Coffee carbon fiber and preparation method thereof

A coffee charcoal fiber and coffee charcoal technology, applied in the fiber field, can solve the problems of high equipment requirements and long preparation time, and achieve the effects of simplifying the preparation process, excellent adsorption performance, and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

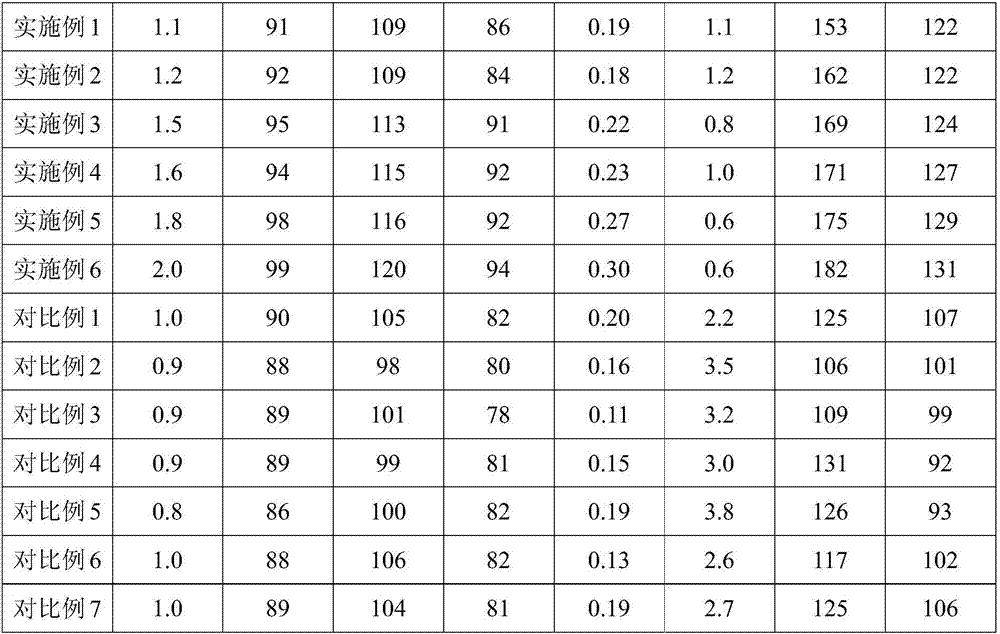

Examples

Embodiment 1

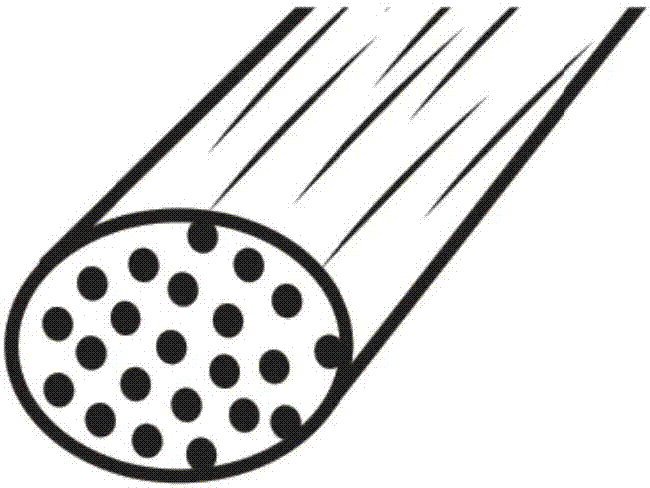

[0038] After the coffee beans are dried, extracted and purified, and impurities are removed, they are calcined into coffee charcoal at 800°C and ground into 2000-mesh coffee charcoal particles. Stir and mix at 200°C to obtain the raw coffee charcoal slurry. Use a high-pressure spinner to spray the raw coffee charcoal slurry at 40MPa and 800°C to form coffee charcoal fibers. The structure of the coffee charcoal fibers is as follows: figure 1 shown.

Embodiment 2

[0040] After the coffee beans are dried, extracted and purified, and impurities are removed, they are calcined into coffee charcoal at 1200°C and ground into 900-mesh coffee charcoal particles. The mass ratio of the coffee charcoal particles and polyester fiber pulp is 1:11 at a temperature Stir and mix at 800°C to obtain the coffee charcoal raw slurry, and use a high-pressure spinner to spray the coffee charcoal raw slurry at 8MPa and 1000°C to form coffee charcoal fibers.

Embodiment 3

[0042] After the coffee beans are dried, extracted and purified, and impurities are removed, they are calcined into coffee charcoal at 900°C and ground into 1500-mesh coffee charcoal particles. The mass ratio of the coffee charcoal particles and polyester fiber pulp is 1:15 at a temperature of Stir and mix at 300°C to obtain the coffee charcoal pulp, and use a high-pressure spinner to spray the coffee charcoal pulp at 30MPa and 850°C to form coffee charcoal fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com