Process for preparing cultural paper by utilizing full-recovered pulp

A culture paper, fully recycled technology, applied in the field of papermaking technology, can solve the problems of dusty impurities and low whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

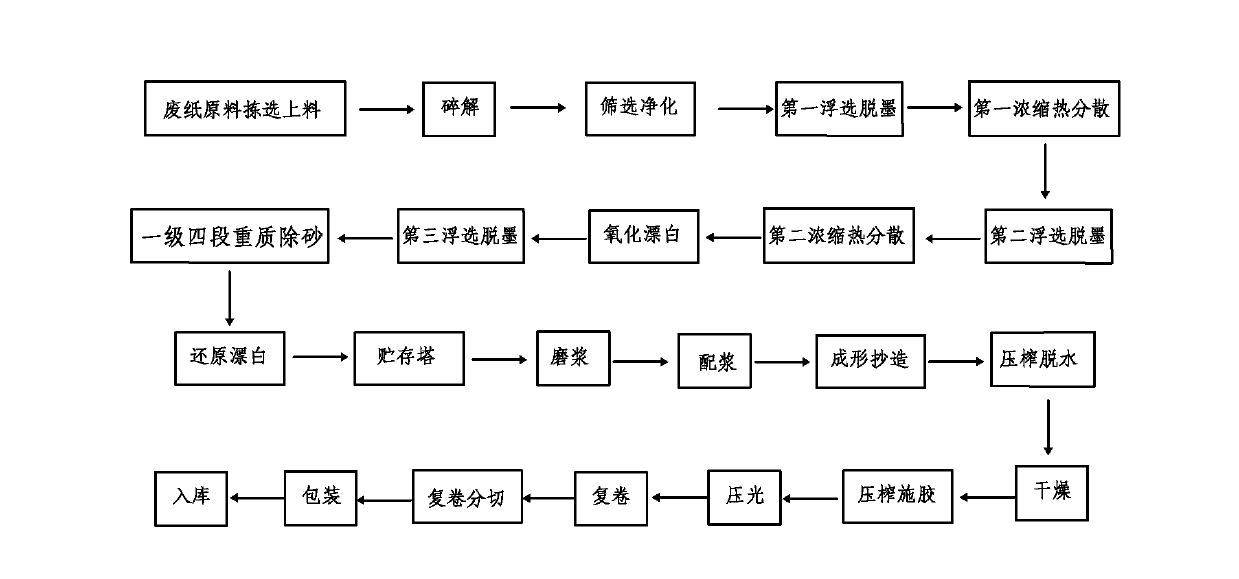

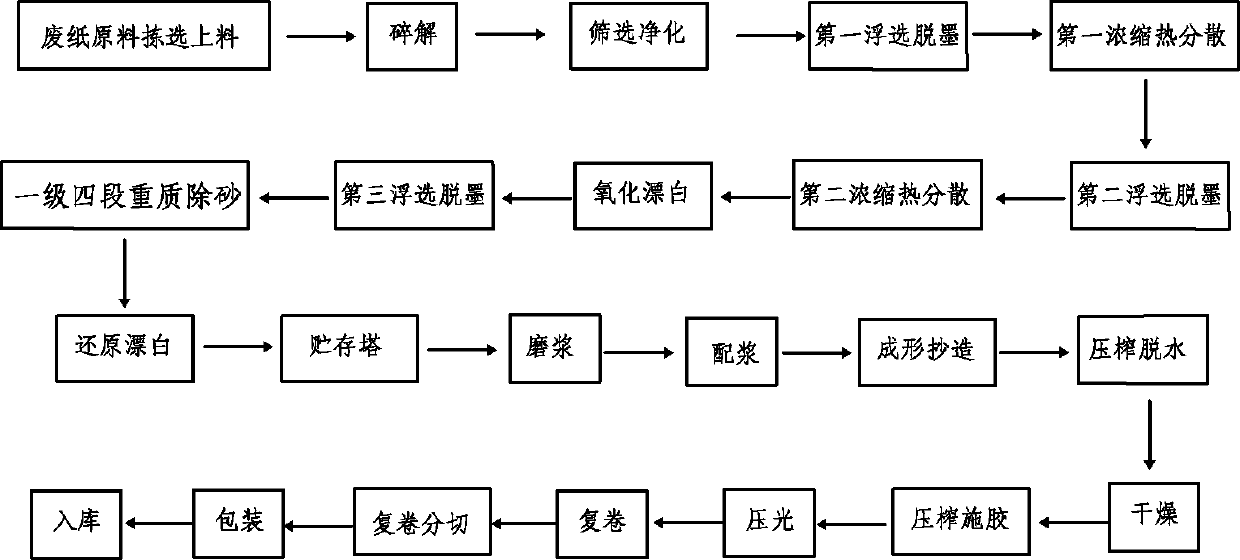

Image

Examples

Embodiment 1

[0054] A process for preparing cultural paper using fully recovered pulp, specifically a process for preparing office paper with fully recovered pulp, comprising the following steps:

[0055] Step A, waste paper raw material selection and feeding: American waste 37#: Japanese waste 5#: American waste 10#: American waste 8# according to the weight percentage of 30%: 30%: 20%: 20% and feeding to shreds in the pulper.

[0056] Step B, disintegration: add 0.4% NaOH, 0.6-0.7% NaOH in the disintegration area of the front section of the drum pulper 2 Sio 2 , 0.2-0.3% industrial soap and 0.05% H 2 o 2 Wait for chemicals, and then add white water at 70-80°C to make the concentration of the disintegration zone 20-22%, the temperature at 50-60°C, and the pH value at 9-10.5. The waste paper raw materials are gently pulped to obtain pulp.

[0057] Step C. Screening and purification: first remove impurities from the slurry, then pass through a high-concentration slag remover, a first-...

Embodiment 2

[0076] A process for preparing cultural paper using fully recovered pulp, specifically a process for preparing office paper with fully recovered pulp, comprising the following steps:

[0077] Step A, waste paper raw material selection and feeding: American waste 37#: Japanese waste 5#: American waste 10#: American waste 8# according to the weight percentage of 20%: 40%: 25%: 15% and feeding to pulping in the plane.

