Method for manufacturing nanofibrillated cellulose pulp and use of the pulp in paper manufacturing or in nanofibrillated cellulose composites

a technology of fibrillated cellulose and nanofibrillation, which is applied in the field of manufacturing nanofibrillated cellulose and its use, can solve the problems of increasing the energy consumption of manufactured pulp, consuming a great deal of energy, and many stages of pulp production, especially refining stages, to achieve the effect of increasing the production efficiency of nanofibrillated cellulose, inhibiting the hydrogen bonding of fibrils, and increasing the production efficiency

Inactive Publication Date: 2013-01-03

UPM-KYMMENE OYJ

View PDF9 Cites 48 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

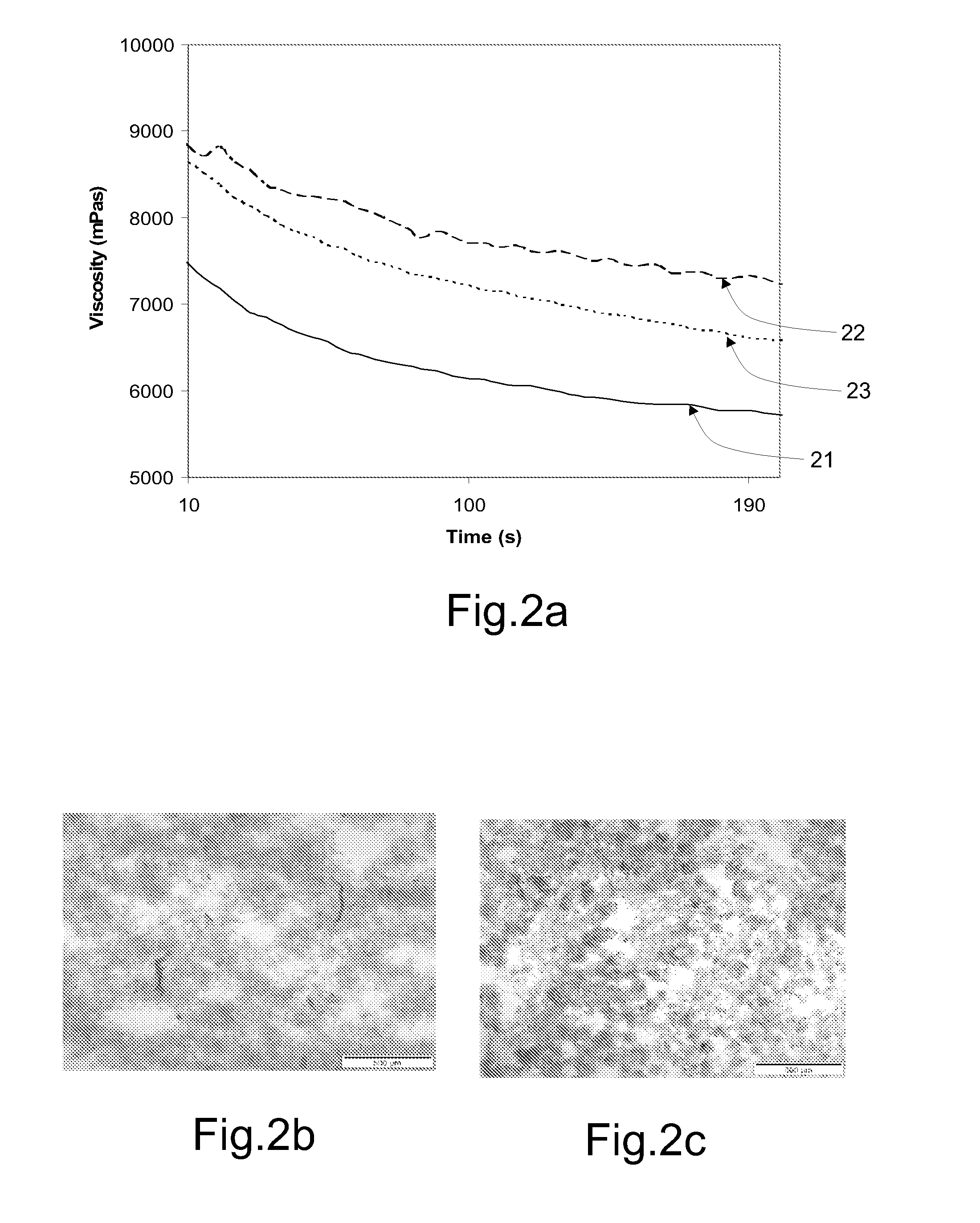

[0007]The inventors of the present invention have surprisingly found that optical brightening agents can increase the production efficiency of the nanofibrillated cellulose pulp if the additives are dosed before or during a pre-refining stage and/or a fibrillation stage. Optical brightening agents have been found to be able to create bonding with cellulose in such a way that the optical brightening agents can act as substituents in inter-fiber bonding and, thus, inhibiting hydrogen bonding of fibrils in cellulose. The increased production efficiency is mainly due to decreased energy consumption of the fibrillation st

Problems solved by technology

Many stages of pulp production, especially refining stages, consume lots of energy.

