Butt hinge of folding case and folding case

A folding box and hinge technology, which is applied to pin hinges, folding panels, door/window accessories, etc., can solve problems such as hidden safety hazards, laborious operation, and large resistance, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

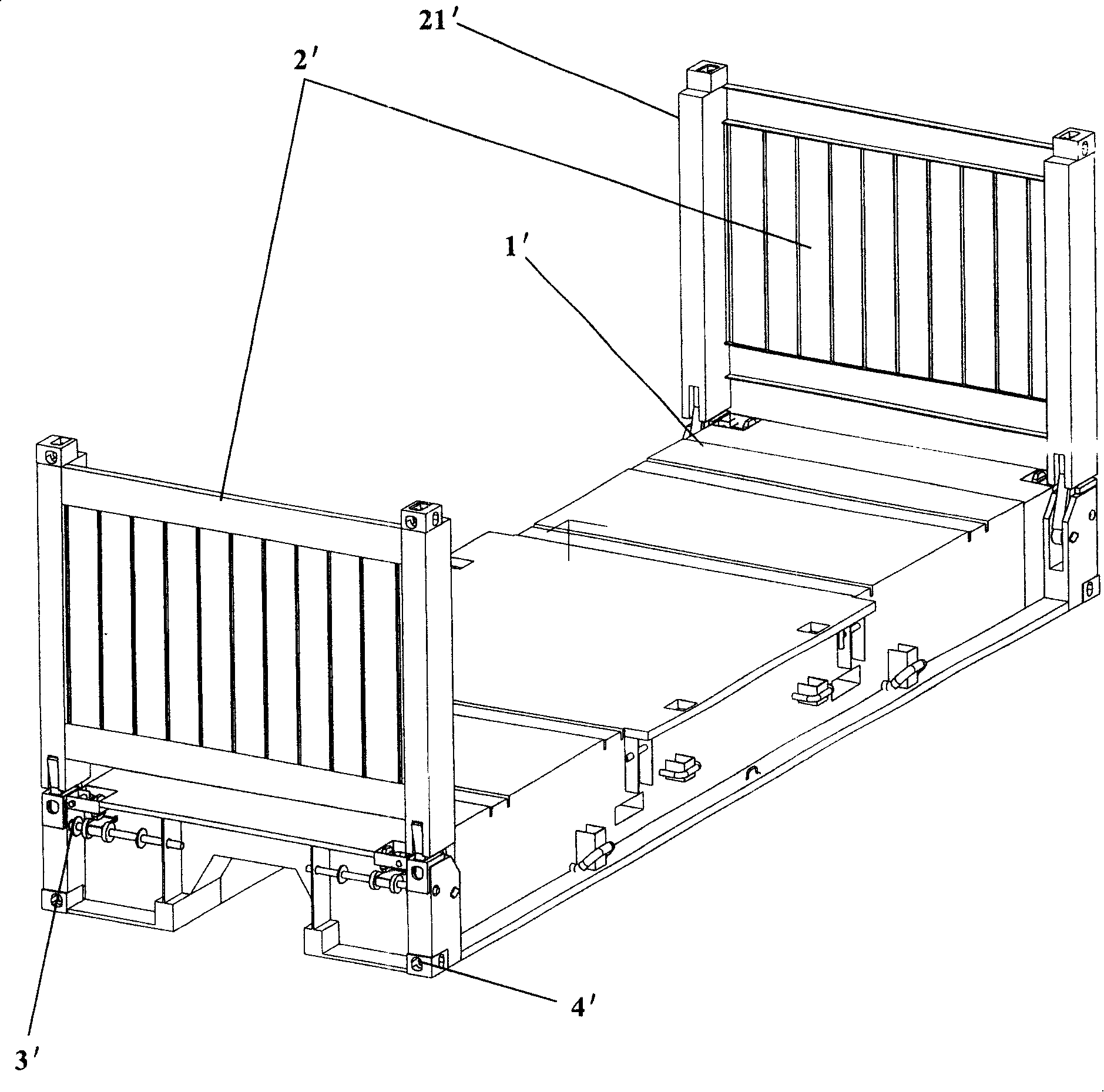

[0124] Figure 4 to Figure 11 Shown is a first embodiment of the invention.

