Water-based air-drying protective coating for escalator and coating process of water-based air-drying protective coating in humid environment

A technology of protective coatings and water-based epoxy coatings, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of difficult to achieve water-based coatings, easy to sag, slow drying, etc., to improve the anti-flash corrosion ability and water resistance, The effect of reducing flash rust and increasing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] (1) Preparation of epoxy phosphate prepolymer: Add 10 to 20 parts of epoxy resin 128 and 5 to 10 parts of n-butanol to a tank equipped with constant pressure funnel, hygrometer, reflux condenser and stirring device In the four-necked baking bottle, heat and stir to 110°C. After the epoxy resin is completely dissolved, slowly add 0.5 to 1.0 parts of phosphoric acid into the four-necked baking bottle, then reflux for 2-3 hours, and then through decompression Recover n-butanol by distillation to obtain epoxy phosphate prepolymer.

[0038] (2) First, 2.0-5.0 parts of deionized water is used to dissolve 0.25%-0.75% of the initiator of the total amount of acrylate monomers to obtain an initiator solution.

[0039] (3) Add 10.0-15.0 parts of deionized water, 0.5-1.5 parts of emulsifier vinyl alkyl phosphate APEO270 into the reaction vessel, stir at high speed for 20 minutes, then add 5.0-10.0 parts of methyl methacrylate and benzene Ethylene compound (methyl methacrylate: sty...

Embodiment 6

[0053] (1) Degrease and polish the escalator workpiece;

[0054] (2) The water-based self-drying protective coating for escalators is diluted with deionized water, sprayed on the surface of the escalator workpiece with a high-pressure mixed air spray gun in a humid and ventilated environment, and the coating film is self-drying at room temperature.

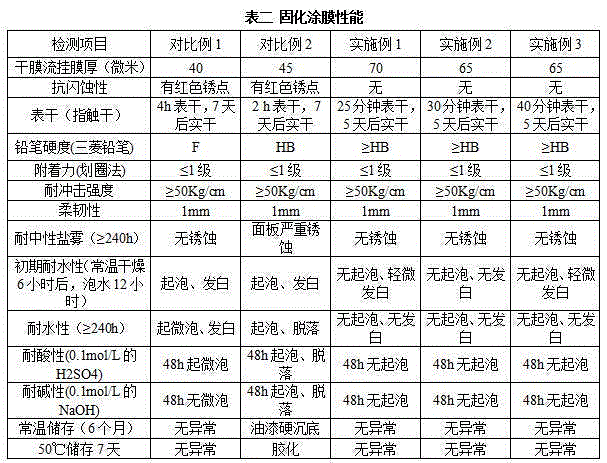

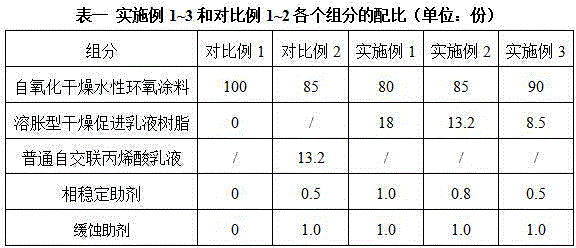

[0055] The 25°C application viscosity of the diluted escalator water-based self-drying protective coating is tested with a rotational viscometer. The viscosity at 6 rotations is 5000-7000 rotations, and the viscosity at 60 rotations is 2000-2500 rotations. The thixotropic value of the paint construction is between 2.5-3.5 . The drying method is self-drying at room temperature, dry to the touch within 30-45 minutes, completely dry after 5-7 days, and after 6 hours of curing at room temperature, it will not foam or turn white when exposed to rain. One-time thick coating is greater than 60 microns dry film thickness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com