Automatic packaging machine

An automatic packaging machine and automatic technology, applied in the direction of packaging machines, packaging, wrapping paper, etc., can solve the problems of single function, error-prone workers, labor intensity, low efficiency, etc., achieve a high degree of automation, avoid the accumulation of cartons, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the drawings and specific embodiments.

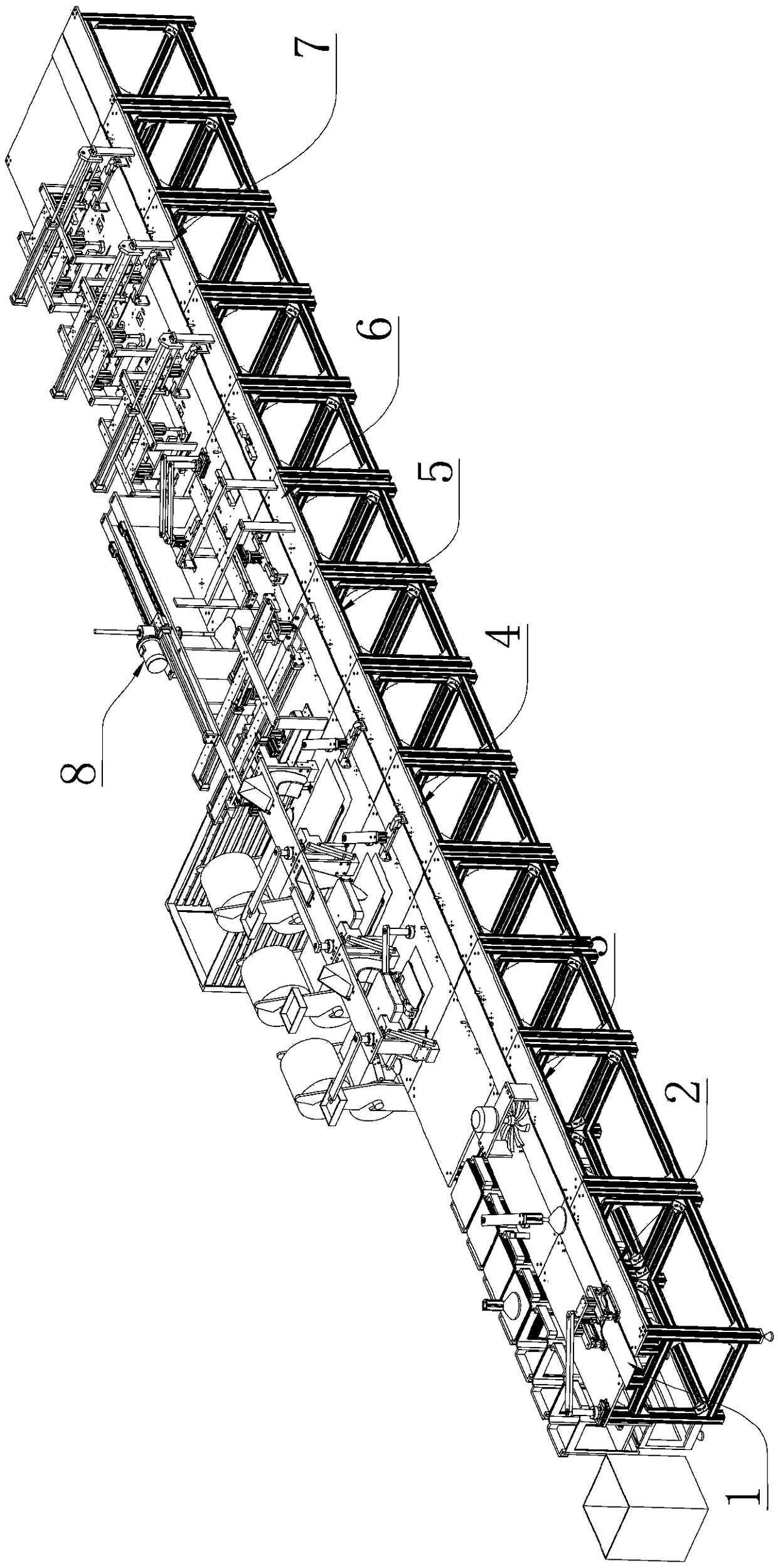

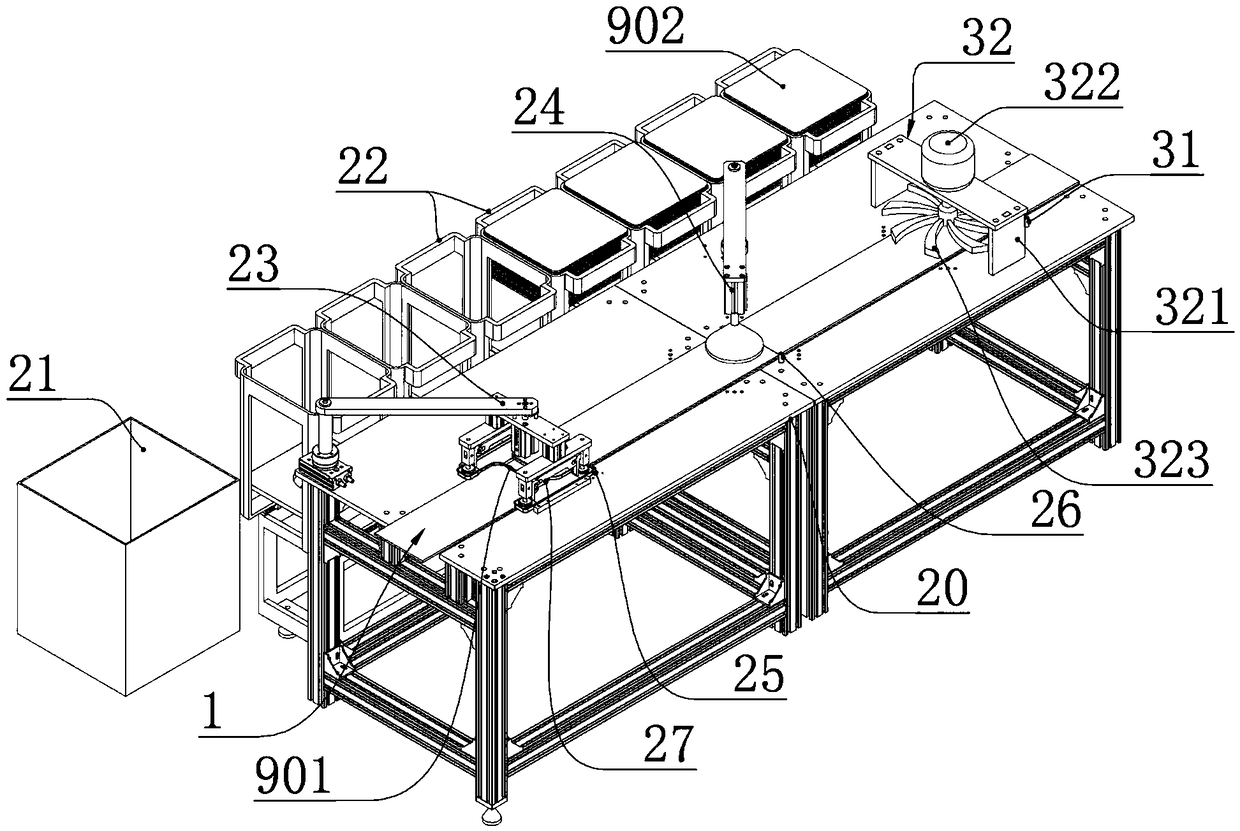

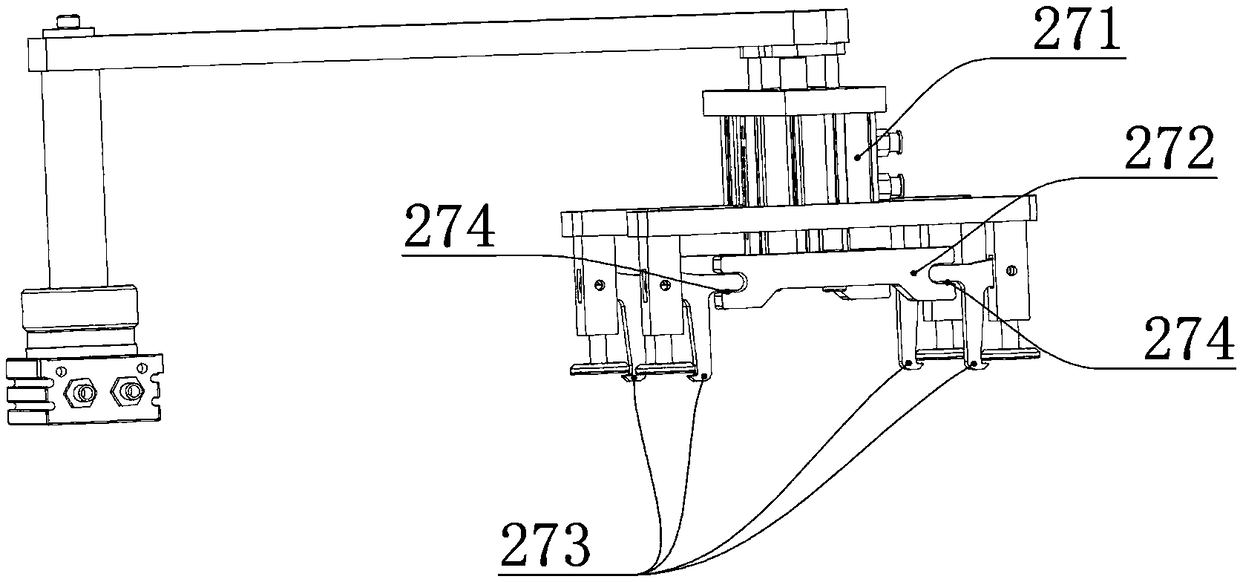

[0040] Such as Figure 1 to Figure 11 As shown, the embodiment of the present invention provides an automatic packaging machine for automatic assembly and packaging of an electronic scale 90. The electronic scale 90 includes a weighing frame 901 and a weighing pan 902. The weighing pan 902 is bonded to the scale by double-sided adhesive tape. On the frame 901, after the electronic scale 90 is packaged by this automatic packaging machine, the electronic scale 90 and the external accessories (manual, charger, etc.) Anti-collision foam 93, the electronic scale 90 that anti-collision foam 93 is housed is packaged in the carton 94.

[0041] An automatic packaging machine, comprising an automatic transmission line 1, the automatic transmission line 1 is used to transmit the weighing frame 901 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com