Expressway sound barrier production line

A technology for expressways and production lines, applied in spray booths, pretreated surfaces, spray devices, etc., can solve the problems of manual spraying and low spraying efficiency, and achieve the effect of improving production efficiency and ensuring air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is attached Figure 1-4 The application is described in further detail.

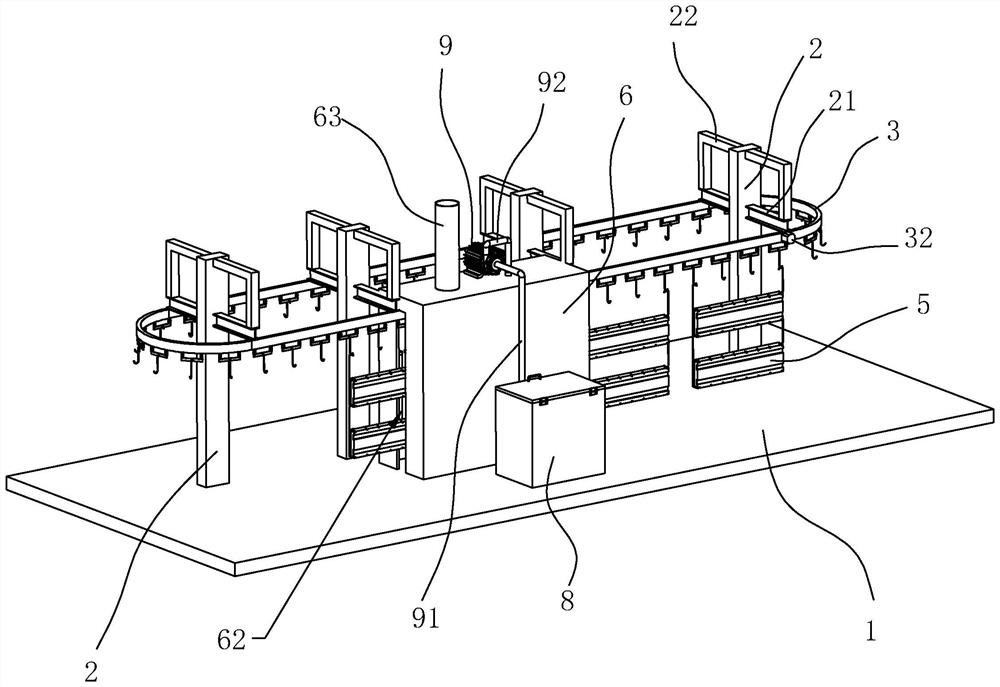

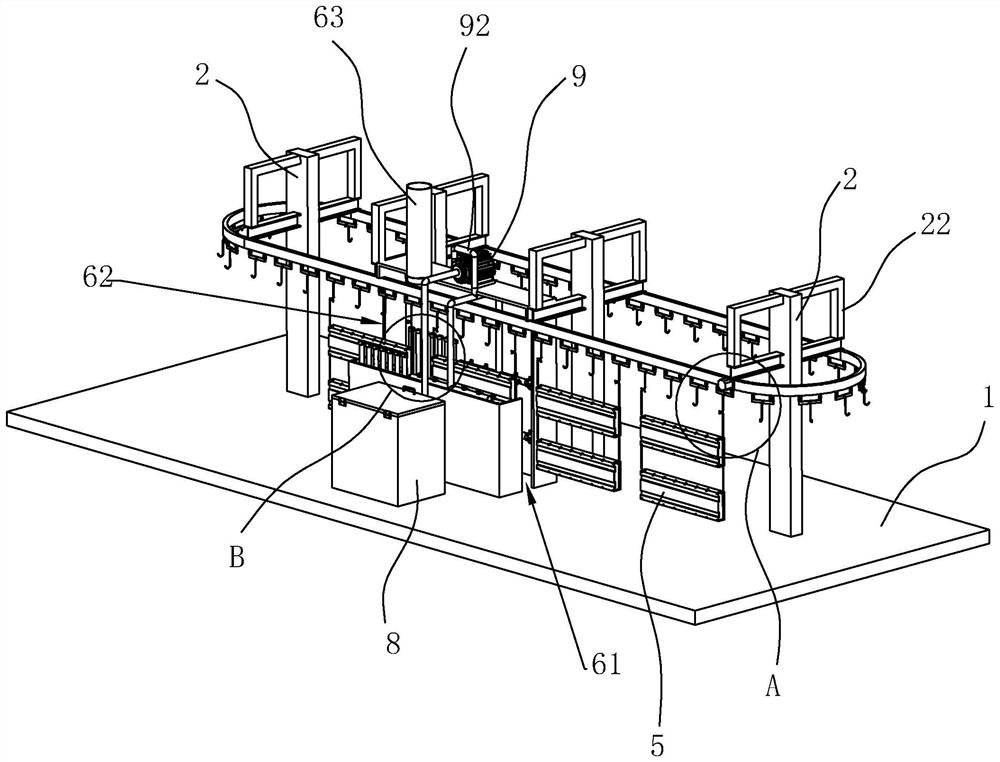

[0032] The embodiment of the present application discloses a production line for expressway noise barriers. refer to figure 1 , the ground 1 is set horizontally, and the installation of this kind of noise barrier production line is