cannot be treated, high energy consumption, and low product purity, so as to reduce energy consumption and production cost, and achieve high recovery efficiency , The effect of high unpacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

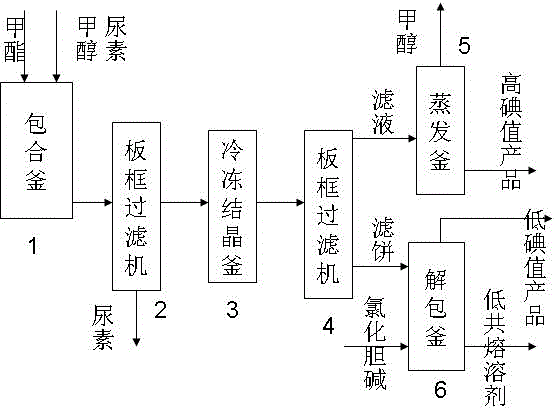

Embodiment 1

[0017] The iodine value is 96gI 2 300 kilograms of mixed solutions of saturated and unsaturated fatty acid methyl esters per 100 g are sent into clathrate kettle 1, and then 950 liters of methanol solution with urea content of 200 kilograms are added in clathrate kettle 1 under stirring condition, and clathrate kettle temperature is At 40°C and a pressure of 0.1 MPa, after the saturated fatty acid methyl ester and urea in the mixed solution of saturated and unsaturated fatty acid methyl ester form an inclusion complex, filter through plate and frame filter press 2 to obtain 28 kg of urea filter cake, which can be recycled; The filtrate is sent to the freezer 3, and is frozen and crystallized at a temperature of 8° C. for 24 hours; afterward, it is filtered with a plate and frame filter press 4, and the filtrate is poured into the evaporation kettle 5, and the methanol in the filtrate is removed under reduced pressure to obtain the Regenerated methanol is used next time, and th...

Embodiment 2

[0019] The iodine value is 86gI 2 300 kilograms of saturated and unsaturated fatty acid methyl ester mixed solutions per 100g are sent into clathrate kettle 1, and then 1060 liters of methanol solution with urea content of 220 kilograms are added in clathrate kettle 1 under stirring conditions, and clathrate kettle temperature is 30°C, pressure 0.1MPa, after the saturated fatty acid methyl ester and urea in the mixed solution of saturated and unsaturated fatty acid methyl ester form an inclusion compound, filter through the plate and frame filter press 2 to obtain 32 kg of urea filter cake, which can be recycled; The filtrate is sent to the freezer 3, and is frozen and crystallized at a temperature of 7° C. for 18 hours; afterward, it is filtered with a plate and frame filter press 4, and the filtrate is poured into the evaporation kettle 5, and the methanol in the filtrate is removed under reduced pressure to obtain Regenerated methanol is used next time, and the filtrate tha...

Embodiment 3

[0021] The iodine value is 103gI 2300 kilograms of mixed solutions of saturated and unsaturated fatty acid methyl esters per 100 g are sent into clathrate kettle 1, and then 920 liters of methanol solution with urea content of 180 kilograms are added in clathrate kettle 1 under stirring conditions, and the clathrate kettle temperature is 30°C and a pressure of 0.1MPa, after the saturated fatty acid methyl ester and urea in the mixed solution of saturated and unsaturated fatty acid methyl ester form an inclusion compound, filter through the plate and frame filter press 2 to obtain 25 kg of urea filter cake, which can be recycled; The filtrate is sent to the freezer 3, and is frozen and crystallized at a temperature of 6° C. for 20 hours; afterward, it is filtered with a plate and frame filter press 4, and the filtrate is poured into the evaporation kettle 5, and the methanol in the filtrate is removed under reduced pressure to obtain the Regenerated methanol is used next time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com