Papermaking processes using coagulants and optical brighteners

a technology of optical brighteners and papermaking processes, applied in the field of papermaking processes and products, can solve the problems of increasing the overall cost of paper products, increasing the cost of optical brighteners, and significant cost differences between paper brightness of 80% and brightness of 96%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

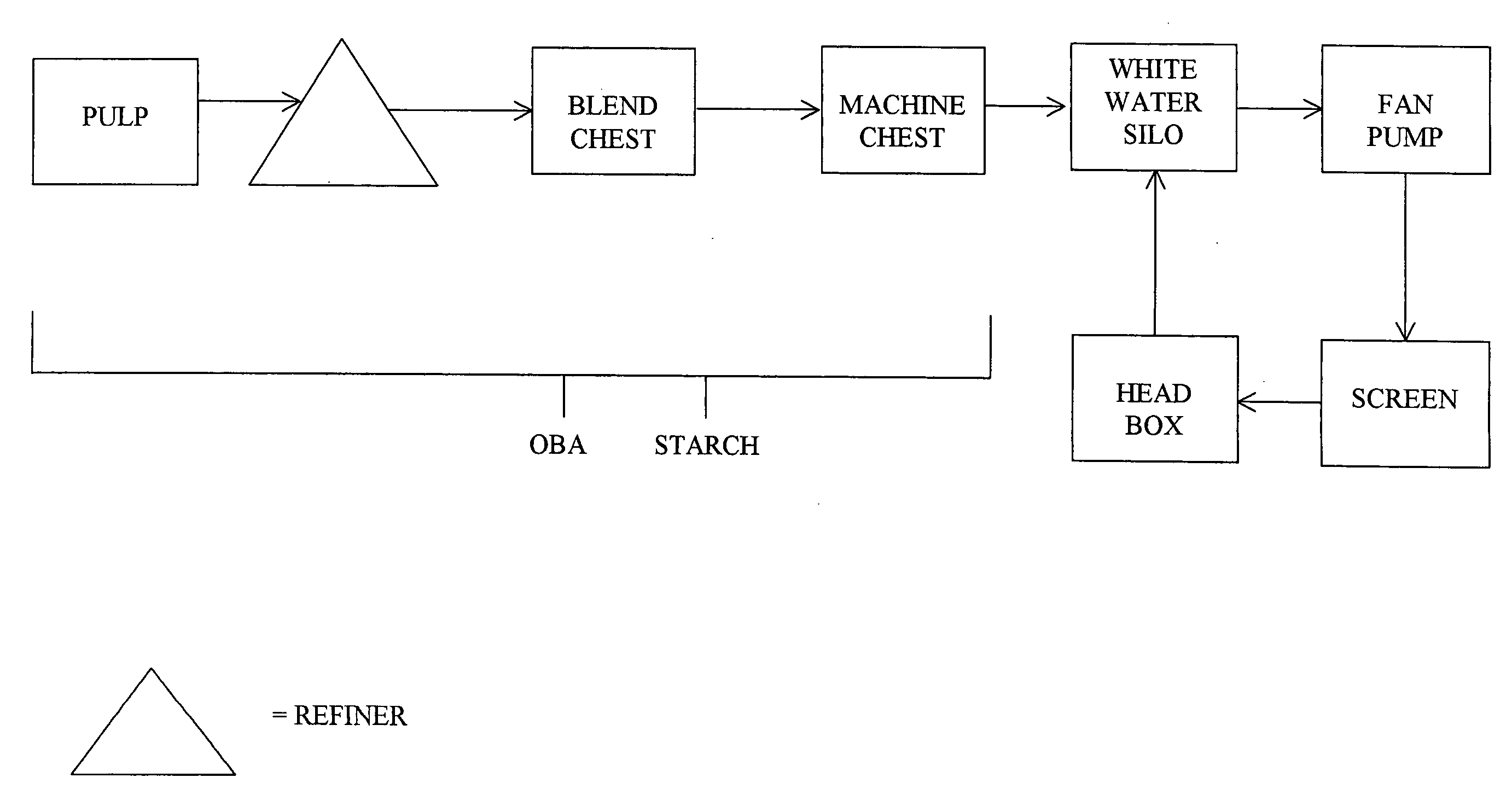

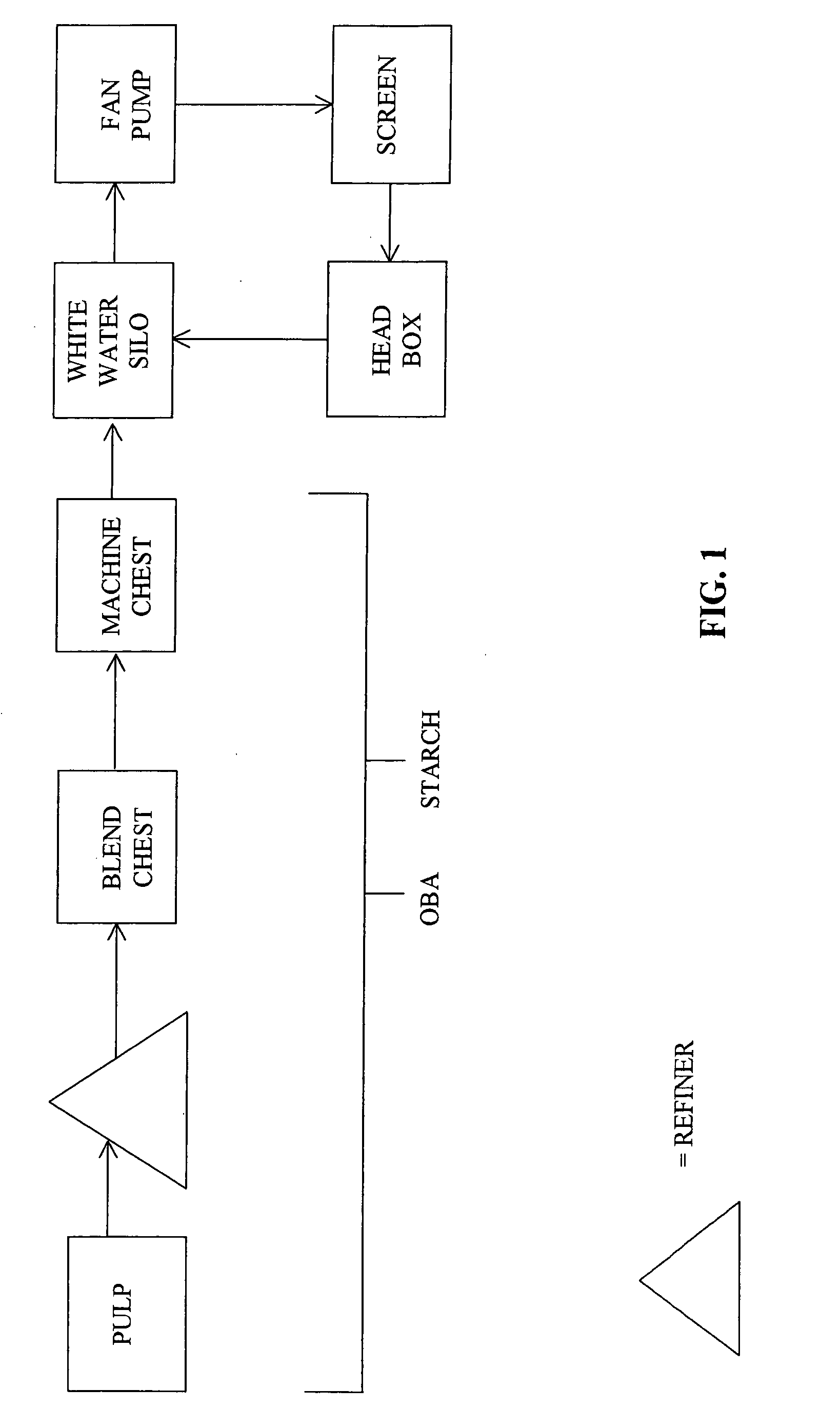

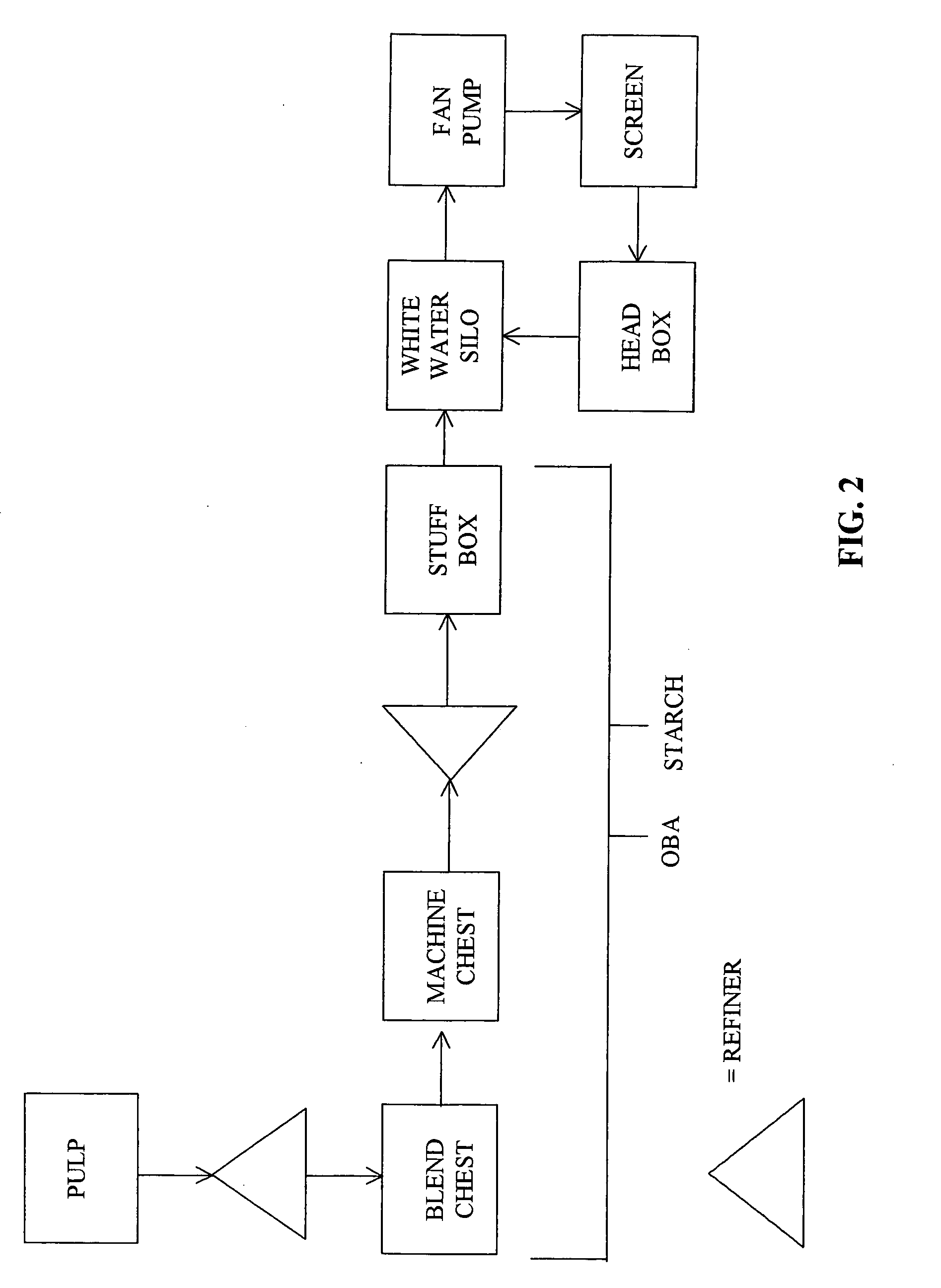

Method used

Image

Examples

examples

[0053]Experimental: The pulp suspension used in this example contained 70% by weight bleached hardwood and 30% by weight bleached softwood with a CSF of 380 mL. Optical brightener used was Tinopal. Both BFL 5521 and BFL 5567 (from Buckman Laboratories International, Inc.) were cationic starches with different charge densities.

[0054]During the handsheet preparation, 15 lb / ton (as received) OBA was first added to the thick pulp stock (consistency 2.2%) followed by the cationic starch. Afterwards, the pulp stock was diluted to 0.4% and the handsheets were prepared by the standard Tappi method T205.