carried out on the ground 1. This kind of expressway noise barrier production line includes several groups of steel structure supports 2 erected vertically on the ground 1, and the installation positions of each group of steel structure supports 2 on the ground 1 are distributed collinearly.

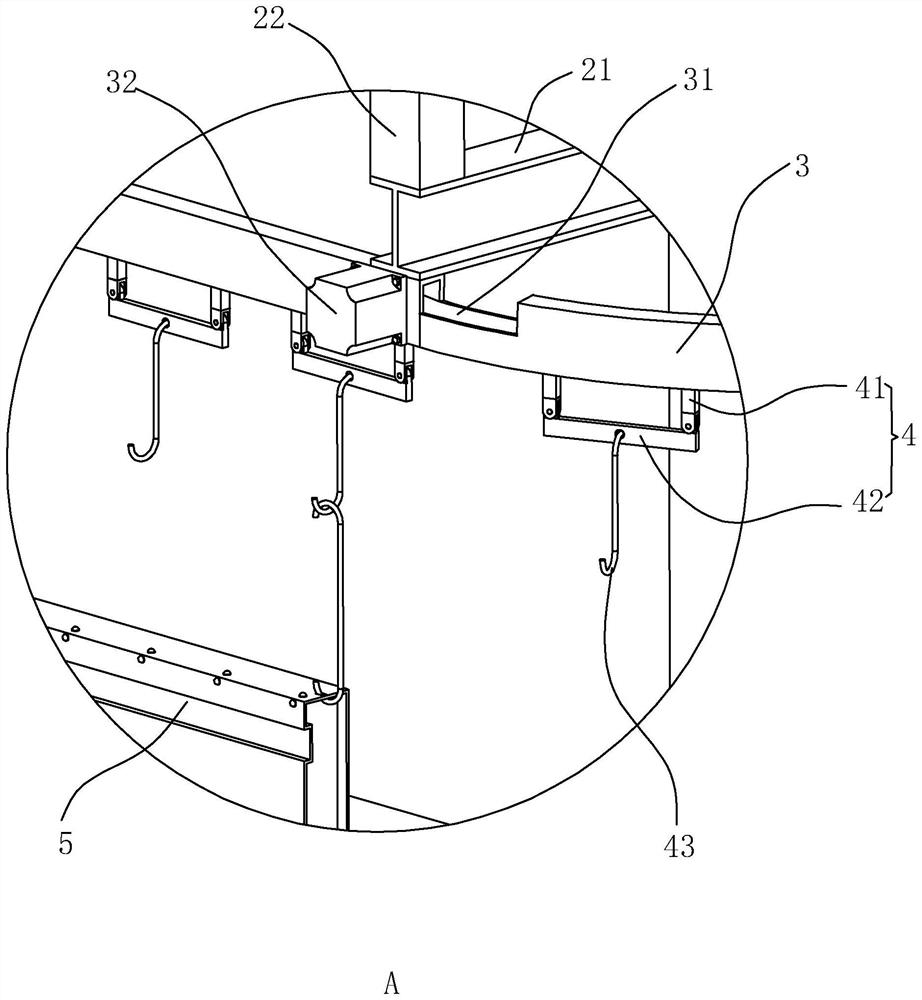

[0033] refer to figure 2 and image 3 Each group of steel structure supports 2 is jointly hoisted with a horizontally arranged and ring-shaped track 3, the vertical section of the track 3 is a groove with the notch facing downward, the lower end of the track 3 is opened, and the inner curling is set, There is a belt 31 inserted and rotated inside the track 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com