Carton folding production line enabling cartons to be automatically formed

An automatic forming and production line technology, applied in carton/carton manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of cardboard folding and forming, and achieve high production efficiency, simple structure, and high processing precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

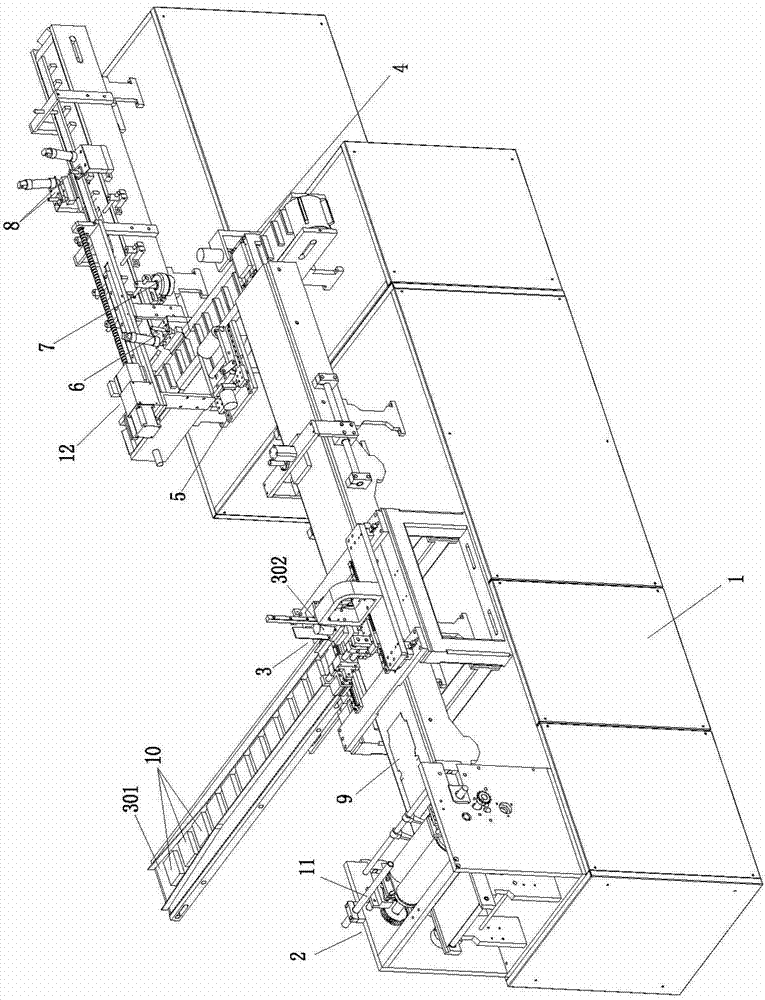

[0045] Such as Figure 1 to Figure 17 As shown, the automatic forming origami box production line includes an assembly line body 1, which is characterized in that the body 1 is respectively provided with an automatic glue applying device 2, an inner box positioning device 3, a box pressing device 4, Roller device 5, outer bottom panel pressing roller device 6, wing plate pressing device 7 and two outer panel pressing roller devices 8;

