Methods To Detect Organic Contaminants In Pulp and Fiber

a technology of organic contaminants and pulp, applied in the field of pulp and fiber, can solve the problems of wet end breakage, high dirt count, wet end breakage,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0062]A fresh 1% w / w solution of a D4 stain (Dupont #4 dye, from E.I. DuPont de Nemours & Co.) in tap water was prepared. To ensure the complete dissolution of the stain, the solution was heated to almost boiling. 0.1 g (0.1 ml) of stock sample was placed into a test tube. 5 mls of D4 solution was added and the tube was put in hot, not boiling, water for 20 minutes. The contents of the test tube were poured onto a watch glass. A very small quantity of fibre and liquor was transferred onto a microscope slide. The slide was examined at ×40, ×100, ×400 magnification.

[0063]The sample appeared as a collection of red and green fibres with coloured and colourless particles distributed around the fibres. Stickies appear as amorphous, slightly rounded not angular particles. They can be either in the water phase or attached to a fibre.

Color ReactionSUBSTANCECOLOR WITH D4 STAINHardwood FibreRedSoftwood FibreGreenSBRGolden / YellowPVADark Red / MaroonEVABright YellowPolyacrylateRed / Pink

[0064]As can...

example 2

[0065]A procedure for enumerating microstickies was experimentally studied in a field application (i.e., an actual paper producing facility). This paper producing facility uses recovered post consumer papers as a raw material to produce a commercial paper product. In the past, this particular location has experienced operational problems due to stickies deposition on the paper machine equipment. These operational “outbreaks” (i.e. off-quality sheet due to holes, defects / contamination, PM breaks, reduced production, downtime, etc.) are costly. Moreover, these stickies-related outbreaks were not predicted in the past.

[0066]Table 1 below lists the excitation and emission wavelengths for the fluorescent tag / microstickies compound of these experiments. The data was generated using a Perkin-Elmer 150 Fluorescence Spectrophotometer with a Xenon Power Supply.

TABLE 1Type of AdhesiveExcitation PeakEmission PeakCommentsFluorescent TAG466536(1% Solvent / TagMixture)Styrene Butadiene464532Polyviny...

example 3

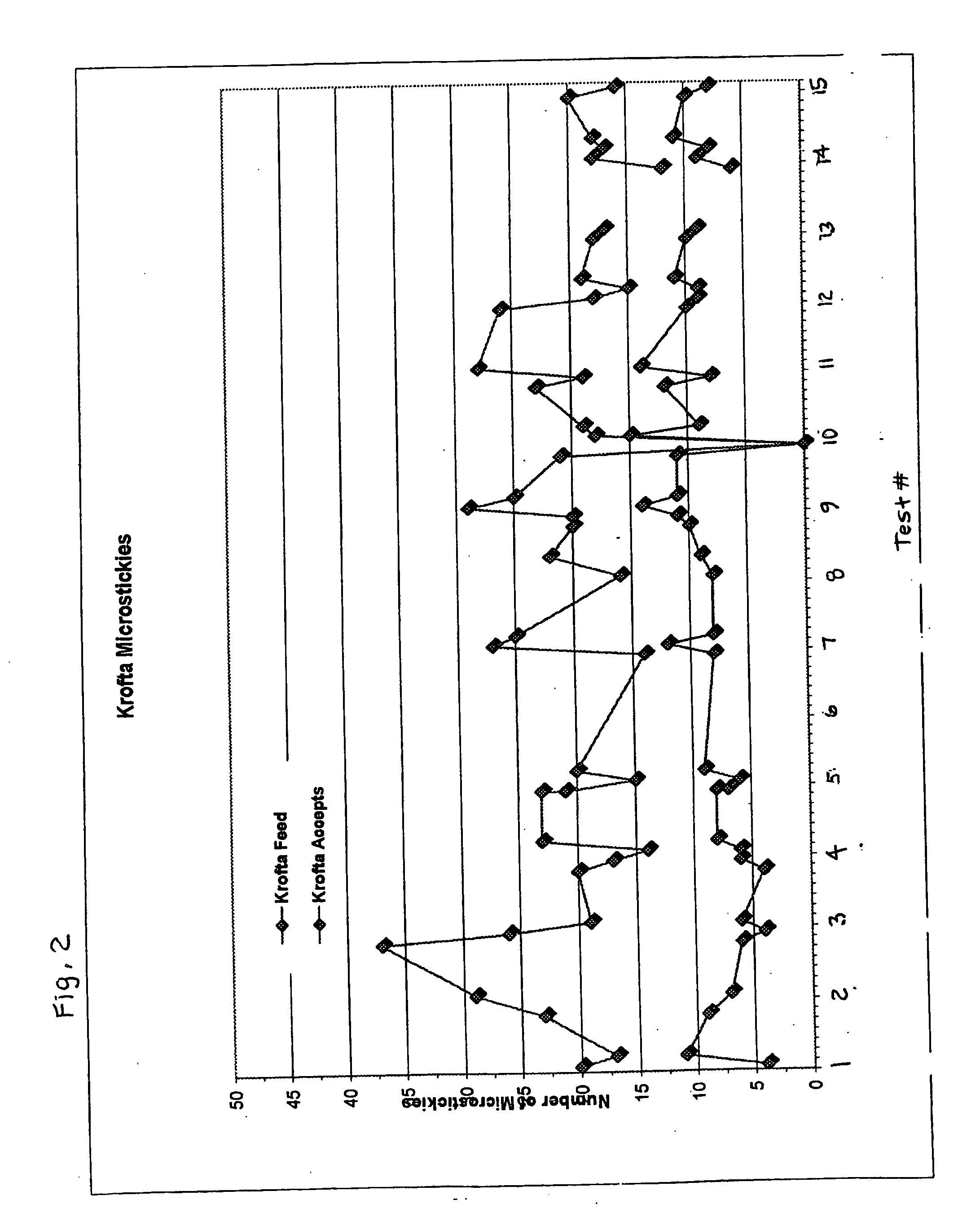

[0098]Experimental evaluations were conducted on BULAB® 5453 bentonite (from Buckman Laboratories, Memphis Term.) to evaluate its performance in reducing the amount of suspend and colloidal material in the Krofta accepts, and specifically focusing on microstickies that were monitored and counted as part of the evaluation. The evaluation was run over a time period of four weeks, in which the BLLAB® 5453 Bentonite was substituted in production runs for an existing inorganic program used in the paper production facility, which was considered the “baseline” for purposes of these studies. The baseline material had been used and monitored in a prior four week production period. Microstickies were detected and enumerated in the manner described below.

[0099]The test results indicated that there was a 43% reduction in online turbidities when comparing the daily average turbidities for the baseline month when compared to the month long bentonite evaluation. In also conducting Krofta efficienc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com