[0078] Step B, disintegration: add 0.5 NaOH, 0.6-0.7% NaOH in the disintegration area of the front section of the drum pulper 2 Sio 2 , 0.2-0.3% industrial soap and 0.03% H 2 o 2 Wait for chemicals, and then add white water at 70-80°C to make the concentration of the disintegration zone 20-22%, the temperature at 50-60°C, and the pH value at 9-10.5. The waste paper raw materials are gently pulped to obtain pulp.

[0079] Step C. Screening and purification: first remove impurities from the slurry, then pass through a high-concentration slag remover, a first-s...

Embodiment 3

[0098] A process for preparing cultural paper using fully recovered pulp, specifically a process for preparing office paper with fully recovered pulp, comprising the following steps:

[0099] Step A, waste paper raw material selection and feeding: American waste 37#: Japanese waste 5#: American waste 10#: American waste 8# according to the weight percentage of 30%: 30%: 30%: 10% and feeding to shreds in the pulper. .

[0100] Step B, disintegration: add 0.6 NaOH, 0.6-0.7% NaOH in the disintegration area of the front section of the drum pulper 2 Sio 2 , 0.2-0.3% industrial soap and 0.06% H 2 o 2 Wait for chemicals, and then add white water at 70-80°C to make the concentration of the disintegration zone 20-22%, the temperature at 50-60°C, and the pH value at 9-10.5. The waste paper raw materials are gently pulped to obtain pulp.

[0101] Step C. Screening and purification: first remove impurities from the slurry, then pass through a high-concentration slag remover, a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com