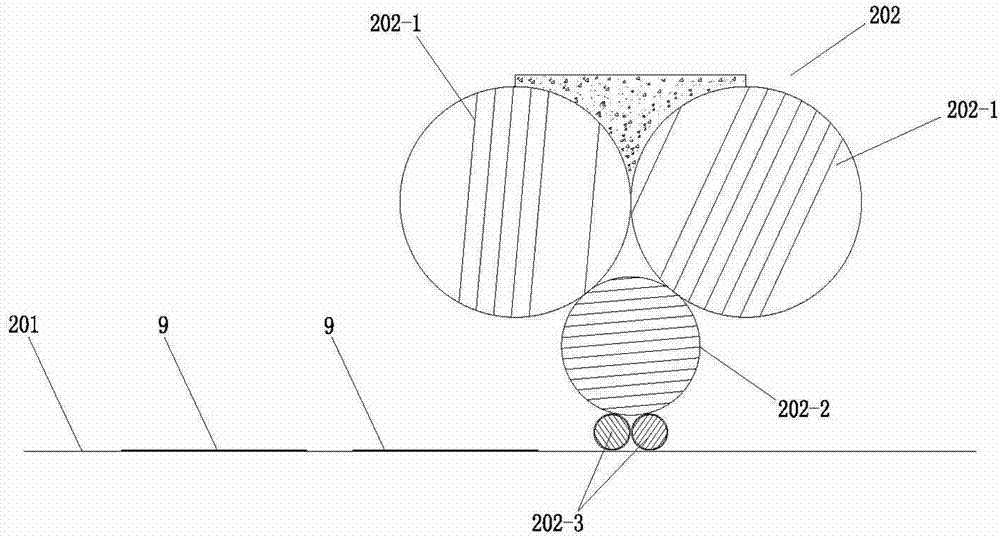

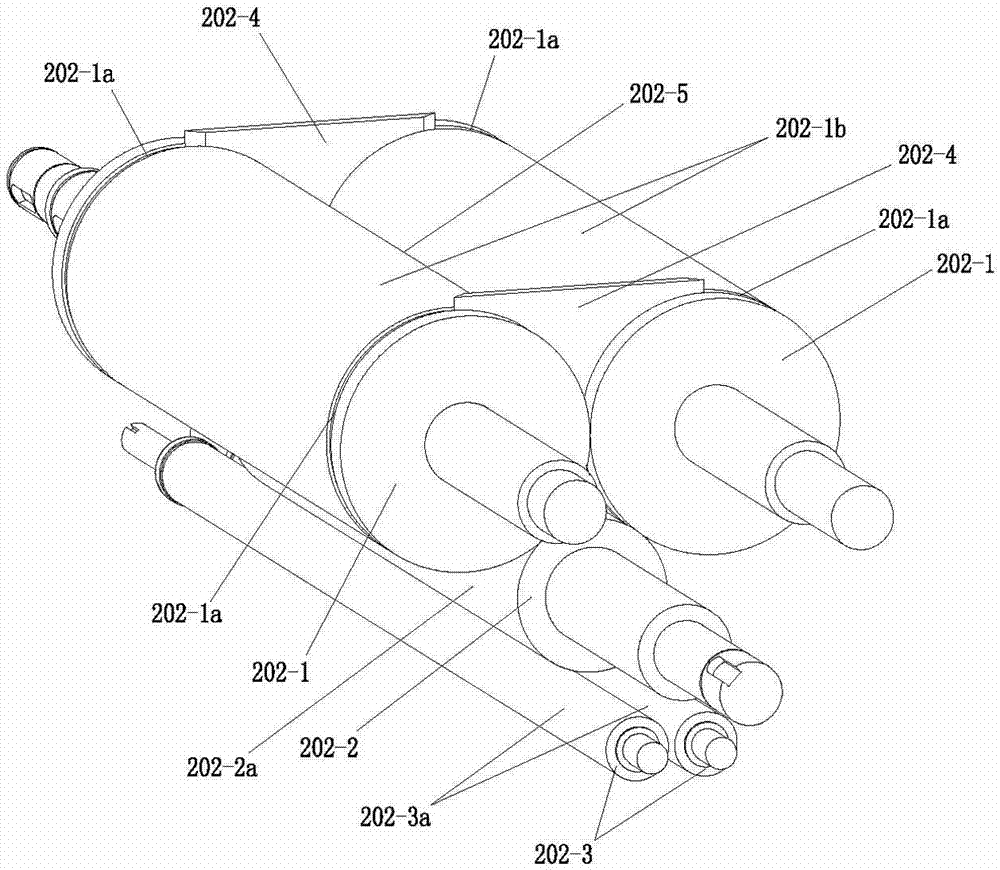

[0046] The automatic gluing water device 2 includes a gluing conveyor belt 201 and a rubber roller assembly 202, and the gluing conveyor belt 201 conveys the blank cardboard 9 in a planar unfolded shape, and the gluing conveyor belt 201 is provided with a rubber roller assembly 202, The rubber roller assembly 202 includes two space-limiting rubber rollers 202-1, a middle rubber roller 202-2, and two pressure-coating rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com