Specially a production of nanofibrillated cellulose consumes a great deal of energy due to several fibrillarion passages that are needed to achieve nano-sized material.

Because the energy consumption of the manufactured pulp increases hugely when the produced pulp includes nanofibrillated cellulose, there may be an efficiency problem wh

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

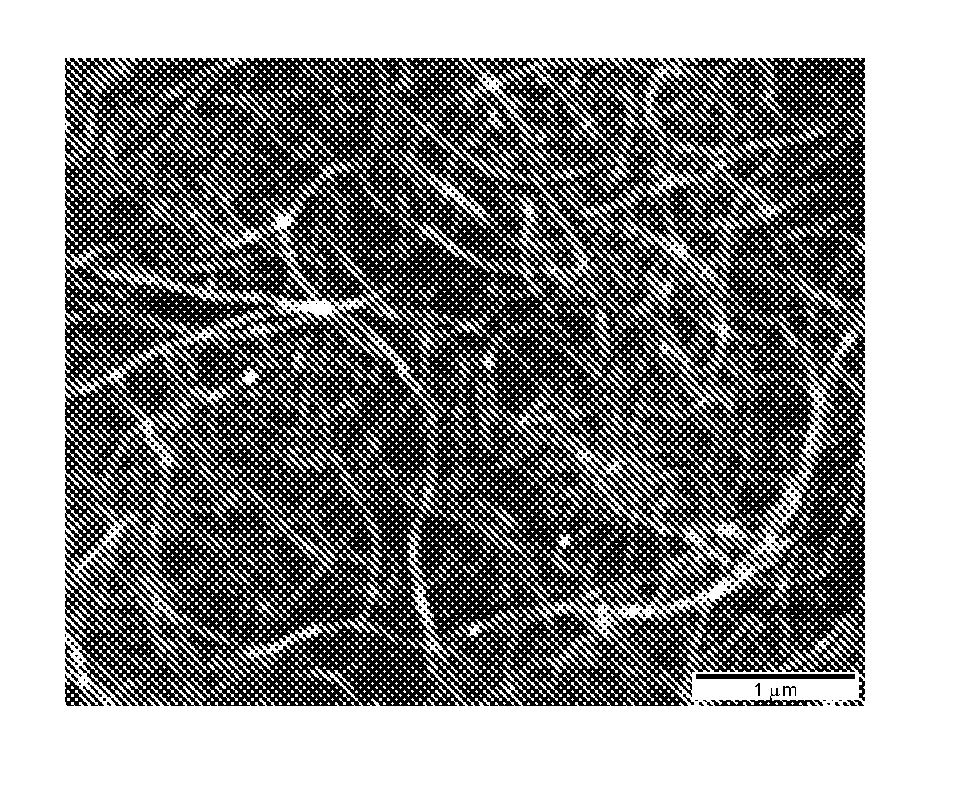

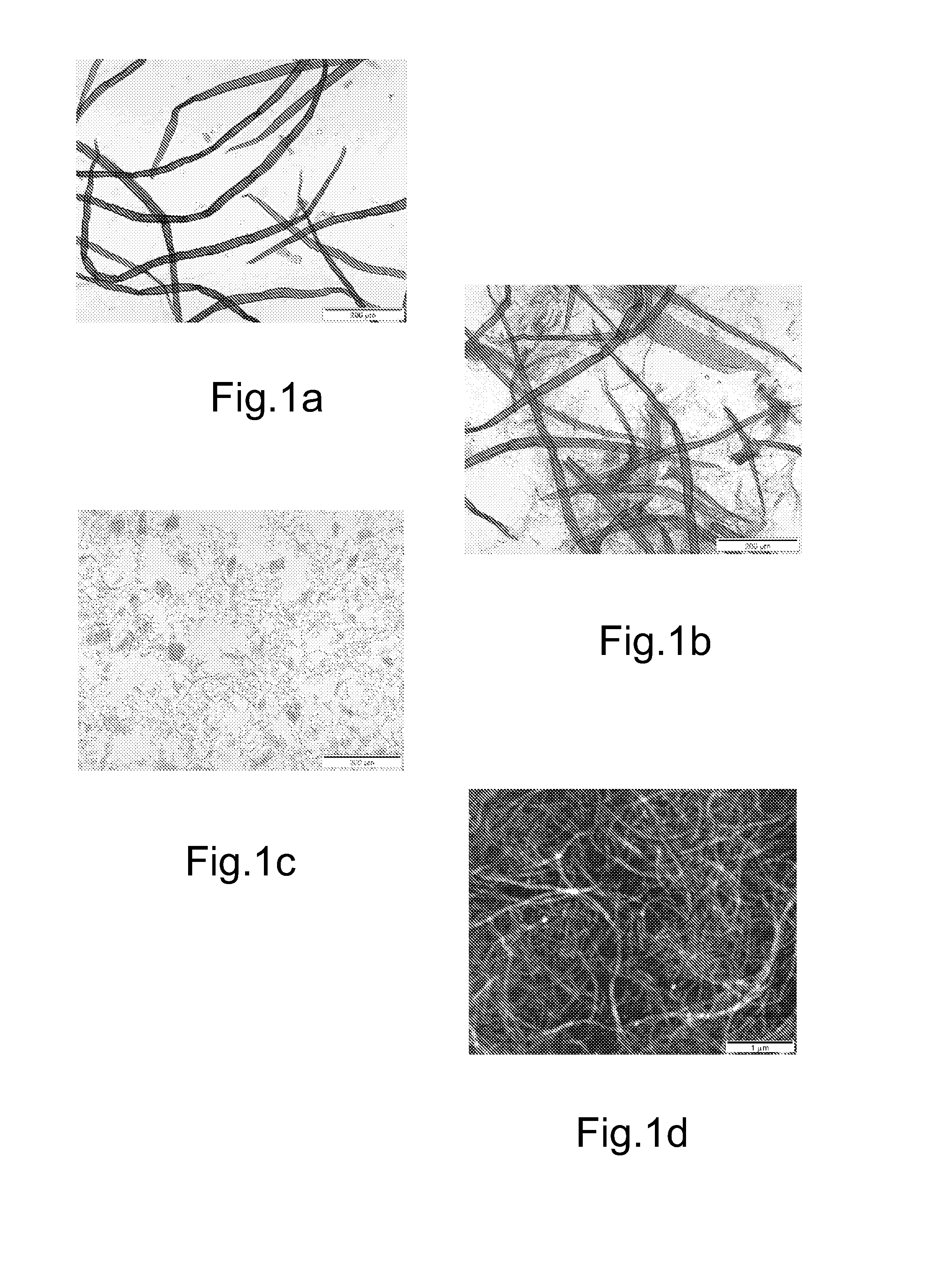

A method for manufacturing pulp. The manufactured pulp includes at least 30 w-% nanofibrillated cellulose material measured from the dried pulp. A raw material is introduced to a system. The raw material includes cellulose. At least one type of an optical brightening agent is dosed as a refining additive to the system. The raw material is refined in the presence of the dosed optical brightening agent in at least one pre-refining stage or fibrillation stage to form fibrillar cellulose material.

Description

FIELD OF THE INVENTION[0001]The invention relates to a method of manufacturing nanofibrillated cellulose pulp. The invention further relates to use of the pulp in paper manufacturing or in nanofibrillated cellulose composites.BACKGROUND OF THE INVENTION[0002]Many stages of pulp production, especially refining stages, consume lots of energy. Specially a production of nanofibrillated cellulose consumes a great deal of energy due to several fibrillarion passages that are needed to achieve nano-sized material. Because the energy consumption of the manufactured pulp increases hugely when the produced pulp includes nanofibrillated cellulose, there may be an efficiency problem when the produced pulp consist at least partly of nanofibrillated cellulose. Sometimes another problem in the nanofibrillated cellulose pulp production is poor water removal due to several strong bonds between cellulose fibers and the water to be removed.[0003]Due to the above mentioned problems, it is beneficial to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D21C3/00D21H23/00

CPCD21H11/18D21H21/32D21H21/30D21C9/005D21D1/20D21H17/42

Inventor NUOPPONEN, MARKUSPAIVALAINEN, TARULAUKKANEN, ANTTIPALTAKARI, JOUNI

Owner UPM-KYMMENE OYJ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com