Preparation method of ultra-quick-drying water-based two-component acrylic acid refinishing paint

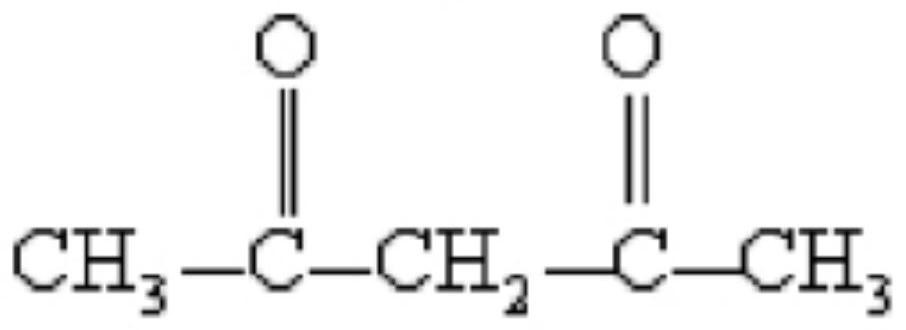

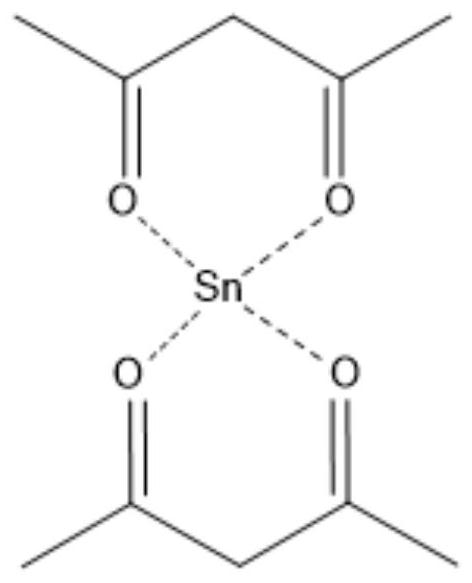

A two-component, acrylic technology, applied in the field of paints, can solve the problems of accelerating the reaction between hydroxyl groups and polyurethane curing agents, inconvenient repairs, slow drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the B component is as follows: 300.00-500.00 parts by mass of an organic solvent and 500.00-700.00 parts by mass of a low-viscosity polyurethane curing agent are stirred at 1000 RPM for 10 minutes.

[0030] Further, the organic solvent is propylene glycol methyl ether acetate.

[0031] Further, the ratio of hydroxyl content to NCO content in components A and B is 1:1.2 to 1.5. When in use, components A and B are mixed at a mass ratio of 6:1, and then added to account for the mass of the mixture Dilute with deionized water with a fraction of 10% to 20% and stir evenly, filter with a 200-mesh filter, and then use a 1.3mm caliber air spray gun to spray on the original topcoat with 320# sandpaper machine grinding defects, and dry naturally. A repair coating with a thickness of 30-50 μm is obtained.

[0032] In order to solve the defects of traditional water-based two-component acrylic topcoats that are slow to dry and inconvenient to repair, the p...

