Apparatus for automatically opening cardboard box for cigarette

A carton and cigarette pack technology, applied in the field of unpacking equipment structure, can solve the problems of difficulty in meeting the higher demands of tobacco production, unfavorable carton recycling and reuse, poor cigarette pack deformation adaptability, etc., and achieves strong production line adaptability, Small footprint and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

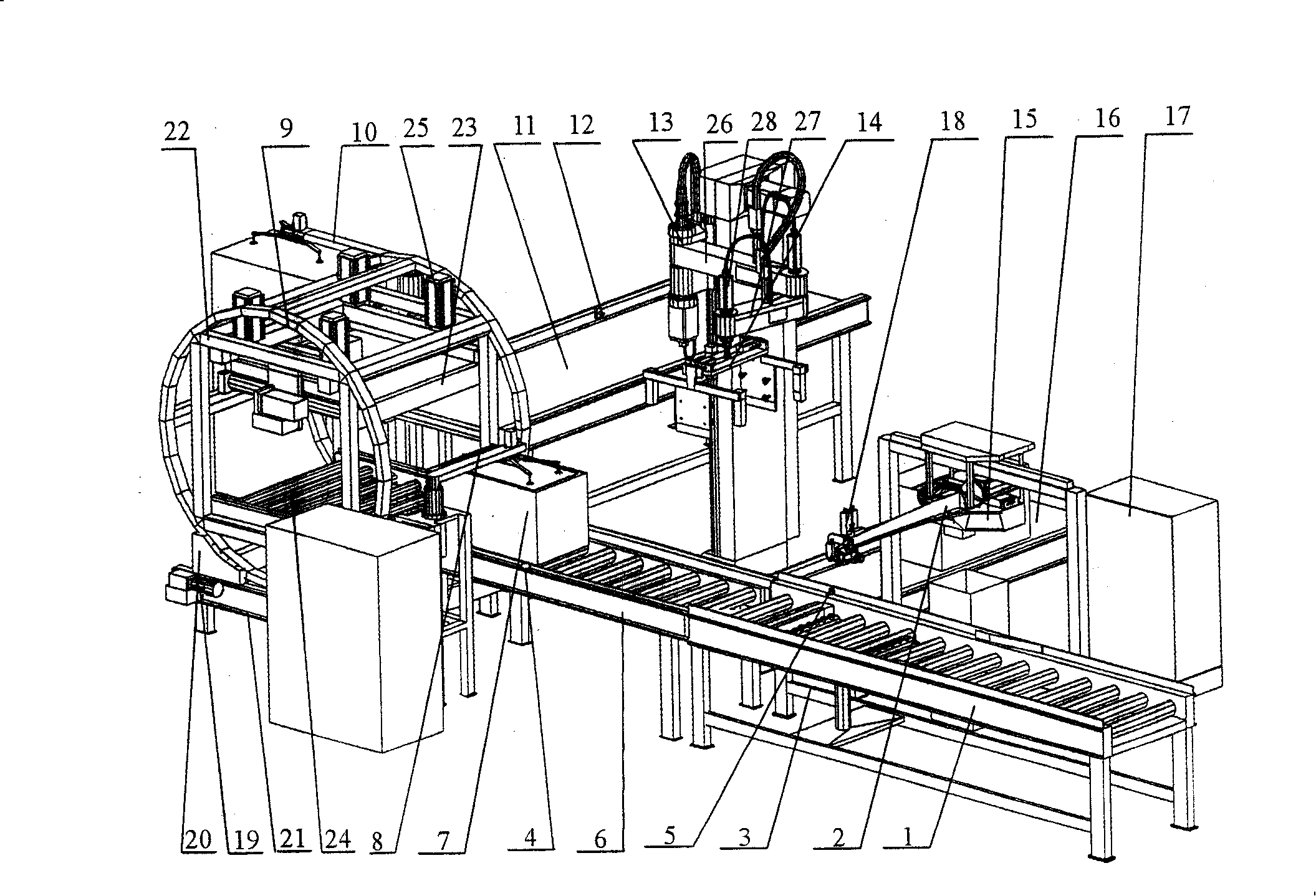

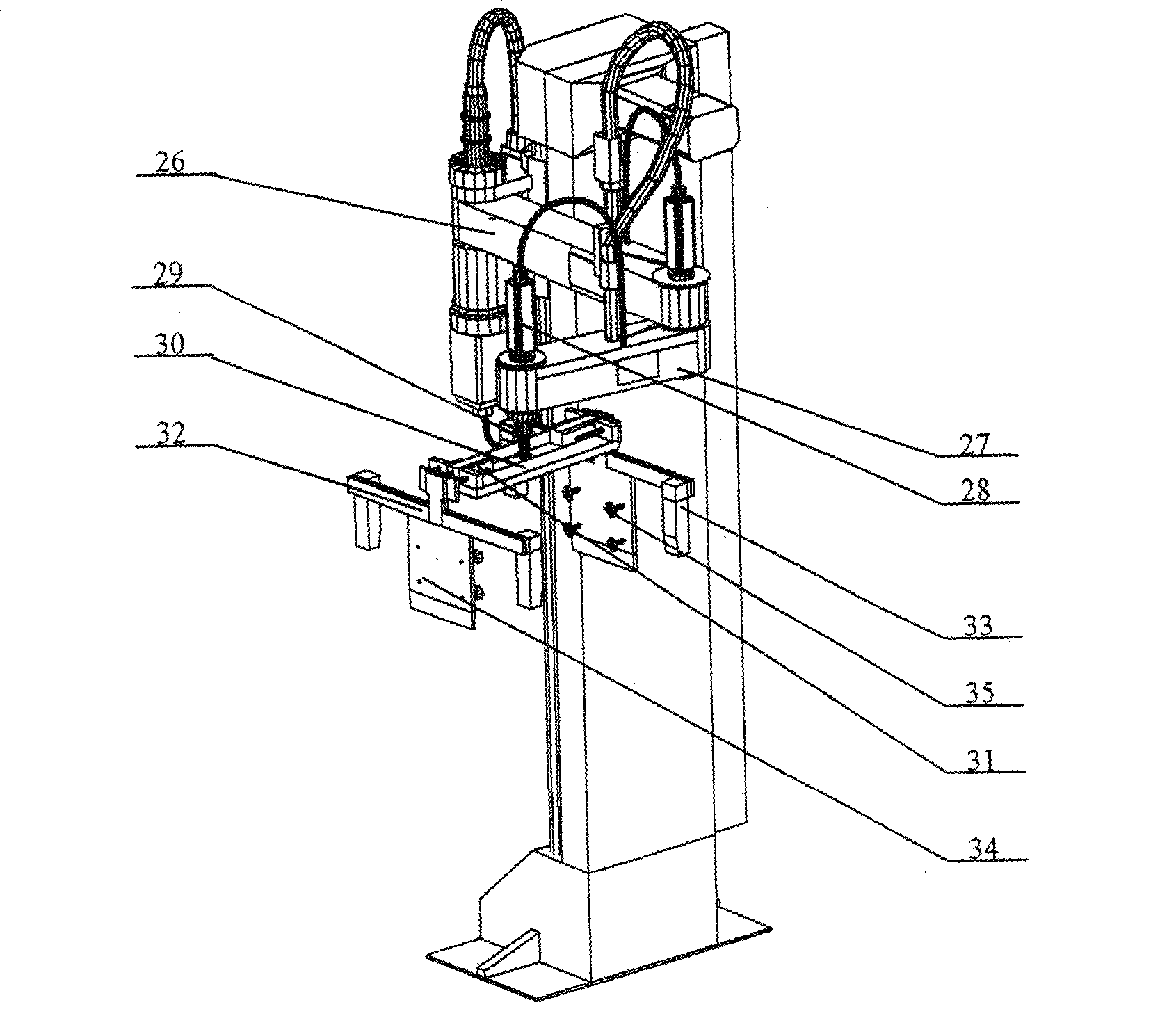

[0012] Such as figure 1 As shown, the unpacking equipment of the present invention includes a roller conveyor 1 for transporting carton cigarette packs 7 and a jacking device 3 arranged under the roller conveyor 1, on the side support of the conveyor 1, located at the jacking device The front part of the machine is provided with a photoelectric detection switch 5, and the lifting device and the detection switch control the strap removal and recovery stations. In order to facilitate the separate control of the strap removal and recycling station and the robot’s removal of the outer carton station, the roller conveyor can be set as two sections 1 and 6 that are controlled separately, and a photoelectric detection switch 4 is installed next to the roller conveyor 1 . On the side of the roller conveyor 1, a strap removal and recycling manipulator 2 is installed to detect, remove, roll up and cut the carton strap, and a liner removal manipulator 8 is provided to take out the liner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com