Water-resistant garment fabric printing method and device

A water-resistant and printing technology, applied in the field of fabric printing, can solve the problems of pollution and slow ink drying, and achieve the effect of reducing emission diffusion, low price, and easy winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

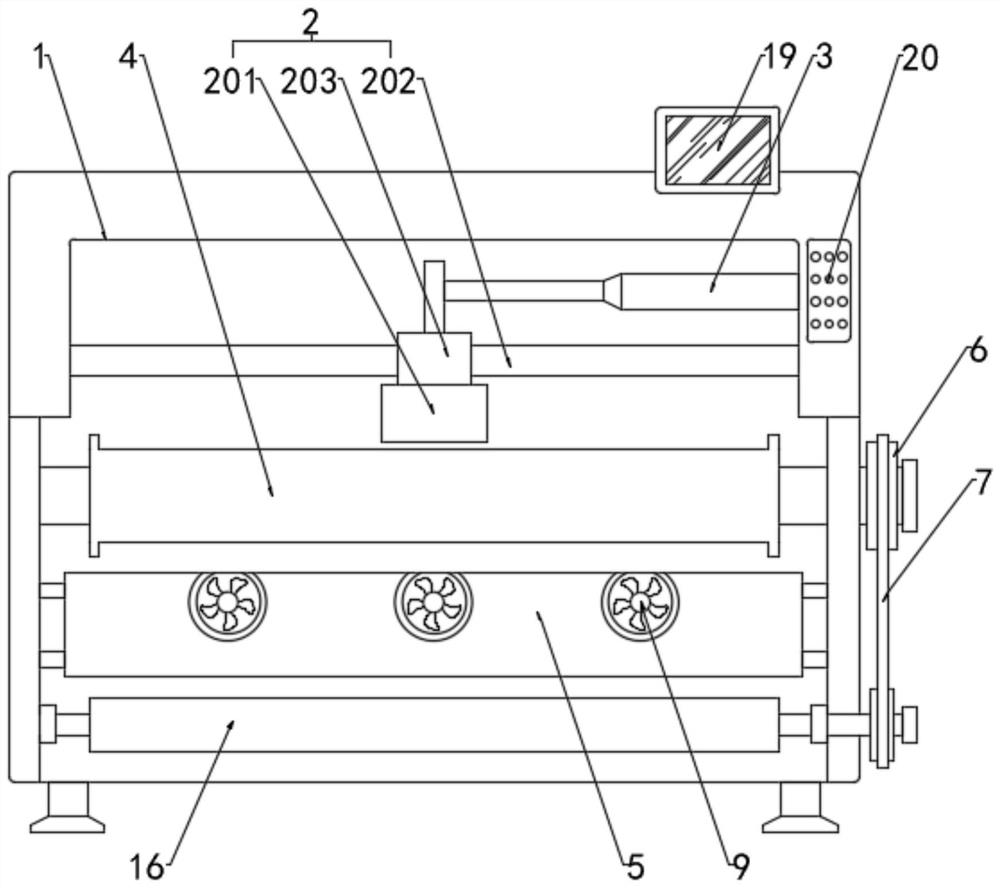

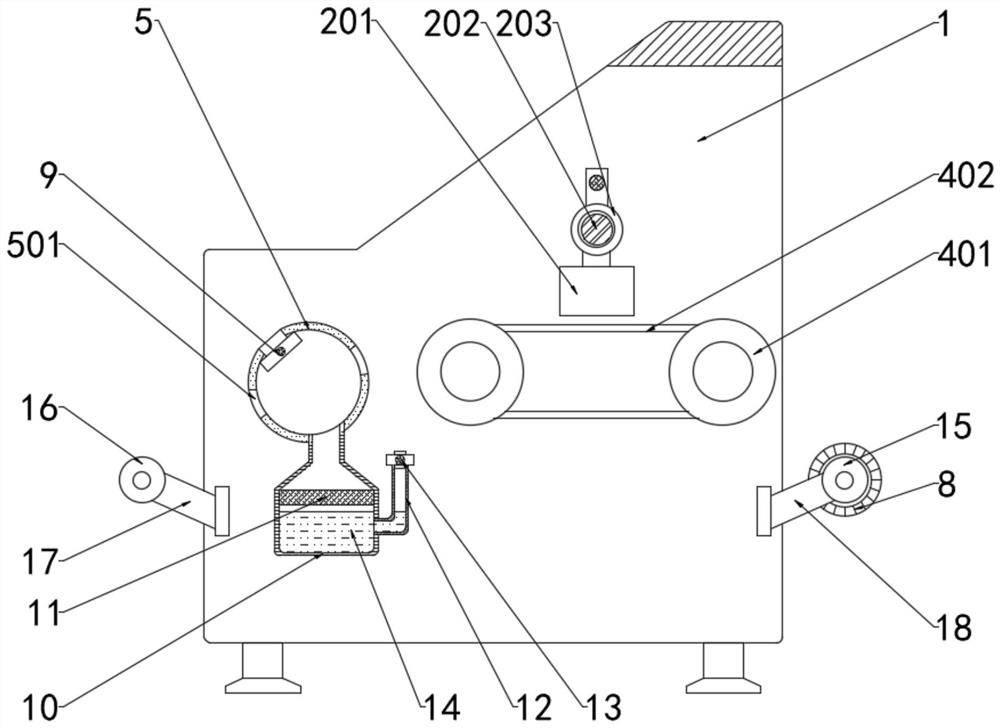

[0031] see Figure 1-2 , a water-resistant garment cloth printing device, comprising a frame 1, a display terminal 19 and a controller 20 arranged on the frame 1, and a printing mechanism 2 arranged inside the frame 1, and the display terminal 19 can intuitively display printing patterns , the printing pattern can be independently selected through the controller 20, and the work of the cylinder 3 and the drive motor 8 can be controlled at the same time. The top side of the printing mechanism 2 is provided with a cylinder 3, and the bottom of the printing mechanism 2 is provided with a transmission mechanism 4. The frame 1 The interior is located in front of the transmission mechanism 4 and is provided with a drying cylinder 5. The inner surface wall of the drying cylinder 5 is provided with a hot air blower 9. The drying cylinder 5 has reserved through grooves 501 symmetrically distributed about the hot air blower 9. The bottom of the cylinder 5 is communicated with a purifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com