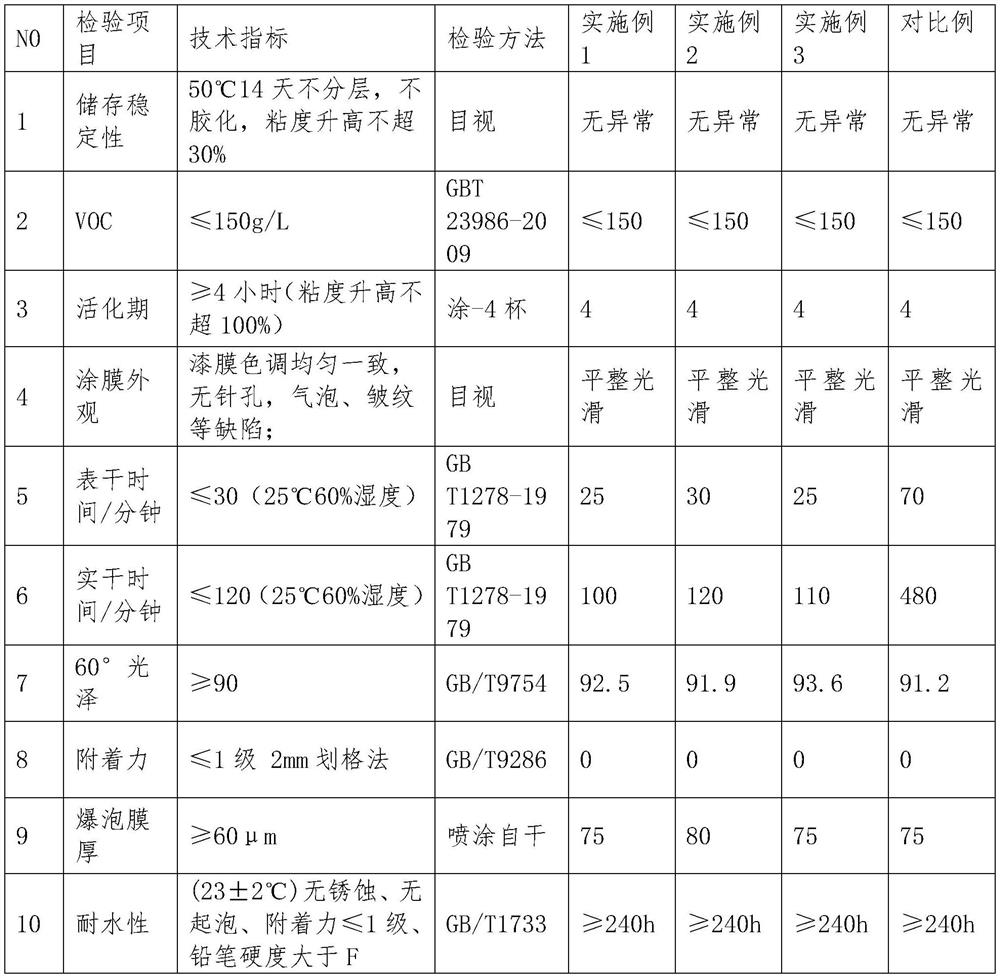

Embodiment 1

[0034] The present invention comprises A and B two components.

[0035]The preparation process of component A is as follows: ①Put 40.00 parts (parts by mass, the same below) of deionized water in the first plastic tank, and then add 1.00 parts of Bentone DE (Deqian Hemings Chemical Co., Ltd. ), then gradually increase the rotating speed to 3000RPM, continue to stir for 20 minutes, and make anti-settling slurry for subsequent use;

[0036] ② Add 210.00 parts of deionized water to the second plastic tank, then add 30.00 parts of dispersant BYK-190 (Byk Chemical Co., Ltd.) and the anti-settling slurry prepared in step ① at a speed of 1500 RPM; then add 30.0 parts at 500 RPM Part MA-100 carbon black pigment (Mitsubishi Chemical Co., Ltd.), stirred at 1500RPM for 10 minutes; added 3.00 parts of defoamer Tego 810 (Evonik Degussa Chemical Co., Ltd.) at 1500RPM and stirred at 2000RPM for 20 minutes;

[0037] ③Put the product prepared in step ② into the dispersion cylinder and grind i...

Embodiment 2

[0044] The present invention comprises A and B two components.

[0045] Wherein the preparation process of component A is as follows: ① put 80.00 parts (parts by mass, the same below) of deionized water in the first plastic tank, and then add 2.00 parts of Bentone DE (Deqian Hemings Chemical Co., Ltd. ), then gradually increase the rotating speed to 3000RPM, continue to stir for 20 minutes, and make anti-settling slurry for subsequent use;

[0046] ②Add 170.00 parts of deionized water to the second plastic tank, then add 20.00 parts of dispersant BYK-2015 (Byk Chemical Co., Ltd.) and the anti-settling slurry prepared in step ① at a speed of 1500 RPM; then add 100.0 parts at 500 RPM 1 part of CINILEX DPP RED SR1C (Xenike Pigment Co., Ltd.), stirred at 1500RPM for 10 minutes; added 2.00 parts of antifoaming agent Tego 810 (Evonik Degussa Chemical Co., Ltd.) at 1500RPM and stirred at 2000RPM for 20 minutes;

[0047] ③Put the product prepared in step ② into the dispersion cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com