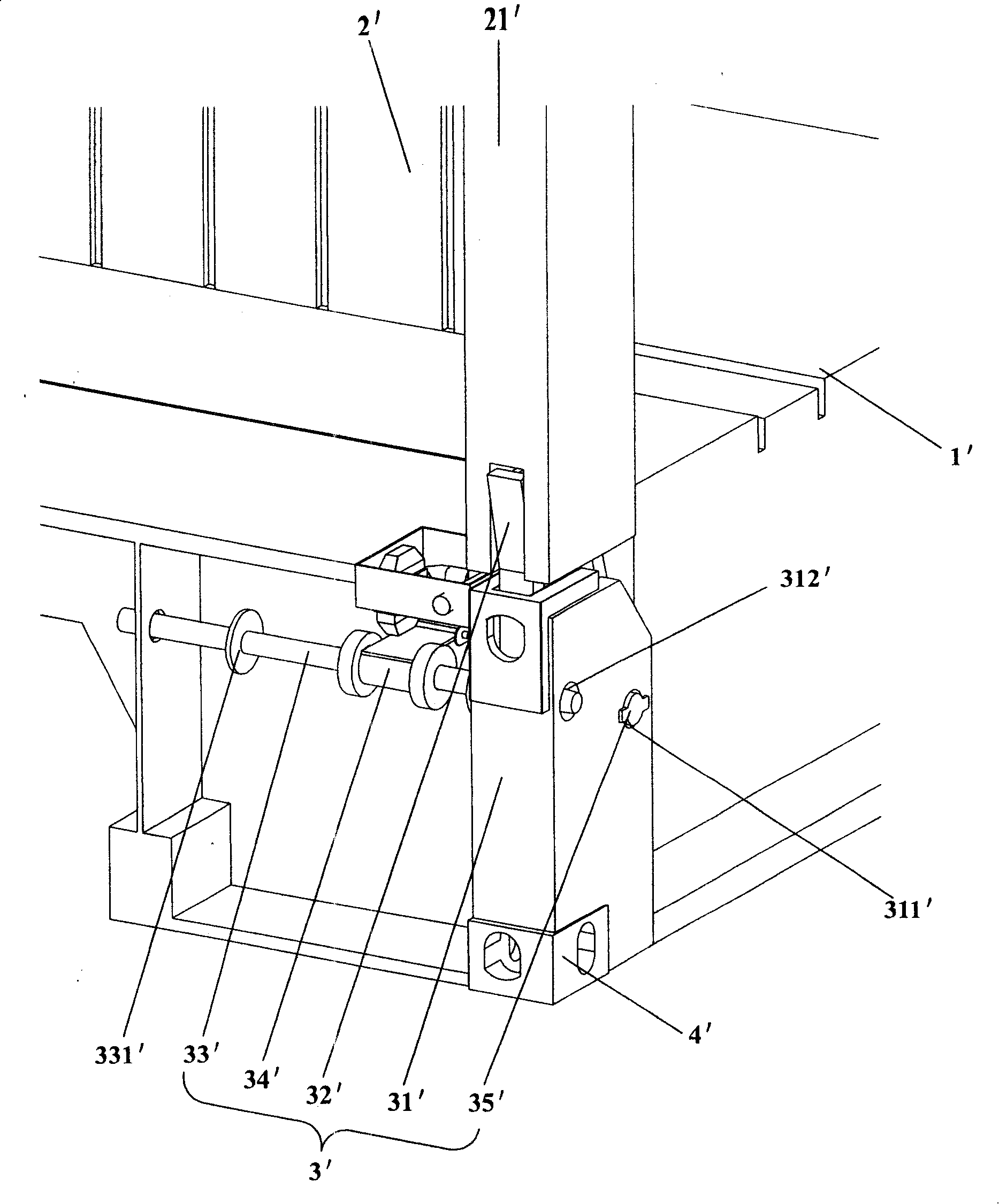

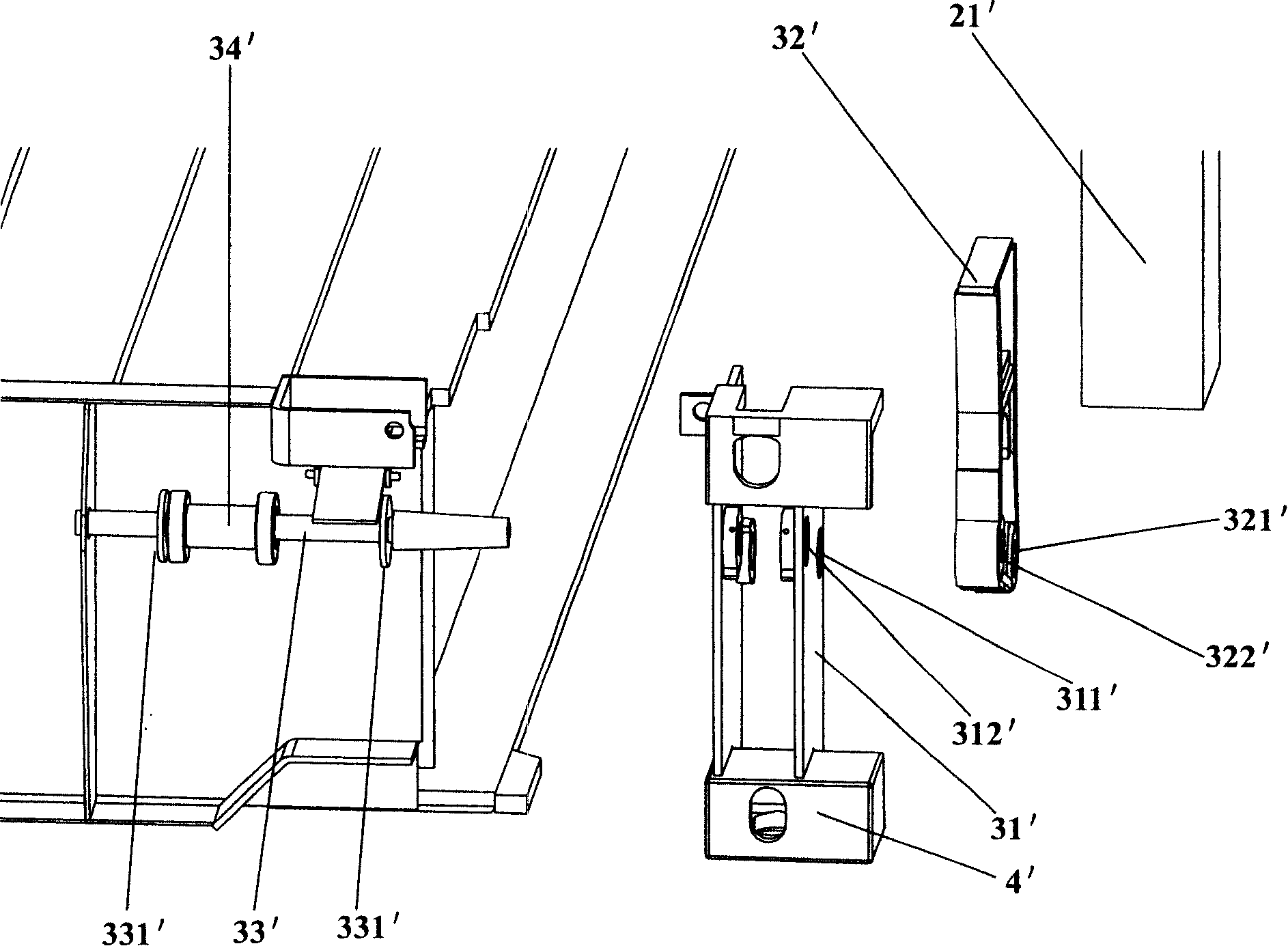

[0125] The hinge of the folding box of the present invention comprises: a fixed hinge plate 2, a movable hinge plate 3, a revolving pin 4, a lock pin 5, a pedal 6 and an elastic locking device 7;

[0126] In this embodiment and other embodiments of the present invention, the movable hinge plate 3 is fixedly connected to the bottom of the corner post 9; the fixed hinge plate 2 is fixedly connected to the side of the end corner of the chassis 1, and the bottom corner piece 15 is fixedly connected At the bottom of the fixed hinge plate 2.

[0127] The fixed hinge plate 2 is set on the outside of the movable hinge plate 3; the fixed hinge plate 2 is provided with a fixed pivot hole 21, and the movable hinge plate 3 is correspondingly provided with a movable pivot hole 31, see Figure 5 and Figure 8A , the revolving pin 4 is inserted in the fixed pivot hole 21 and the movable pivot hole 31 to pivotall...

Embodiment 2

[0138] Figure 12 Shown is the second embodiment of the present invention, its structure is the same as that of the first embodiment, and a slide hammer 54 is added. In order to make the locking of the movable hinge plate 3 and the fixed hinge plate 2 by the lock pin 5 more reliable, a sliding hammer 54 is set on the base 51 of the lock pin 5, a hammering plate 55 is arranged on the base, and a locking part of the lock pin 5 After 53 is inserted in the fixed locking hole 22 and the sub-lock 32, knock the hammer plate 55 with a slide hammer 54 to make the locking of the movable hinge plate 3 and the fixed hinge plate 2 more reliable. The clamping plate 13 connected by the pin, at this moment, the clamping plate 13 can just lean against the inner side of the hammering plate 55 to prevent the locking pin 5 from receding and cause the locking of the movable hinge plate and the fixed hinge plate to be unstable.

Embodiment 3

[0140] Figure 13 to Figure 15 Shown is the third embodiment of the present invention, its structure is similar to the first embodiment, the difference lies in the structure and installation of the elastic locking device 7, the elastic locking device only includes the tension spring 72B, stretching One end of the spring 72B is hung on the hanging column 56 provided on the base 51 of the lock pin 5, and the other end is hung on the hanging column 14 fixedly connected to the end of the chassis 1, and the hanging column 14 is located away from the fixed hinge. Plate 2 nearer position and hanging post 56 are positioned at far away from fixed hinge plate 2; And the structure of spring seat 52 of lock pin 5 can be omitted, and this end of lock pin 5 directly passes on the vertical plate 11. The working principle of this embodiment is the same as that of the first embodiment, except that during the working stroke, the tension spring 72B is stretched, so that the tension spring 72B is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com