One-component epoxy aluminum-rich coating for steel structure, and preparation method thereof

A one-component, steel structure technology, applied in the field of coatings, can solve the problems of slow reaction and strict ratio of two-component epoxy, and achieve the effect of excellent adhesion and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] First take 40% of one-component epoxy resin, 40% of aluminum powder, 15% of solvent, and 5% of additives, calculated by mass percentage.

[0015] Put the resin, additives and aluminum powder into the dispersing tank, turn on the agitator and stir slowly at a stirring speed of 300 rpm, after stirring for 30 minutes, check that it is uniform and transparent visually, control the temperature of the dispersing tank to ≤45°C (if necessary A jacket type device can be used), and after checking the viscosity ≧ 90s, the solid content ≧ 70%, the finished product is obtained.

[0016] Effect of use: Make 5 test panels with the above formula, one of which is tested for mechanical properties, and the rest for chemical properties.

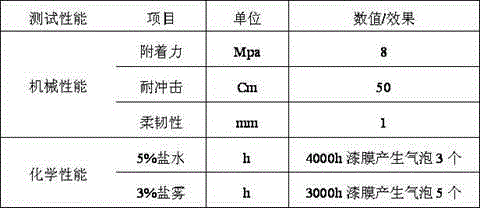

[0017] The performance data of the prepared coating of table 1 embodiment 1

[0018]

Embodiment 2

[0020] First take 30% of one-component epoxy resin, 50% of aluminum powder, 15% of solvent, and 5% of additives, calculated by mass percentage.

[0021] Put the resin, additives and aluminum powder into the dispersing tank, turn on the agitator and stir slowly at a stirring speed of 300 rpm, after stirring for 30 minutes, check that it is uniform and transparent visually, control the temperature of the dispersing tank to ≤45°C (if necessary A jacket type device can be used), and after checking the viscosity ≧ 90s, the solid content ≧ 70%, the finished product is obtained.

[0022] Effect of use: Make 5 test panels with the above formula, one of which is used for mechanical performance test, and the rest is used for chemical performance test. The film thickness is 80 microns.

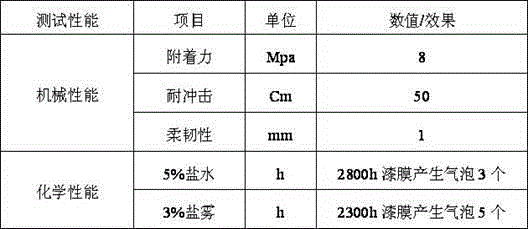

[0023] The prepared coating property data of table 2 embodiment 2

[0024]

Embodiment 3

[0026] First take 27% of one-component epoxy resin, 53% of aluminum powder, 15% of solvent, and 5% of additives, calculated by mass percentage.

[0027] Put the resin, additives and aluminum powder into the dispersing tank, turn on the agitator and stir slowly at a stirring speed of 300 rpm, after stirring for 30 minutes, check that it is uniform and transparent visually, control the temperature of the dispersing tank to ≤45°C (if necessary A jacket type device can be used), and after checking the viscosity ≧ 90s, the solid content ≧ 70%, the finished product is obtained.

[0028] Effect of use: Make 5 test panels with the above formula, one of which is used for mechanical performance test, and the rest is used for chemical performance test. The film thickness is 80 microns.

[0029] The prepared coating performance data of table 3 embodiment 3

[0030]

[0031] The application of a single-component epoxy aluminum-rich coating for steel structures in the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com