Box opening and conveying device

A box feeding and conveyor belt technology, which is applied in the field of box opening and box delivery devices, can solve the problems of low efficiency, high production costs, and high management costs, and achieve the effects of precise and stable motion strokes, low management costs, and high box opening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

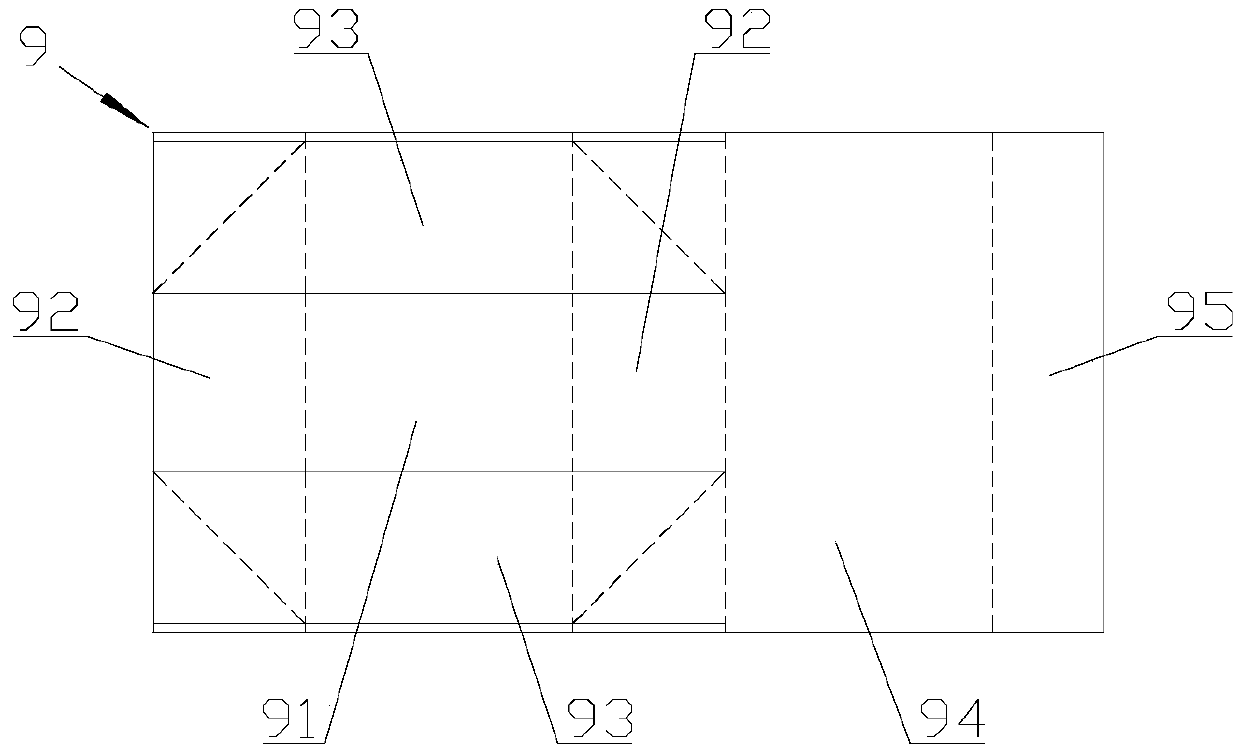

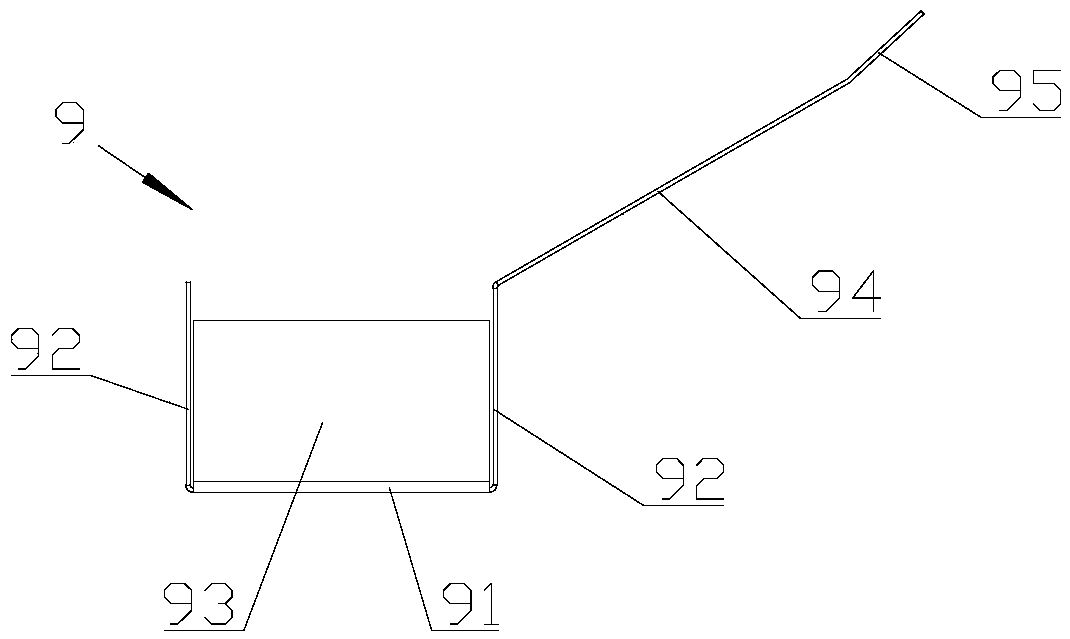

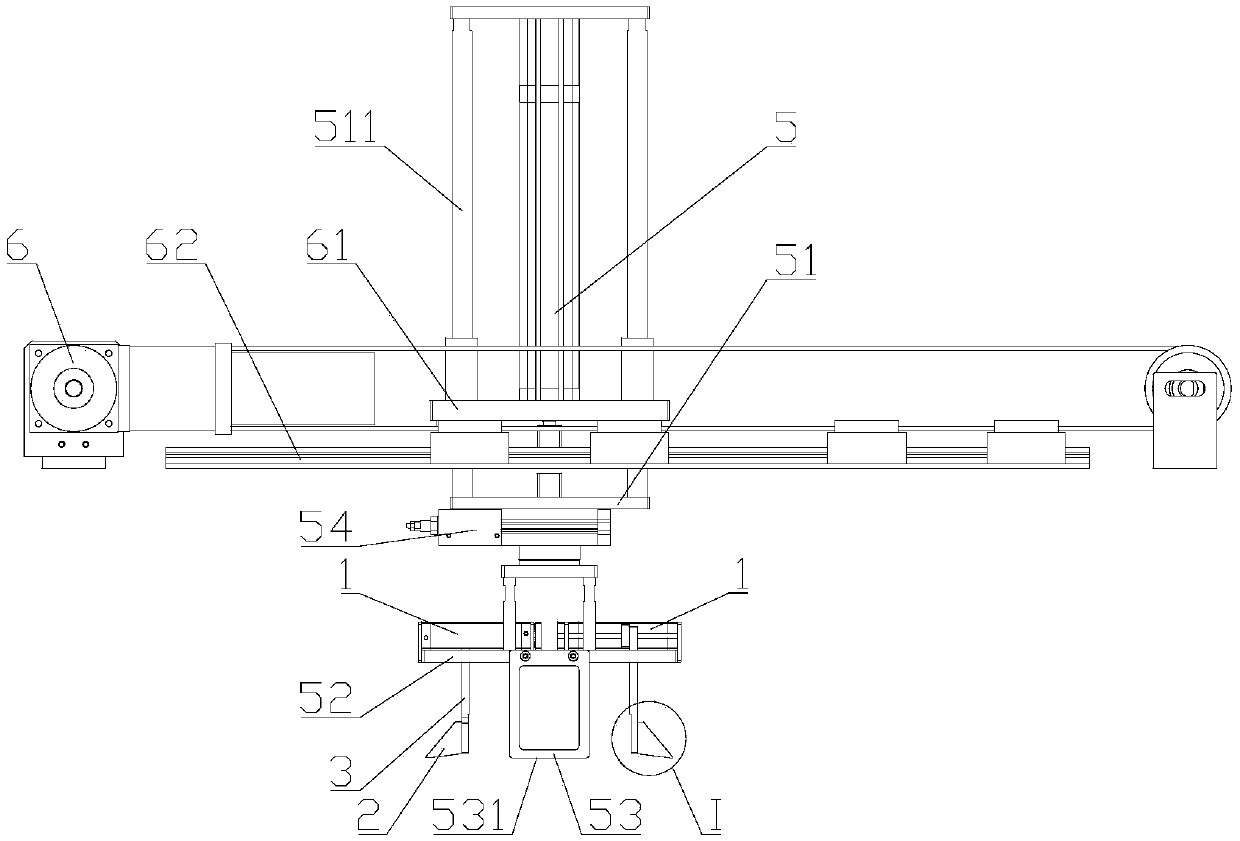

[0041] like image 3 , Figure 4 and Figure 5 As shown, the present invention provides a kind of unpacking delivery device, comprises unpacking part, lifting part, conveying part and material shifting part, and lifting part drives unpacking part lifting, and material moving part drives lifting part, unpacking part from sheet material Linear reciprocating motion is made between the storage area of the packing box of the structure and the conveying part.

[0042] The material shifting part drives the lifting part and the unpacking part to move above the storage area of the packing box of the sheet structure, and then the lifting part drives the unpacking part to descend, and the unpacking part performs unpacking operation on the packing box of the sheet structure, and then the lifting part Drive the unpacking part to lift, the packing box on the unpacking part moves with the unpacking part, and then the moving part drives the lifting part, the unpacking part and the packi...

Embodiment 2

[0059] If it is only to realize the automatic box unpacking operation and box feeding operation, the material shifting part can be omitted on the basis of the first embodiment. It is necessary to manually install the packaging box on the unpacking part, and then the unpacking part is driven by the lifting part during the unpacking operation to send the packaging box to the clamping area of the conveying part, and then the unpacking part is separated from the packaging box. The lifting part drives the unpacking part to leave the clamping area. However, the material of the packaging box can realize the ideal unpacking work only through the unpacking parts, and the second shaping plate 43 can be omitted.

Embodiment 3

[0061] In Embodiment 1 and Embodiment 2, if the packaging box does not need to be rotated, the posture adjustment assembly can also be omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com