High-whiteness coated paper coated by using raw paper with medium whiteness, coating method and coating

A coating method and technology for coating paper, applied in paper coating, fiber raw material treatment, coating, etc., can solve problems such as paper becoming brittle, and achieve the goal of reducing processing load, production cost, dosage and bleaching energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

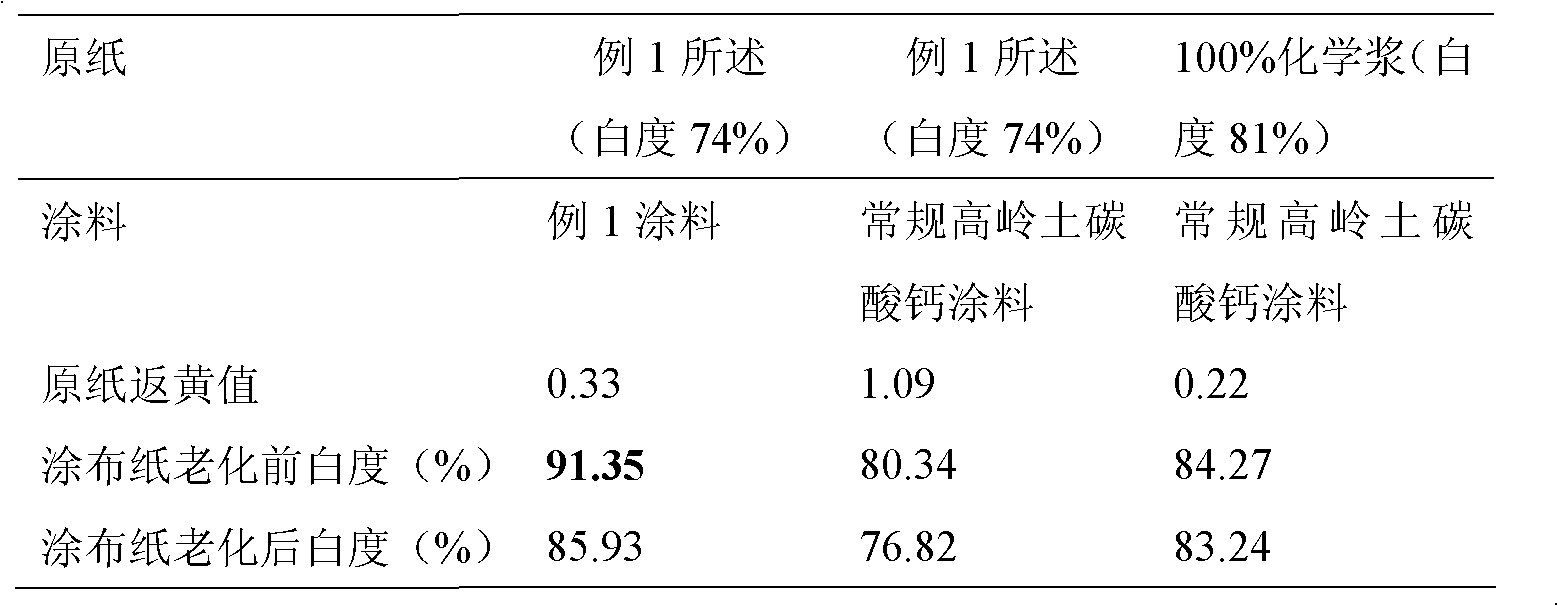

Embodiment 1

[0049] The method for producing high-whiteness coated paper from medium whiteness base paper and the coatings, ingredients and steps used are as follows:

[0050] (1) A kind of medium whiteness (about 74%) base paper, its slurry composition and weight ratio are:

[0051] Alkaline hydrogen peroxide mechanical pulp (PRC-APMP): 30%, whiteness 69% (GB / T 7974-2002, the same below);

[0052] Bleached softwood chemical pulp (NBKP): 30%, brightness 88%;

[0053] Bleached broadleaf chemical pulp (LBKP): 40%, brightness 85%;

[0054] The weight of the base paper produced is 100±2g / m 2 , the whiteness is 74%, ready for use after calendering.

[0055] (2) Use the coating device to implement primer coating, double-sided coating, and the coating amount on each side is 9-12g / m 2 . The paint formula is as follows: (the solid content of the paint is about 60%, the rest is water (the same below) and the pH is about 8.5)

[0056] Heavy calcium carbonate: 70 parts, 55 grades;

[0057] Kaolin...

Embodiment 2

[0078] The method for producing high-whiteness coated paper from medium whiteness base paper and the coatings, ingredients and steps used are as follows:

[0079] (1) The size composition and weight ratio of base paper (brightness is 80.5%) are:

[0080] Mechanical pulp (PRC-APMP): 20%, whiteness 74%;

[0081] Softwood chemical pulp: 30%, whiteness 89%;

[0082] Hardwood chemical pulp: 50%, whiteness 89%;

[0083] The weight of the base paper produced is 100±2g / m 2 , and the whiteness is 80.5% (distilled water copy sheet), and it is used after calendering.

[0084] (2) Use the coating device to apply the primer coating, double-sided coating, and the coating amount on each side is 9-12g / m 2 . The paint formula is as follows: (the solid content of the paint is about 60%, and the pH is about 8.5)

[0085] Heavy calcium carbonate: 70 parts, 55 grades;

[0086] Kaolin: 30 parts, more than 90% less than 2 microns;

[0087] Carboxylated styrene-butadiene latex: 8 parts;

[0...

Embodiment 3

[0102] The method for producing high-whiteness coated paper from medium whiteness base paper and the coatings, ingredients and steps used are as follows:

[0103] (1) A kind of medium-low whiteness base paper (about 61% of whiteness), its slurry is:

[0104] Softwood chemical pulp, whiteness 62%.

[0105] The pulp is obtained by bleaching unbleached softwood chemical pulp with a brightness of 24.0% with hydrogen peroxide.

[0106] The weight of the base paper produced is 70±2g / m 2 , the whiteness is 61%, ready for use after calendering.

[0107] (2) Use the coating device to apply the primer coating, double-sided coating, and the coating amount on each side is 12-15g / m 2 . The paint formula is as follows: (the solid content of the paint is about 60%, and the pH is about 8.5)

[0108] Heavy calcium carbonate: 60 parts, 55 grade slurry calcium;

[0109] Kaolin: 40 parts, more than 90% less than 2 microns;

[0110] Carboxylated styrene-butadiene latex: 8 parts;

[0111] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com