Multiple reversible color change microcapsule anti-counterfeiting material and preparation method and application thereof

A microcapsule and multiple technology, applied in microcapsule preparations, color-changing fluorescent materials, luminescent materials, etc., can solve the problems of limited application range, single function, oily temperature-changing inks that cannot be miscible with water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

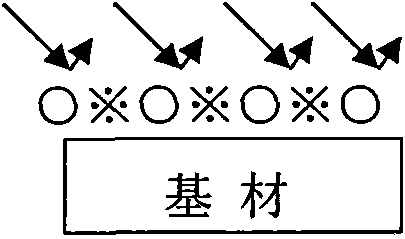

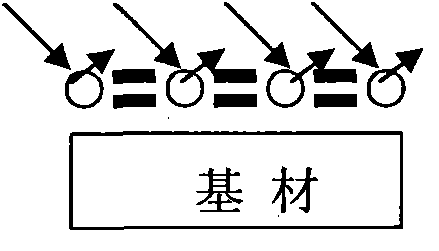

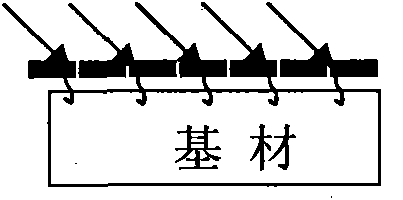

Method used

Image

Examples

Embodiment 1

[0089] (1) Preparation of capsule core material:

[0090] 20 parts by mass of red temperature-changing material (temperature-changing powder of Beijing Chenlei Technology Co., Ltd.), 6 parts by mass of ultraviolet-excited fluorescent material (ultraviolet fluorescent powder of Guangzhou Mingbo Anti-counterfeiting Technology Co., Ltd.), 6 parts by mass of infrared-excited fluorescent material ( Infrared fluorescent powder of Shanghai Kerun Photoelectric Material Co., Ltd.), 10 mass parts of humidity-sensitive color-changing powder (Seilkaduel Colour of Japan Dainichi Seika Industry Co., Ltd.), 2 mass parts of ultraviolet absorber UV327 and 2 mass parts of antioxidant 1010, dissolved in 100 In mass parts diisopropyl naphthalene, obtain solution A; With 200 mass parts containing the aqueous solution of 5% polyethylene maleic anhydride copolymer (EMA-31) and 15 mass parts containing 5% hydroxyethyl cellulose protective colloid aqueous solution Mix to obtain solution B; add solutio...

Embodiment 2

[0097] (1) Preparation of moisture-sensitive material (cobalt chloride-hexamethylenetetramine-diatomite pigment microcapsules):

[0098] A, preparation of microcapsule capsule core

[0099] Dissolve 20 parts by mass of cobalt chloride, 20 parts by mass of hexamethylenetetramine and 20 parts by mass of urea with 100 parts by mass of deionized water, add 50 parts by mass of diatomaceous earth, disperse for 30 minutes at 3000 rpm, and then soak for 2 hours, and then centrifuged, the filter cake is dried, and crushed into a fine powder of more than 800 mesh to obtain the microcapsule capsule core;

[0100] B, preparation of microcapsule wall material

[0101]30 parts by mass of urea, 60 parts by mass of melamine, 200 parts by mass of 37% formaldehyde aqueous solution (mass percentage) and 100 parts by mass of deionized water are mixed evenly, and the pH value is adjusted to 8 to 9 with 20% NaOH. After sub-stirring for 2 hours, water-cooled to obtain a urea-melamine-formaldehyde ...

Embodiment 3

[0112] (1) Preparation of capsule core material: 100 parts by mass of green temperature-changing material (temperature-changing powder of Beijing Chenlei Technology Co., Ltd.), 50 parts by mass of ultraviolet-excited fluorescent material (ultraviolet fluorescent powder of Guangzhou Mingbo Anti-counterfeiting Technology Co., Ltd.) , 50 parts by mass of infrared-excited fluorescent material (infrared fluorescent powder of Shanghai Kerun Photoelectric Material Co., Ltd.), 30 parts by mass of ultraviolet absorber UV327 and 50 parts by mass of antioxidant 1076, dissolved in 300 parts by mass of dibutyl phthalate , to obtain solution A; 600 parts by mass of aqueous solution containing 5% styrene maleic anhydride copolymer and 20 parts by mass of 10% polyvinyl alcohol aqueous solution were mixed to obtain solution B; solution A was added to solution B, at 8000 rpm Emulsify at a stirring speed of 30 minutes per minute, use a 400 times microscope to check that the particle size of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com