A preparation method of hot-press stress-hardened tubular parts of galvanized sheet

A technology for parts and galvanized sheets, applied in the field of preparation of hot-compressed stress-hardened tubular parts of galvanized sheets, can solve problems such as LMIE cracking, and achieve the effect of strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

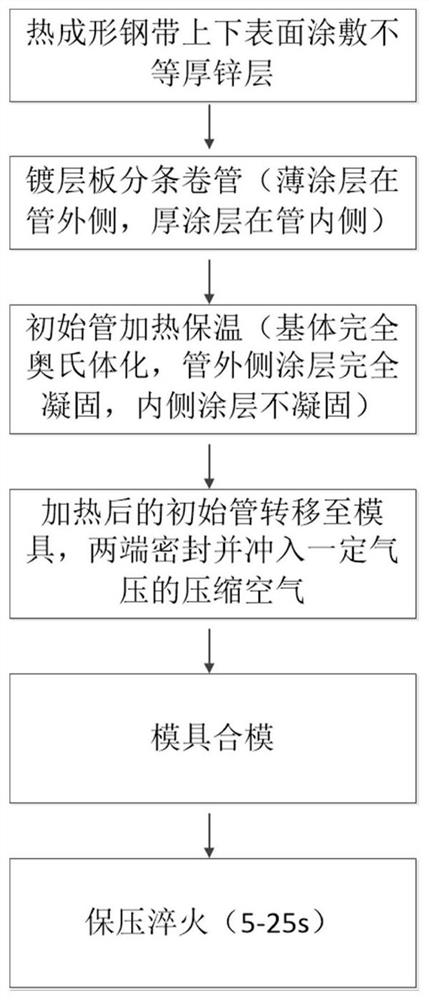

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation cases, and the specific implementation steps are as follows:

[0025] A method for preparing a hot-compression stress-hardened tubular part of a galvanized sheet is acid-rolled with a thickness of 1.5 mm (chemical composition C: 0.2%; Si: 0.25%; Mn: 1.2%; Cr: 0.25; B: 0.003%; Ti: 0.015%) After passing through the GI type hot-dip galvanizing production line, the galvanized content of the upper and lower surfaces of the steel strip is controlled by the air knife to obtain hot-formed steel with unequal thickness zinc layer (one side of the thin zinc layer: 45g / m2; one thick zinc layer Side: 90g / m2);

[0026] The initial tube blank is obtained from the hot-formed steel slit coil of unequal thickness galvanized layer, which ensures that the inner wall coating of the tube is thick and the outer wall coating is thin; the circumference d of the initial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com