[0055]FIG. 3 shows the brightness results of the prepared handsheets. The introduction of OBA increased the paper ISO brightness from 64.0 to 65.2. Upon the addition of 7 lb / ton (as received) cationic starches of BFL 5521 and BFL 5567, the brightness further increased to 65.2 and 66.0 respectively.

[0056]FIG. 4 shows the fluorescence image of the prepared paper samples. In this experiment, sma...

example 2

[0060]In an experiment, a five-day experimental trial on a paper machine was conducted to determine the effects of using a cationic starch along with an optical brightener. In particular, BUFLOC 5567 organic coagulant was used. More specifically, BUFLOC 5567 coagulant was introduced into the thin stock stage starting at an amount of 0.5 lb / ton, which was gradually increased to 2 lb / ton, and then increased to 3 lb / ton, and then increased to 4 lb / ton for the remainder of the trial. The dosage was then decreased by 1 lb / ton every reel until the trial was finished.

[0061]From this experiment, it was noticed that the breaks on the machine dropped from an average of 2.4 breaks per day (based on a one month average) to an average of 1.6 breaks per day during the trial. The breaks on the machine is a term understood to those skilled in the art and refers to the paper that is formed on the machine does not break prior to it being rolled up.

[0062]Furthermore, during the experiment, there were ...

example 3

[0068]In this experiment, a forty-five day experimental trial was run on a paper machine to determine the longer term effects of using BUFLOC 5567 coagulant in view of OBA efficiency. Specifically, during a forty-five day period, BUFLOC 5567 coagulant was used in the amount of 2.6 lbs / ton. As stated, an OBA was also present. The following observations were made from the experiment:[0069]Break time on the machine was reduced by 13 to 17 minutes per day when the 45 days of usage were compared to the 104 days without BUFLOC 5567.[0070]The draw between the 2nd press and 1st dryer section was reduced by 4 to 5 feet with the added drainage from BUFLOC 5567.[0071]First pass ash retentions increased a minimum of 11% with the added usage of BUFLOC 5567.[0072]ULMA Small Holes decreased from 3.8 small holes per 1,000,000 lineal feet to 0.75 small holes per 1,000,000 lineal feet with BUFLOC 5567.[0073]ULMA Medium Holes decreased from 5.9 medium holes per 1,000,000 lineal feet to 0.4 medium hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| steam pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com